|

市场调查报告书

商品编码

1692097

北美绝缘运输货柜:市场占有率分析、行业趋势和成长预测(2025-2030 年)North America Insulated Shipping Containers - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

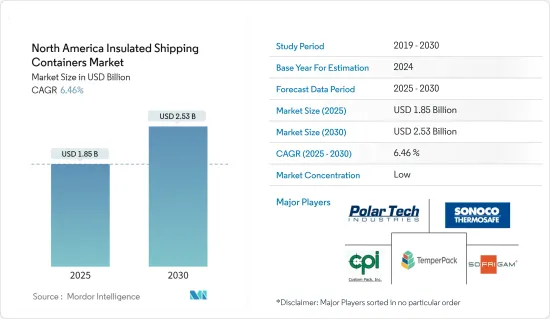

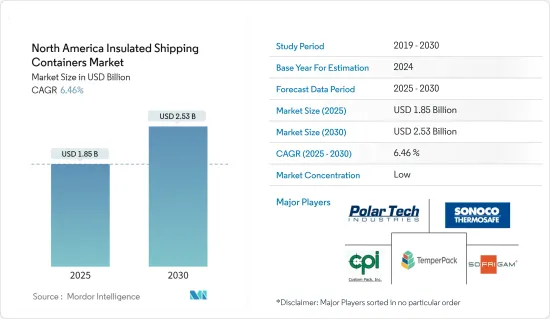

北美绝缘运输货柜市场规模预计在 2025 年为 18.5 亿美元,预计到 2030 年将达到 25.3 亿美元,预测期内(2025-2030 年)的复合年增长率为 6.46%。

主要亮点

- 储存箱通常用于隔离运输货柜,以保护其免受极端温度变化的影响。世界各地有许多种水果和蔬菜都是有机种植的。因此这些包装材料被广泛采用以保持水果在运输过程中的新鲜度。

- 化学品、药品、新鲜蔬菜、饮料和冷冻食品等产品需要精确的温度控制以防止感染疾病。进出货柜的空气必须经过过滤,因此隔热材料起着关键作用。透过将运输货柜与外部完全隔离,可以保持运输产品的完整性。

- 热感包装绝缘运输容器内衬套件旨在显着降低受潮风险,使其成为储存期间保护产品的最经济的方式。必须在稳定温度下运输的易腐货物(例如食品、饮料和药品)也可以使用内衬保存。

- 发泡聚苯乙烯 (EPS) 容器是食品和製药业最常用的绝缘运输容器之一。 EPS 冷却器具有多种优点,包括隔热、重量轻和价格实惠。由于发泡聚苯乙烯产品对环境有负面影响且不具备生物分解性,因此已被纽约、洛杉矶、华盛顿特区和波特兰等美国 100 多个县禁止使用。

- 药品的储存环境对药品温度变化的速度有很大影响。如果在没有防护的情况下暴露在高温或低温下,疫苗很快就会超出其所需的温度范围,从而降低其有效性。这些因素正在推动隔热运输货柜市场的扩张。

- 整个市场的仓库都开始储存大量冷藏食品。尤其是美国农业部近日透露,美国仓库正在囤积大量冷冻蔬菜。库存激增将在预测期内刺激对绝缘运输货柜的需求。

- 由于新冠疫情,优质冷藏运输货柜已成为医药产品运输的重要组成部分,确保製药公司能够克服许多运输障碍,因为货柜製造商遵守严格的公众监管标准。美国食品药物管理局(FDA) 和其他监管机构对药物物质和产品以及用于运输它们的容器有严格的规定。

北美绝缘运输货柜市场趋势

生命科学和製药领域占据了很大的市场占有率

- 在美国,许多对温度敏感的药物,包括昂贵且高度专业的癌症治疗药物和预防感染疾病的疫苗,都生产和运输。因此,隔热运输容器对于防止昂贵药品因温度变化而损失至关重要。

- 处理对温度敏感的药品的需求不断增长,刺激了隔热运输容器的销售成长。越来越多的法规强调遵守储存温度标准将推动製药和医疗应用的需求。

- 凭藉对生物医学研究的投入,美国已成为药物研发领域的全球领导者,并拥有大量製造商。此类容器的需求量很大,而且由于美国和加拿大生命科学和製药行业蓬勃发展,产量增加,预计需求量将继续增长。

- 2024 年 2 月,合约物流公司 DHL Supply Chain 宣布了一项 2 亿美元的投资计划,致力于加强其在生命科学和医疗保健领域的能力。这项策略性倡议包括开发仓储设施,这将使 DHL 的营运空间增加到惊人的 1,300 万平方英尺。此外,DHL 计划投资先进技术,旨在简化营运并增强其医疗保健和生命科学供应链的弹性。此项重大投资彰显了 DHL 坚定不移地致力于为业界提供可靠、高效和温控的物流解决方案。

- 生命科学产业的成长主要受到製药业的崛起的推动,其标誌是创新治疗方法的不断涌入,尤其是针对体重管理和糖尿病的创新疗法。这一趋势,加上当地製药业的復苏,正在推动对额外生产能力的需求激增。随着越来越多的品牌转向国内生产,简化入境物流以支持这些生产线已成为当务之急。

预计美国将实现最高成长率

- 北美是全球最重要的绝缘运输货柜市场之一,其中美国占据了相当大的市场份额。大量供应商的存在和进出口活动的蓬勃发展导致该国的需求量很大。出口贸易的扩大可能会为隔热运输的使用带来巨大的前景。

- 此外,该国还有几项与该行业相关的法律。例如,美国食品药物管理局对食品接触包装产业进行严格监管。由于食品是运输和储存最精细的物品之一,预计这项规定将鼓励全国使用隔热运输容器。

- 市场正在扩大,泰森食品、肯塔基州州长安迪贝希尔和鲍灵格林市领导宣布新建一个价值 3.55 亿美元的培根生产工厂证明了这一点。该工厂占地 40 万平方英尺,计划于 2023 年投入运营,将僱用 450 名员工,旨在满足该公司 Jimmy Dean 和 Lite 品牌日益增长的需求。这些发展增加了用于运输食品的隔热集装箱的需求。

- 根据美国商务部Census.gov网站的数据,美国电子商务销售额十多年来一直稳定成长,过去两年成长尤为显着。根据美国人口普查局的贸易数据,2023年美国新鲜水果和蔬菜出口将达70亿美元,与前一年同期比较增加2%。新鲜水果和蔬菜出口需求的激增预计将成为北美市场成长的主要驱动力。

- 最近发生的事件凸显了美国和全球生命科学和医疗保健产业建立敏捷且有弹性的供应链的必要性。因此,供应商正在增加对技术和战略位置的投资。此举旨在透过为客户提供主动应对中断的工具来保障基本物资的无缝流动。

北美绝缘运输货柜产业概况

北美隔热运输货柜市场较为分散,有 Polar Tech Industries、Sonoco Thermosafe、Custom Pack Inc.、TemperPack 和 Sofrigam 等多家公司,使得市场竞争更加激烈。

- 2024 年 5 月,标准和改装仓储及运输货柜供应商 Conexwest 推出了一系列可供购买和租赁的新型隔热冷藏集装箱。这些货柜有多种尺寸,从 10 英尺到 45 英尺不等。这些储存容器製造商和经销商现在可以为丰塔纳和洛杉矶的企业提供最广泛、最优质的冷藏解决方案。 Conexwest 在所有货柜的製造过程中优先使用最高品质的材料和节能隔热材料。这项承诺不仅保证了客户能够负担得起的购买和租赁价格,而且还保证了长期的能源节约。

- 2024 年 5 月,创新供应链和技术公司 CJ 物流 America 透露计划在堪萨斯州新世纪(距离堪萨斯城仅 30 英里)开设一个新的冷藏仓库。该合资企业是国家冷藏仓库开发商 Yukon Real Estate Partners 与冷藏仓库房地产领域知名品牌 BGO 的合资企业,拥有配备 Alta EXPERT 冷冻系统的 291,000 平方英尺仓库。该设施预计将于 2025 年第三季投入营运。国内外客户都将从降低的物流成本以及提高的环境永续性和运输效率中受益匪浅。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 研究范围

第二章调查方法

- 研究框架

- 二次调查

- 主要研究方法及主要受访者

- 数据三角测量与洞察生成

第三章执行摘要

第四章 市场动态

- 市场概览

- 产业价值链分析

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争强度

- COVID-19 市场影响评估

第五章 陶瓷市场

- 市场驱动因素

- 製药和医疗保健行业的成长将推动市场

- 消费者对生鲜食品的需求不断增加

- 市场挑战

- 原料成本上涨

- 关键市场创新与合作

- 分析师对 Direct2Consumer 绝缘托运产业需求的评论

- 市场区隔分析

第六章市场区隔

- 依材料类型

- 发泡聚苯乙烯(EPS)

- 聚氨酯泡棉(PU)

- 发泡聚丙烯(EPP)

- 其他材料类型

- 按最终用户应用程式

- 已调理食品食品及冷冻食品

- 生命科学与製药

- 生鲜肉

- 新鲜农产品

- 麵包店、植物、花卉

- 其他最终用户应用(化妆品、葡萄酒、其他饮料)

- 按国家

- 美国

- 加拿大

第七章竞争格局

- 公司简介

- Polar Tech Industries

- Sonoco Thermosafe(sonoco Products Company)

- Custom Pack Inc.

- Temperpack

- Sofrigam

- Intelsius(A DGP Company)

- Cascades Inc.

- Softbox Systems Ltd(CSAFE Global)

- Insulated Products Corporation

- Chill-Pak

- Airlite Plastics Co.(KODIAKOOLER)

- Therapak(AVANTOr Group)

- Thermal Shipping Solution

第八章投资分析

第九章 未来市场展望

简介目录

Product Code: 90471

The North America Insulated Shipping Containers Market size is estimated at USD 1.85 billion in 2025, and is expected to reach USD 2.53 billion by 2030, at a CAGR of 6.46% during the forecast period (2025-2030).

Key Highlights

- Storage containers are frequently used to protect against extreme temperature swings by insulating transport containers. Many different kinds of fruits and vegetables are grown utilizing organic methods worldwide. These packing materials are, therefore, widely employed to keep fruit fresh during transportation.

- To protect from infection, products such as chemicals, medicines, fresh vegetables, beverages, and frozen goods require precise temperature control. As the air entering and leaving the containers must be filtered, insulation plays a significant role. It maintains the condition of the conveyed products by completely closing off a shipping container from the outside.

- Thermal packing insulated shipping container liner kits are the most economical way to protect products in storage since they are made to lower the risk of moisture considerably. Perishable commodities that must be mandatorily transported at steady temperatures, such as food, beverages, and medicines, can also be preserved using liners.

- Expanded polystyrene (EPS) containers are among the most frequently used insulated transportation containers in the food and pharmaceutical industries. EPS coolers provide several benefits, including thermal insulation, being lightweight, and being affordable. Due to their negative environmental effects and lack of biodegradability, polystyrene foam products are prohibited in over 100 counties across the United States, including New York, Los Angeles, Washington, DC, and Portland.

- The environment in which medicine is kept significantly impacts how quickly it changes temperature. When left unprotected and exposed to heat or cold, a vaccination can leave the necessary temperature range within a short period, thereby disrupting its efficacy. Because of such factors, the usage of insulated shipping containers is fueling market expansion.

- Warehouses across the market are increasingly stocking a substantial volume of chilled food products. Notably, the US Department of Agriculture recently highlighted a significant inventory of frozen vegetables across US warehouses, closely trailed by dairy products and frozen potatoes. This surge in inventory is poised to drive up the demand for insulated shipping containers over the forecast period.

- Due to the COVID-19 pandemic, high-quality cold transport containers emerged as a vital component in the transportation of pharmaceuticals, guaranteeing that pharmaceutical companies could overcome the many shipping obstacles since container makers abide by stringent regulatory standards for the benefit of the general population. The US Food and Drug Administration and other regulatory authorities have strict rules governing pharmaceutical substances, goods, and the containers used to carry them.

North America Insulated Shipping Containers Market Trends

The Life Sciences and Pharmaceutical Segment Holds a Significant Market Share

- In the United States, many temperature-sensitive medications are produced and shipped, including expensive and highly specialized cancer therapies and vaccines against infectious diseases. Insulated shipping containers, therefore, prove crucial in preventing the loss of expensive drugs due to temperature variations.

- Rising demand for handling temperature-sensitive pharmaceuticals is fueling a sales increase for insulated shipping containers. A growing regulatory emphasis on compliance with storage temperature standards will promote demand in medicine and medical applications.

- Due mostly to its investments in biomedical research, the United States has emerged as a global leader in drug discovery and development, with a sizable number of manufacturers. The demand for these containers is considerable and is expected to continue to rise with the increase of production in the United States and Canada, which have notable life sciences and pharmaceutical industries.

- In February 2024, DHL Supply Chain, a contract logistics company, unveiled plans for a USD 200 million investment, specifically earmarked for bolstering its life sciences and healthcare capabilities. This strategic initiative encompasses the development of warehouse facilities, poised to expand the company's operational space to a staggering 13 million sq. ft. Moreover, DHL plans to channel funds into advanced technologies aimed at streamlining operations and fortifying the resilience of its healthcare and life sciences supply chains. This substantial investment underscores DHL's unwavering dedication to furnishing the industry with dependable, efficient, and temperature-controlled logistics solutions.

- The growth in this industry is primarily fueled by the pharmaceutical segment's rise, marked by a consistent influx of innovative treatments, notably those targeting weight management and diabetes. This trend, alongside the resurgence of local drug manufacturing, has catalyzed a surge in demand for expanded capacity. With more brands pivoting toward domestic production, the necessity for streamlined inbound logistics to support these manufacturing lines has become paramount.

The United States is Expected to Register the Highest Growth Rate

- North America is considered one of the important markets worldwide for insulated shipping containers, with the United States making up a sizeable portion of that market. The substantial presence of numerous vendors, exports, and imports can be linked to the nation's high demand. The use of insulated shipping will see substantial prospects as a result of this expansion in export trade.

- Additionally, there are several laws pertaining to the industry in the nation. For instance, the Food and Drug Administration in the United States heavily regulates the industry of food-contact packaging. The rules are anticipated to encourage the use of insulated shipping containers nationwide because food is one of the most delicate things to move and store.

- The market is expanding, as was witnessed by the announcement of a new USD 355 million bacon manufacturing facility made by Tyson Foods, Kentucky Governor Andy Beshear, and Bowling Green city leaders. The 450 workers at the 400,000 sq. ft plant, scheduled to debut in 2023, aimed to help meet growing demand for the company's Jimmy Dean and Wright brands. These developments increase the demand for insulated shipping containers for moving food.

- According to the US Department of Commerce's Census.gov website, e-commerce sales in the United States have shown a consistent upward trend for over a decade, with particularly notable increases in the last two years. Data from the US Census Bureau Trade Data reveals that in 2023, the country's fresh fruit and vegetable exports were valued at USD 7.0 billion, marking a 2% rise over the previous year. This surge in demand for fresh produce exports is expected to be a key driver of market growth in North America.

- Recent events underscore the critical need for agile and resilient supply chains in the life sciences and healthcare industries, both in the United States and worldwide. Consequently, market vendors are ramping up investments in technology and strategic locations. This move aims to equip their customers with tools to proactively tackle disruptions, thereby safeguarding the seamless flow of essential supplies.

North America Insulated Shipping Containers Industry Overview

The North American insulated shipping containers market is fragmented due to the presence of many players, such as Polar Tech Industries, Sonoco Thermosafe, Custom Pack Inc., TemperPack, and Sofrigam, which are making the market competitive.

- In May 2024, Conexwest, a supplier of standard and modified storage and shipping containers, unveiled a new range of insulated cold storage reefer containers for both purchase and rental. These containers come in sizes varying from 10 to 45 feet. The fabricators and retailers of these storage containers can now provide companies in Fontana and Los Angeles with the most extensive and top-quality line of cold storage solutions. Conexwest has been prioritizing using the highest-quality materials and energy-efficient insulation in all its container fabrications. This commitment not only ensures an affordable purchase or rental price for customers but also promises long-term energy savings.

- In May 2024, CJ Logistics America, an innovative supply chain and technology firm, revealed plans to inaugurate a new cold storage warehouse in New Century, Kansas, a mere 30 miles from Kansas City. This venture, a collaboration between national cold storage developer Yukon Real Estate Partners and BGO, a prominent player in cold storage real estate, features a 291,000 sq. ft warehouse equipped with Alta EXPERT refrigeration. The facility is set to commence operations in Q3 2025. Customers stand to gain significantly, with reduced logistics costs, alongside enhanced environmental sustainability and heightened shipping efficiency, both domestically and internationally.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

- 2.1 Research Framework

- 2.2 Secondary Research

- 2.3 Primary Research Approach and Key Respondents

- 2.4 Data Triangulation and Insight Generation

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Assessment of the Impact of COVID-19 on the Market

5 MARKET DYAMICS

- 5.1 Market Drivers

- 5.1.1 Growth in the Pharmaceutical and Healthcare Industries to Boost the Market

- 5.1.2 Increasing Consumer Demand for Perishable Food

- 5.2 Market Challenges

- 5.2.1 Rising Cost of Raw Materials

- 5.3 Key Market Innovations and Collaborations

- 5.4 Analyst Commentary on the Demand for Direct2Consumer Insulated Shipper Industry

- 5.5 Market Breakdown Analysis

6 MARKET SEGMENTATION

- 6.1 By Material Type

- 6.1.1 Expanded Polystyrene (EPS)

- 6.1.2 Polyurethane Foam (PU)

- 6.1.3 Expanded Polypropylene (EPP)

- 6.1.4 Other Material Types

- 6.2 By End-user Application

- 6.2.1 Pre-cooked Food and Frozen Food

- 6.2.2 Life Sciences and Pharmaceutical

- 6.2.3 Fresh Meat

- 6.2.4 Fresh Produce

- 6.2.5 Bakery, Plants, and Flowers

- 6.2.6 Other End-user Applications (Cosmetics, Wine, and Other Beverages)

- 6.3 By Country

- 6.3.1 United States

- 6.3.2 Canada

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Polar Tech Industries

- 7.1.2 Sonoco Thermosafe (sonoco Products Company)

- 7.1.3 Custom Pack Inc.

- 7.1.4 Temperpack

- 7.1.5 Sofrigam

- 7.1.6 Intelsius (A DGP Company)

- 7.1.7 Cascades Inc.

- 7.1.8 Softbox Systems Ltd (CSAFE Global)

- 7.1.9 Insulated Products Corporation

- 7.1.10 Chill-Pak

- 7.1.11 Airlite Plastics Co. (KODIAKOOLER)

- 7.1.12 Therapak (AVANTOr Group)

- 7.1.13 Thermal Shipping Solution

8 INVESTMENT ANALYSIS

9 FUTURE MARKET OUTLOOK

02-2729-4219

+886-2-2729-4219