|

市场调查报告书

商品编码

1844446

功能印刷:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Functional Printing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

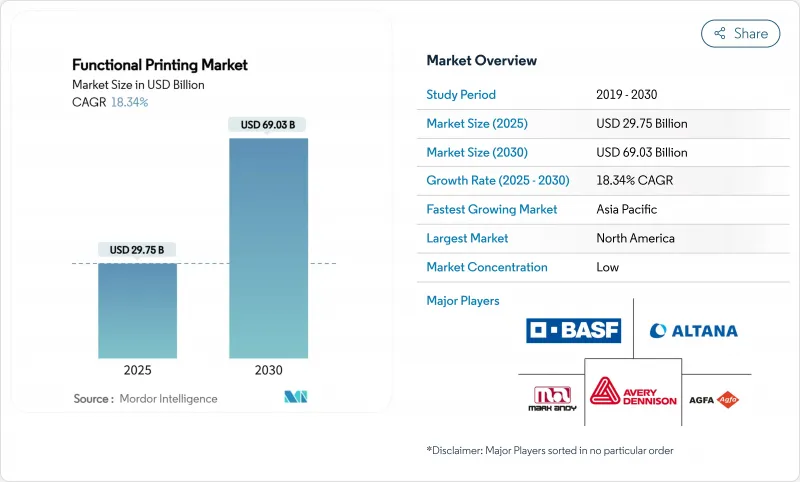

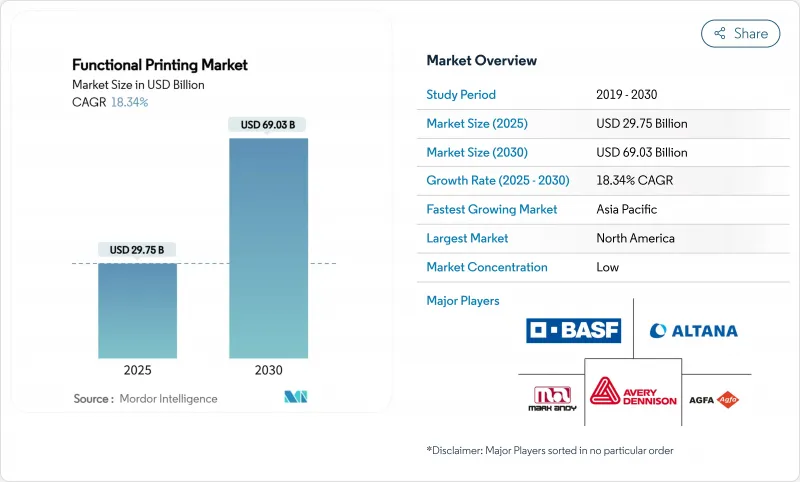

预计2025年功能印刷市场规模将达297.5亿美元,2030年将达690.3亿美元。

导电油墨化学技术的进步已将可实现的线宽推至 10µm 以下,而材料成本使大规模生产触手可及。灵活的外形规格、轻量化组装和低温处理提供了优于传统硅技术的成本优势,加速了汽车、包装和医疗设备等领域的需求。对于诊断贴片和智慧标籤等新兴产品,製造商越来越多地转向支援大批量、在地化生产的捲对卷设备,从而降低了资本强度并缩短了供应链。随着对奈米银线生产和喷墨製程优化的投资增加,规模经济正稳步转向有利于感测器、天线、电源管理薄膜和其他应用的印刷解决方案。市场风险仍然存在,包括贵金属原料的波动和不断变化的废弃物管理规则,这些可能会使首选的基材转向可回收纸和陶瓷。

全球功能印刷市场趋势与洞察

对低成本、高速电子产品生产的需求

消费品和汽车行业的成本压力正促使原始设备製造商 (OEM) 以不需要无尘室基础设施的捲绕式功能电路取代微影术。汽车电池管理系统现已整合印刷温度和电流感测器,可将电子成本降低高达 60%,同时满足非关键精度阈值。拥有捲对卷生产线的区域晶圆厂可以在六个月内实现本地化生产,从而实现比传统硅片代工厂更快的设计迭代。这种灵活性使亚洲契约製造製造商能够透过将设计支援与利润率较低的量产捆绑在一起,赢得智慧包装插页和蓝牙天线的新计画。随着卓越的油墨烧结技术提高了性能上限,功能印刷市场正在获得中阶电子产品的市场份额,而此前这些市场仅限于刚性 PCB。

柔性和穿戴式电子产品的迅速普及

数位化医疗保健正在拥抱能够随着身体运动自然弯曲的贴肤设备,而刚性硅基基板在这方面处于劣势。西北大学的皮肤健康贴片可以捕捉水分和pH值数据,且不会给使用者带来不适。欧洲心臟病诊所正在试用印刷式心电图贴片,可连续佩戴96小时且不会产生刺激,从而提高了患者的依从性。可拉伸电路的高产量比率印刷消除了昂贵的组装步骤,并可实现大规模部署,因为每个单元在印刷机出厂时都能完全正常工作。亚洲製造商正在利用规模经济效应,每年出货数千万个血糖监测贴片,为全球客户提供装置量,从而推动对云端基础的辅助分析的持续需求。

与硅电子元件的性能差异

印刷IGZO电晶体的迁移率仍落后于硅基基准,限制了其在运算和高速通讯设备的应用。碳化硅的熔点为2700 度C,超过了印刷电子产品低于200 度C的热上限,这使得印刷电路无法应用于极端温度的汽车领域。由于聚合物油墨长期漂移有失效风险,关键任务航太设备和医疗植入必须使用成熟的硅基材料。这限制了功能性印刷市场的发展,其应用领域将灵活性和价格置于最终性能之上。

細項分析

预计到2030年,玻璃和陶瓷基板的复合年增长率将达到22.56%,超过更广泛的功能性印刷市场。其热稳定性和光学透明度使其非常适合用于汽车HUD显示器和高温压力感测器。到2024年,塑胶薄膜的功能性印刷市场份额将维持在54.56%,支援超高速、低成本的捲对卷生产线,为智慧标籤和消费性穿戴设备提供原料。虽然玻璃的处理成本较高,但其在微米间距下尺寸稳定性的提升使其能够实现多层OLED背板,而塑胶无法以足够的产量比率满足这一需求。

PET 可在几秒钟内将银光烧结,而陶瓷工艺则可透过热烧结实现高导电性,且基板不会翘曲。纸张和奈米纤维素基板正逐渐成为符合循环经济法规的一次性生物设备贴片的主流选择。金属箔在电磁干扰屏蔽和大电流总线领域仍占有一席之地,其导电性可抵消增加的重量。基板的多样化为原始设备製造商提供了多种选择,使其能够兼顾性能和永续性目标,从而推动功能性印刷市场各个细分领域的均衡成长。

导电油墨仍是大多数印刷电路的基础,到2024年将占其总收入的65.45%。然而,基于奈米粒子的功能性油墨预计将以22.89%的复合年增长率增长,这突显了其在不提高固化温度的情况下降低线路电阻的卓越能力。银奈米粒子浆料在光烧结后可达到10^5 S/m的电导率,这一数字先前仅限于块状金属。虽然铜油墨可以降低材料成本,但它们需要惰性气体固化站来防止氧化,因此需要采用在过程中切换气体的混合印刷生产线。

介电油墨与导体油墨一同持续发展,低损耗有机硅酸盐配方可在薄PET上实现GHz频段天线,并在低功耗物联网节点中取代蚀刻FR-4。光伏和热电油墨系统使製造商能够在几分钟内完成大型太阳能电池和能量收集层的涂覆,从而拓展了功能性印刷市场的潜在应用场景。随着化学创新的加速,油墨供应商正在透过薄片形态、黏合剂生物学和烧结相容性来实现差异化,深化与印表机原始设备製造商的研发合作。

功能印刷市场按基材(纸张/纸板、塑胶薄膜等)、油墨(导电油墨、介电油墨、绝缘油墨等)、印刷技术(喷墨印刷、丝网印刷、凹版印刷、柔版印刷等)、应用(感测器、显示器、OLED照明面板等)和地区细分。市场规模和预测以美元计算。

区域分析

到2024年,北美将以32.45%的市占率保持领先地位,这主要得益于国防航空电子设备和使用尖端印刷薄膜的先进汽车内装。由于柔性PCB生产线的设备更换週期较长,北美功能性印刷市场规模预计将强劲成长。同时,受中国和日本为卷对卷生产提供资本支出补偿的激励措施的推动,亚太地区预计将以21.78%的复合年增长率快速增长。 Elephantech的2,010万美元E轮融资显示了国内市场对永续印刷电路基板的需求。

欧洲供应商正专注于医疗穿戴式装置和汽车光达外壳等高端领域,并利用严格的监管障碍作为竞争壁垒。 「改革计划」等倡议旨在确保关键油墨和基板的本地供应链,并降低地缘政治风险。中东和非洲的公司正在投资用于非电力照明的印刷太阳能箔,而南美洲的农业企业则正在推出低成本的土壤湿度标籤,以优化灌溉。这些不同的重点表明,区域专业化而非一刀切的解决方案将推动功能性印刷的市场渗透。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场状况

- 市场概况

- 市场驱动因素

- 对低成本、高速电子产品生产的需求

- 柔性和穿戴式电子产品的迅速普及

- 导电和介电油墨化学进展

- 物联网主导的智慧包装量

- 电动车中的捲对卷 3D 结构电子装置

- 远端医疗皮肤诊断贴片

- 市场限制

- 与硅电子装置的性能差距

- 缺乏全球製造标准

- 银奈米粒子供应不稳定

- 电子废弃物法规针对不可回收基板

- 供应链分析

- 监管状况

- 技术展望

- 投资金筹措格局

- 波特五力分析

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争的激烈程度

第五章市场规模及成长预测

- 按基材

- 纸和纸板

- 塑胶薄膜

- 玻璃和陶瓷

- 金属箔和柔性金属

- 透过墨水

- 导电油墨

- 介电/绝缘油墨

- 半导体和光伏油墨

- 基于奈米粒子的功能墨水

- 透过印刷技术

- 喷墨列印

- 按需喷墨

- 普通喷墨

- 网版印刷

- 凹版印刷

- 柔版印刷

- 气溶胶喷射列印

- 其他印刷技术

- 喷墨列印

- 按用途

- 感应器

- 温湿度感测器

- 压力/力道感测器

- 生物感测器和穿戴式设备

- 展示

- 电子纸显示器

- 有机发光二极体显示器

- 有机发光二极体照明面板

- 柔性薄膜电池

- 太阳能电池

- 有机光伏

- 钙钛矿太阳能电池

- RFID 和 NFC 标籤

- 其他用途

- 感应器

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 其他欧洲国家

- 亚太地区

- 中国

- 日本

- 韩国

- 印度

- ASEAN

- 澳洲

- 其他亚太地区

- 中东和非洲

- 中东

- GCC

- 土耳其

- 其他中东地区

- 非洲

- 南非

- 埃及

- 奈及利亚

- 其他非洲国家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 北美洲

第六章 竞争态势

- 市场集中度

- 策略倡议

- 市占率分析

- 公司简介

- Avery Dennison Corp.

- BASF SE

- Blue Spark Technologies

- E Ink Holdings Inc.

- Eastman Kodak Co.

- Enfucell Oy

- GSI Technologies LLC

- Isorg SA

- Mark Andy Inc.

- ALTANA AG

- Agfa-Gevaert NV

- Ceradrop-MGI Group

- DuPont de Nemours Inc.

- Samsung Electronics(Printed Solutions)

- LG Display Co.

- Molex LLC

- Thinfilm Electronics ASA

- Toppan Forms Co.

- Toyo Ink SC Holdings

- Optomec Inc.

- Xaar PLC

- Xennia Technology Ltd.

- Kateeva Inc.

- NovaCentrix

- Cambrios Advanced Materials

- Nano Dimension Ltd.

第七章 市场机会与未来展望

The functional printing market size reached a value of USD 29.75 billion in 2025 and is forecast to climb to USD 69.03 billion by 2030, translating into an 18.34% CAGR.

At this trajectory the functional printing market size is positioned to more than double within five years, largely because advances in conductive ink chemistry have pushed achievable line widths below 10 µm while keeping material costs within reach for mass production. Demand accelerates across automotive, packaging, and medical devices where flexible form factors, lightweight assemblies, and low-temperature processing give printed electronics a cost advantage over traditional silicon technology. Manufacturers are increasingly shifting to roll-to-roll equipment that supports high-volume regional production, which reduces capital intensity and shortens supply chains for emerging products such as diagnostic patches and smart labels. Heightened investment flows into silver nanowire production and inkjet process optimization indicate that scale economics are moving steadily in favor of printed solutions for sensors, antennas, and power management films. Market risks remain around precious-metal feedstock volatility and evolving waste-management rules that could shift preferred substrate choices toward recyclable papers or ceramics.

Global Functional Printing Market Trends and Insights

Demand for Low-Cost, High-Speed Electronic Production

Cost pressure across the consumer and automotive sectors prompts OEMs to replace photolithography with roll-processed functional circuits that require no cleanroom infrastructure infinitypv.com. Automotive battery-management systems now integrate printed temperature and current sensors that cut electronics cost by up to 60% while meeting non-critical accuracy thresholds. Regional fabs equipped with roll-to-roll lines can localize production in under six months, allowing quicker response to design iterations than traditional silicon foundries. This flexibility helps Asian contract manufacturers win new projects for smart packaging inserts and Bluetooth antennas by bundling design support with low-margin, high-volume output. As performance ceilings rise through better ink sintering, the functional printing market gains share in mid-range electronics previously reserved for rigid PCBs.

Rapid Adoption of Flexible and Wearable Electronics

Digitized healthcare embraces on-skin devices that flex naturally with body movement, an area where rigid silicon substrates underperform. Northwestern University's skin health patch captures hydration and pH data without user discomfort. European cardiology clinics are piloting printed ECG stickers that achieve 96-hour wear without irritation, improving patient compliance. High-yield printing of stretchable circuits enables mass adoption because each unit ships fully functional from the press, reducing costly assembly steps. Asian manufacturers capitalize on scale economics to ship tens of millions of glucose-monitoring patches annually, feeding a global installed base that drives recurring demand for ancillary cloud-based analytics.

Performance Gap vs. Silicon Electronics

Printed IGZO transistors still lag silicon mobility benchmarks, limiting uptake in computing and high-speed telecom devices. Silicon carbide's 2700 °C melting point dwarfs printed electronics' thermal ceiling below 200 °C, excluding printed circuits from harsh-temperature automotive zones. Mission-critical aerospace and medical implants remain tethered to proven silicon because long-term drift in polymer inks risks field failures. This ceiling confines the functional printing market to segments where flexibility or price trumps ultimate performance.

Other drivers and restraints analyzed in the detailed report include:

- Advances in Conductive and Dielectric Ink Chemistry

- IoT-Driven Smart Packaging Volumes

- Lack of Global Manufacturing Standards

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Glass and ceramic substrates are projected to grow at 22.56% CAGR, outpacing the wider functional printing market through 2030. Their thermal stability and optical clarity suit automotive HUD displays and high-temperature pressure sensors. Plastic films retained 54.56% functional printing market share in 2024 by supporting ultrafast, low-cost roll-to-roll lines that supply smart labels and consumer wearables. Despite higher handling costs, glass improves dimensional stability at micron pitches, enabling multilayer OLED backplanes that plastic cannot achieve with sufficient yield.

Manufacturers optimize each substrate choice around curing profiles; PET allows photo-sintered silver within seconds, while ceramic routes use thermal sintering to achieve high conductivity without substrate warping. Paper and nanocellulose boards gain traction for disposable biodevice patches, aligning with circular-economy regulations. Metal foils remain niche for EMI shielding and high-current bus lines where their conductivity offsets added weight. Substrate diversification gives OEMs a palette to match performance with sustainability targets driving balanced growth across segments of the functional printing market.

Conductive inks captured 65.45% of revenue in 2024 and remain the bedrock of most printed circuits. Yet nanoparticle-based functional inks are forecast to escalate at 22.89% CAGR, underscoring their prowess in reducing line resistance without elevating curing temperature. Silver nanoparticle pastes now reach 10^5 S/m conductivity after photonic sintering, a figure once reserved for bulk metal. Copper inks pare material spend but demand inert-atmosphere curing stations to prevent oxidation, prompting hybrid printing lines that switch atmospheres mid-run.

Dielectric inks evolve alongside conductors; low-loss organosilicate formulations permit GHz-range antennas on thin PET, replacing etched FR-4 in low-power IoT nodes. Photovoltaic and thermoelectric ink systems widen functional printing market addressable use-cases by letting manufacturers coat large solar or energy-harvest layers in minutes. As chemistry innovation accelerates, ink suppliers differentiate on flake geometry, binder biology, and sintering compatibility, deepening collaborative R&D with printer-OEMs.

Functional Printing Market is Segmented by Substrates (Paper and Paperboard, Plastic Films, and More), Ink (Conductive Inks, Dielectric and Insulating Inks, and More), Printing Technology (Inkjet Printing, Screen Printing, Gravure Printing, Flexography Printing, and More), Application (Sensors, Displays, OLED Lighting Panels, and More), and Geography. The Market Sizes and Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America maintained leadership with 32.45% share in 2024 on the back of defense avionics and advanced automotive interiors that specify cutting-edge printed films. The functional printing market size for North America is slated to grow steadily on high equipment replacement cycles in flexible PCB lines. Asia-Pacific, meanwhile, is forecast for the quickest 21.78% CAGR, buoyed by Chinese and Japanese incentives that reimburse capital outlays for roll-to-roll production. Elephantech's USD 20.1 million Series E demonstrates domestic appetite for sustainable printed PCBs.

European suppliers focus on premium segments such as medical wearables and automotive lidar housings, leveraging stringent regulatory hurdles as a competitive moat. Initiatives like the Reform Project aim to secure a local supply chain for critical inks and substrates, mitigating geopolitical risk . The Middle East and Africa invest in printed solar foils for off-grid lighting, while South American agribusiness deploys low-cost soil-moisture labels to optimize irrigation. These divergent priorities underline why regional specialization rather than one-size-fits-all solutions will drive functional printing market adoption.

- Avery Dennison Corp.

- BASF SE

- Blue Spark Technologies

- E Ink Holdings Inc.

- Eastman Kodak Co.

- Enfucell Oy

- GSI Technologies LLC

- Isorg SA

- Mark Andy Inc.

- ALTANA AG

- Agfa-Gevaert NV

- Ceradrop - MGI Group

- DuPont de Nemours Inc.

- Samsung Electronics (Printed Solutions)

- LG Display Co.

- Molex LLC

- Thinfilm Electronics ASA

- Toppan Forms Co.

- Toyo Ink SC Holdings

- Optomec Inc.

- Xaar PLC

- Xennia Technology Ltd.

- Kateeva Inc.

- NovaCentrix

- Cambrios Advanced Materials

- Nano Dimension Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Demand for low-cost, high-speed electronic production

- 4.2.2 Rapid adoption of flexible and wearable electronics

- 4.2.3 Advances in conductive and dielectric ink chemistry

- 4.2.4 IoT-driven smart packaging volumes

- 4.2.5 Roll-to-roll 3D structural electronics in e-mobility

- 4.2.6 On-skin diagnostic patches for tele-health

- 4.3 Market Restraints

- 4.3.1 Performance gap vs. silicon electronics

- 4.3.2 Lack of global manufacturing standards

- 4.3.3 Silver nanoparticle supply volatility

- 4.3.4 E-waste rules targeting non-recyclable substrates

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Investment and Funding Landscape

- 4.8 Porter's Five Forces Analysis

- 4.8.1 Threat of New Entrants

- 4.8.2 Bargaining Power of Buyers

- 4.8.3 Bargaining Power of Suppliers

- 4.8.4 Threat of Substitutes

- 4.8.5 Intensity of Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Substrates

- 5.1.1 Paper and Paperboard

- 5.1.2 Plastic Films

- 5.1.3 Glass and Ceramics

- 5.1.4 Metal Foils and Flex-metals

- 5.2 By Inks

- 5.2.1 Conductive Inks

- 5.2.2 Dielectric and Insulating Inks

- 5.2.3 Semiconductive and PV Inks

- 5.2.4 Nanoparticle-based Functional Inks

- 5.3 By Printing Technology

- 5.3.1 Inkjet Printing

- 5.3.1.1 Drop-on-Demand Inkjet

- 5.3.1.2 Continuous Inkjet

- 5.3.2 Screen Printing

- 5.3.3 Gravure Printing

- 5.3.4 Flexography Printing

- 5.3.5 Aerosol Jet Printing

- 5.3.6 Other Printing Technology

- 5.3.1 Inkjet Printing

- 5.4 By Application

- 5.4.1 Sensors

- 5.4.1.1 Temperature and Humidity Sensors

- 5.4.1.2 Pressure and Force Sensors

- 5.4.1.3 Biosensors and Wearables

- 5.4.2 Displays

- 5.4.2.1 E-paper Displays

- 5.4.2.2 OLED Displays

- 5.4.3 OLED Lighting Panels

- 5.4.4 Flexible Thin-film Batteries

- 5.4.5 Photovoltaic

- 5.4.5.1 Organic PV

- 5.4.5.2 Perovskite PV

- 5.4.6 RFID and NFC Tags

- 5.4.7 Other Application

- 5.4.1 Sensors

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 Germany

- 5.5.2.2 United Kingdom

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Russia

- 5.5.2.7 Rest of Europe

- 5.5.3 Asia-Pacific

- 5.5.3.1 China

- 5.5.3.2 Japan

- 5.5.3.3 South Korea

- 5.5.3.4 India

- 5.5.3.5 ASEAN

- 5.5.3.6 Australia

- 5.5.3.7 Rest of Asia-Pacific

- 5.5.4 Middle East and Africa

- 5.5.4.1 Middle East

- 5.5.4.1.1 GCC

- 5.5.4.1.2 Turkey

- 5.5.4.1.3 Rest of Middle East

- 5.5.4.2 Africa

- 5.5.4.2.1 South Africa

- 5.5.4.2.2 Egypt

- 5.5.4.2.3 Nigeria

- 5.5.4.2.4 Rest of Africa

- 5.5.5 South America

- 5.5.5.1 Brazil

- 5.5.5.2 Argentina

- 5.5.5.3 Rest of South America

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Avery Dennison Corp.

- 6.4.2 BASF SE

- 6.4.3 Blue Spark Technologies

- 6.4.4 E Ink Holdings Inc.

- 6.4.5 Eastman Kodak Co.

- 6.4.6 Enfucell Oy

- 6.4.7 GSI Technologies LLC

- 6.4.8 Isorg SA

- 6.4.9 Mark Andy Inc.

- 6.4.10 ALTANA AG

- 6.4.11 Agfa-Gevaert NV

- 6.4.12 Ceradrop - MGI Group

- 6.4.13 DuPont de Nemours Inc.

- 6.4.14 Samsung Electronics (Printed Solutions)

- 6.4.15 LG Display Co.

- 6.4.16 Molex LLC

- 6.4.17 Thinfilm Electronics ASA

- 6.4.18 Toppan Forms Co.

- 6.4.19 Toyo Ink SC Holdings

- 6.4.20 Optomec Inc.

- 6.4.21 Xaar PLC

- 6.4.22 Xennia Technology Ltd.

- 6.4.23 Kateeva Inc.

- 6.4.24 NovaCentrix

- 6.4.25 Cambrios Advanced Materials

- 6.4.26 Nano Dimension Ltd.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment