|

市场调查报告书

商品编码

1846194

低温阀门:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Cryogenic Valves - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

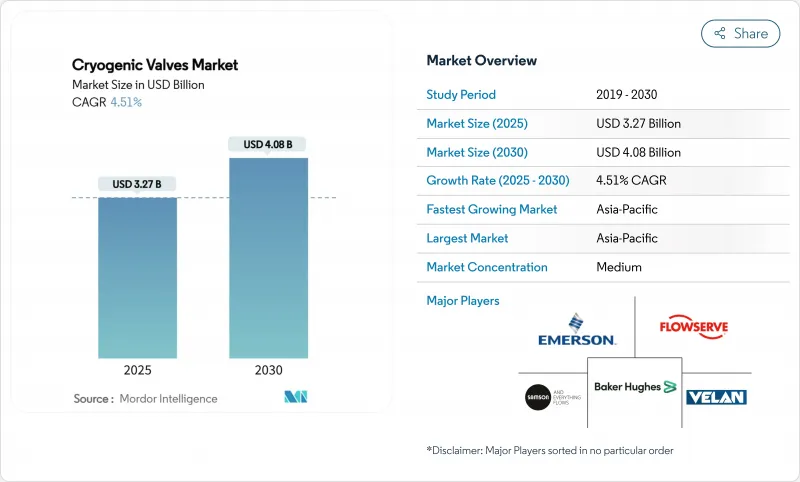

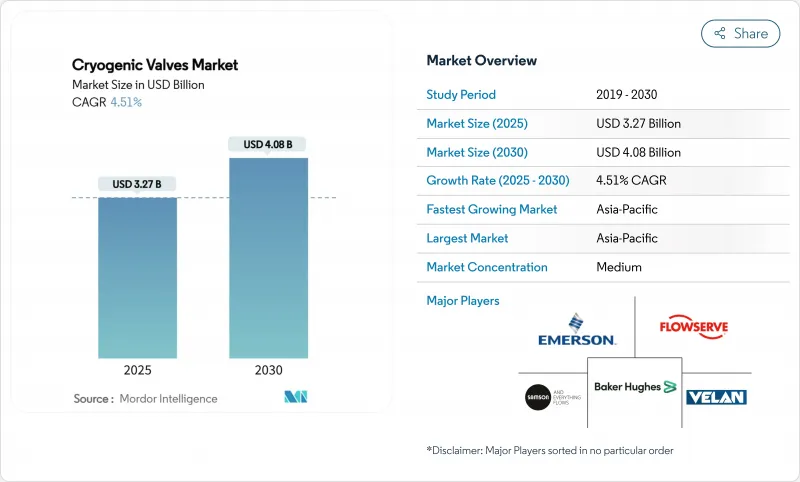

预计到 2025 年,低温阀门市场规模将达到 32.7 亿美元,到 2030 年将达到 40.8 亿美元,预测期(2025-2030 年)复合年增长率为 4.51%。

液化天然气 (LNG) 接收站、绿色氢能计划和石化扩建专案的投资不断增长,支撑着这一稳步发展趋势。大型设施都需要数百个能够在低于 -150 度C 的温度下密封的阀门,因此业主更倾向于选择能够快速通过多项标准认证的供应商。亚太地区仍然是最大的设备买家,而北美则为氢气试点工厂提供了高价值的商机。能够将低温工程与售后服务相结合的製造商正在赢得高额合同,因为终端用户需要长期可靠性和快速的维护週转时间。

全球低温阀门市场趋势及洞察

增加液化天然气基础设施投资

2024年至2028年间的扩建计画将使全球液化天然气(LNG)产能提升40%,届时美国将超越卡达成为主导的出口国,而亚太地区将购买新增货物的大部分。贝克休斯公司已获得路易斯安那州两套LNG生产线的56亿美元订单,这表明承包商对拥有现场验证经验、能够保证超低洩漏性能的阀门合作伙伴的需求旺盛。预计到2030年,船舶燃料需求将超过每年1,600万吨,促使港口指定使用具有整合式紧急切割阀的自动化低温输送组件。企业产品合作伙伴公司(Enterprise Products Partners)将把休士顿航道的冷却能力扩大至每日30万桶,从而产生新的订单,用于生产工作温度低至-162°C的三偏心截止阀。沙乌地阿美投资 77 亿美元的法迪利升级项目将增加 13 亿立方英尺/天的脱臭气处理能力,每条生产线都配备冗余的低温流动路径来处理混合冷媒。

工业气体需求不断成长

液化空气集团位于德克萨斯州的四套模组化空气分离装置每天向埃克森美孚的低碳氢化合物生产联合体供应9000吨氧气,并生产北美最大的氩气流。随着医疗保健行业的扩张持续推动液态氧消费量,医院要求采用能够防止颗粒物在患者迴路中逸出的阀门设计。食品加工商倾向于使用液态氮隧道进行深度冷冻,并使用能够承受低至-196°C快速热循环并保持卫生洁净的阀门。可再生驱动的空气分离装置需要快速反应的控制微调装置,以便操作人员能够根据电网电价的波动调整输出。

安全与合规的复杂性

ASME B31.3 要求材料必须经过衝击试验,温度低于 -425°F(-220°C)。符合标准的阀门采用经摆锤测试认证的奥氏体不銹钢或铝合金。 2025 年 ASME VIII 更新将引入新的低温案例研究,要求设计人员增加更厚的阀盖或波纹管密封件以满足新规要求。 MSS SP-158-2021 强制要求进行高压气体测试,这增加了开发成本,但也鼓励公用事业公司要求进行认证以降低停电风险。美国联邦法规 49 CFR 要求阀门能够承受储罐测试压力而不被穿透,并包含坚固的机械损伤防护装置,这影响了拖车布局的选择。安全阀的五年重新认证週期虽然带来了持续的服务收入,但也增加了小型业者的拥有成本。小型製造商难以跟上多个司法管辖区的规范更新,导致现有品牌的竞争力下降。

细分市场分析

到2024年,球阀将占据低温阀门市场34.18%的份额。製造商提供加长阀桿设计,可将阀座与沸腾的液化气体隔离,防止结冰和阀座损坏。艾默生Fisher HP系列采用弹簧活化的聚四氟乙烯(PTFE)环,可在-198 ℃下维持VI级密封性能。儘管截止阀的装置量较小,但由于其节流精度高,在氢气液化计划中备受青睐,预计其年复合成长率将达到5.41%。在生产8至10吨/小时液氢的试验工厂中,截止阀的市场规模预计将显着扩大,因为这些工厂需要可变流量控制来管理正仲氢转化过程中的热量。

技术改进在两条产品线中持续进行。球阀製造商正在增加符合 ISO 15848-1 A 级认证的石墨阀盖密封件,以实现超低逸散排放,这对于寻求 ESG 积分的操作员而言至关重要。截止阀 OEM 厂商正在采用轮廓阀芯,以实现等比特性,从而提高多级膨胀机的製程稳定性。闸阀和止回阀继续保持其在特定领域的应用。闸阀适用于最大 42 英吋的全通径 LNG 装载管线,而双板低温止回阀可防止蒸发气再循环迴路中的突波。专用蝶阀和塞阀填补了诸如超低密度氦气应用等对超低扭矩要求极高的应用空白。

到2024年,手动齿轮和手轮操作器将占据低温阀门市场59.82%的份额,其优势在于操作简便,且在断电情况下具有固有的故障安全能力。液化天然气出口终端依靠手动隔离阀在泊位紧急情况下保护货物管线。然而,由于设施业主转向远端操作以减少人力投入,该领域的成长较为缓慢。气动驱动装置到2030年将以5.57%的复合年增长率成长,利用封闭式压缩空气或氮气在故障关闭逻辑下快速行程。氢气生产设施倾向于采用气动驱动装置,以避免与电动马达相关的火灾风险。

电动致动器在需要数据丰富的定位回馈的领域找到了用武之地,例如在数位管理的氮气冷冻隧道中,它可以微调流量以保持产品质地。将可分离式变速箱与气压驱动装置连接的混合解决方案,结合了手动超控和自动调速功能,在双用途设备中越来越受欢迎。原始设备製造商 (OEM) 越来越多地采用智慧定位器,这些定位器可以测量阀桿摩擦和循环次数,并将资料输入工厂历史记录,从而在洩漏发生之前触发服务工单。这种预测性维护模式加强了售后市场联繫,并提高了已安装阀门的终身收益。

区域分析

预计到2024年,亚太地区将占低温阀门市场26.55%的份额,并在2030年之前以5.72%的复合年增长率持续成长。中国天然气发电政策的转变以及印度热浪带来的需求正在推动进口成长,而日本和韩国正在投资建设转运中心,以重新定位来自美国的货物。在澳大利亚,老旧的液化装置正进入维修週期,从而促进了售后阀门服务的发展。中国、韩国和澳洲政府制定的氢能发展蓝图,正在增加试点液化装置对高压截止阀的竞标。

北美受惠于美国成为全球最大的液化天然气出口国以及联邦政府对氢能中心的大力资助。墨西哥湾沿岸的棕地液化计划要求加入北美阀门工业协会,这有利于拥有本地库存的国内供应商。液化空气集团在贝城的投资以及多个中型液态氧生产项目将维持工业气体阀门的稳定需求。加拿大首批液化天然气预计将于2027年从不列颠哥伦比亚省交付,将提振西半球的需求。

儘管2024年液化天然气进口量下降,欧洲仍积极发展氢能。德国计划建造10吉瓦的电解槽,该电解槽与液化和地下储存计画密切相关,这两个计画都指定使用超低洩漏隔离阀。欧洲地平线计画正在资助西班牙和荷兰之间的移动式液氢储罐试验,并由此获得了一批专用货物装卸阀的订单。北欧港口正在加速液化天然气燃料库的部署,以支援绿色走廊航运联盟。

中东和非洲正在兴建大规模的天然气加工待开发区。沙乌地阿美公司的法迪利扩建计画、卡达的北方南气田计画以及阿曼的多个石化联合装置都需要能够耐受酸性气体化合物的耐久性低温冶金技术。阿布达比正在探索蓝氨技术,并将液化天然气生产线和阀门组件的设计概念融入其中。在非洲,莫三比克陆上液化天然气工厂的建设已被推迟,但一旦安全局势稳定,预计将启动新一轮阀门采购。

南美洲的液化天然气市场尚处于起步阶段,但已展现出巨大潜力。巴西正在考虑采用浮体式储存再气化装置(FSRA)来应对季节性天然气短缺,因此需要紧凑型低温阀门撬装设备。阿根廷的瓦卡穆尔塔页岩气最终可能为液化天然气出口驳船计划提供气源,但目前由于时间上的不确定性,需求暂时受到抑制。智利的采矿业正在探索使用液态氧来提高製程效率,这预示着小型但利润丰厚的阀门应用前景广阔。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 增加液化天然气基础设施投资

- 工业气体需求不断成长

- 加速氢能经济计划建设进程

- 石化和特种气体厂产能扩张

- 全球港口的小规模液化天然气燃料库

- 市场限制

- 安全与合规的复杂性

- 不銹钢和镍的价格波动

- 硬焊零件的供应链差异

- 价值链分析

- 五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模与成长预测

- 依产品类型

- 球阀

- 闸阀

- 截止阀

- 单向阀

- 其他产品类型

- 透过驱动

- 手动型

- 气压

- 电的

- 气体

- 液态氮

- 液化天然气

- 氢

- 氧

- 其他气体

- 按最终用户产业

- 石油和天然气

- 能源和电力

- 化学

- 饮食

- 医疗保健

- 其他终端用户产业

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 其他欧洲国家

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 其他亚太地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 北美洲

第六章 竞争情势

- 市场集中度分析

- 策略倡议

- 市占率分析

- 公司简介

- BAC Valves

- Baker Hughes

- Bray International

- Burkert India Private Limited

- Cryofab Inc.

- Emerson Electric Co.

- Flowserve Corporation

- Habonim

- HEROSE GmbH

- L&T Valves Limited

- Meca-Inox

- Neway Valve

- OPW, A Dover Company

- Parker Hannifin Corp

- Powell Valves

- Samson AG

- Swagelok Company

- Velan

第七章 市场机会与未来展望

The Cryogenic Valves Market size is estimated at USD 3.27 billion in 2025, and is expected to reach USD 4.08 billion by 2030, at a CAGR of 4.51% during the forecast period (2025-2030).

Rising investment in liquefied natural gas (LNG) terminals, green-hydrogen projects, and petro-chemical expansions underpins this steady trajectory. Large-scale facilities each require hundreds of valves capable of sealing at temperatures below -150 °C, and owners favour suppliers able to certify products quickly for multiple codes. Asia-Pacific remains the largest regional buyer of equipment, while North America delivers high-value opportunities tied to hydrogen pilot plants. Producers able to combine cryogenic engineering depth with aftermarket services are attracting premium contract awards, as end-users seek long-term reliability and fast turn-round maintenance.

Global Cryogenic Valves Market Trends and Insights

Rising LNG Infrastructure Investments

Expansions slated between 2024-2028 will lift global LNG liquefaction capacity by 40%, with the United States overtaking Qatar as lead exporter while Asia-Pacific purchases the bulk of incremental cargoes. Baker Hughes secured USD 5.6 billion of LNG equipment awards for two Louisiana trains, illustrating contractor appetite for field-proven valve partners able to guarantee ultra-low-leak performance. Marine bunkering demand is forecast to exceed 16 million t annually by 2030, prompting ports to specify automated cryogenic transfer assemblies that integrate emergency shut-off valves. Enterprise Products Partners is expanding Houston Ship Channel refrigeration capacity by 300,000 bbl/d, creating new orders for triple-offset stop-valves rated down to -162 °C. Saudi Aramco's USD 7.7 billion Fadhili upgrade will add 1.3 Bcf/d of sweet-gas processing, each train fitted with redundant cryogenic flow-paths to handle mixed refrigerants.

Growth in Industrial Gas Demand

Air Liquide's four modular air-separation units in Texas will deliver 9,000 t/d of oxygen to ExxonMobil's low-carbon hydrogen complex and generate the continent's largest argon stream, placing long-cycle demand on valve makers able to certify for oxygen service. Healthcare expansion keeps liquid-oxygen consumption rising, and hospitals mandate valve designs that prevent particle shedding in patient circuits. Food processors favour liquid nitrogen tunnels for flash-freezing, with valves that tolerate rapid thermal cycling down to -196 °C while maintaining hygienic finishes. Renewable-powered air-separation plants require fast-response control trim so operators can throttle output to match fluctuating grid tariffs.

Safety & Compliance Complexities

ASME B31.3 mandates impact-tested materials below -425 °F; complying valves use austenitic stainless or aluminium alloys proven by Charpy testing. The 2025 ASME VIII update introduces fresh cryogenic case studies, prompting designers to add thicker bonnets or bellows seals to satisfy the new rules. MSS SP-158-2021 requires high-pressure gas tests that inflate development costs, yet utilities increasingly insist on the certification to reduce outage risk. U.S. Code 49 CFR obliges valves to hold tank test pressure without seepage and to include robust guards against mechanical damage, shaping layout choices on trailers. Five-year recertification cycles for safety valves generate recurring service revenue but raise ownership costs for small operators. Smaller fabricators struggle to keep pace with multi-jurisdiction code work, giving established brands a competitive edge.

Other drivers and restraints analyzed in the detailed report include:

- Hydrogen-Economy Project Pipeline Acceleration

- Capacity Additions in Petro-chem & Specialty Gas Plants

- Stainless-Steel & Nickel Price Volatility

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Ball valves held a dominant 34.18% cryogenic valves market share in 2024, owing to proven tight shut-off and straightforward maintenance. Manufacturers supply extended-stem designs that isolate the seat from boiling liquefied gases, cutting ice buildup and seat damage. Emerson's Fisher HP series uses spring-energised PTFE rings to hold Class VI shut-off at -198 °C. Globe valves, though smaller in installed base, are expected to grow at 5.41% CAGR as hydrogen liquefaction projects favour their throttling precision. The cryogenic valves market size for globe valves is anticipated to widen notably in pilot plants producing 8-10 t/h of liquid hydrogen, each calling for variable-flow control to manage ortho-para conversion heat.

Technical enhancements continue across both lines. Ball-valve makers are adding graphite bonnet seals certified to ISO 15848-1 Class A for ultra-low fugitive emissions, an important factor for operators seeking ESG credits. Globe-valve OEMs are deploying contoured plugs that deliver equal-percentage characteristics, enhancing process stability in multi-stage expanders. Gate and check valves retain niche uses: gate valves accommodate full-bore LNG loading lines up to 42 in, while dual-plate cryogenic check valves prevent reverse surge in boil-off gas recirculation loops. Specialty butterfly and plug valves fill gaps such as helium service at ultra-low density where very low torque is essential.

Manual gear and hand-wheel operators represented 59.82% of the cryogenic valves market in 2024, prized for simplicity and intrinsic fail-safe capability during power loss. LNG export terminals rely on manual isolation valves to secure cargo lines during berth-side emergencies. The segment, however, grows slowly as facility owners look to remote operation to cut staffing. Pneumatic actuation will expand at 5.57% CAGR to 2030, leveraging plant air or nitrogen to deliver quick stroke times under fail-closed logic. Hydrogen sites favour pneumatic drives to avoid ignition risks linked to electric motors.

Electric actuators achieve niche uptake where data-rich position feedback is essential, such as in digitally managed nitrogen freezing tunnels that fine-tune flow to maintain product texture. Hybrid solutions that bolt a declutchable gearbox onto a pneumatic drive combine manual override with automated speed, capturing demand in dual-use installations. OEMs increasingly embed smart positioners measuring stem friction and cycle count, feeding plant historians that trigger service work orders before leakage occurs. This predictive-maintenance model strengthens aftermarket ties and lifts lifetime revenue per installed valve.

The Cryogenic Valves Market Report is Segmented by Product Type (Ball Valve, Gate Valve, Globe Valve, Check Valve, Other Product Types), Actuation (Manual, Pneumatic, Electric), Gas (Liquid Nitrogen, Liquid Natural Gas, and More), End-User Industry (Oil and Gas, Energy and Power, Chemicals, and More), and Geography (Asia-Pacific, North America, Europe, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific controlled 26.55% of the cryogenic valves market in 2024 and is projected to expand by a 5.72% CAGR through 2030. China's gas-to-power policy reversal and India's heat-wave-driven demand are reviving import growth, while Japan and South Korea invest in re-loading hubs that reposition cargoes from the United States. Australia's ageing liquefaction trains enter refurbishment cycles, pushing aftermarket valve services. Government hydrogen roadmaps in China, South Korea and Australia create incremental bids for high-pressure globe valves at pilot liquefier sites.

North America benefits from the United States becoming the world's largest LNG exporter and from aggressive federal funding for hydrogen hubs. Gulf Coast brownfield liquefaction projects stipulate North American Valve Manufacturers Association membership, favouring domestic suppliers with local inventories. Air Liquide's Baytown investment plus multiple mid-scale liquid-oxygen build-owns maintain steady industrial-gas valve uptake. Canada's first LNG shipment slated for 2027 from British Columbia will add western-hemisphere demand.

Europe, despite softer LNG imports in 2024, commits heavily to hydrogen. Germany's planned 10 GW of electrolyser capacity links to liquefaction and underground storage schemes, each specifying ultra-low-leak isolation valves. Horizon Europe funds mobile LH2 tank trials between Spain and the Netherlands, generating specialty cargo-handling valve orders. Nordic ports accelerate LNG bunkering roll-outs supporting green-corridor shipping alliances.

The Middle East and Africa witness sizeable greenfield gas processing. Saudi Aramco's Fadhili expansion, Qatar's North Field South and multiple Omani petro-chem complexes need durable cryogenic metallurgy that resists sour-gas compounds. Abu Dhabi is exploring blue-ammonia, which will import design philosophies from LNG trains to valve packages. In Africa, Mozambique's postponed onshore LNG plant, once security stabilises, promises a fresh cycle of valve procurement.

South America remains nascent yet promising. Brazil eyes floating storage and regasification units to manage seasonal gas deficits, requiring compact cryogenic valve skids. Argentina's Vaca Muerta shale may eventually feed LNG export barge projects, though timetable uncertainty tempers near-term demand. Chile's mining sector investigates liquid oxygen for process efficiency, presenting small but high-margin valve prospects.

- BAC Valves

- Baker Hughes

- Bray International

- Burkert India Private Limited

- Cryofab Inc.

- Emerson Electric Co.

- Flowserve Corporation

- Habonim

- HEROSE GmbH

- L&T Valves Limited

- Meca-Inox

- Neway Valve

- OPW, A Dover Company

- Parker Hannifin Corp

- Powell Valves

- Samson AG

- Swagelok Company

- Velan

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising LNG infrastructure investments

- 4.2.2 Growth in industrial gas demand

- 4.2.3 Hydrogen-economy project pipeline acceleration

- 4.2.4 Capacity additions in petro-chem & specialty gas plants

- 4.2.5 Small-scale LNG bunkering at global ports

- 4.3 Market Restraints

- 4.3.1 Safety & compliance complexities

- 4.3.2 Stainless-steel & nickel price volatility

- 4.3.3 Supply-chain gaps in vacuum-brazed components

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Competitive Rivalry

5 Market Size & Growth Forecasts (Value)

- 5.1 By Product Type

- 5.1.1 Ball Valve

- 5.1.2 Gate Valve

- 5.1.3 Globe Valve

- 5.1.4 Check Valve

- 5.1.5 Other Product Types

- 5.2 By Actuation

- 5.2.1 Manual

- 5.2.2 Pneumatic

- 5.2.3 Electric

- 5.3 By Gas

- 5.3.1 Liquid Nitrogen

- 5.3.2 Liquid Natural Gas

- 5.3.3 Hydrogen

- 5.3.4 Oxygen

- 5.3.5 Other Gases

- 5.4 By End-user Industry

- 5.4.1 Oil and Gas

- 5.4.2 Energy and Power

- 5.4.3 Chemicals

- 5.4.4 Food and Beverage

- 5.4.5 Medical

- 5.4.6 Other End-user Industries

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 Italy

- 5.5.3.4 France

- 5.5.3.5 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 India

- 5.5.4.3 Japan

- 5.5.4.4 South Korea

- 5.5.4.5 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 South Africa

- 5.5.5.3 Rest of Middle East and Africa

- 5.5.1 North America

6 Competitive Landscape

- 6.1 Market Concentration Analysis

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 BAC Valves

- 6.4.2 Baker Hughes

- 6.4.3 Bray International

- 6.4.4 Burkert India Private Limited

- 6.4.5 Cryofab Inc.

- 6.4.6 Emerson Electric Co.

- 6.4.7 Flowserve Corporation

- 6.4.8 Habonim

- 6.4.9 HEROSE GmbH

- 6.4.10 L&T Valves Limited

- 6.4.11 Meca-Inox

- 6.4.12 Neway Valve

- 6.4.13 OPW, A Dover Company

- 6.4.14 Parker Hannifin Corp

- 6.4.15 Powell Valves

- 6.4.16 Samson AG

- 6.4.17 Swagelok Company

- 6.4.18 Velan

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-need Assessment