|

市场调查报告书

商品编码

1846228

欧洲电动车电池管理系统:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Europe Electric Vehicle Battery Management System - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

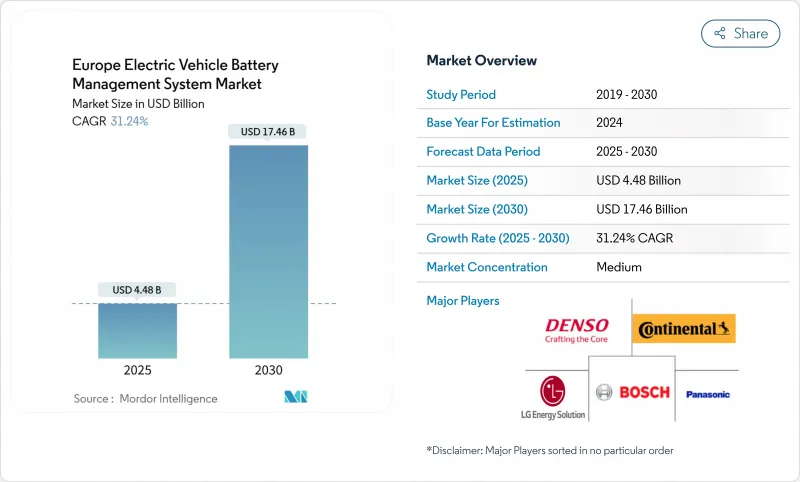

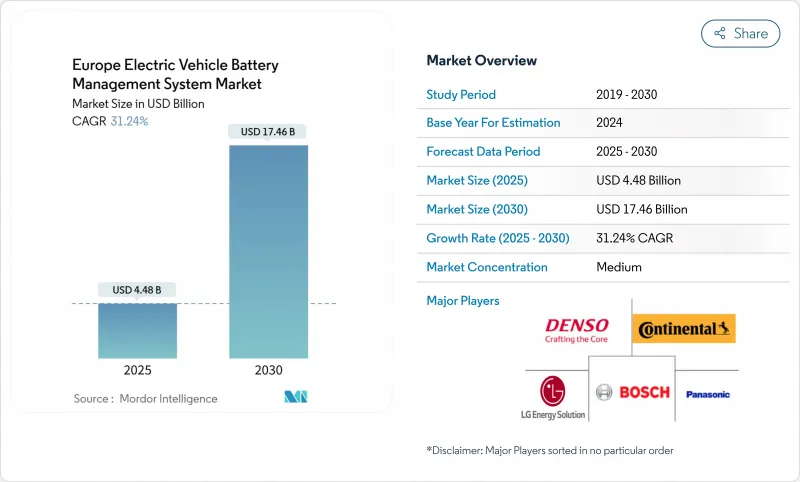

欧洲电动车电池管理系统市场预计到 2025 年将达到 44.8 亿美元,到 2030 年将达到 174.6 亿美元,年复合成长率为 31.24%。

此次市场扩张反映了欧盟严格的二氧化碳排放法规(要求所有新乘用车到2035年实现零排放)、高端市场向800V电动平台的活性化,以及中欧地区超级工厂的积极建设。此外,保险主导的电池可追溯性法规和电池护照的早期试点也推动了市场需求,促使原始设备製造商(OEM)采用更强大、网路安全性更高的电池管理软体。模组化电池组架构降低了设计成本,并加速了多品牌电动平台的部署。儘管半导体供应和高压认证流程仍面临压力,但大多数OEM仍优先考虑电池管理系统(BMS)的投资,以避免因热失控事故而遭受巨额二氧化碳排放罚款和召回成本。

欧洲电动车电池管理系统市场趋势与洞察

2035年电动车二氧化碳排放法规

欧盟强制要求在2035年实现100%零排放汽车销售,并对每超标1克二氧化碳排放的汽车製造商处以95欧元的罚款,这将不可逆转地刺激对先进电池管理系统(BMS)解决方案的需求。这个法律规范将促使製造商加快纯电动车(BEV)的生产,使其市场基准值超过目前的13.5%,并要求年增长率达到14%,同时需要先进的电池管理能力来适应更大容量和更高能量密度的电池组。该法规的另一个影响是,保险公司正在强制要求安装全面的电池监控系统,这为能够证明其具备故障预测能力并能降低保固成本的BMS供应商创造了新的收益来源。高阶汽车製造商正在积极回应,大力投资800V架构,这需要更先进的温度控管和电池平衡演算法,从而直接惠及拥有先进电力电子技术的BMS供应商。合规期限造成了供应链瓶颈,其中BMS认证是关键环节,这使得拥有ISO 26262功能安全认证的现有供应商相对于新参与企业拥有显着的竞争优势。

OEM厂商正迅速转向800V架构

汽车产业向800V电气架构的转型代表着一次根本性的变革,这需要全新的电池管理系统(BMS)设计,以应对更高的电压差和更复杂的热动态。 BMW与Rimac Technologies合作开发下一代电池组,沃尔沃与Vitesco Technologies合作,都表明高端汽车製造商正在优先考虑快速充电功能,而这需要先进的电压监控和电池均衡演算法。对于缺乏高压技术专长的BMS供应商而言,这种架构转型构成了巨大的进入门槛,因为在800V运作等级下,ISO 26262认证的要求将呈指数级增长。虽然这种转型使得充电10分钟即可增加200英里的续航里程成为可能,但也为电池单元带来了传统BMS设计无法有效应对的极端热应力,迫使供应商整合先进的冷却演算法和预测性热模型。欧洲汽车製造商正利用这项转型来区别于主要使用400V系统的中国竞争对手,从而建造起暂时的技术护城河,使拥有先进电力电子技术的本土BMS供应商受益。

半导体供应链紧张

全球半导体短缺持续限制电池管理系统(BMS)的产能,导致汽车晶片的前置作业时间超过26週,并引发欧洲电动车生产计画的连锁延误。这项限制对先进的BMS设计影响尤其显着,因为这些设计需要专用的电源管理IC和微控制器,能够支援800V架构和复杂的散热演算法。欧洲BMS供应商面临更大的压力,他们与消费性电子产品製造商争夺有限的晶片配额,并且由于其订单量低于智慧型手机和运算应用,往往处于优先顺序。这种短缺迫使製造商围绕现有组件重新设计BMS架构,这可能会影响效能最佳化,并将开发週期延长12至18个月。供应链的韧性是至关重要的竞争因素,各公司正在维持策略库存缓衝并建立替代采购关係,以确保生产的连续性。这项制约为欧洲半导体製造商从亚洲供应商手中夺取市场份额创造了机会。然而,这些措施需要大量的资本投资和2-3年的开发週期,可能无法满足当前的供应需求。

细分市场分析

到2024年,纯电动车将占据72.48%的市场份额,并在2030年之前以32.86%的复合年增长率引领成长。这反映出市场正朝着纯电动动力传动系统发生决定性转变,汽车製造商放弃了混合动力策略,转而追求平台简化。纯电动车(BEV)的主导地位主要得益于欧盟二氧化碳排放法规的压力,以及消费者对简化用车体验、避免插电式混合动力车复杂性带来的里程焦虑的偏好。插电式混合动力车(PHEV)在营运灵活性至关重要的商业应用中仍然具有重要意义。然而,随着製造商将研发资源转向具有更优规模经济效益的纯电动车平台,对插电式混合动力车的投资正在减少。细分市场的动态变化揭示了一个关键的曲折点,即电池管理系统(BMS)的要求会因动力类型的不同而显着变化。同时,插电式混合动力车需要复杂的功率仲裁演算法来实现双动力传动系统的协调。

面向纯电动车 (BEV) 的先进电池管理系统 (BMS) 架构越来越多地采用机器学习演算法进行预测性热建模。 LG Energy Solutions 的 B.around 平台分析超过 13 万个电池单元的数据,以优化充电曲线并延长电池组寿命。这种技术上的复杂性为缺乏软体专业知识的传统汽车零件製造商设定了准入门槛,使得像 Munich Electrification 这样的新兴参与企业能够透过专为 1500V 及以下能源储存系统设计的 BMS 解决方案来抢占市场份额。动力系统类型的细分日益反映出围绕 BEV 平台的更广泛的整合产业,这影响着 BMS 供应商,他们必须在迎合日渐萎缩的插电式混合动力汽车 (PHEV) 市场和大力投资下一代 BEV 技术之间做出选择。

到2024年,乘用车将占车辆总需求的67.91%。然而,受城市物流转型和共用出行平台扩张的推动,两轮车和微型出行领域将呈现令人瞩目的成长,到2030年复合年增长率将达到32.64%。商用车占据着战略性的中间位置,其电池管理系统(BMS)要求专注于耐久性和预测性维护,而非性能优化,这为能够展现总拥有成本优势的供应商创造了机会。微型出行的普及反映了城市交通模式的根本性变化,轻量化BMS设计必须在安全要求和成本限制之间取得平衡,以满足共用车辆在高强度使用週期和多样化环境条件下的需求。

车队营运商对先进的电池分析技术的需求日益增长,以实现预测性维护和营运最佳化,这推动了云端连接电池管理系统 (BMS) 解决方案的普及。此类解决方案能够汇总整个车队的性能数据,并在故障模式影响服务可用性之前识别出来。戴姆勒卡车与波兰联邦经济合作暨发展部 (BMZ) 的电池系统合作,充分体现了商用车製造商如何优先选择能够提供全面生命週期管理的 BMS 供应商,而不是仅仅依赖独立的硬体解决方案。乘用车 BMS 着重于性能和使用者体验,而商用车系统则更注重可靠性和成本效益。同时,超小型行动应用需要采用超紧凑型设计,并具备无线连接功能,以实现车辆管理整合。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 2035年纯电动车二氧化碳排放车队法规

- OEM厂商迅速转向800V架构

- 中欧超级工厂建设激增

- 网路安全的空中下载 (OTA) 电池管理系统 (BMS) 更新

- 保险公司强制要求的电池可追溯性平台

- 欧盟电池护照检查(根据CSRD)

- 市场限制

- 半导体供应链紧张

- 高压电池管理系统认证瓶颈

- 热失控事故召回事件削弱了消费者信心

- 功能安全工程师短缺

- 价值/供应链分析

- 监管状况

- 技术展望

- 五力分析

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争的激烈程度

第五章 市场规模与成长预测

- 依推进类型

- 插电式混合动力汽车(PHEV)

- 纯电动车(BEV)

- 按车辆类型

- 搭乘用车

- 商用车辆

- 摩托车和超小型移动车辆

- 电池化学

- 锂离子

- 固态(预商业化)

- 其他化学

- 按拓扑学

- 集中

- 去中心化

- 模组化的

- 按国家/地区

- 德国

- 英国

- 法国

- 义大利

- 挪威

- 荷兰

- 瑞典

- 其他欧洲国家

第六章 竞争情势

- 市场集中度

- 策略倡议

- 市占率分析

- 公司简介

- Robert Bosch GmbH

- Denso Corporation

- LG Energy Solution

- Panasonic Holdings Corp.

- Marelli

- Continental AG

- Hitachi Astemo

- Mitsubishi Electric Corp.

- Lithium Balance

- Preh GmbH

- NXP Semiconductors

- Renesas Electronics

- Analog Devices Inc.

- Texas Instruments

- Infineon Technologies

- Sensata Technologies

- Johnson Matthey Battery Systems

- CATL(Europe)

- BYD Europe

- Rimac Technology

第七章 市场机会与未来展望

The Europe Electric Vehicle Battery Management System market is valued at USD 4.48 billion in 2025 and is forecast to reach USD 17.46 billion by 2030, advancing at a 31.24% CAGR.

This expansion reflects forceful EU CO2 fleet-emission limits that require all new passenger vehicles to be zero-emission by 2035, the premium segment's brisk conversion to 800 V electrical platforms, and vigorous gigafactory construction across Central Europe. Demand also benefits from insurance-led battery-traceability rules and early battery-passport pilots that push OEMs to install more capable, cyber-secure battery management software. Added momentum comes from modular battery-pack architectures that lessen design cost and speed the rollout of multi-brand electric platforms. Pressures remain in semiconductor availability and high-voltage certification queues, yet most OEMs prioritize BMS investments to avoid heavy CO2 penalties and recall costs tied to thermal runaway incidents.

Europe Electric Vehicle Battery Management System Market Trends and Insights

EV-only CO2-fleet Rules for 2035

The European Union's mandate requiring 100% zero-emission vehicle sales by 2035 creates an irreversible demand catalyst for sophisticated BMS solutions, as automakers face EUR 95 per gram penalties for exceeding CO2 thresholds. This regulatory framework forces manufacturers to accelerate BEV production beyond the current 13.5% market penetration, requiring a 14% annual growth rate that necessitates advanced battery management capabilities for larger pack sizes and higher energy densities. The regulation's secondary effect drives insurance companies to mandate comprehensive battery monitoring systems, creating additional revenue streams for BMS providers who can demonstrate predictive failure detection and warranty cost reduction. Premium automakers are responding by investing heavily in 800V architectures that require more sophisticated thermal management and cell balancing algorithms, directly benefiting BMS suppliers with advanced power electronics expertise. The compliance timeline creates a supply chain bottleneck where BMS certification becomes the critical path item, giving established players with ISO 26262 functional safety credentials significant competitive advantages over new entrants.

Rapid OEM Shift to 800-V Architectures

The automotive industry's migration to 800V electrical architectures represents a fundamental shift that demands entirely new BMS designs capable of managing higher voltage differentials and more complex thermal dynamics. BMW's partnership with Rimac Technology for next-generation battery packs and Volvo's collaboration with Vitesco Technologies demonstrate how premium manufacturers prioritize fast-charging capabilities requiring sophisticated voltage monitoring and cell balancing algorithms. This architectural transition creates significant barriers to entry for BMS suppliers lacking high-voltage expertise, as certification requirements under ISO 26262 become exponentially more complex at 800V operating levels. The shift enables 10-minute charging sessions for 200-mile range, but places extreme thermal stress on battery cells that traditional BMS designs cannot adequately manage, forcing suppliers to integrate advanced cooling algorithms and predictive thermal modeling. European automakers are leveraging this transition to differentiate from Chinese competitors who predominantly use 400V systems, creating a temporary technological moat that benefits local BMS suppliers with advanced power electronics capabilities.

Semiconductor Supply-chain Squeezes

The global semiconductor shortage continues to constrain BMS production capacity, with automotive-grade chips experiencing lead times exceeding 26 weeks and creating cascading delays across European EV manufacturing schedules. This constraint particularly impacts advanced BMS designs that require specialized power management ICs and microcontrollers capable of handling 800V architecture and complex thermal algorithms. European BMS suppliers face additional pressure as they compete with consumer electronics manufacturers for limited chip allocation, often losing priority due to lower volume commitments than smartphone and computing applications. The shortage forces manufacturers to redesign BMS architecture around available components, potentially compromising performance optimization and extending development cycles by 12-18 months. Supply chain resilience becomes a critical competitive factor, with companies maintaining strategic inventory buffers and developing alternative sourcing relationships to ensure production continuity. The constraint creates opportunities for European semiconductor manufacturers to capture market share from Asian suppliers. Still, it requires significant capital investment and 2-3 year development timelines that may not address immediate supply needs.

Other drivers and restraints analyzed in the detailed report include:

- Surging Gigafactory Build-out in Central Europe

- Cyber-secure Over-the-air (OTA) BMS Updates

- High-voltage BMS Certification Bottlenecks

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Battery Electric Vehicles command a 72.48% market share in 2024 and lead growth projections at 32.86% CAGR through 2030, reflecting the market's decisive shift toward pure electric powertrains as automakers abandon hybrid strategies in favor of platform simplification. The BEV segment's dominance stems from regulatory pressure under EU CO2 fleet rules and consumer preference for simplified ownership experiences without range anxiety associated with plug-in hybrid complexity. Plug-in Hybrid Electric Vehicles (PHEVs) maintain relevance in commercial applications where operational flexibility remains critical. Still, face declining investment as manufacturers reallocate R&D resources toward BEV platforms that offer superior economies of scale. The segment dynamics reveal a critical inflection point where BMS requirements diverge significantly between propulsion types, with BEVs demanding sophisticated thermal management for larger battery packs. At the same time, PHEVs require complex power arbitration algorithms for dual-powertrain coordination.

Advanced BMS architectures for BEVs increasingly incorporate machine learning algorithms for predictive thermal modeling. LG Energy Solution's B.around platform analyzes data from over 130,000 battery cells to optimize charging profiles and extend pack life. This technological sophistication creates barriers to entry for traditional automotive suppliers lacking software expertise, enabling new entrants like Munich Electrification to capture market share through specialized BMS solutions for energy storage systems up to 1500V. The propulsion type segmentation increasingly reflects broader industry consolidation around BEV platforms, with implications for BMS suppliers who must choose between serving declining PHEV markets or investing heavily in next-generation BEV technologies.

Passenger cars represent 67.91% of vehicle type demand in 2024. Still, the two-wheeler and micro-mobility segment exhibits a remarkable 32.64% CAGR growth through 2030, driven by urban logistics transformation and shared mobility platform expansion across European cities. Commercial vehicles occupy a strategic middle ground where BMS requirements emphasize durability and predictive maintenance over performance optimization, creating opportunities for suppliers who can demonstrate total cost of ownership advantages. The micro-mobility surge reflects fundamental changes in urban transportation patterns, where lightweight BMS designs must balance cost constraints with safety requirements for shared vehicle applications that experience intensive usage cycles and varied environmental conditions.

Fleet operators increasingly demand sophisticated battery analytics for predictive maintenance and operational optimization, driving the adoption of cloud-connected BMS solutions that aggregate performance data across vehicle populations and identify emerging failure patterns before they impact service availability. Daimler Truck's partnership with BMZ Poland for battery systems exemplifies how commercial vehicle manufacturers prioritize BMS suppliers who can provide comprehensive lifecycle management rather than standalone hardware solutions. The vehicle type segmentation reveals diverging technology requirements, where passenger car BMS focuses on performance and user experience while commercial vehicle systems emphasize reliability and cost efficiency. At the same time, micro-mobility applications demand ultra-compact designs with wireless connectivity for fleet management integration.

The Europe Electric Vehicle Battery Management System Market Report is Segmented by Propulsion Type (Plug-In Hybrid Electric Vehicle and Battery Electric Vehicle), Vehicle Type (Passenger Cars, Commercial Vehicles, and More), Battery Chemistry (Lithium-Ion, Solid-State, and More), Topology (Centralized, Distributed, and More), and Country. The Market Forecasts are Provided in Terms of Value (USD).

List of Companies Covered in this Report:

- Robert Bosch GmbH

- Denso Corporation

- LG Energy Solution

- Panasonic Holdings Corp.

- Marelli

- Continental AG

- Hitachi Astemo

- Mitsubishi Electric Corp.

- Lithium Balance

- Preh GmbH

- NXP Semiconductors

- Renesas Electronics

- Analog Devices Inc.

- Texas Instruments

- Infineon Technologies

- Sensata Technologies

- Johnson Matthey Battery Systems

- CATL (Europe)

- BYD Europe

- Rimac Technology

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 EV-only CO2-fleet rules for 2035

- 4.2.2 Rapid OEM shift to 800-V architectures

- 4.2.3 Surging gigafactory build-out in Central Europe

- 4.2.4 Cyber-secure over-the-air (OTA) BMS updates

- 4.2.5 Insurance-mandated battery traceability platforms

- 4.2.6 EU battery passport pilots (under CSRD)

- 4.3 Market Restraints

- 4.3.1 Semiconductor supply-chain squeezes

- 4.3.2 High-voltage BMS certification bottlenecks

- 4.3.3 Thermal-runaway recalls hurting consumer trust

- 4.3.4 Scarcity of functional-safety engineers

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Rivalry

5 Market Size and Growth Forecasts (Value (USD))

- 5.1 By Propulsion Type

- 5.1.1 Plug-in Hybrid Electric Vehicle (PHEV)

- 5.1.2 Battery Electric Vehicle (BEV)

- 5.2 By Vehicle Type

- 5.2.1 Passenger Cars

- 5.2.2 Commercial Vehicles

- 5.2.3 Two-Wheeler and Micro-mobility

- 5.3 By Battery Chemistry

- 5.3.1 Lithium-ion

- 5.3.2 Solid-state (pre-commercial)

- 5.3.3 Other Chemistries

- 5.4 By Topology

- 5.4.1 Centralized

- 5.4.2 Distributed

- 5.4.3 Modular

- 5.5 By Country

- 5.5.1 Germany

- 5.5.2 United Kingdom

- 5.5.3 France

- 5.5.4 Italy

- 5.5.5 Norway

- 5.5.6 Netherlands

- 5.5.7 Sweden

- 5.5.8 Rest of Europe

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 Robert Bosch GmbH

- 6.4.2 Denso Corporation

- 6.4.3 LG Energy Solution

- 6.4.4 Panasonic Holdings Corp.

- 6.4.5 Marelli

- 6.4.6 Continental AG

- 6.4.7 Hitachi Astemo

- 6.4.8 Mitsubishi Electric Corp.

- 6.4.9 Lithium Balance

- 6.4.10 Preh GmbH

- 6.4.11 NXP Semiconductors

- 6.4.12 Renesas Electronics

- 6.4.13 Analog Devices Inc.

- 6.4.14 Texas Instruments

- 6.4.15 Infineon Technologies

- 6.4.16 Sensata Technologies

- 6.4.17 Johnson Matthey Battery Systems

- 6.4.18 CATL (Europe)

- 6.4.19 BYD Europe

- 6.4.20 Rimac Technology

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment