|

市场调查报告书

商品编码

1846231

丙烯酸乳化:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Acrylic Emulsions - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

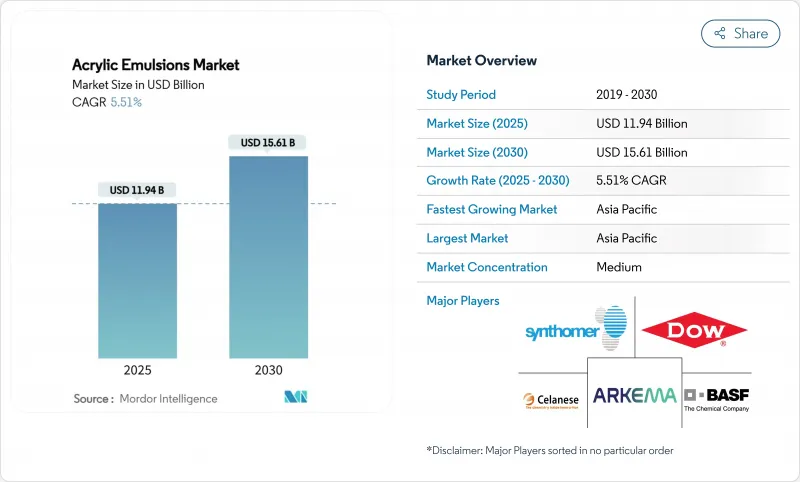

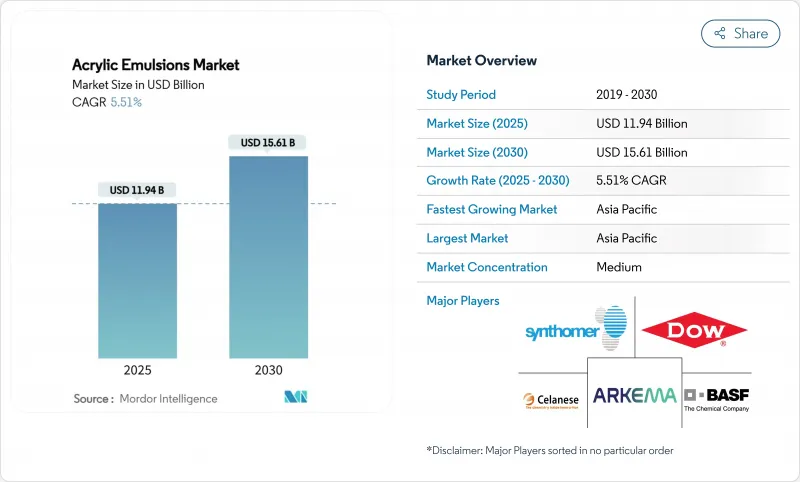

预计到 2025 年,丙烯酸乳化市场规模将达到 119.4 亿美元,到 2030 年将达到 156.1 亿美元,预测期(2025-2030 年)复合年增长率为 5.51%。

有利于水性配方的监管压力、亚太地区强劲的基础设施投资以及数位印刷技术的快速普及,都推动了这一扩张。涂料、黏合剂和造纸製造商正持续从溶剂型系统转向水性体系,以确保符合美国、加拿大和欧盟的低VOC法规。同时,製造商正投资自交联和不含PFAS的化学品,以抢占高端市场,而美国和荷兰的产能扩张则保障了供应安全。儘管原材料价格波动挤压了利润空间,但技术升级和永续性承诺为基于价值的定价提供了喘息之机,使生产商即使在单体成本波动的情况下也能保持盈利。

全球丙烯酸乳化市场趋势与洞察

推广低VOC水性被覆剂

加州已将建筑用平涂涂料的挥发性有机化合物(VOC)含量限制在50克/公升,迫使配方师逐步淘汰溶剂含量高的化学物质。美国环保署已将气雾剂涂料的合规期限延长至2027年1月,使生产商有时间完善水性配方,使其性能可与溶剂型涂料媲美。加拿大将于2024年1月对130个消费品产品类型实施VOC限制,进一步强化了推动丙烯酸乳化需求的全球监管转变。因此,生产商正在扩展其自交联体系,该体系无需使用外部交联剂即可提高漆膜硬度,从而扩大了目标市场。此类政策措施为丙烯酸乳化市场提供了多年发展前景,并有助于抵消单体成本的波动。

新兴国家建筑支出激增

中国2025年预算维持5%的GDP成长目标,基础建设支出将达到1.11兆美元。同时,印度2025-2026财年的资本支出成长11.1%,达到11.11兆印度卢比。新建高速公路、地铁和工业将增加建筑涂料、混凝土添加剂和使用丙烯酸分散体的软包装黏合剂的消耗量。在东南亚,製造业的转移正在推动工厂建设并提高产量。丙烯酸乳化凭藉其耐久性、附着力和低气味等优点,仍然是必须遵守更严格环保标准的建筑商的首选黏合剂。中产阶级收入水准的提高也刺激了住宅重新粉刷的周期,从而维持了稳定的基准需求。

聚氨酯分散体偏好

水性聚氨酯分散体在耐化学性和耐磨性方面通常优于丙烯酸酯,因此在汽车装饰、地板和耐用金属涂料领域占据了一席之地。近期一项针对双组分紫外光固化聚氨酯化学的调查显示,其在低排放气体性能方面取得了突破性进展。丙烯酸酯则透过混合设计和自交联网路技术予以应对,但在极高应力环境下仍存在不足,这限制了其在一些高端细分市场的份额成长。儘管如此,丙烯酸酯在中等性能领域仍保持着成本和製程优势,确保了市场竞争的平衡,而非完全取代。

细分市场分析

到2024年,苯乙烯-丙烯酸酯类涂料将占全球销售量的45.18%。其均衡的硬度、耐水性和价格使其成为饱和型室内建筑涂料和纸张生产线的主力。预计到2030年,苯乙烯-丙烯酸酯类涂料的销量将稳步增长,但随着用户转向以乙烯基为主的涂料体系,该细分市场的份额预计将会下降。受柔性建筑胶黏剂、密封剂和低温涂层板材需求的推动,乙烯基-丙烯酸酯乳化预计将以每年6.22%的速度成长。纯丙烯酸乳化在对保色性和抗紫外线性能要求极高的亮光外墙和冷屋顶弹性体领域占据高端地位。

先进的自交联技术强化了这种层级结构。研究表明,苯乙烯-丙烯酸类道路密封剂中的DAAM-ADH网络比传统等级的密封剂黏结强度提高了50%以上。生产商正在销售模组化平台,使客户能够以最小的实验室配方调整来微调玻璃化转变温度(Tg)和硬度,从而缩短产品上市时间。同时,乙烯基丙烯酸树脂供应商强调其不含塑化剂的柔韧性,以使其能够承受超耐磨地板和防风雨膜的热循环。纯丙烯酸树脂正在利用生物基单体来吸引具有永续性意识的建筑师,并透过降低化学品成本来扩大价值差距。

区域分析

到2024年,亚太地区将占全球销售额的46.21%,到2030年将以6.09%的复合年增长率成长。中国不断扩大的钢筋加工厂将为蓬勃发展的公共工程涂料需求提供本地黏合剂,而印度不断增长的资本投资将直接转化为新的商业和住宅占地面积。越南和印尼等东协成员国拥有出口导向的家具和包装产业丛集,这些集群依赖水性涂料来满足经合组织买家的标准。该地区还拥有世界一流的原材料工厂,使一体化製造商能够平衡成本压力并实现规模经济。

北美仍然是监管潮流的领导者。美国环保署 (EPA) 的气雾剂法规和加州空气资源委员会 (CARB) 的低挥发性有机化合物 (VOC) 排放上限,促使研发投入持续增长,同时也扶持了那些拥有良好合规记录的成熟企业。根据美国《基础设施投资与就业法案》,基础设施升级项目正在投资建造桥樑、交通枢纽和公共建筑,这些项目都使用耐用、低气味的涂料。加拿大将于 2024 年生效的全国性 VOC 法规将统一相关要求,并简化跨境产品系列。墨西哥的加工出口网路 (maquiladora network) 正在吸引家电和汽车製造商指定使用水性涂料以获得出口核准。

欧洲正致力于引领永续性。BASF转向生物基丙烯酸乙酯以及在荷兰扩大分散体业务,都反映了该地区推动化学价值链脱碳的决心。德国透过建筑节能补贴支持冷屋顶维修,并扩大反射性丙烯酸膜的市场。法国和英国正在公共采购中推广循环经济标准,优先选择经过生命週期评估的树脂。儘管南美洲和中东及非洲的消费量合计不到全球的10%,但都市化进程的加速和房屋抵押贷款的改善将推动房屋翻新和基础设施建设计划,从而带来长期的增长潜力。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 推广低VOC水性涂料

- 新兴经济体建筑支出激增

- 数位喷墨墨水的普及

- 朝向柔性食品包装黏合剂的转变

- 对冷屋顶和反射涂层的需求

- 市场限制

- 聚氨酯分散体偏好

- 丙烯酸单体价格波动

- 富含苯乙烯乳化的紫外线黄变。

- 价值链分析

- 五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模与成长预测

- 按类型

- 纯丙烯酸乳化

- 苯丙乳化

- 乙烯基丙烯酸乳化

- 透过使用

- 画

- 建筑材料添加剂

- 纸张涂层

- 胶水

- 其他用途(纤维和不织布整理等)

- 按地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 东南亚国协

- 其他亚太地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 北欧国家

- 其他欧洲国家

- 南美洲

- 巴西

- 阿根廷

- 其他南美

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略倡议

- 市占率(%)/排名分析

- 公司简介

- AICA Kogyo Co.Ltd.

- AkzoNobel NV

- Allnex GMBH

- Anhui Sinograce Chemical Co., Ltd.

- Arkema

- Asian Paints Ltd.

- Axalta Coating Systems LLC

- BASF

- Celanese Corporation

- DIC Corporation

- Dow

- Gellner Industrial, LLC.

- HB Fuller Company

- Lubrizol

- Mallard Creek Polymers

- Nippon Paint Holdings Co., Ltd.

- Osaka Organic Chemical

- PPG Industries, Inc.

- Synthomer plc

- The Cary Company

第七章 市场机会与未来展望

The Acrylic Emulsions Market size is estimated at USD 11.94 billion in 2025, and is expected to reach USD 15.61 billion by 2030, at a CAGR of 5.51% during the forecast period (2025-2030).

Regulatory pressure that favors water-borne formulations, steady infrastructure spending in Asia-Pacific, and rapid adoption of digital printing technologies underpin this expansion. Paint makers, adhesive formulators, and paper converters continue to switch from solvent to water-borne systems to secure compliance with low-VOC rules in the United States, Canada, and the European Union. At the same time, manufacturers are investing in self-crosslinking and PFAS-free chemistries to capture premium niches, while capacity additions in the United States and the Netherlands safeguard supply security. Though feedstock price volatility presses margins, technology upgrades and sustainability commitments provide headroom for value-based pricing, enabling producers to preserve profitability even when monomer costs fluctuate.

Global Acrylic Emulsions Market Trends and Insights

Low-VOC Push for Water-Borne Paints and Coatings

California continues to cap VOC content for flat architectural paint at 50 g/L, compelling formulators to phase out solvent-rich chemistries. The United States Environmental Protection Agency extended aerosol coating compliance dates to January 2027, granting producers time to perfect water-based blends that match solvent-borne performance. Canada enforced VOC limits across 130 consumer product categories in January 2024, reinforcing a global regulatory shift that channels demand toward acrylic emulsions. Producers are therefore scaling self-crosslinking systems that raise film hardness without external crosslinkers, widening the addressable market. These policy moves give the acrylic emulsions market multi-year visibility and help offset monomer-cost swings.

Booming Construction Spending in Developing Countries

China's 2025 budget maintains a 5% GDP growth target, supported by USD 1.11 trillion in infrastructure outlays, while India increased 2025-26 capital expenditure by 11.1% to INR 11.11 lakh crore. New highways, metros, and industrial parks lift consumption of architectural coatings, concrete additives, and flexible packaging adhesives that employ acrylic dispersions. Across Southeast Asia, manufacturing relocations drive factory construction, magnifying volumes. Because acrylic emulsions provide durability, adhesion, and low odor, they remain the binder of choice for builders that must meet tightening environmental standards. Rising middle-class income levels also spur residential repaint cycles, keeping baseline demand resilient.

Preference for Polyurethane Dispersions

Water-borne polyurethane dispersions often outclass acrylics in chemical and abrasion resistance, allowing them to gain ground in automotive trim, wood flooring, and heavy-duty metal coatings. Recent research on 2K UV-curable polyurethane chemistries highlights breakthroughs in low-emission performance. While acrylics answer with hybrid designs and self-crosslinking networks, the gap in very high-stress environments remains, capping share growth in select premium niches. Yet acrylics retain cost and process advantages in the mid-performance tier, ensuring balanced competition rather than outright displacement.

Other drivers and restraints analyzed in the detailed report include:

- Digital Ink-Jet Printing Inks Adoption

- Shift to Food-Grade Flexible-Pack Adhesives

- Acrylic Monomer Price Volatility

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Styrene-acrylic grades held 45.18% of global revenue in 2024. Their balanced hardness, water resistance, and price position them as the workhorse for interior architectural paint and paper saturation lines. Through 2030, styrene-acrylic volumes will climb steadily, but the segment's share will edge downward as users diversify into vinyl-rich systems. Vinyl-acrylic emulsions are set to grow 6.22% annually, riding demand for flexible construction adhesives, sealants, and low-temperature coated boards. Pure acrylics command the premium tier, favored in high-gloss exterior walls and cool-roof elastomeric where colour retention and UV durability are paramount.

Advanced self-crosslinking technologies reinforce this hierarchy. Studies show DAAM-ADH networks in styrene-acrylic road sealants boost bond strength by more than 50% over conventional grades. Producers market modular platforms that let customers fine-tune Tg and hardness with minimal lab reformulation, saving time to market. Meanwhile, vinyl-acrylic suppliers stress plasticizer-free flexibility that withstands thermal cycling in laminate flooring and weather-barrier membranes. Pure acrylics leverage bio-based monomer options to target sustainability-conscious architects, widening the value gap versus lower-priced chemistries.

The Acrylic Emulsions Market Report is Segmented by Type (Pure Acrylic Emulsion, Styrene Acrylic Emulsion, and Vinyl Acrylic Emulsion), Application (Paints and Coatings, Construction Material Additives, and More), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific contributed 46.21% of global revenue in 2024 and will post a 6.09% CAGR to 2030. China's Verbund site expansions supply local binders for booming public-works paint consumption, while India's elevated capex pipeline translates directly into fresh commercial and residential floor space. ASEAN members such as Vietnam and Indonesia host export-oriented furniture and packaging clusters that rely on water-borne coatings to meet OECD buyer standards. The region also houses world-scale feedstock plants, enabling integrated players to balance cost pressure and drive economies of scale.

North America remains a regulatory trendsetter. The EPA's revised aerosol rules and CARB's low-VOC caps force continuous R&D investment, yet they simultaneously defend incumbents with proven compliance credentials. Infrastructure renewal under the U.S. Infrastructure Investment and Jobs Act pumps spending into bridges, transit hubs, and public buildings, all of which favor durable, low-odor coatings. Canada's country-wide VOC regulations, effective 2024, harmonize requirements and simplify cross-border product portfolios. Mexico's maquiladora network attracts appliance and automotive manufacturers that specify water-borne finishes to secure export approvals.

Europe emphasizes sustainability leadership. BASF's shift to bio-based ethyl acrylate and the Dutch dispersion expansion illustrate the region's drive to decarbonize the chemicals value chain. Germany supports cool-roof retrofits through building-efficiency subsidies, widening the market for reflective acrylic membranes. France and the United Kingdom promote circular-economy criteria in public procurement, favoring resins with life-cycle-assessment backing. Although South America and the Middle-East and Africa together represent less than 10% of global consumption, rising urbanization and increased access to mortgage financing encourage residential repainting and infrastructure projects, providing long-run upside.

- AICA Kogyo Co.Ltd.

- AkzoNobel N.V.

- Allnex GMBH

- Anhui Sinograce Chemical Co., Ltd.

- Arkema

- Asian Paints Ltd.

- Axalta Coating Systems LLC

- BASF

- Celanese Corporation

- DIC Corporation

- Dow

- Gellner Industrial, LLC.

- H.B. Fuller Company

- Lubrizol

- Mallard Creek Polymers

- Nippon Paint Holdings Co., Ltd.

- Osaka Organic Chemical

- PPG Industries, Inc.

- Synthomer plc

- The Cary Company

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Low-VOC Push for Water-Borne Paints and Coatings

- 4.2.2 Booming Construction Spending in Developing Countries

- 4.2.3 Digital Ink-Jet Printing Inks Adoption

- 4.2.4 Shift to Food-Grade Flexible-Pack Adhesives

- 4.2.5 Cool-Roof and Reflective Coatings Demand

- 4.3 Market Restraints

- 4.3.1 Preference For Polyurethane Dispersions

- 4.3.2 Acrylic Monomer Price Volatility

- 4.3.3 UV-Yellowing of Styrene-Rich Emulsions

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Consumers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Type

- 5.1.1 Pure Acrylic Emulsion

- 5.1.2 Styrene-Acrylic Emulsion

- 5.1.3 Vinyl-Acrylic Emulsion

- 5.2 By Application

- 5.2.1 Paints and Coatings

- 5.2.2 Construction Material Additives

- 5.2.3 Paper Coating

- 5.2.4 Adhesives

- 5.2.5 Other Applications (Textile and Non-woven Finishes, etc.)

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 Japan

- 5.3.1.3 India

- 5.3.1.4 South Korea

- 5.3.1.5 ASEAN Countries

- 5.3.1.6 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Spain

- 5.3.3.6 Russia

- 5.3.3.7 NORDIC Countries

- 5.3.3.8 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 AICA Kogyo Co.Ltd.

- 6.4.2 AkzoNobel N.V.

- 6.4.3 Allnex GMBH

- 6.4.4 Anhui Sinograce Chemical Co., Ltd.

- 6.4.5 Arkema

- 6.4.6 Asian Paints Ltd.

- 6.4.7 Axalta Coating Systems LLC

- 6.4.8 BASF

- 6.4.9 Celanese Corporation

- 6.4.10 DIC Corporation

- 6.4.11 Dow

- 6.4.12 Gellner Industrial, LLC.

- 6.4.13 H.B. Fuller Company

- 6.4.14 Lubrizol

- 6.4.15 Mallard Creek Polymers

- 6.4.16 Nippon Paint Holdings Co., Ltd.

- 6.4.17 Osaka Organic Chemical

- 6.4.18 PPG Industries, Inc.

- 6.4.19 Synthomer plc

- 6.4.20 The Cary Company

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment

- 7.2 Advancements in Self-crosslinking Technology of Acrylic Emulsion