|

市场调查报告书

商品编码

1846315

管道隔热材料:市场占有率分析、产业趋势、统计数据和成长预测(2025-2030 年)Pipe Insulation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

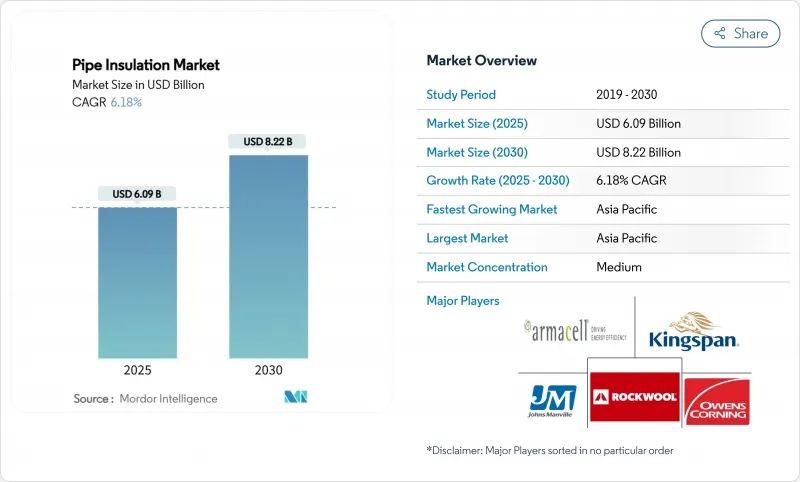

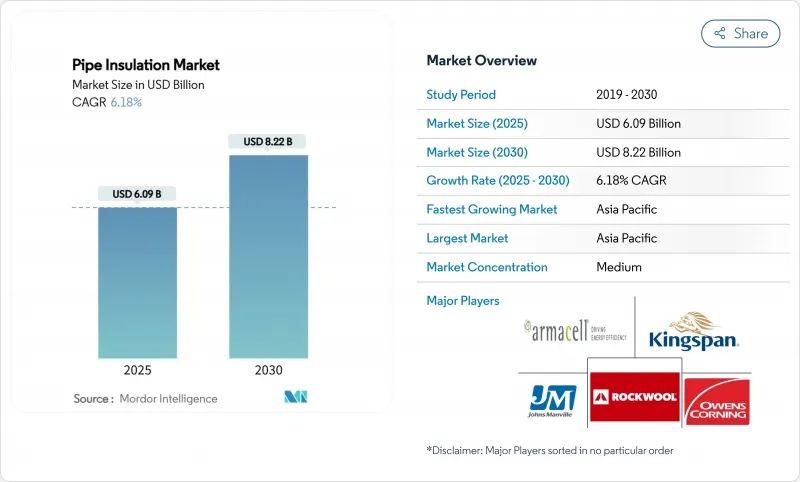

预计到 2025 年,管道隔热材料市场规模将达到 60.9 亿美元,到 2030 年将达到 82.2 亿美元,预测期(2025-2030 年)复合年增长率为 6.18%。

受日益严格的建筑节能法规、行业脱碳要求以及基础设施升级浪潮的推动,管道隔热材料市场持续保持强劲成长。北美和欧洲的建筑法规要求使用更厚、性能更高的隔热材料,而亚太地区各国政府则将公共部门融资与可衡量的节能目标挂钩。液化天然气出口能力的提升和第四代区域供热网路的建设,使得管道保温市场的应用范围远远超出传统建筑。随着主要企业整合区域竞争对手、投资智慧感测器平台以及授权先进气凝胶技术,市场竞争日益激烈。儘管短期净利率受到石化原料价格波动和薄壁塑胶管道普及的挤压,但拥有多元化材料组合和预製安装解决方案的製造商,在全球碳中和进程加速推进之际,仍有望抓住市场成长机会。

全球管道隔热材料市场趋势与洞察

严格的节能建筑规范

建筑规范正将管道隔热材料从可选项转变为强制性要求。 2024 年国际节能规范 (IECC) 规定热水管道保温层的最大厚度为 5 英寸,预计这项规定将使美国住宅的能源消耗降低 7.80% 。美国州正在逐步实施 2024 年 IECC,东北能源效率合作组织预测,率先采用该规范的业主可实现 6.80% 的能源消耗降低。商业不动产也正在效仿这些要求,鼓励业主优先考虑全生命週期的节能效益,而非前期成本。

液化天然气和低温管道计划扩建

美国墨西哥湾沿岸的液化天然气出口终端需要超过19,800英里的新建或更换管道,其中大部分管道的设计动作温度为-160 度C 。常压气凝胶管中管设计可降低安装成本,同时将收缩应力控制在可接受的范围内。随着亚太地区浮体式天然气枢纽的运作,对长期海底保温管道的需求不断增长,并推高了优质材料的价格。拥有低温级聚氨酯和泡沫玻璃产品线的製造商正享受更高的利润,并在多年期大型企划中率先赢得合约。

安装成本高,劳力密集

现场喷涂聚氨酯泡沫和多层护套需要合格的工人和专用设备,导致在大都市地区,每线性英尺的施工成本超过 15 美元。虽然维修可以降低 30% 的能源费用,但「更佳建筑社区」的数据显示,每投入 1 美元,第一年仅能节省 0.08 美元,从而延长了房主的投资回收期。预製管段在一定程度上缓解了技能缺口,但直径超过 12 英吋的管段运输受限,阻碍了其广泛应用。北欧的劳动力短缺问题最为严重,老化技工的退休速度超过了学徒进入训练计画的速度。生产商已推出卡扣式矿物纤维外壳和自黏气凝胶包裹层,可减少高达 40% 的现场施工,但推广速度缓慢。

细分市场分析

玻璃纤维凭藉其低成本和接近0.04 W/(m*K)的导热係数λ值,在管道隔热材料领域保持领先地位,预计到2024年将占据39.65%的市场份额。 Rockwool品牌利用其固有的耐火性和循环利用特性,将其2023年的销售额转化为预计的818 TWh的终身节能效益。岩绒用于600°C以上的特定炼油厂和发电厂管道,而采用生物基配方的硬质聚氨酯泡棉则可实现低于0.02 W/(m*K)的导热係数。橡胶发泡体因其在热循环中具有良好的柔韧性,仍然是暖通空调(HVAC)领域的主要材料。

其他类型的隔热材料(主要是气凝胶毯和蜂窝玻璃)将以7.51%的复合年增长率快速增长,直至2030年,因为计划对超低热损耗的需求日益增长。新一代Si3N4增强气凝胶的密度低至0.033克/立方厘米,可承受893摄氏度的温差。蜂巢玻璃具有零吸水率,设计寿命长达100年,适用于液化天然气和低温管道。高昂的资本支出可透过节省维护成本来抵消,这促使专案业主在基于性能的竞标中优先选择优质材料。

区域分析

亚太地区在管道隔热材料市场占据主导地位,其庞大的市场规模以及政策支持是其发展的关键因素。中国省级政府已将建筑许可与检验的热能模型挂钩,《国家节能三年行动计划》也将管道保温列为一级节能措施。印度大力推动可再生能源併网,促使製程工业减少蒸气管道损耗,推动了对矿物纤维层压板外壳的需求。亚洲开发银行的联合融资机制降低了风险,并确保了待开发区供热管网计划的材料供应稳定。

北美将受益于液化天然气管道的扩建和法规的更新。美国能源部确认了基于2024年国际节能规范(IECC)的7.80%的住宅能源效率目标,这使得各省无需进行冗长的成本效益讨论即可推进相关工作。联邦政府提供的涵盖30%隔热材料成本的税额扣抵进一步缩短了投资回收期。加拿大各省正在利用低利率维修贷款,而亚伯达的行业相关人员则透过改用高效隔热层来应对原材料价格波动,从而缓衝燃料成本。

欧洲的目标是到2042年将巴黎等城市的区域供冷管道数量增加两倍,同时欧盟也发起了一项翻新浪潮,旨在到2030年维修3500万栋建筑。使用生物黏合剂的负碳隔热材料正在斯堪地那维亚市场进行试验,并为专业製造商带来了早期收益。公共产业正在将隔热材料合约与热泵采购捆绑在一起,将与供应商的谈判重点转移到总拥有成本(TCO)指标上。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 严格的节能建筑规范

- 液化天然气和低温管道计划扩建

- 区域供热和製冷投资快速成长

- 内建感测器的智慧隔热材料

- 碳价格主导的工业维修

- 市场限制

- 安装成本高,劳力密集

- 石油化工原料价格波动剧烈

- 过渡到薄壁塑胶管道

- 价值链分析

- 五力分析

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争程度

第五章 市场规模与成长预测

- 按类型

- 玻璃纤维

- 岩绒

- 硅酸盐

- 聚氨酯

- 橡胶发泡体

- 其他类型(气凝胶毯、蜂巢玻璃等)

- 按最终用户行业划分

- 建筑/施工

- 石油和天然气

- 运输

- 一般工业

- 其他终端用户产业(发电和公共产业、化学和石化加工等)

- 按地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 东南亚国协

- 亚太其他地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 北欧国家

- 其他欧洲

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略倡议

- 市占率(%)/排名分析

- 公司简介

- Armacell

- Aspen Aerogels, Inc.

- BASF

- Beijing Coowor Network Technology Co., Ltd.

- Cellofoam North America Inc.

- Covestro AG

- Frost King Weatherization Products/Thermwell Products Co., Inc.

- Huamei Energy-saving Technology Group Co., Ltd.

- Huntsman International LLC

- Isoclima SpA

- Johns Manville

- Kingspan Group

- Knauf Insulation, Inc.

- L'Isolante K-Flex SpA

- NMC sa

- ODE YalItIm AS

- Owens Corning

- Polyguard

- Rockwool International

- Saint-Gobain

- Thermaflex

- Zotefoams plc.

第七章 市场机会与未来展望

The Pipe Insulation Market size is estimated at USD 6.09 billion in 2025, and is expected to reach USD 8.22 billion by 2030, at a CAGR of 6.18% during the forecast period (2025-2030).

Tighter building-energy codes, industrial decarbonization mandates, and a wave of infrastructure upgrades keep the pipe insulation market on a firm growth footing. North American and European building regulations demand thicker, higher-performance insulation, while Asia-Pacific governments link public-sector lending to demonstrable energy-savings targets. LNG export capacity additions and fourth-generation district heating networks extend the addressable opportunity well beyond conventional buildings. Competitive intensity has risen as large incumbents consolidate regional players, invest in smart-sensor platforms, and license advanced aerogel technologies. Although price volatility for petrochemical feedstocks and the spread of thin-wall plastic piping temper short-term margins, manufacturers with diversified materials portfolios and prefabricated installation solutions remain positioned to capture upside as global carbon-neutrality timetables accelerate.

Global Pipe Insulation Market Trends and Insights

Stringent Energy-Efficiency Building Codes

Building codes are turning pipe insulation from a discretionary line item into a legal requirement. The 2024 International Energy Conservation Code (IECC) mandates thicknesses of up to 5 inches for hot-water pipelines, a rule expected to cut residential site-energy use by 7.80% in the United States. California's Title 24 and similar European directives specify minimum R-values, effectively sidelining low-performance wraps. With 14 U.S. states already on the 2024 IECC path, Northeast Energy Efficiency Partnerships forecasts 6.80% source-energy savings for early adopters. Commercial facilities mirror these requirements, pushing owners to favor lifecycle energy savings over upfront costs-another lever that expands the pipe insulation market.

Expansion of LNG and Cryogenic Pipeline Projects

Liquefied-natural-gas export terminals along the U.S. Gulf Coast require more than 19,800 miles of new or replacement piping, much of it designed for -160 °C operating temperatures. Ambient-pressure aerogel pipe-in-pipe designs cut installation costs while keeping contraction stresses within allowable limits. As Asia-Pacific commissions floating LNG hubs, demand for long-run subsea insulation miles pushes premium material pricing. Manufacturers with cryogenic-grade polyurethane or cellular glass lines enjoy margin upside and early-mover contracts on multi-year megaprojects.

High Installed Cost and Labour Intensity

Field application of spray polyurethane foam and multi-layer jacketing requires certified crews and specialized rigs, pushing installation charges above USD 15/linear foot in large metro markets. Although energy bills can drop 30% post-retrofit, Better Buildings Neighborhood data show that every USD 1 invested yields only USD 0.08 in first-year savings, stretching homeowner payback horizons. Prefabricated pipe spools partially solve the skills gap, yet transport limits hamper uptake for diameters above 12 inches. Labor scarcity is most acute in Northern Europe, where aging tradespeople retire faster than apprentices enter vocational programs. Producers respond with snap-fit mineral-fiber shells and self-adhesive aerogel wraps that cut site labor by up to 40%, but widespread adoption lags.

Other drivers and restraints analyzed in the detailed report include:

- Surging District Heating and Cooling Investments

- Smart Insulation with Embedded Sensors

- Volatile Petrochemical Feedstock Prices

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Fiberglass maintained the leading 39.65% pipe insulation market share in 2024, underpinned by low cost and a λ-value near 0.04 W/(m*K). Rockwool leverages inherent fire resistance and circularity claims; the brand's 2023 sales translated to anticipated lifetime energy savings of 818 TWh. Silicate wraps own niche refinery and power-plant lines above 600 °C, while rigid polyurethane foams post sub-0.02 W/(m*K) conductivities in bio-based formulations. Rubber foams remain HVAC staples because they flex with thermal cycling.

Other Types-primarily aerogel blankets and cellular glass-grow fastest at 7.51% CAGR through 2030 as mega-projects demand ultra-low heat loss. Next-gen Si3N4-reinforced aerogels come in at densities as low as 0.033 g/cm3 withstanding 893 °C differentials. Cellular glass appeals to LNG and cryogenic pipelines for zero water absorption and 100-year design life. Higher capex is offset by maintenance savings, leading process owners to specify performance-based tenders that favor premium materials.

The Pipe Insulation Market Report is Segmented by Type (Fiberglass, Rockwool, Silicates, Polyurethane, Rubber Foams, Other Types), End-User Industry (Buildings and Construction, Oil and Gas, Transportation, General Industrial, Other End-User Industries), and Geography (Asia-Pacific, North America, Europe, South America, Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific dominates the pipe insulation market, pairing volume scale with policy support. Chinese provincial authorities now tie building permits to verified thermal-energy models, and the national Three-Year Action Plan for energy conservation identifies pipework insulation as a Tier-1 measure. India's renewable-integration drive requires process industries to cut steam line losses, sending demand toward laminated mineral-fiber shells. The Asian Development Bank's blended-financing tools de-risk greenfield heat-network projects, assuring steady material off-take.

North America benefits from LNG pipeline rollouts and code updates. The U.S. DOE's confirmation of 7.80% residential energy savings from the 2024 IECC emboldens states to adopt without lengthy cost-effectiveness debates. Federal tax credits covering 30% of insulation spend further shorten paybacks. Canadian provinces tap low-interest retrofit loans, while industrial players in Alberta hedge feedstock volatility by switching to higher-efficiency jacketing to buffer fuel bills.

Europe's ambition is to treble district cooling pipes by 2042 in cities like Paris, intertwining with the EU Renovation Wave that targets 35 million building upgrades by 2030. Scandinavian markets trial carbon-negative insulation made with biogenic binders, providing early revenue for specialty manufacturers. Utilities bundle insulation contracts with heat-pump procurement, shifting supplier negotiations toward total-cost-of-ownership metrics.

- Armacell

- Aspen Aerogels, Inc.

- BASF

- Beijing Coowor Network Technology Co., Ltd.

- Cellofoam North America Inc.

- Covestro AG

- Frost King Weatherization Products / Thermwell Products Co., Inc.

- Huamei Energy-saving Technology Group Co., Ltd.

- Huntsman International LLC

- Isoclima S.p.A.

- Johns Manville

- Kingspan Group

- Knauf Insulation, Inc.

- L'Isolante K-Flex S.p.A.

- NMC sa

- ODE YalItIm A.S.

- Owens Corning

- Polyguard

- Rockwool International

- Saint-Gobain

- Thermaflex

- Zotefoams plc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Stringent Energy-Efficiency Building Codes

- 4.2.2 Expansion of LNG and Cryogenic Pipeline Projects

- 4.2.3 Surging District Heating and Cooling Investments

- 4.2.4 Smart Insulation with Embedded Sensors

- 4.2.5 Carbon-Pricing Led Industrial Retrofits

- 4.3 Market Restraints

- 4.3.1 High Installed Cost and Labour Intensity

- 4.3.2 Volatile Petrochemical Feedstock Prices

- 4.3.3 Shift to Thin-Wall Plastic Piping Alternatives

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Type

- 5.1.1 Fiberglass

- 5.1.2 Rockwool

- 5.1.3 Silicates

- 5.1.4 Polyurethane

- 5.1.5 Rubber Foams

- 5.1.6 Other Types (Aerogel Blankets,Cellular Glass, etc.)

- 5.2 By End-User Industry

- 5.2.1 Buildings and Construction

- 5.2.2 Oil and Gas

- 5.2.3 Transportation

- 5.2.4 General Industrial

- 5.2.5 Other End-user Industries (Power Generation and Utilities, Chemical and Petrochemical Processing, etc.)

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 Japan

- 5.3.1.3 India

- 5.3.1.4 South Korea

- 5.3.1.5 ASEAN Countries

- 5.3.1.6 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Spain

- 5.3.3.6 Russia

- 5.3.3.7 NORDIC Countries

- 5.3.3.8 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share(%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Armacell

- 6.4.2 Aspen Aerogels, Inc.

- 6.4.3 BASF

- 6.4.4 Beijing Coowor Network Technology Co., Ltd.

- 6.4.5 Cellofoam North America Inc.

- 6.4.6 Covestro AG

- 6.4.7 Frost King Weatherization Products / Thermwell Products Co., Inc.

- 6.4.8 Huamei Energy-saving Technology Group Co., Ltd.

- 6.4.9 Huntsman International LLC

- 6.4.10 Isoclima S.p.A.

- 6.4.11 Johns Manville

- 6.4.12 Kingspan Group

- 6.4.13 Knauf Insulation, Inc.

- 6.4.14 L'Isolante K-Flex S.p.A.

- 6.4.15 NMC sa

- 6.4.16 ODE YalItIm A.S.

- 6.4.17 Owens Corning

- 6.4.18 Polyguard

- 6.4.19 Rockwool International

- 6.4.20 Saint-Gobain

- 6.4.21 Thermaflex

- 6.4.22 Zotefoams plc.

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment