|

市场调查报告书

商品编码

1851056

工具工具机:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Machine Tools - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

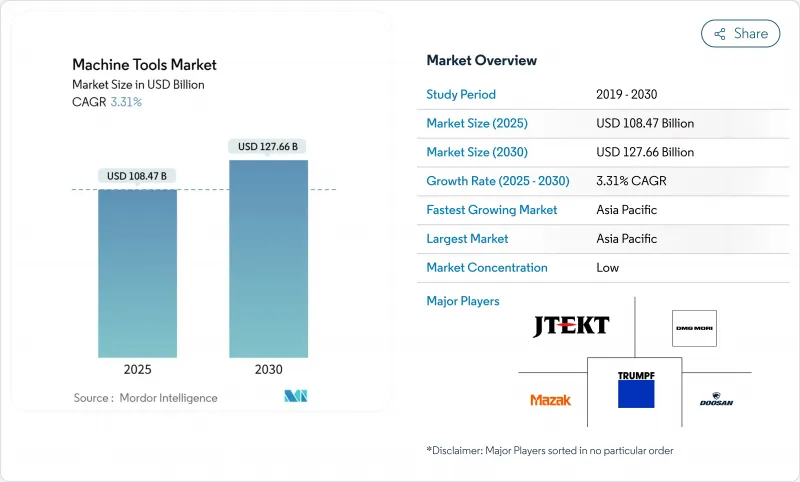

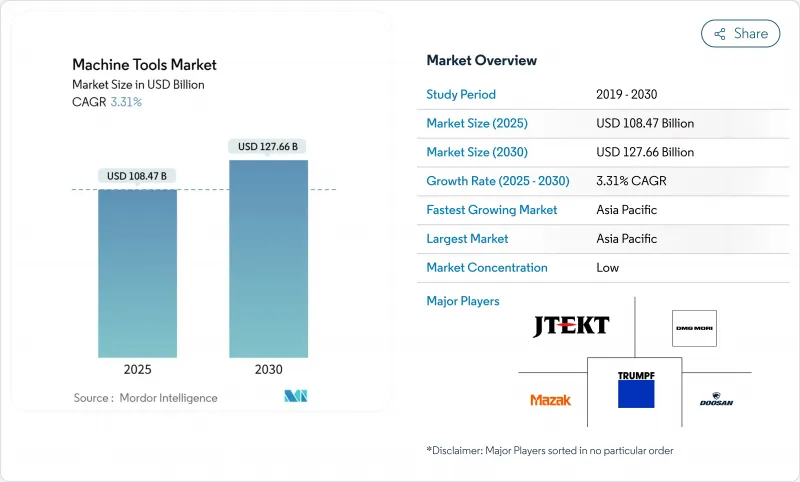

预计工具机市场将从 2025 年的 1,084.7 亿美元成长到 2030 年的 1,276.6 亿美元,复合年增长率为 3.31%。

此次市场扩张的驱动力来自供应链重组、更严格的贸易规则以及半导体工厂创纪录的投资,而这些都对超精密加工能力提出了更高的要求。 ASML 的高数值孔径 EUV 系统,每台售价超过 4 亿美元,充分展现了新一代微影术如何提升奈米级金属切削和精加工的性能标准。工业 4.0计划也越来越多采用人工智慧驱动的数控系统,实现进给速度和刀具路径的自我最佳化。区域投资格局显示,亚洲占据了新增产能的大部分,但美国的回流奖励和欧洲关税的不确定性正促使未来的需求转向更多元化的工厂。儘管直销仍然是全球分销的主导方式,但电商平台正在加速中价格分布数控机床和替换刀具的采购週期。

全球工具机市场趋势与洞察

电气化推动精密电动动力传动系统总成加工

电动车电机工厂通常采用五轴加工中心,将公差控制在微米级,并透过自动定子插入和髮夹式绕线,省去了二次表面处理工程。采埃孚的目标是到2030年实现其电动车动力总成生产线70%的自动化,而中国供应商预测,到2034年,年产量将超过1.2亿台。通用汽车和梅赛德斯-奔驰正在内部资源,并倾向于使用能够无振动振动的铝硅合金加工机床。市场对製程测量、封闭式管理以及用于抑制微米级形状误差产生的电磁杂讯的闭环补偿技术的需求日益增长。

半导体工厂的扩张需要超精密设备

预计到2027年,全球300毫米晶圆厂投资将达到1,370亿美元,其中美洲地区的投资每三年翻倍。 ASML的多吨级投影光学元件需要钻石车削和气浮研磨系统,以确保每公尺行程的形状误差小于50奈米。台积电在亚利桑那州投资1,650亿美元的工厂项目,充分展现了「自主晶片计画」如何为超精密加工工厂创造在地化需求,从而在组装过程中实现重型零件的本土化生产。洁净室相容性、静压滑轨和无污染润滑方法,如今已成为服务于此细分市场的设备製造商的标准配置。

先进的数控系统需要高额的资本投入和较长的投资回收期。

根据亚特兰大联邦储备银行的一项调查,80%的製造商在购买资本设备前会将利率视为重要因素,而2025年基准利率的上升将进一步加剧这一趋势。一台顶级的五轴加工中心成本可能超过300万美元,这意味着中型加工厂的损益平衡点可能需要五年以上的时间。设备即服务(EaaS)合约已成为过渡解决方案,但许多财务长担心,软体升级会导致旧一代控制器过时,从而带来残值风险。

细分市场分析

到2025年,多轴工具机精加工复杂壳体的五轴联动平台。汽车製造商正在用电力驱动壳体单元取代内燃机汽缸体生产线,并采用多轴工具机来减少占地面积和搬运成本。一家主要的航太製造商正在增加一台高扭矩倾斜主轴中心,用于铣削钛合金翼梁,同时保持1.2米长度上0.015毫米的平面度。工具车间操作员仍然依赖三轴立式铣床,但带有数字显示计数器和探针的改装套件正在帮助他们在维护作业中保持竞争力。

随着人工智慧引导的参数嚮导降低薄板不銹钢的废品率,雷射切割系统的需求正在回升。电火花加工在需要小半径角落的模具型腔加工领域仍然占据一席之地,而铣床难以经济高效地完成此类加工。结合指向性能量沉积技术和精铣的混合型工具机正在原型实验室中投入使用,因为缩短加工週期带来的效益超过了设备成本。面向重型加工场所的等离子切割和水刀切割平台正开始整合闭合迴路高度控制功能,以确保在翘曲金属板上的切割品质。

到2024年,CNC平台将占总营收的68.98%,复合年增长率达6.20%,巩固在工具机市场的核心地位。新兴控制器采用GPU加速演算法,可直接将STEP檔案转换为最佳化的刀具路径,进而缩短小批量零件的程式时间。中国第一自动化获得了约1亿元的资金,用于伺服驱动器和PLC堆迭的在地化,凸显了其避免依赖海外韧体风险的战略倡议。虽然传统的手动机床仍然在小型车间和职业学校中使用,但越来越多的新工具机正在向伺服机架过渡,即使最初购买时未配备控制设备,也是为了应对未来的维修。混合增材-减材系统处于领先地位,它将雷射金属沉积与五轴铣削相结合,从而省去了航太支架的支撑结构去除步骤。

数位双胞胎系统可模拟刀具挠曲和热漂移,从而实现离线检验,防止首件试製过程中发生碰撞。 ChatCNC™ 外挂程式可辨识棱柱形状并自动产生从粗加工到精加工的加工序列,即使是经验不足的程式设计人员也能达到专业级的加工週期。预测分析平台可在发生灾难性故障之前标记主轴异常。

工具机市场报告按产品类型(金属切削刀具、金属成形刀具)、技术类型(传统工具机机、数控工具机、其他)、终端用户产业类型(汽车、航太与国防、其他)、销售管道类型(直销、其他)和地区类型(北美、亚太、欧洲、其他)进行细分。报告提供了上述所有细分市场的市场规模和预测(以美元计)。

区域分析

亚太地区引领战略转型,北美地区復苏,欧洲地区克服逆境不断创新。预计到2025年,亚太地区将占全球营收的45.43%,复合年增长率达6.20%。中国正将其小批量生产设施升级为高阶CNC单元工厂,以抵销美国即将对中阶设备征收的25%关税的影响。印度的生产挂钩激励计画正引导资金流向300毫米晶圆厂和国防飞机机身製造,从而为精密卧式和立式加工中心创造订单。日本正利用其数十年的运动控制技术,出口可在多班次作业週期内保持亚微米级重复精度的超精密研磨;韩国电子集团则投资于折迭式行动电话铰链板和相机模组的加工能力。随着原始设备製造商(OEM)采用「中国+1」采购模式,强调地域风险分散,越南和泰国等东南亚国协正在扩大其市场份额。

北美受惠于旨在重组战略製造业的回流政策。美国工具机消费份额达到11.9%,创2001年以来新高,这主要得益于区域工具製造商提高了用于航太发射结构的大型立式车床的产能。墨西哥9.1%的成长主要由离岸汽车组装推动,新莱昂州的一个州立工业提供24小时核准。加拿大在采矿业和低碳能源计划中赢得了工具工具机订单,但技术纯熟劳工短缺阻碍了整体成长势头,这也是整个北美大陆通用的限制因素。

欧洲虽然面临电费上涨和外汇波动带来的利润压力,但在高精度五轴加工中心和雷射金属沉积设备领域仍保持绝对领先地位。德国製造商正透过推广售后服务合约和改装来应对国内订单疲软的局面,其中包括主轴更换计划,该计划保证48小时内交付。通快(Trumpf)计划在2025年投资5.3亿欧元用于研发,儘管销售额下降了9%,但在光束源效率方面仍保持领先地位。北欧企业则透过在每台新机器交付时提供碳足迹证书,来强调其在永续性的领导地位。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 电气化浪潮推动高精度电动动力传动系统总成加工

- 工业4.0的普及推动了对智慧数控平台的需求

- 轻质合金和复合材料的普及需要高速多轴加工工具

- 半导体工厂的扩张需要超精密设备

- 全球老旧(20年以上)工具机的更换週期

- 适用于自动化多品种、小批量生产的灵活加工

- 市场限制

- 特种钢材和直线运动部件成本上涨

- 先进的数控系统需要高额的资本投入和较长的投资回收期。

- 全球熟练的CNC程式设计师/操作员短缺

- 利用积层製造

- 价值/供应链分析

- 监管环境(主要政府法规和倡议)

- 技术概览

- 互联自动化机器

- 先进控制/运动系统

- 数位化和工业4.0

- 利用人工智慧提高金属切削精度

- 金属加工产业概况

- 地缘政治对工具机市场的影响

- 产业吸引力—五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模与成长预测

- 副产品

- 金属切削工具

- 铣床

- 钻孔机

- 车床

- 研磨

- 雷射切割机

- 电火花加工工具机(EDM)

- 水刀切割机

- 电浆切割机

- 多轴加工中心

- 其他(保龄球等)

- 金属成型工具

- 压力机(机械式、液压式、伺服)

- 锻造机

- 折弯机

- 其他(剪切、挤压、轧延等)

- 金属切削工具

- 透过技术

- 传统机器(手动或半手动)

- CNC工具机

- 积层製造/混合型机器

- 按最终用户行业划分

- 车

- 航太/国防

- 电气和电子

- 工业机械及设备

- 医疗设备

- 造船/海洋

- 精密工程

- 能源与电力

- 金属加工(单件加工车间等)

- 其他行业(铁路、其他一般製造业等)

- 按销售管道

- 直接销售(OEM 直接面向最终用户)

- 经销商和分销商

- 线上/电子商务

- 其他(系统整合商、活动和展览、翻新商和翻新产品等)

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 南美洲

- 巴西

- 阿根廷

- 秘鲁

- 其他南美洲

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 比荷卢经济联盟(比利时、荷兰、卢森堡)

- Nordix(丹麦、芬兰、冰岛、挪威、瑞典)

- 其他欧洲地区

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 韩国

- 东协(印尼、泰国、菲律宾、马来西亚、越南)

- 亚太其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 卡达

- 科威特

- 土耳其

- 埃及

- 南非

- 奈及利亚

- 其他中东和非洲地区

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Yamazaki Mazak Corporation

- DMG MORI Co. Ltd

- TRUMPF Group

- JTEKT Corporation

- Doosan Machine Tools

- Okuma Corporation

- Makino Milling Machine Co. Ltd

- Haas Automation Inc.

- FANUC Corporation

- Hyundai Wia Corp.

- Schuler AG

- Sandvik AB(Seco & Walter)

- GF Machining Solutions

- Fives Group

- GROB-Werke GmbH & Co. KG

- Hermle AG

- EMAG GmbH & Co. KG

- Hardinge Inc.

- HURCO Companies Inc.

- Amada Co. Ltd

第七章 市场机会与未来展望

The Machine Tools Market is valued at USD 108.47 billion in 2025 and is set to reach USD 127.66 billion by 2030, advancing at a 3.31% CAGR.

This expansion occurs against a backdrop of realigned supply chains, stricter trade rules, and record investment in semiconductor fabs, each of which demands ultra-precision machining capacity. ASML's High-NA EUV systems, which cost more than USD 400 million apiece, exemplify how next-generation lithography is lifting the performance bar for nanometer-level metal cutting and finishing . Electrification in automotive and ongoing aerospace modernization are spurring purchases of multi-axis machining centers, while Industry 4.0 projects increasingly bundle AI-enabled CNC controls that self-optimize feed rates and tool paths. Regional investment patterns show Asia drawing the bulk of new capacity additions, yet reshoring incentives in the United States and tariff uncertainty in Europe are tilting future demand toward more diversified plant footprints. Direct sales still dominate the global distribution mix, but e-commerce portals are accelerating procurement cycles for mid-ticket CNC models and replacement tooling.

Global Machine Tools Market Trends and Insights

Electrification Surge Driving Precision e-Powertrain Machining

Electric-vehicle motor plants are pushing tolerances to micro-scale ranges, often pairing automated stator insertion and hairpin winding with five-axis machining centers that eliminate secondary finishing steps. ZF targets 70% automation for EV drive-train lines by 2030, and Chinese suppliers project annual output exceeding 120 million e-motors by 2034. General Motors and Mercedes-Benz have both insourced e-motor housing production, favouring machines that cut aluminum-silicon alloys without creating pass-off chatter. Demand is intensifying for in-process gauging, coolant management, and closed-loop compensation to suppress electromagnetic noise that would otherwise arise from micron-level form errors.

Semiconductor Fab Expansion Necessitating Ultra-Precision Equipment

Global 300 mm fab spending is forecast to hit USD 137 billion in 2027, with the Americas doubling outlays in three years. ASML's multi-ton projection optics require diamond-turning and air-bearing grinding systems that hold sub-50 nm form error over 1 m travel. TSMC's USD 165 billion Arizona complex exemplifies how sovereign chip programs create local pull for ultraprecision machine shops that can keep heavy components in-state during assembly. Clean-room compatibility, hydrostatic slideways, and contamination-free lubrication schemes are now baseline specifications for equipment makers serving this niche.

High Capex & Lengthy Payback for Advanced CNC Systems

Atlanta Fed surveys reveal that 80% of manufacturers weigh interest rates heavily before committing to capital equipment, a dynamic amplified by prime-rate increases in 2025. A top-tier five-axis cell can exceed USD 3 million installed, pushing breakeven past five years for medium-volume job shops. Equipment-as-a-service contracts are emerging as an interim solution, though many CFOs remain wary of residual value risk once software upgrades render early-generation controllers obsolete.

Other drivers and restraints analyzed in the detailed report include:

- Industry 4.0 Adoption Boosting Demand for Smart CNC Platforms

- Lightweight Alloy & Composite Uptake Requiring High-Speed Multi-Axis Tools

- Surging Specialty Steel & Linear-Motion Component Costs

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

The multi-axis segment started 2025 commanding USD 24.6 billion of the machine tools market size and is heading toward a 7.00% CAGR to 2030. Milling machines retain the biggest revenue pool with 28.23% share in 2024, yet growth now concentrates on simultaneous five-axis platforms that finish complex housings in one clamp. Automakers replacing ICE cylinder-block lines with e-drive casing cells embrace multi-axis machines to lower floor-space and handling costs. Aerospace primes add high-torque tilt-spindle centres to mill titanium spars while maintaining 0.015 mm flatness over 1.2 m lengths. Toolroom operators still rely on three-axis knee mills, but retrofit kits with digital readouts and probing keep them competitive for maintenance work.

Demand for laser cutting systems is rebounding as AI-guided parameter wizards reduce scrap rates on thin-gauge stainless. Electrical-discharge machining maintains a niche in tool-and-die cavities that require micro-corner radii which mills cannot reach economically. Hybrid machines that mix directed-energy deposition with finish milling are entering prototype labs where cycle-time savings outweigh equipment cost. Plasma and waterjet platforms serve heavy-fabrication yards; however, both are starting to integrate closed-loop height control to maintain cut quality on warped plates.

CNC platforms represented 68.98% revenue in 2024 and will climb at 6.20% CAGR, solidifying their position at the heart of the machine tools market. Emerging controllers employ GPU-accelerated algorithmsthat translate STEP files directly to optimized toolpaths, slashing programming time for short-run parts. China's First Automation secured nearly RMB 100 million to localize servo drives and PLC stacks, highlighting strategic efforts to de-risk foreign firmware dependencies. Conventional manual machines endure in small workshops and vocational schools, yet new builds are trending toward servo-ready frames even when purchased without controls, anticipating future retrofits. Hybrid additive-subtractive systems occupy the cutting edge, combining laser metal deposition with five-axis milling to eliminate support-structure removal steps in aerospace brackets.

Digital twins now simulate tool deflection and thermal drift, allowing off-machine validation that prevents collision during first-article runs. ChatCNC(TM) plug-ins recognise prismatic features and auto-generate rough-to-finish sequences, enabling less-experienced programmers to achieve veteran-level cycle times. Predictive analytics platforms flag spindle anomalies well before catastrophic failure, an especially valuable feature for lights-out processing where operator oversight is minimal.

The Machine Tools Market Report is Segmented by Product (Metal Cutting Tools, Metal Forming Tools), by Technology (Conventional Machines, CNC Machines, and More), by End-User Industry (Automotive, Aerospace & Defense, and More), by Sales Channel (Direct Sales, and More), and by Geography (North America, Asia-Pacific, Europe, and More). The Report Offers Market Size and Forecasts in Value (USD) for all the Above Segments.

Geography Analysis

Asia-Pacific Leads Amid Strategic Shifts, While North America Reshores and Europe Innovates Through Headwinds. Asia-Pacific entered 2025 with 45.43% of global revenue and a 6.20% CAGR outlook as governments funnel incentives into EV, aerospace, and semiconductor clusters. China is upgrading small-batch workshops into high-end CNC cell factories to offset looming 25% U.S. tariffs on mid-range machinery. India's production-linked incentive program is steering capital toward 300 mm wafer fabs and defence airframe work, generating orders for precision horizontals and vertical machining centres. Japan leverages decades of motion-control know-how to export ultra-precision grinders that hold sub-micron repeatability across multi-shift duty cycles, while South Korea's consumer-electronics conglomerates invest in machining capacity for foldable-phone hinge plates and camera modules. ASEAN nations such as Vietnam and Thailand gain share as OEMs adopt a China-plus-one sourcing model that values geographic risk dispersion.

North America benefits from reshoring policies aimed at rebuilding strategic manufacturing self-reliance. United States consumption reached its highest 11.9% share since 2001 as regional tool builders added capacity for large-format vertical lathes used in space-launch structures. Mexico's 9.1% uptick stems from near-shore vehicle assembly, with state-backed industrial parks in Nuevo Leon offering 24-hour permit approvals. Canada draws machine-tool orders from the mining sector and low-carbon energy projects, though overall momentum is tempered by skilled-labour shortages, a constraint echoed across the entire continent.

Europe faces margin erosion from elevated electricity costs and currency volatility, yet it preserves a commanding lead in high-accuracy five-axis and laser-metal-deposition systems. German builders are responding to soft domestic orders by pushing into after-sales contracts and retrofits, including spindle-exchange programmes that guarantee 48-hour turnaround. TRUMPF invested EUR 530 million in R&D during 2025 to maintain its edge in beam-source efficiency despite a 9% revenue dip. Nordic firms highlight sustainability leadership by offering carbon-footprint certificates with each new machine shipment, a feature increasingly mandated in public-sector tenders.

- Yamazaki Mazak Corporation

- DMG MORI Co. Ltd

- TRUMPF Group

- JTEKT Corporation

- Doosan Machine Tools

- Okuma Corporation

- Makino Milling Machine Co. Ltd

- Haas Automation Inc.

- FANUC Corporation

- Hyundai Wia Corp.

- Schuler AG

- Sandvik AB (Seco & Walter)

- GF Machining Solutions

- Fives Group

- GROB-Werke GmbH & Co. KG

- Hermle AG

- EMAG GmbH & Co. KG

- Hardinge Inc.

- HURCO Companies Inc.

- Amada Co. Ltd

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Electrification Surge Driving Precision e-Powertrain Machining

- 4.2.2 Industry 4.0 Adoption Boosting Demand for Smart CNC Platforms

- 4.2.3 Lightweight Alloy & Composite Uptake Requiring High-Speed Multi-Axis Tools

- 4.2.4 Semiconductor Fab Expansion Necessitating Ultra-Precision Equipment

- 4.2.5 Global Replacement Cycle of Ageing (>20 yrs) Machine Tool Fleet

- 4.2.6 Automation of High-Mix/Low-Volume Production Via Flexible Machining

- 4.3 Market Restraints

- 4.3.1 Surging Specialty Steel & Linear-Motion Component Costs

- 4.3.2 High Capex & Lengthy Payback for Advanced CNC Systems

- 4.3.3 Worldwide Shortage of Skilled CNC Programmers/Operators

- 4.3.4 Capital Diversion to Additive Manufacturing Technologies

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Outlook (Key Government Regulations & Initiatives)

- 4.6 Technology Snapshot

- 4.6.1 Connected & Automated Machines

- 4.6.2 Advanced Controls / Motion Systems

- 4.6.3 Digitalisation & Industry 4.0

- 4.6.4 AI-Enhanced Metal Cutting Accuracy

- 4.7 Metalworking Industry Snapshot

- 4.8 Impact of Geopolitics on the Machine Tools Market

- 4.9 Industry Attractiveness - Porter's Five Forces

- 4.9.1 Bargaining Power of Suppliers

- 4.9.2 Bargaining Power of Buyers

- 4.9.3 Threat of New Entrants

- 4.9.4 Threat of Substitutes

- 4.9.5 Competitive Rivalry

5 Market Size & Growth Forecasts (Value, In USD Billion)

- 5.1 By Product

- 5.1.1 Metal Cutting Tools

- 5.1.1.1 Milling Machines

- 5.1.1.2 Drilling Machines

- 5.1.1.3 Turning (Lathe) Machines

- 5.1.1.4 Grinding Machines

- 5.1.1.5 Laser Cutting Machines

- 5.1.1.6 Electrical Discharge Machines (EDM)

- 5.1.1.7 Waterjet Cutting Machines

- 5.1.1.8 Plasma Cutting Machines

- 5.1.1.9 Multi-Axis Machining Centres

- 5.1.1.10 Others (Boring, etc.)

- 5.1.2 Metal Forming Tools

- 5.1.2.1 Presses (Mechanical, Hydraulic, Servo)

- 5.1.2.2 Forging Machines

- 5.1.2.3 Bending Machines

- 5.1.2.4 Others (Shearing, Extrusion, Rolling, etc.)

- 5.1.1 Metal Cutting Tools

- 5.2 By Technology

- 5.2.1 Conventional Machines (Manually or Semi-Manually)

- 5.2.2 CNC Machines

- 5.2.3 Additive Manufacturing / Hybrid Machines

- 5.3 By End-User Industry

- 5.3.1 Automotive

- 5.3.2 Aerospace & Defence

- 5.3.3 Electrical & Electronics

- 5.3.4 Industrial Machinery & Equipment

- 5.3.5 Medical Devices

- 5.3.6 Shipbuilding & Marine

- 5.3.7 Precision Engineering

- 5.3.8 Energy & Power

- 5.3.9 Metal Fabrication (Job Shops, etc.)

- 5.3.10 Other Industries (Railway, Other General Manufacturing, etc.)

- 5.4 By Sales Channel

- 5.4.1 Direct Sales (OEMs to End Users)

- 5.4.2 Dealers & Distributors

- 5.4.3 Online / E-commerce

- 5.4.4 Others (System Integrators, Events & Exhibitions, Rebuilders & Refurbished, etc.)

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Peru

- 5.5.2.4 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 United Kingdom

- 5.5.3.2 Germany

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 BENELUX (Belgium, Netherlands, and Luxembourg)

- 5.5.3.7 NORDICS (Denmark, Finland, Iceland, Norway, and Sweden)

- 5.5.3.8 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 India

- 5.5.4.3 Japan

- 5.5.4.4 Australia

- 5.5.4.5 South Korea

- 5.5.4.6 ASEAN (Indonesia, Thailand, Philippines, Malaysia, Vietnam)

- 5.5.4.7 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Saudi Arabia

- 5.5.5.2 United Arab Emirates

- 5.5.5.3 Qatar

- 5.5.5.4 Kuwait

- 5.5.5.5 Turkey

- 5.5.5.6 Egypt

- 5.5.5.7 South Africa

- 5.5.5.8 Nigeria

- 5.5.5.9 Rest of Middle East and Africa

- 5.5.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials as available, Strategic Information, Products & Services, Recent Developments)

- 6.4.1 Yamazaki Mazak Corporation

- 6.4.2 DMG MORI Co. Ltd

- 6.4.3 TRUMPF Group

- 6.4.4 JTEKT Corporation

- 6.4.5 Doosan Machine Tools

- 6.4.6 Okuma Corporation

- 6.4.7 Makino Milling Machine Co. Ltd

- 6.4.8 Haas Automation Inc.

- 6.4.9 FANUC Corporation

- 6.4.10 Hyundai Wia Corp.

- 6.4.11 Schuler AG

- 6.4.12 Sandvik AB (Seco & Walter)

- 6.4.13 GF Machining Solutions

- 6.4.14 Fives Group

- 6.4.15 GROB-Werke GmbH & Co. KG

- 6.4.16 Hermle AG

- 6.4.17 EMAG GmbH & Co. KG

- 6.4.18 Hardinge Inc.

- 6.4.19 HURCO Companies Inc.

- 6.4.20 Amada Co. Ltd