|

市场调查报告书

商品编码

1851395

软包装产业:市场占有率分析、产业趋势、统计数据和成长预测(2025-2030 年)Flexible Packaging Industry - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

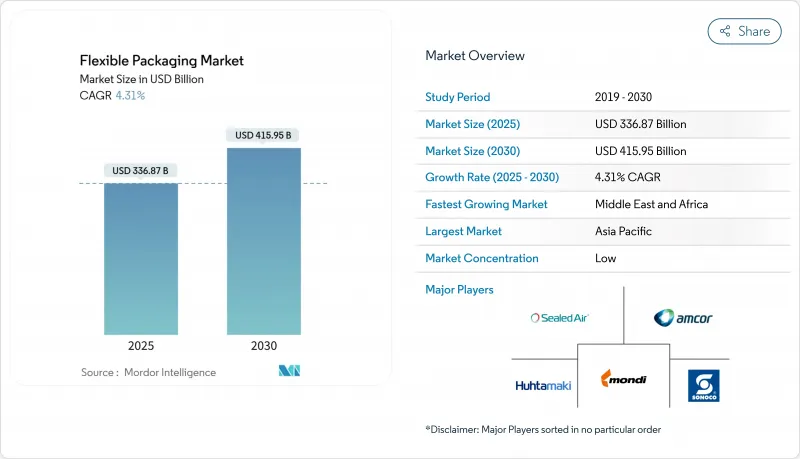

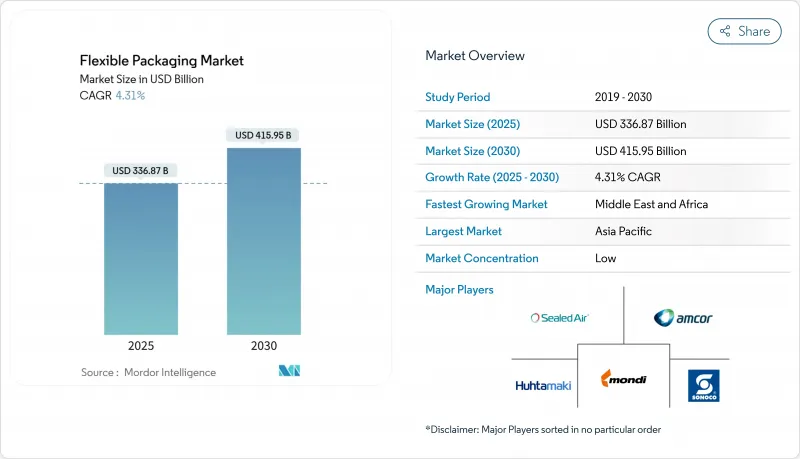

预计到 2025 年,软质包装市场规模将达到 3,368.7 亿美元,到 2030 年将达到 4,159.5 亿美元,年复合成长率为 4.31%。

永续性需求、电子商务的快速发展以及品牌对轻质阻隔性包装的需求不断增长,正在为软包装市场带来更多机会。材料科学的突破,尤其是在单一材料结构方面的突破,正在减轻掩埋的压力,并为加工商开闢新的循环收入来源。数位印刷缩短了小众产品的上市週期,而准时制工作流程则缓解了聚烯价格波动所带来的收入波动。从区域来看,亚太地区不断壮大的中阶和日益增长的製造业规模巩固了其领先地位,而中东和非洲包装基础设施的蓬勃发展正在加速其追赶步伐。

全球软包装产业市场趋势与洞察

电子商务对轻型保护性邮寄袋的需求激增

预计到2024年,北美线上销售额将成长15.4%,这将推动零售商采用柔性气泡信封,进而降低高达30%的体积重量费用。亚马逊在印度减少了9,100吨塑胶的使用,并广泛推广可回收垫片气泡袋,这表明企业碳排放承诺正朝着纤维薄膜混合包装的方向发展。随着包装尺寸调整政策的加强,这种趋势正蔓延至欧洲,亚洲的小包裹网路也正在效仿这些经济高效的包装形式。最终结果是,对聚涂层信封的需求持续成长,使软质包装市场超越了传统的快速消费品终端用途。

亚洲快速消费品品牌转向使用可回收的单一材料薄膜

印度2025年塑胶废弃物管理规则要求品牌所有者证明其包装足迹的量化回收利用情况,迫使大型食品和口腔护理产品製造商用纯聚烯薄膜取代多层复合材料。例如,Wipf AG的PP基WICOFILM等解决方案可以无缝融入现有的回收流程,同时保持氧气和香气阻隔性能。东协个人护理品牌正在积极拥抱这一转变,利用单一材料包装袋来确保货架吸引力,并满足零售商的回收计划。供应端的创新正在亚太地区蔓延,协助该地区巩固其在软包装市场45.24%的份额。随着大多数生产者责任延伸(EPR)费率逐年提高,扩大单一材料产能的加工商将更有可能获得高合约和稳定的利润率。

聚烯价格波动挤压转换器利润

预计到2024年,原料价格波动幅度将达到两位数,这将侵蚀采用季度价格合约的加工商的息税折旧摊销前利润(EBITDA)。亚洲地区聚乙烯(PE)和聚丙烯(PP)供应过剩以及运输中断加剧了价格波动。为了缓解利润衝击,主要加工商正在采用更薄的薄膜规格、实现库存计划数位化,并探索生物质基石脑油合约以分散风险。儘管这些市场限制是暂时的,但它们正在加速价格稳定并向可回收材料的转变,从而间接地推动了软包装市场供应链的现代化。

细分市场分析

聚乙烯凭藉其低成本和优异的防潮性能,在食品包装领域占据核心地位,预计到2024年将占软包装市场份额的34.71%。由于树脂种类繁多且回收渠道完善,聚乙烯仍是谷物内衬、冷冻食品薄膜和清洁剂袋等应用的首选材料。然而,随着零售商推出可家庭堆肥的自有品牌产品线,以及市政当局改进有机废弃物处理项目,可生物降解和可堆肥聚合物将在2025年至2030年间以7.76%的复合年增长率实现最快增长。这一趋势将推动研发预算转向以PLA和PHA为基础的挤压树脂,这些树脂既能模拟LDPE的韧性,又能在工业废弃物循环中降解。在对水蒸气的要求不高的情况下,纸质复合材料也正在重新流行,而铝箔则在需要近乎零氧气透过率的场合保持着独特的地位。 EVOH(乙烯-醋酸乙烯酯共聚物)在无菌肉汤和营养补充品凝胶等领域仍发挥重要作用,儘管目前主要以微层形式存在。总体而言,材料组合正朝着减少范围 3排放而不牺牲可加工性的解决方案转变,从而加强了柔性包装市场的循环经济重点。

受快速消费品产业脱碳蓝图和掩埋转移费的推动,可生物降解软包装市场预计将从2025年的324亿美元成长到2030年的472亿美元。儘管聚乙烯目前仍占据销售优势,但随着消费者对最低再生材料含量标准的提高,其主导地位预计将会下降。双向拉伸聚丙烯(BOPP)的透明度和刚性使其在零嘴零食领域保持领先地位,而聚氯乙烯(CPP)的热封可靠性则确保了其在蒸馏袋和扭结包装中的应用。树脂生产商正在投资化学回收技术以回收聚丙烯(PP)和聚乙烯(PE)单体,从而实现真正的聚合物-聚合物循环,以保持材料性能。随着这些努力的扩展,加工商预见到混合产品组合的出现,其中机械、化学和生物降解途径并存,每种途径都能满足软质包装市场中不同管道的需求。

2024年,软包装袋将占总销售额的46.74%,凸显了其在减少运输排放方面的优势。软包装袋重量减轻70%,可取代玻璃瓶和易拉罐。立式袋增加了广告空间,并能促进调味品和宠物食品的衝动性购买。高解析度喷墨印刷机的出现减少了印刷前的浪费,使季节性口味的SKU得以扩展,并支持了直销品牌和自有品牌的更新换代。薄膜和包装纸虽然在货架上不太显眼,但随着厚度的减少而又不牺牲抗穿刺性,其复合年增长率高达5.72%,成为增长最快的包装形式。奈米黏土和二氧化硅阻隔涂层取代了铝层,提高了分类性和可回收性。

同时,受化肥、水泥和宠物食品等产品需求的推动,软包装市场(包括袋装和包装袋)规模依然强劲。小袋装和条状包装在单份营养补充剂和即溶饮料领域持续占据主导地位,尤其是在东南亚地区,该地区的即饮消费正在不断增长。未来五年,数位印刷、无溶剂运作和电子束固化技术的协同作用可望将前置作业时间从数週缩短至数天,迫使加工商重新思考其工厂布局。最终,产品组合将有利于那些能够灵活切换的营运模式,既能满足食品服务的大量生产需求,又能满足网红合作的小批量生产需求的企业。

这份软质包装市场报告按材料类型(塑胶、纸张、铝箔、可生物降解材料)、产品类型(包装袋、薄膜、其他)、终端用户行业(食品、食品饮料、医药、化妆品、工业、其他)、分销管道(直接、间接)和地区(北美、欧洲、亚太、南美、中东和非洲)进行细分。市场预测以美元(USD)计价。

区域分析

预计到2024年,亚太地区将继续维持其在软包装市场45.24%的主导地位,这主要得益于都市化、可支配收入的成长以及扶持製造业的政策。中国的智慧工厂投资和印度针对食品加工的生产连结奖励计画正在推动国内树脂和薄膜产能的提升。 UFlex公司将其聚酯切片产量翻了一番,并运作了一座整合消费后材料的PCR工厂,从而强化了其循环供应链提案。本地加工商也率先推出单一材料解决方案,以应对即将实施的生产者责任延伸(EPR)费用,进一步巩固了该地区的发展势头。同时,东南亚国家正利用免税贸易丛集出口立式袋,活性化区域内贸易往来。

北美是第二大节点,这主要得益于电子商务包装袋的普及和医药低温运输的成长。零售商要求使用经How2Recycle认证的包装袋,推动了PE薄膜可回收性的提升。原始设备製造商(OEM)正在整合数位化检测技术,以确保符合FDA标准的可追溯性,从而加强市场诚信。欧洲正转向其欧盟PPWR战略,投资建造化学回收试点工厂和纤维基柔性产品。 Mondi和Haftamaki分别扩大了其可回收蒸馏线和Blue Loop产品组合,以大规模应用「面向回收的设计」原则。

预计到2030年,中东和非洲将以6.16%的复合年增长率实现最快增长,这主要得益于沙乌地阿拉伯和埃及等外国直接投资支持的食品中心的发展。非洲包装产业预计在2030年达到545.4亿美元,其中软包装市场规模到2032年可能超过32.6亿美元。现代零售连锁店需要适用于干旱气候的保质期长的包装袋,这刺激了阻隔性薄膜的进口。南美洲专门食品咖啡的蓬勃发展增强了对排气阀包装袋的需求,而外汇波动则提升了软质包装比硬质玻璃和金属包装更轻。各地区的通用是,监管主导的回收目标正在促使加工商的研发蓝图趋向单一材料。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 北美地区对轻型防护邮寄袋的电子商务需求激增

- 亚洲快速消费品品牌转向使用单一材料可回收薄膜以满足生产者责任延伸制度的要求

- 蒸馏食品在欧洲迅速普及

- 南美洲咖啡和专门食品饮品品牌改用高阻隔薄膜

- 投资数位印刷技术,实现化妆品包装的大规模客製化

- 低温运输生技药品包装需求的成长泡壳了药品软包装的发展

- 市场限制

- 聚烯价格波动挤压转换器利润

- 欧盟和美国多层复合材料的回收基础设施分散

- 加强主要新兴国家(如印度、肯亚)对一次性塑胶製品的禁令

- 硬质宝特瓶阻碍了立式袋在中东碳酸饮料市场的渗透。

- 供应链分析

- 监理展望

- 技术展望

- 贸易情景(依相关HS编码)

- 波特五力分析

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

- 回收与永续性概况

第五章 市场规模与成长预测

- 依材料类型

- 塑胶

- 聚乙烯

- 双轴延伸聚丙烯(BOPP)

- 流延聚丙烯(CPP)

- 聚氯乙烯(PVC)

- 乙烯 - 乙烯醇(EVOH)

- 其他软塑胶

- 纸

- 铝箔

- 可生物降解和可堆肥材料

- 塑胶

- 依产品类型

- 小袋

- 袋子和麻袋

- 薄膜和包装

- 其他产品类型

- 按最终用途行业划分

- 食物

- 冷冻食品

- 乳製品

- 肉类和海鲜

- 烘焙点心和糖果甜点

- 生鲜食品

- 其他食物

- 饮料

- 果汁和花蜜

- 乳製品饮料

- 其他饮料

- 製药

- 化妆品和个人护理

- 工业的

- 其他终端用户产业

- 食物

- 透过分销管道

- 直销通路

- 间接销售管道

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 北欧国家

- 亚太地区

- 中国

- 日本

- 印度

- ASEAN

- 韩国

- 澳洲

- 纽西兰

- 南美洲

- 巴西

- 阿根廷

- 智利

- 中东和非洲

- 中东

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 土耳其

- 其他中东地区

- 非洲

- 南非

- 肯亚

- 其他非洲地区

- 北美洲

第六章 竞争情势

- 市场集中度

- 市占率分析

- 公司简介

- Amcor plc

- Sealed Air Corporation

- Mondi plc

- Huhtamaki Oyj

- Constantia Flexibles Group GmbH

- Sonoco Products Company

- ProAmpac LLC

- Coveris Management GmbH

- Uflex Ltd.

- Sigma Plastics Group

- Schur Flexibles Holding

- Wipf AG

- Glenroy Inc.

- Printpack Inc.

- Clondalkin Flexible Packaging

- American Packaging Corporation

- FlexPak Services LLC

- Arabian Flexible Packaging LLC

- Gulf East Paper & Plastic Industries LLC

- Plastipak Packaging Inc.

第七章 市场机会与未来展望

The flexible packaging market size stands at USD 336.87 billion in 2025 and is forecast to reach USD 415.95 billion by 2030, advancing at a 4.31% CAGR.

Rising sustainability mandates, rapid e-commerce expansion, and brand demand for lightweight, high-barrier formats are widening the flexible packaging market opportunity. Material science breakthroughs, particularly in mono-material structures, are reducing landfill pressure and unlocking new circular revenue streams for converters. Digital printing is compressing launch cycles for niche products, while just-in-time workflows mitigate the earnings volatility caused by polyolefin price swings. Regionally, Asia Pacific's expanding middle class and manufacturing scale underpin its leadership, whereas the Middle East and Africa's packaging infrastructure boom is accelerating its catch-up growth.

Global Flexible Packaging Industry Market Trends and Insights

Surge in e-commerce demand for lightweight protective mailers

North American online sales expanded by 15.4% in 2024, pushing retailers to adopt flexible bubble mailers that cut dimensional-weight fees up to 30%. Amazon's removal of 9,100 metric tons of plastic in India and its wider rollout of recyclable paper padded bags illustrate how corporate carbon pledges are steering procurement toward fiber-and-film hybridsConverter order books now favor curbside-recyclable mailers with high recycled-content films, spawning capacity additions across the United States and Mexico. Volumes are also spilling into Europe as right-sizing mandates tighten, while Asian parcel networks replicate these cost-efficient formats. The net effect is a sustained uplift in poly-coated mailer demand that lifts the flexible packaging market beyond traditional FMCG end uses.

Shift of Asian FMCG brands toward mono-material recyclable films

India's Plastic Waste Management Rules in FY 2025 require brand owners to demonstrate quantifiable recycling of their packaging footprints, compelling leading food and oral-care players to replace multilayer laminates with polyolefin-only films. Solutions such as PP-based WICOFILM from Wipf AG preserve oxygen and aroma barriers yet flow seamlessly through existing recycling streams. ASEAN personal-care brands echo this switch, leveraging mono-material pouches to secure shelf appeal while satisfying retailer take-back schemes. Supply-side innovation is spreading across Asia Pacific, helping the region reinforce its 45.24% hold on the flexible packaging market. With most EPR fees escalating annually, converters that scale mono-material capacity are positioned to secure premium contracts and margin resilience.

Volatile polyolefin prices squeezing converter margins

Feedstock volatility reached double-digit spreads in 2024, eroding EBITDA for converters locked into quarterly price agreements. Asian PE and PP oversupply and shipping disruptions amplify the swings. To blunt margin shocks, leading converters deploy thinner gauge films, digitalize inventory planning, and explore biomass-based naphtha contracts to diversify risk exposure. This restraint remains transitory yet accelerates the shift toward materials that provide price stability and recycled content, indirectly modernizing the flexible packaging market supply base.

Other drivers and restraints analyzed in the detailed report include:

- Rapid adoption of retort pouches for ready-to-eat meals

- Coffee and specialty-drink brands' switch to high-barrier films

- Fragmented recycling infrastructure for multilayer laminates

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Polyethylene underpinned 34.71% of flexible packaging market share in 2024, leveraging its low cost and moisture barrier attributes to anchor core food applications. Its wide resin availability and established recycling streams keep it the default choice for cereal liners, frozen food films, and detergent pouches. However, biodegradable and compostable polymers exhibit the fastest 7.76% CAGR from 2025-2030 as retailers introduce home-compostable private-label lines and municipalities upgrade organic waste programs. This momentum realigns R&D budgets toward PLA- and PHA-based coextrusions that mimic LDPE toughness yet break down within industrial composting cycles. Paper laminates also resurge where water vapor requirements are moderate, while aluminum foil defends niche roles that demand near-zero oxygen transmission. EVOH, albeit used in microlayer form, remains critical for aseptic broths and nutraceutical gels. Collectively, the material portfolio is pivoting toward solutions that reduce Scope 3 emissions without forfeiting machinability, reinforcing the flexible packaging market's pivot to circularity.

The flexible packaging market size for biodegradable materials is projected to climb from USD 32.4 billion in 2025 to USD 47.2 billion in 2030, fueled by FMCG decarbonization roadmaps and landfill diversion fees. Polyethylene still commands the volume crown, yet its dominance is expected to edge down as consumer-facing categories impose minimum recycled-content thresholds. BOPP's clarity and stiffness uphold its presence in snack foods, while CPP's heat-seal reliability ensures its inclusion in retort and twist-wrap packs. Resin makers are investing in chemical recycling to recapture PP and PE monomers, enabling true polymer-to-polymer loops that preserve material performance. As these initiatives scale, converters foresee a blended portfolio where mechanical, chemical, and bio-degradation pathways coexist, each serving distinct channel needs within the flexible packaging market.

Pouches generated 46.74% of 2024 revenue, spotlighting their ability to replace glass jars and tins with 70% lighter formats that lower freight emissions. Stand-up pouches enhance billboard space, driving impulse purchases in condiments and pet food. The advent of high-definition inkjet presses slashes make-ready waste and enables SKU proliferation for seasonal flavors, supporting D2C brands and private-label refreshes. Films and wraps, while less visible on shelf, register the sharpest 5.72% CAGR by trimming gauge thicknesses without sacrificing puncture resistance. Nanoclay and silicon oxide barrier coatings now substitute aluminum layers, improving sortability and stream recyclability.

Meanwhile, the flexible packaging market size for bags and sacks holds steady, buoyed by fertilizer, cement, and dog-food demand. Sachets and stick packs continue to penetrate single-serve nutraceuticals and instant beverages, particularly in Southeast Asia where on-the-go consumption is rising. Over the next five years the interplay between digital press uptime, solvent-less lamination, and e-beam curing is expected to compress lead times from weeks to days, pushing converters to rethink plant layouts. The end result is a product mix that rewards agile operations able to toggle between long food-service runs and micro batches for influencer collaborations.

The Flexible Packaging Market Report is Segmented by Material Type (Plastic, Paper, Aluminum Foil, Biodegradable Materials), Product Type (Pouches, Bags, Films, Others), End-Use Industry (Food, Beverage, Pharmaceutical, Cosmetics, Industrial, Others), Distribution Channels (Direct, Indirect), and Geography (North America, Europe, Asia Pacific, South America, MEA). Market Forecasts are in Value (USD).

Geography Analysis

Asia Pacific retained a commanding 45.24% share of the flexible packaging market in 2024 due to urbanization, rising disposable incomes, and pro-manufacturing policies. China's smart-factory investments and India's Production Linked Incentive scheme for food processing underpin domestic resin and film capacity. UFlex doubled polyester chip output and commissioned a PCR plant to integrate post-consumer feedstock, fortifying a circular supply proposition. Local converters also spearhead mono-material rollouts to comply with forthcoming EPR fees, reinforcing the region's trajectory. Meanwhile, Southeast Asian nations leverage duty-free trade clusters to export stand-up pouches, lifting intraregional trade flows.

North America is the second-largest node, propelled by e-commerce mailer adoption and pharmaceutical cold-chain growth. Retailers press for How2Recycle-certified pouches, prompting PE film recyclability upgrades. OEMs integrate digital inspection to guarantee FDA-grade traceability, reinforcing market integrity. Europe anchors its strategy around the EU PPWR, channeling funds into chemical-recycling pilot plants and fiber-based flexibles. Mondi and Huhtamaki expand recyclable retort lines and blueloop portfolios, respectively, embedding design-for-recycling principles at scale.

The Middle East & Africa is forecast to post the fastest 6.16% CAGR to 2030, aided by FDI-backed food hubs in Saudi Arabia and Egypt. Africa's packaging sector is on course to hit USD 54.54 billion by 2030, of which flexible formats could surpass USD 3.26 billion by 2032. Modern retail chains require extended-shelf-life pouches for arid climates, stimulating imports of high-barrier films. South America's specialty coffee boom strengthens demand for degassing valve pouches, while currency volatility makes the lighter flexible packaging market more attractive than rigid glass or metal. Across regions, a common thread is regulatory-driven recycling targets that unify converter R&D roadmaps toward mono-materials.

- Amcor plc

- Sealed Air Corporation

- Mondi plc

- Huhtamaki Oyj

- Constantia Flexibles Group GmbH

- Sonoco Products Company

- ProAmpac LLC

- Coveris Management GmbH

- Uflex Ltd.

- Sigma Plastics Group

- Schur Flexibles Holding

- Wipf AG

- Glenroy Inc.

- Printpack Inc.

- Clondalkin Flexible Packaging

- American Packaging Corporation

- FlexPak Services LLC

- Arabian Flexible Packaging LLC

- Gulf East Paper & Plastic Industries LLC

- Plastipak Packaging Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surge in e-commerce demand for lightweight protective mailers in North America

- 4.2.2 Shift of Asian FMCG brands toward mono-material recyclable films to meet EPR mandates

- 4.2.3 Rapid adoption of retort pouches for ready-to-eat meals in Europe

- 4.2.4 Coffee and specialty-drink brands' switch to high-barrier films in South America

- 4.2.5 Investments in digital printing enabling mass customization for cosmetics packs

- 4.2.6 Growth in cold-chain biologics blister demand boosting pharma flexible packaging

- 4.3 Market Restraints

- 4.3.1 Volatile polyolefin prices squeezing converter margins

- 4.3.2 Fragmented recycling infrastructure for multilayer laminates in EU and US

- 4.3.3 Stricter single-use plastic bans in key emerging economies (e.g., India, Kenya)

- 4.3.4 Rigid PET bottles limiting stand-up pouch penetration in Middle-East CSD segment

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory Outlook

- 4.6 Technological Outlook

- 4.7 Trade Scenario (Under Relevant HS Code)

- 4.8 Porter's Five Forces Analysis

- 4.8.1 Threat of New Entrants

- 4.8.2 Bargaining Power of Buyers

- 4.8.3 Bargaining Power of Suppliers

- 4.8.4 Threat of Substitutes

- 4.8.5 Intensity of Competitive Rivalry

- 4.9 Recycling and Sustainability Landscape

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material Type

- 5.1.1 Plastic

- 5.1.1.1 Polyethylene (PE)

- 5.1.1.2 Biaxially Oriented Polypropylene (BOPP)

- 5.1.1.3 Cast Polypropylene (CPP)

- 5.1.1.4 Polyvinyl Chloride (PVC)

- 5.1.1.5 Ethylene-Vinyl Alcohol (EVOH)

- 5.1.1.6 Other Flexible Plastic

- 5.1.2 Paper

- 5.1.3 Aluminum Foil

- 5.1.4 Biodegradable and Compostable Materials

- 5.1.1 Plastic

- 5.2 By Product Type

- 5.2.1 Pouches

- 5.2.2 Bags and Sacks

- 5.2.3 Films and Wraps

- 5.2.4 Other Product Types

- 5.3 By End-use Industry

- 5.3.1 Food

- 5.3.1.1 Frozen Food

- 5.3.1.2 Dairy Based Products

- 5.3.1.3 Meat and Seafood

- 5.3.1.4 Baked Snacks and Confectionery

- 5.3.1.5 Fresh Produce

- 5.3.1.6 Other Food Products

- 5.3.2 Beverage

- 5.3.2.1 Juice and Nectare

- 5.3.2.2 Dairy Based Drinks

- 5.3.2.3 Other Beverages

- 5.3.3 Pharmaceutical

- 5.3.4 Cosmetics and Personal Care

- 5.3.5 Industrial

- 5.3.6 Other End -Use Industry

- 5.3.1 Food

- 5.4 By Distribution Channels

- 5.4.1 Direct Sales Channel

- 5.4.2 Indirect Sales Channel

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 Europe

- 5.5.2.1 United Kingdom

- 5.5.2.2 Germany

- 5.5.2.3 France

- 5.5.2.4 Italy

- 5.5.2.5 Spain

- 5.5.2.6 Nordics

- 5.5.3 Asia Pacific

- 5.5.3.1 China

- 5.5.3.2 Japan

- 5.5.3.3 India

- 5.5.3.4 ASEAN

- 5.5.3.5 South Korea

- 5.5.3.6 Australia

- 5.5.3.7 New Zealand

- 5.5.4 South America

- 5.5.4.1 Brazil

- 5.5.4.2 Argentina

- 5.5.4.3 Chile

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 United Arab Emirates

- 5.5.5.1.2 Saudi Arabia

- 5.5.5.1.3 Turkey

- 5.5.5.1.4 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Kenya

- 5.5.5.2.3 Rest of Africa

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Market Share Analysis

- 6.3 Company Profiles (includes Global level Overview, Market level Overview, Core Segments, Financials, Strategic Info, Market Rank/Share, Products and Services, Recent Developments)

- 6.3.1 Amcor plc

- 6.3.2 Sealed Air Corporation

- 6.3.3 Mondi plc

- 6.3.4 Huhtamaki Oyj

- 6.3.5 Constantia Flexibles Group GmbH

- 6.3.6 Sonoco Products Company

- 6.3.7 ProAmpac LLC

- 6.3.8 Coveris Management GmbH

- 6.3.9 Uflex Ltd.

- 6.3.10 Sigma Plastics Group

- 6.3.11 Schur Flexibles Holding

- 6.3.12 Wipf AG

- 6.3.13 Glenroy Inc.

- 6.3.14 Printpack Inc.

- 6.3.15 Clondalkin Flexible Packaging

- 6.3.16 American Packaging Corporation

- 6.3.17 FlexPak Services LLC

- 6.3.18 Arabian Flexible Packaging LLC

- 6.3.19 Gulf East Paper & Plastic Industries LLC

- 6.3.20 Plastipak Packaging Inc.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment