|

市场调查报告书

商品编码

1851570

宠物食品包装:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Pet Food Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

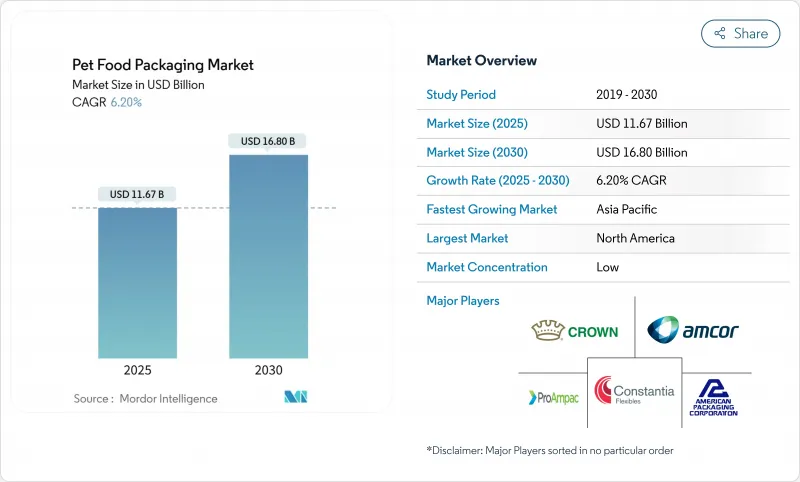

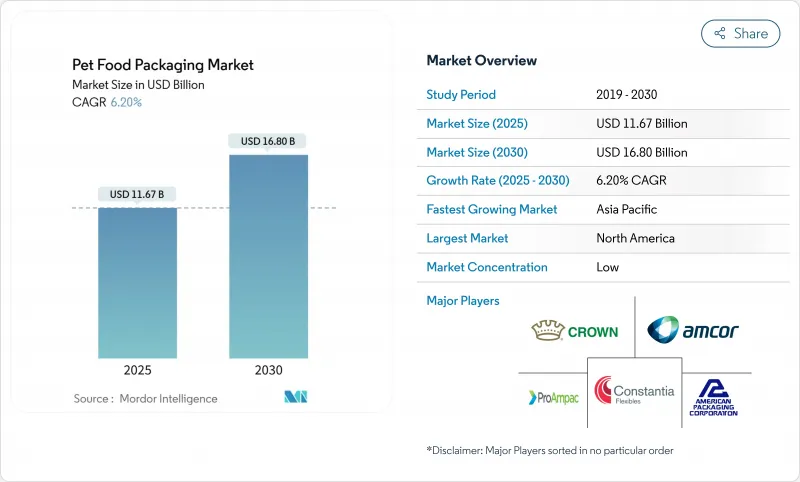

预计到 2025 年,宠物食品包装市场规模将达到 116.7 亿美元,到 2030 年将扩大到 168 亿美元,年复合成长率为 6.2%。

欧洲和美国日益增长的监管压力、湿包装形式的快速优质化以及颠覆性材料科学创新,共同推动了对兼顾阻隔保护和可回收性的解决方案的持续需求。北美仍然是最大的消费地区,这得益于其强大的电子商务渗透率和对单一材料软包装的早期应用;而亚太地区则实现了最快的区域增长,这主要得益于中国都市区宠物饲养量的不断增长。品牌所有者的2025年永续性承诺、原材料价格波动加剧以及FDA逐步取消35种含PFAS的食品接触核准,都促使加工商从传统的多层塑胶转向可回收纸张、单层聚乙烯(单层PE)和生物复合复合材料。儘管大型一体化製造商凭藉其规模优势,竞争强度仍然适中,但灵活的专业製造商正透过提供不含PFAS的阻隔层、智慧包装功能以及知名品牌所有者日益增长的可回收设计服务,不断扩大市场份额。

全球宠物食品包装市场趋势与洞察

SUP指令出台后,可回收单材料包装袋的需求激增。

Siegwerk 的 CIRKIT 涂层可保护单层 PE 内部免受油脂、油污和氧气的侵害,而 Longdapac 为北美品牌生产的 100% 可回收高阻隔包装袋正在欧洲以外的地区产生监管连锁反应。

湿狗粮优质化推动了杀菌袋包装的普及

北美消费者愿意为厨师级湿包装产品支付30%至50%的溢价,这促使安姆科公司投资研发AmLite HeatFlex可回收包装袋,该包装袋在高温灭菌过程中能够保留营养成分。 Special Dog Company的100%覆盖式线上密封检测系统等设备保障了产品质量,而NaturPak Pet公司年产5,000万盒的产能则展现了高端市场成长所需的扩充性。

PET和铝价波动对转换器利润带来压力

反倾销措施和物流中断导致欧洲PET价格在2025年初超过每吨1130欧元,全球对铝罐的需求超过590亿美元,挤压了加工商的利润,加速了人们对再生和替代基材的兴趣。

细分市场分析

到2024年,塑胶将占销售额的67%,使材料产业成为市场区隔的经济支柱。然而,品牌承诺和欧盟法规将推动生物基材料和复合材料实现10.6%的复合年增长率。聚乙烯在单一材料设计中表现出色,而PET的不稳定性促使人们关注化学回收和rPET共混物。随着包装废弃物法规截止日期的临近,纸板技术得到发展,而木质素-生物奈米复合材料则展现出抗氧化能力,有望应用于未来的高阻隔领域。在Billerud公司每年供应30万吨纸板的计画支撑下,预计到2030年,纸基和纸板宠物食品包装市场将以约15%的速度成长。

第二代生物复合材料利用农业废弃物降低碳排放强度,同时不影响其加工性能,从而为加工商提供了规避化石基原料风险的方案。安姆科与诺瓦化学公司在印第安纳州达成的再生聚乙烯协议,支持了北美循环经济平台的发展,并确保了单层聚乙烯包装袋所需的树脂供应。同时,铝的高回收率缓解了成本压力,使得罐头成为蒸馏湿食品的理想选择,即使加工商正在探索不含全氟烷基和多氟烷基物质(PFAS)的环氧树脂替代品。

由于其便利性、货架展示效果和电商适用性,预计到2024年,袋装食品将占据43%的市场份额。蒸馏食品推动了湿食品的优质化,而立式食品则受益于都市区消费者对拉炼封口的青睐。其他以9.5%复合年增长率成长的产品类型包括智慧标籤、定量分配器以及结合了纤维强度和阻隔涂层的纸杯。安姆科公司80%可回收的AmFiber高性能纸证明,纸张可以在对湿度敏感的应用中使用,而不会影响品牌识别。

包装袋在影像品质、操作效率和包装与产品比例方面仍保持优势,但零售商的回收试点计画仍处于有限阶段。整合保鲜感测器和变色油墨的智慧包装原型也在研发中,但要大规模普及,成本必须与其他包装方式持平。大容量干货产品仍以包装袋为主,但单份包装的趋势可能会逐渐将部分市占率转移到软罐包装。儘管铝价波动,但凭藉完善的回收基础设施,金属罐在传统湿货产品线中仍拥有一定的用户忠诚度。

宠物食品包装市场报告按材料(塑胶、纸张、金属、生物基材料)、产品类型(软包装袋、金属罐、其他)、食品类型(干粮、湿粮、冷藏/冷冻食品、零食)、宠物类型(狗粮、猫粮、其他)和地区(北美、欧洲、亚太、南美、中东和非洲)进行细分。市场预测以美元计价。

区域分析

北美地区预计到2024年将占全球销售额的34%,反映出该地区在包装领域的领先地位以及对可回收包装袋的早期转型。 2021年及以后,更高的生产者价格将推动包装成本和碳排放的最佳化,从而促进轻质软包装在电商领域的应用。美国食品药物管理局(FDA)逐步淘汰全氟烷基和多氟烷基物质(PFAS)将加速纸张和聚合物阻隔材料的研发,而加州和缅因州的强制性规定则形成了一种有利于拥有实验室检验合规套件包的供应商的局面。

亚太地区是成长最快的地区,年复合成长率达7.5%,这主要得益于中国418亿美元的宠物经济规模以及消费者以数位化为先的消费习惯。当地加工商正面临EVOH树脂短缺的困境,这限制了包装袋的产能,促使他们研发二氧化硅和等离子涂层单聚氯乙烯(PVC)等替代阻隔材料。在二线城市,本土品牌正在推广在地化图案和QR码溯源,而越来越多的中等收入宠物饲主也加入了这一成长趋势。

在强有力的法规推动下,欧洲经济保持稳定成长,这些法规强制要求可回收性和再生材料的应用。包装和包装废弃物法规设定了明确的2030年目标,促使企业投资于纸袋生产线和新型耐油涂层。一次性塑胶包装正在取代干货包装中传统的多层结构,并推动了可回收设计指南的发展。像Saica-Mondelez这样的跨行业联盟正在将专业知识转移到宠物食品领域,并扩大纸基软包装的供应。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 欧盟SUP指令出台后,可回收单一材料包装袋的需求激增。

- 北美湿狗粮优质化推动了高阻隔杀菌袋的普及

- 中国都市区宠物饲养热潮推动可重复密封袋的发展

- 美国特色食品电子商务的成长推动了轻质柔性包装的发展。

- 品牌所有者2025年永续性承诺推动欧洲纸袋投资

- 欧盟关于矿物油迁移的2024/354号法规促进了功能性阻隔层压板的发展

- 市场限制

- PET和铝价不稳定,挤压湿式食品罐加工商利润空间

- 美国禁止在食品接触盘中使用 PFAS,迫使製造商进行代价高昂的配方变更。

- EVOH阻隔树脂短缺限制亚太地区立式袋容量

- 有限的路边回收设施蒸馏阻碍了零售商的积极性。

- 供应链分析

- 技术展望

- 监理展望

- 波特五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

- 投资分析

第五章 市场规模与成长预测

- 材料

- 塑胶

- 聚乙烯(PE)

- 聚丙烯(PP)

- 聚对苯二甲酸乙二醇酯(PET)

- 其他塑料

- 纸和纸板

- 金属

- 生物基和可堆肥材料

- 塑胶

- 依产品类型

- 小袋

- 包包

- 金属罐

- 其他产品类型

- 依食物类型

- 干粮

- 湿粮

- 冷藏和冷冻

- 糖果甜点和零食

- 依宠物类型

- 狗粮

- 猫粮

- 其他宠物食品

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 其他欧洲地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- ASEAN

- 澳洲和纽西兰

- 亚太其他地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 中东和非洲

- 中东

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 其他中东地区

- 非洲

- 南非

- 肯亚

- 奈及利亚

- 其他非洲地区

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Amcor plc

- Mondi plc

- ProAmpac LLC

- Sonoco Products Company

- Constantia Flexibles Group GmbH

- Crown Holdings Inc.

- Ardagh Group SA

- Silgan Holdings Inc.

- Coveris Holdings SA

- American Packaging Corporation

- Huhtamaki Oyj

- Sealed Air Corporation

- Printpack Inc.

- AptarGroup Inc.

- Smurfit Westrock plc

- Goglio SpA

- Glenroy Inc.

- Winpak Ltd.

- Tetra Pak International SA

- Wipak Oy

第七章 市场机会与未来展望

The pet food packaging market size reached USD 11.67 billion in 2025 and is projected to expand to USD 16.8 billion by 2030, advancing at a 6.2% CAGR.

Growing regulatory pressure in Europe and the United States, rapid premiumization of wet formats, and disruptive material science innovations together create a steady demand pipeline for solutions that balance barrier protection with recyclability. North America remains the largest consuming region, supported by strong e-commerce penetration and early adoption of mono-material flexibles, while Asia-Pacific records the fastest regional growth as urban pet ownership rises in China. Brand owners' 2025 sustainability pledges, rising raw-material volatility, and the FDA's phase-out of 35 PFAS food-contact approvals reinforce the need for converters to shift away from conventional multi-layer plastics toward recyclable paper, mono-PE, and bio-composite alternatives. Competitive intensity stays moderate as large integrated players capitalize on scale, but nimble specialists gain share by offering PFAS-free barriers, smart-packaging features, and design-for-recycling services that major brand owners increasingly require.

Global Pet Food Packaging Market Trends and Insights

Surge in demand for recyclable mono-material pouches post-SUP Directive

European Single-Use Plastics rules compel brand owners to abandon complex laminates, prompting converters to commercialize mono-PE structures that equal traditional barrier performance yet meet recyclability targets.Siegwerk's CIRKIT coatings now enable grease, oil, and oxygen protection inside mono-PE, while Longdapac's 100% recyclable high-barrier pouches for North American brands confirm regulatory ripple effects beyond Europe.

Premiumization of wet dog food driving retort pouch adoption

North American consumers pay 30-50% premiums for chef-style wet formats, spurring investments in Amcor's AmLite HeatFlex recycle-ready pouches that preserve nutrients during thermal sterilization. Inline seal-inspection systems such as Special Dog Company's 100% coverage model safeguard quality, and NaturPak Pet's 50 million-carton annual capacity illustrates scalability requirements for premium growth.

Volatile PET and aluminum prices squeezing converter margins

Anti-dumping measures and logistics disruptions pushed European PET above EUR 1,130 t in early 2025, while global aluminum demand for cans topped USD 59 billion, compressing converter profits and hastening interest in recycled content or alternative substrates.

Other drivers and restraints analyzed in the detailed report include:

- Urban pet ownership boom in China fueling small formats

- E-commerce growth for specialty diets accelerating flexibles

- U.S. PFAS bans triggering costly reformulations

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Plastics supplied 67% of 2024 revenues, making the material segment the economic backbone of the pet food packaging market. Yet brand commitments and EU rules spur a 10.6% CAGR for bio-based and composite formats. Polyethylene thrives in mono-material designs, whereas PET's volatility drives interest in chemically recycled and rPET blends. Paperboard progresses as Packaging-and-Waste Regulation deadlines approach, while lignin-bionanocomposites showcase antioxidant capabilities for future high-barrier adoption. The pet food packaging market size attached to paper and board is projected to expand at a mid-teens pace through 2030, supported by Billerud's plan to supply 300 kilotons of cartonboard annually.

Second-generation bio-composites use agricultural waste streams to cut carbon intensity without compromising machinability, offering converters a hedge against fossil feedstock risk. Amcor's Indiana recycled-PE agreement with NOVA Chemicals underpins a North American circular platform, ensuring resin availability for mono-PE pouches. Meanwhile, aluminum's high recycling rate cushions cost headwinds, keeping cans relevant for retort wet food even as converters investigate PFAS-free epoxy replacements.

Pouches captured 43% 2024 share owing to convenience, shelf appeal, and e-commerce compatibility. Retort variants underpin wet-food premiumization, while stand-up formats benefit from zipper-reseal trends among urban consumers. The other-product-types bucket, expanding at 9.5% CAGR, covers smart labels, portion-controlled dispensers, and paper-based cups that meld fiber strength with barrier coatings. Amcor's 80%-recyclable AmFiber Performance Paper proves the viability of paper for moisture-sensitive applications without sacrificing branding surface.

Graphics quality, handling efficiency, and pack-to-product ratios keep pouches favorable, yet retailer take-back pilots for curbside recycling remain limited. Smart-packaging prototypes embed freshness sensors and color-change inks, but mass uptake awaits cost parity. Bags still dominate large-volume dry food, though single-serve trends could gradually migrate volume into flexibles. Metal cans hold niche loyalty for heritage wet lines despite aluminum volatility, supported by robust recycling infrastructure.

The Pet Food Packaging Market Report is Segmented by Material (Plastic, Paper, Metal, Biobased Materials), Product Type (Pouches, Bags, Metal Cans, and More), Food Type (Dry Food, Wet Food, Chilled and Frozen, Treats), Pet Type (Dog Food, Cat Food, and More), and Geography (North America, Europe, Asia-Pacific, South America, Middle East and Africa). Market Forecasts in Value (USD).

Geography Analysis

North America controlled 34% of 2024 sales, reflecting established ownership rates and the region's early pivot to recycle-ready pouches. High producer-price inflation since 2021 elevates packaging optimization on cost and carbon, driving uptake of lightweight flexibles seasoned for e-commerce shocks. The FDA's PFAS phase-out accelerates paper-and-polymer barrier R&D, while California and Maine mandates create a patchwork that favors suppliers with lab-validated compliance toolkits.

Asia-Pacific is the fastest-growing region at 7.5% CAGR, led by China's USD 41.8 billion pet economy and digital-first purchasing habits. Local converters grapple with EVOH resin shortages that cap pouch capacity, prompting R&D into silicon-oxide and plasma-coated mono-PE as substitute barriers. Tier-2 cities show domestic brands advancing localized graphics and QR code traceability to court rising middle-income pet owners.

Europe's growth remains steady, anchored by robust regulation that forces recyclability and recycled-content integration. The Packaging-and-Packaging-Waste Regulation sets firm 2030 targets, spurring investment in paper-based bag lines and new grease-proof coatings. Single-Use Plastics requirements bring forward design-for-recycling guidelines that displace legacy multilayer structures in dry food. Cross-industry alliances such as Saica-Mondelez transfers know-how to pet food, widening supply of paper flexibles.

- Amcor plc

- Mondi plc

- ProAmpac LLC

- Sonoco Products Company

- Constantia Flexibles Group GmbH

- Crown Holdings Inc.

- Ardagh Group SA

- Silgan Holdings Inc.

- Coveris Holdings SA

- American Packaging Corporation

- Huhtamaki Oyj

- Sealed Air Corporation

- Printpack Inc.

- AptarGroup Inc.

- Smurfit Westrock plc

- Goglio SpA

- Glenroy Inc.

- Winpak Ltd.

- Tetra Pak International SA

- Wipak Oy

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surge in Demand for Recyclable Mono-Material Pouches Post-Europe SUP Directive

- 4.2.2 Premiumization of Wet Dog Food Driving High-Barrier Retort Pouch Adoption in North America

- 4.2.3 Urban Pet Ownership Boom in China Fueling Small-Pack Formats with Reclosable Zippers

- 4.2.4 E-commerce Growth for Specialty Diets Accelerating Lightweight Flexible Packaging in the US

- 4.2.5 Brand Owner 2025 Sustainability Pledges Catalyzing Paper-Based Bag Investments in Europe

- 4.2.6 EU Regulation 2024/354 on Mineral-Oil Migration Spurring Functional Barrier Laminates

- 4.3 Market Restraints

- 4.3.1 Volatile PET and Aluminum Prices Squeezing Converter Margins for Wet-Food Cans

- 4.3.2 US PFAS Bans in Food-Contact Boards Forcing Costly Reformulations

- 4.3.3 EVOH Barrier Resin Shortages Limiting Stand-Up Pouch Capacity in APAC

- 4.3.4 Limited Curb-Side Recyclability of Retort Structures Discouraging Retailers

- 4.4 Supply-Chain Analysis

- 4.5 Technological Outlook

- 4.6 Regulatory Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Investment Analysis

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material

- 5.1.1 Plastic

- 5.1.1.1 Polyethylene (PE)

- 5.1.1.2 Polypropylene (PP)

- 5.1.1.3 Polyethylene Terephthalate (PET)

- 5.1.1.4 Other Plastics

- 5.1.2 Paper and Paperboard

- 5.1.3 Metal

- 5.1.4 Biobased and Compostie Materials

- 5.1.1 Plastic

- 5.2 By Product Type

- 5.2.1 Pouches

- 5.2.2 Bags

- 5.2.3 Metal Cans

- 5.2.4 Other Product Types

- 5.3 By Type of Food

- 5.3.1 Dry Food

- 5.3.2 Wet Food

- 5.3.3 Chilled and Frozen

- 5.3.4 Treats and Snacks

- 5.4 By Pet Type

- 5.4.1 Dog Food

- 5.4.2 Cat Food

- 5.4.3 Other Pet Food

- 5.5 By Geography

- 5.5.2 North America

- 5.5.2.1 United States

- 5.5.2.2 Canada

- 5.5.2.3 Mexico

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 India

- 5.5.4.3 Japan

- 5.5.4.4 South Korea

- 5.5.4.5 ASEAN

- 5.5.4.6 Australia and New Zealand

- 5.5.4.7 Rest of Asia-Pacific

- 5.5.5 South America

- 5.5.5.1 Brazil

- 5.5.5.2 Argentina

- 5.5.5.3 Rest of South America

- 5.5.6 Middle East and Africa

- 5.5.6.1 Middle East

- 5.5.6.1.1 Saudi Arabia

- 5.5.6.1.2 United Arab Emirates

- 5.5.6.1.3 Rest of Middle East

- 5.5.6.2 Africa

- 5.5.6.2.1 South Africa

- 5.5.6.2.2 Kenya

- 5.5.6.2.3 Nigeria

- 5.5.6.2.4 Rest of Africa

- 5.5.2 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 Amcor plc

- 6.4.2 Mondi plc

- 6.4.3 ProAmpac LLC

- 6.4.4 Sonoco Products Company

- 6.4.5 Constantia Flexibles Group GmbH

- 6.4.6 Crown Holdings Inc.

- 6.4.7 Ardagh Group SA

- 6.4.8 Silgan Holdings Inc.

- 6.4.9 Coveris Holdings SA

- 6.4.10 American Packaging Corporation

- 6.4.11 Huhtamaki Oyj

- 6.4.12 Sealed Air Corporation

- 6.4.13 Printpack Inc.

- 6.4.14 AptarGroup Inc.

- 6.4.15 Smurfit Westrock plc

- 6.4.16 Goglio SpA

- 6.4.17 Glenroy Inc.

- 6.4.18 Winpak Ltd.

- 6.4.19 Tetra Pak International SA

- 6.4.20 Wipak Oy

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-Space and Unmet-Need Assessment