|

市场调查报告书

商品编码

1851819

低温运输包装:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Cold Chain Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

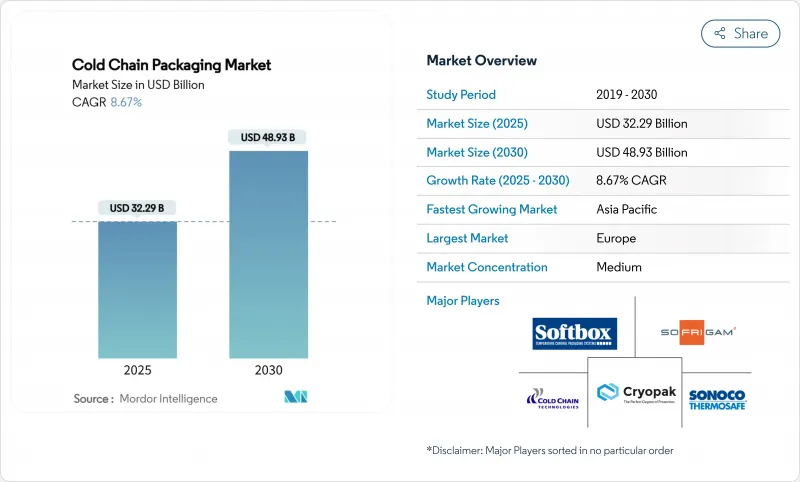

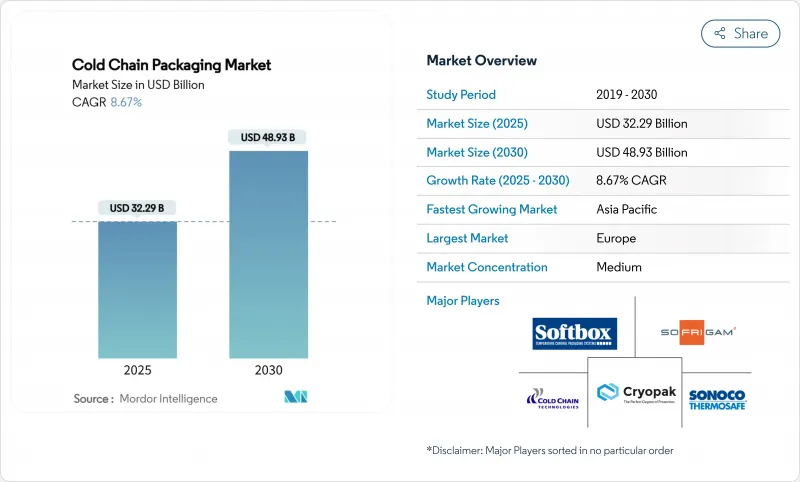

预计到 2025 年,低温运输包装市场规模将达到 322.9 亿美元,到 2030 年将达到 489.3 亿美元,年复合成长率为 8.67%。

生技药品需求量的成长、电商生鲜履约的扩张以及全球疫苗计画对温控配送的标准化,共同推动了冷链包装市场的发展。美国食品药物管理局(FDA) 的 21 CFR 600.15法律规范和欧盟 (EU) 新的包装及包装废弃物法规等监管框架,要求采用有效的解决方案,而即时物联网监控则提高了人们对包装性能的期望。此外,企业环境、社会和治理 (ESG) 目标的推进,也加速了向可重复使用和生物基包装形式的转变,重塑了低温运输包装市场的供应商策略。

全球低温运输包装市场趋势与洞察

生技药品、细胞和基因治疗物流的蓬勃发展

近一半的新药需要温度控制,许多先进疗法更需要在低于-150°C的低温条件下进行。 2025年1月,Cryoport推出了HV3运输箱,该运输箱能够长时间维持超低温,标誌着该领域正朝着专业化设计方向发展。美国食品药物管理局(FDA)的生技药品许可要求提供运输过程中稳定性的有效证据,因此包装合格对于产品认证至关重要。个人化医疗的发展趋势正在推动运输频率和出货收益的提升,从而带动低温运输包装市场的高端需求。

电子商务杂货和食材自煮包宅配服务的扩张

随着冷藏和冷冻食品的线上销售量成长,对轻便、节省空间且能应对「最后一公里」运输波动的隔热材料的需求也日益增长。 HelloFresh 利用人工智慧技术,根据特定天气和路线调整包装配置,从而展示了数据驱动的材料选择方法。 Ranpak 于 2024 年 4 月推出的可路边回收的 climaliner Plus 保温材料,可提供 72 小时的保温保护,满足了消费者永续性的期望。这些创新将低温运输包装市场拓展到传统医药领域之外。

聚合物原料价格波动

聚乙烯和聚丙烯价格上涨可能会挤压加工商的利润空间,并延缓可重复使用包装的转型,因为可重复使用包装的前期成本更高。小型製造商往往缺乏对冲机制,这促使它们调整产品组合,优先考虑价值较高的製药客户。

细分市场分析

保温容器将成为运输的支柱,到2024年将占据低温运输包装市场35.53%的份额。儘管保温容器占据主导地位,但随着供应链对持续可视性的需求,温度监测设备预计将以12.95%的复合年增长率成长。像Timestrip的Semaglutide指示器这样的智慧标籤正在扩大高价值生技药品的合规性,并被医疗保健机构广泛采用。

物联网晶片与低功耗网路的融合,将被动式设备升级为互联资产。 SkyCell 的 1500X 混合型货柜可连续运作270 小时,并即时传输资料。诸如此类的进步正吸引保险公司,他们如今更青睐经实践验证的风险缓解措施,同时也为低温运输包装市场的设备製造商拓展了潜在业务量。

被动式冷链包装箱预计在2024年仍将占据低温运输包装市场55.32%的份额,其优势在于操作简单且符合相关法规。然而,混合式冷链包装箱将以10.32%的复合年增长率成为成长最快的选择,它们透过在传统箱体内部整合感测器和有限的电力辅助功能,实现了成本和控制之间的平衡。 Va-Q-Tec公司的Thermal Coat热涂层为传统包装箱增加了一层智慧层,从而减少了对全功率设备的依赖。

全球航空公司正在收紧锂电池运输规定,设定30%的充电状态限制。太阳能采集和超级电容的整合正在缓解这一障碍,推动製造商转向被动-主动混合电池。随着合规性审核的加强,托运人将越来越倾向于购买具有内建可追溯性的电池,这将促进混合动力汽车在低温运输包装市场的成长。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 生技药品、细胞和基因治疗的物流繁荣

- 电子商务杂货和食材自煮包宅配业务蓬勃发展

- 新兴国家的全球疫苗倡议

- 分散式临床实验小包裹的需求

- 采用可重复使用的被动式托运人以实现ESG目标

- 保险公司主导的智慧指标推广

- 市场限制

- 聚合物原料价格波动

- 欧盟关于EPS的循环经济法规

- 大型货主航空货运能力下降

- 锂电池在主动系统中的局限性

- 供应链分析

- 监理展望

- 技术展望

- 波特五力分析

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模与成长预测

- 副产品

- 保温容器

- 保温运输箱

- 冷媒凝胶包和相变材料

- 温度监测装置

- 真空绝热板

- 干冰系统

- 透过包装系统

- 主动系统

- 被动系统

- 混合系统

- 材料

- 发泡聚苯乙烯(EPS)

- 聚氨酯(PUR)

- 真空绝热板(VIP)

- 发泡聚丙烯(EPP)

- 生物基相变材料

- 有阻隔衬垫的瓦楞纸板

- 高性能泡沫(酚醛、聚异氰脲酸酯)

- 透过可用性

- 一次使用

- 可重复使用的

- 透过使用

- 製药和生物技术

- 临床试验和诊断

- 乳製品和冷冻甜点

- 肉类和水产品

- 其他应用

- 按地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 其他欧洲地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲和纽西兰

- 亚太其他地区

- 中东和非洲

- 中东

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 土耳其

- 其他中东地区

- 非洲

- 南非

- 奈及利亚

- 埃及

- 其他非洲地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Sonoco ThermoSafe

- Cold Chain Technologies

- Pelican BioThermal

- Softbox Systems

- Intelsius(DGP)

- Cryopak

- Sofrigam

- Tempack

- CSafe Global

- Va-Q-Tec

- SkyCell

- CrodaTherm

- Sealed Air Corp.

- DS Smith(International Paper)

- Storopack

- Cascades Inc.

- Cryoport

- Thermo King

- Marken

- Timestrip

第七章 市场机会与未来展望

The cold chain packaging market size stands at USD 32.29 billion in 2025 and is projected to reach USD 48.93 billion by 2030, expanding at an 8.67% CAGR.

Growth is underpinned by rising biologics volumes, expanding e-commerce grocery fulfilment, and global vaccine initiatives that standardize temperature-controlled distribution. Regulatory frameworks such as the United States Food and Drug Administration's 21 CFR 600.15 and the European Union's new Packaging and Packaging Waste Regulation compel validated solutions, while real-time IoT monitoring elevates performance expectations. Consolidation among logistics majors amplifies technology diffusion, and corporate ESG targets accelerate the pivot toward reusable and bio-based formats, reshaping supplier strategies across the cold chain packaging market.

Global Cold Chain Packaging Market Trends and Insights

Boom in Biologics and Cell-/Gene-Therapy Logistics

Nearly half of new pharmaceuticals require temperature control, and many advanced therapies need cryogenic conditions below -150 °C. In January 2025 Cryoport introduced the HV3 shipper that maintains such ultra-low levels for prolonged periods, illustrating the sector's shift toward specialised designs. The FDA's biologics licensing requirements demand validated evidence of stability throughout transit, making packaging qualification integral to product approval. Personalised medicine trends intensify shipment frequency and value, driving premium demand across the cold chain packaging market.

Expansion of E-commerce Grocery and Meal-Kit Delivery

Online grocery volumes for chilled and frozen foods increase the need for lightweight, space-efficient insulation that withstands last-mile variability. HelloFresh employs AI to adjust pack configuration to weather and route specifics, demonstrating how data drives material selection. Ranpak's curbside-recyclable climaliner Plus, launched April 2024, offers 72 hours of thermal protection and responds to consumers' sustainability expectations. These innovations expand the cold chain packaging market beyond traditional pharmaceutical lanes.

Polymer Feedstock Price Volatility

Upward swings in polyethylene and polypropylene costs compress converter margins and can delay switching to reusable packaging that carries higher upfront spend. Smaller producers often lack hedging mechanisms, prompting them to rationalise portfolios and prioritise high-value pharmaceutical accounts.

Other drivers and restraints analyzed in the detailed report include:

- Global Vaccine Initiatives in Emerging Nations

- Decentralized Clinical-Trial Parcel Demand

- EU Circular-Economy Limits on EPS

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Insulated containers provided the backbone of shipments and accounted for 35.53% of the cold chain packaging market in 2024. Despite this dominance, temperature-monitoring devices post a 12.95% CAGR as supply chains demand continuous visibility. Smart labels such as Timestrip's semaglutide indicator extend compliance to high-value biologics, capturing adoption across healthcare providers.

The convergence of IoT chips and low-power networks upgrades passive boxes into connected assets. SkyCell's 1500X hybrid container runs for 270 hours and transmits live data, illustrating how monitoring devices integrate with insulation substrates to limit excursions. These advances attract insurers that now reward proven risk reduction, expanding addressable volumes for device makers within the cold chain packaging market.

Passive shippers retained 55.32% share of the cold chain packaging market size in 2024, valued for simplicity and regulatory familiarity. Hybrid formats, however, post the fastest 10.32% CAGR by embedding sensors and limited power assistance inside traditional shells, thereby balancing cost and control. Va-Q-Tec's Thermal Coat adds an intelligent layer to legacy boxes and reduces reliance on fully powered units.

Global airlines tighten lithium-battery carriage rules, capping state-of-charge at 30%, which constrains active container usage. Solar harvesting and supercapacitor integration mitigate this hurdle and push manufacturers toward passive-active hybrids. As compliance audits intensify, shippers with built-in traceability gain procurement preference, strengthening hybrid growth across the cold chain packaging market.

The Global Cold Chain Packaging Market Report is Segmented by Product (Insulated Containers, Insulated Shippers, Refrigerants, and More), Packaging System (Active, Passive, Hybrid), Material (EPS, PUR, VIP, EPP, and More), Usability (Single-Use, Reusable), Application (Pharmaceuticals and Biotechnology, Clinical Trials and Diagnostics, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

List of Companies Covered in this Report:

- Sonoco ThermoSafe

- Cold Chain Technologies

- Pelican BioThermal

- Softbox Systems

- Intelsius (DGP)

- Cryopak

- Sofrigam

- Tempack

- CSafe Global

- Va-Q-Tec

- SkyCell

- CrodaTherm

- Sealed Air Corp.

- DS Smith (International Paper)

- Storopack

- Cascades Inc.

- Cryoport

- Thermo King

- Marken

- Timestrip

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Boom in biologics and cell-/gene-therapy logistics

- 4.2.2 Expansion of e-commerce grocery and meal-kit delivery

- 4.2.3 Global vaccine initiatives in emerging nations

- 4.2.4 Decentralized clinical-trial parcel demand

- 4.2.5 Reusable passive shipper adoption for ESG targets

- 4.2.6 Insurer-driven smart indicator uptake

- 4.3 Market Restraints

- 4.3.1 Polymer feedstock price volatility

- 4.3.2 EU circular-economy limits on EPS

- 4.3.3 Air-freight capacity squeeze for bulky shippers

- 4.3.4 Lithium-battery limits on active systems

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory Outlook

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Product

- 5.1.1 Insulated Containers

- 5.1.2 Insulated Shippers

- 5.1.3 Refrigerants Gel Packs and PCMs

- 5.1.4 Temperature-Monitoring Devices

- 5.1.5 Vacuum-Insulated Panels

- 5.1.6 Dry-Ice Systems

- 5.2 By Packaging System

- 5.2.1 Active Systems

- 5.2.2 Passive Systems

- 5.2.3 Hybrid Systems

- 5.3 By Material

- 5.3.1 Expanded Polystyrene (EPS)

- 5.3.2 Polyurethane (PUR)

- 5.3.3 Vacuum Insulation Panels (VIP)

- 5.3.4 Expanded Polypropylene (EPP)

- 5.3.5 Bio-based PCMs

- 5.3.6 Corrugated Cardboard with Barrier Liners

- 5.3.7 High-performance Foams (Phenolic, PIR)

- 5.4 By Usability

- 5.4.1 Single-use

- 5.4.2 Reusable

- 5.5 By Application

- 5.5.1 Pharmaceuticals and Biotechnology

- 5.5.2 Clinical Trials and Diagnostics

- 5.5.3 Dairy and Frozen Desserts

- 5.5.4 Meat and Seafood

- 5.5.5 Other Application

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.2 Europe

- 5.6.2.1 Germany

- 5.6.2.2 United Kingdom

- 5.6.2.3 France

- 5.6.2.4 Italy

- 5.6.2.5 Spain

- 5.6.2.6 Russia

- 5.6.2.7 Rest of Europe

- 5.6.3 Asia-Pacific

- 5.6.3.1 China

- 5.6.3.2 India

- 5.6.3.3 Japan

- 5.6.3.4 South Korea

- 5.6.3.5 Australia and New Zealand

- 5.6.3.6 Rest of Asia-Pacific

- 5.6.4 Middle East and Africa

- 5.6.4.1 Middle East

- 5.6.4.1.1 United Arab Emirates

- 5.6.4.1.2 Saudi Arabia

- 5.6.4.1.3 Turkey

- 5.6.4.1.4 Rest of Middle East

- 5.6.4.2 Africa

- 5.6.4.2.1 South Africa

- 5.6.4.2.2 Nigeria

- 5.6.4.2.3 Egypt

- 5.6.4.2.4 Rest of Africa

- 5.6.5 South America

- 5.6.5.1 Brazil

- 5.6.5.2 Argentina

- 5.6.5.3 Rest of South America

- 5.6.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 Sonoco ThermoSafe

- 6.4.2 Cold Chain Technologies

- 6.4.3 Pelican BioThermal

- 6.4.4 Softbox Systems

- 6.4.5 Intelsius (DGP)

- 6.4.6 Cryopak

- 6.4.7 Sofrigam

- 6.4.8 Tempack

- 6.4.9 CSafe Global

- 6.4.10 Va-Q-Tec

- 6.4.11 SkyCell

- 6.4.12 CrodaTherm

- 6.4.13 Sealed Air Corp.

- 6.4.14 DS Smith (International Paper)

- 6.4.15 Storopack

- 6.4.16 Cascades Inc.

- 6.4.17 Cryoport

- 6.4.18 Thermo King

- 6.4.19 Marken

- 6.4.20 Timestrip

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment