|

市场调查报告书

商品编码

1851926

矿业化学品:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Mining Chemicals - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

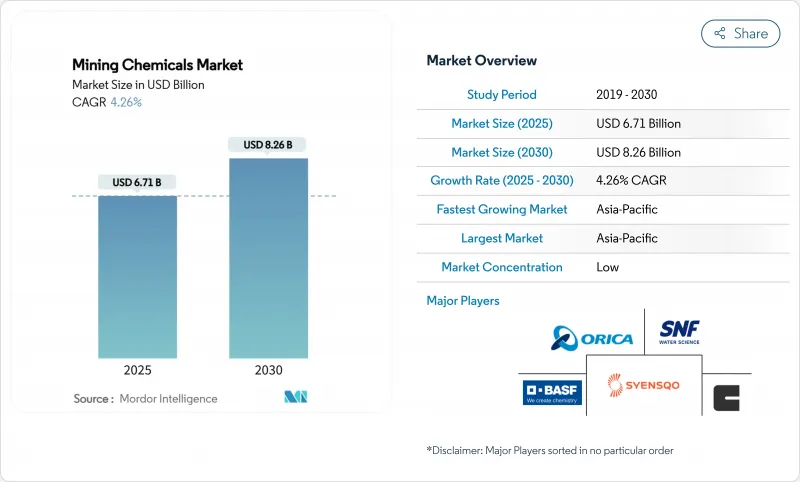

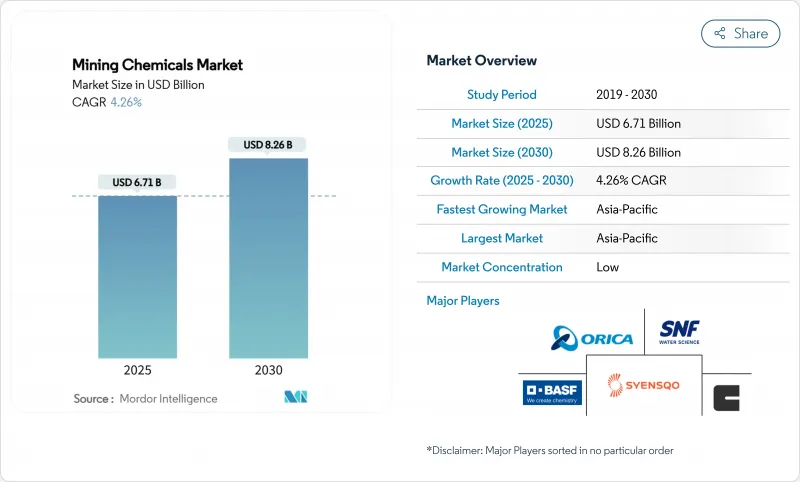

预计到 2025 年,矿业化学品市场规模将达到 67.1 亿美元,到 2030 年将达到 82.6 亿美元,预测期(2025-2030 年)复合年增长率为 4.26%。

电池金属需求的成长、日益严格的环境法规以及加速的能源转型,正引导采购决策转向更具选择性、更环保高效的试剂配方,这些配方能够在提高金属回收率的同时,降低水和电力消耗。亚太地区仍然是主要的生产基地,但北美新增产能以及对湿式冶金的战略投资,正支撑着亚太其他地区需求的稳定成长。浮选剂仍然是收入的主要驱动力,但成长势头最强劲的是溶剂萃取剂,它能够实现锂、镍、钴和稀土的低碳製程。市场竞争适中,老牌供应商透过併购和数位化优化来维持市场份额,而规模较小的参与企业则正在拓展生物基化学品和干法加工助剂业务,以在矿业化学品市场中开闢尚未被充分满足的细分领域。

全球矿业化学品市场趋势与洞察

亚太和北美地区的采矿资本支出增加

美国正在推动矿业化学品市场试剂需求的强劲成长。光是在澳大利亚,资源出口收入预计在2024-2025年就将达到3,800亿美元,而一系列新的铜、锂和镍计划正在推动浮选、浸出和水处理试剂包的竞标竞标扩大。铜冶炼厂的加工成本在2024年转为负值,显示精矿供应紧张,并刺激了依赖高纯度溶剂抽取剂的新型湿式冶金投资。金融分析师估计,广泛的工业资本支出週期每年将向基础设施注入2.5兆至5兆美元,透过增加对关键矿物的需求,间接增强矿业化学品市场。能够将数位化计量控制与专用配方相结合的供应商正在赢得长期供应合同,因为营运商正在新资产中实现工厂化学製程的标准化。

电动车和可再生能源供应链推动矿产需求成长

对锂、镍和钴矿的勘探正在加速,预计到2030年,全球矿产需求将增加三倍。每加工一吨锂辉石或红土矿,所需的化学试剂比传统基底金属製程多消耗40%至200%,这推动了整个矿业化学品市场溶剂萃取和结晶试剂用量的成长。同时,电池製造商转向磷酸锂铁和钠离子电池工艺,也带来了新的製程控制挑战,需要客製化螯合剂。随着地缘政治摩擦加剧关键矿产供应中断的可能性,矿商正在签订多年期试剂合同,以对冲供应风险并增强矿业化学品市场的结构性增长。

加强对有毒试剂的全球监管

各国政府目前要求氰化物、汞和黄药的使用者按照更严格的法规进行註册,这些法规要求持续监测、紧急时应对计画,并为矿山关闭后的水处理提供财务担保。 《国际氰化物管理规范》和美国土地管理局近期关于长期处理资金的规定,都推高了合规成本。欧洲监管机构正在考虑进一步禁止使用含全氟烷基和多氟烷基物质(PFAS)的发泡,这将加速矿业化学品市场向替代界面活性剂的转型。供应商要么进行改革,要么面临市场准入限制,这将减缓短期成长,但会刺激长期创新。

细分市场分析

到2024年,浮选药剂将占矿业化学品市场份额的55.88%,凸显了其在从日益复杂的矿石中分离铜、锌和贵金属硫化物方面的重要作用。捕收剂占据了该市场收入的最大份额,其次是减压剂、凝聚剂、搅拌剂和分散剂,这些产品用于调节矿浆化学成分以实现最佳动力学效果。像Syensqo的AEROPHINE系列这样的优质捕收剂,在用量比传统黄原酸盐低30%的情况下,仍能提升选择性。减压剂可以消除硫化铁的稀释,而合成絮凝剂则可以稳定粗粒浮选迴路中的气泡尺寸。受矿石品位下降的推动,浮选药剂的矿业化学品市场规模预计将稳步增长,因为矿石品位下降需要更细的研磨工艺和增加化学品用量以维持回收率。

萃取试剂、稀释剂、萃取剂和反萃取液的复合年增长率 (CAGR) 为 4.39%,在所有功能领域中最高。这一成长趋势源自于计画建造的用于锂卤水、镍红土矿和多金属精矿的大型湿式冶金生产线。BASF的湿式冶金平台能够以比冶炼低 40% 的能耗生产高纯度金属盐,使溶剂萃取成为极具吸引力的脱碳途径。

矿业化学品报告按功能(浮选化学品、萃取化学品、磨矿助剂)、应用(矿物加工、污水处理)和地区(亚太地区、北美地区、欧洲地区、南美地区、中东和非洲)进行细分。市场预测以美元计价。

区域分析

亚太地区预计2024年将维持54.56%的矿业化学品市场收入份额,主要得益于中国在铜、镍和稀土加工领域的领先地位,以及印度大力推进国内矿产蕴藏量的商业化。中国的锂和镍精炼产业丛集,加上国家对非洲和拉丁美洲矿山的投资,在整体经济放缓的情况下,支撑了强劲的需求。

随着华盛顿致力于保障先进电池和关键矿产的供应链安全,北美市场正蓬勃发展。联邦政府的激励措施已推动超过1500亿美元的电池和材料计划投资,从而提振了锂、镍和钴提取生产线的试剂需求。预计到2024年,加拿大探勘支出将增加至41亿美元,其中小型矿业公司将积极进行稀土和关键金属矿床的湿式冶金试验。

欧洲正经历密集的创新,儘管规模不大。欧盟的《关键原料法》支持国内精炼和回收利用,促进了电池材料循环中特殊试剂的使用。BASF和科莱恩从欧洲工厂供应不含PFAS的起泡剂和生物收集器,提高了区域自给自足能力和竞争优势。南美洲锂三角和智利铜矿的扩张巩固了其关键地位,而非洲丰富的矿产资源为能够克服基础设施和管治复杂性的供应商提供了发展机会。中东的需求虽然不大,但磷酸盐肥料和铝的垂直整合大型企划表明,该地区存在一些选择性增长点。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 亚太和北美地区的矿业资本投资正在成长

- 电动车和可再生能源供应链推动矿产需求

- 大型矿场应制定更严格的水循环标准

- 商品价格回升为勘探预算提供支持

- 为符合ESG要求,转向生物基吸附剂

- 市场限制

- 全球范围内加强对有毒试剂的监管

- 波动性原油衍生原料的成本

- 无需湿试剂的新型干加工技术

- 价值链分析

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模与成长预测

- 按功能

- 漂浮化学品

- 浮选剂

- 抑制剂

- 凝聚剂

- 牙线器

- 分散剂

- 萃取化学品

- 冲淡

- 抽取剂

- 研磨辅助设备

- 漂浮化学品

- 透过使用

- 矿物加工

- 污水处理

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 印尼

- 马来西亚

- 澳洲、纽西兰

- 亚太其他地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 俄罗斯

- 其他欧洲地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲国家

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- BASF

- 3M

- AECI

- Arkema

- Betachem(Pty)Ltd

- Celanese Corporation

- Chevron Phillips Chemical Company LLC

- Clariant

- CTC(Tennant Consolidated Group)

- Ecolab

- FMC Corporation

- Indorama Ventures Public Limited

- Kemira

- NASACO

- Orica Limited

- Qingdao Ruchang Mining Industry Co. Ltd

- Sasol

- SNF Group

- Syensqo

第七章 市场机会与未来展望

The Mining Chemicals Market size is estimated at USD 6.71 billion in 2025, and is expected to reach USD 8.26 billion by 2030, at a CAGR of 4.26% during the forecast period (2025-2030).

Rising demand for battery metals, stricter environmental regulations, and the accelerated energy transition are steering purchasing decisions toward more selective and eco-efficient reagent formulations that raise metal recovery while cutting water and power use. Asia-Pacific remains the dominant production hub, while new capacity in North America and strategic investments in hydrometallurgy underpin steady offtake growth across the rest of the mining chemicals market. Flotation agents continue to anchor revenue, yet the strongest momentum lies in solvent-extraction reagents that enable low-carbon flowsheets for lithium, nickel, cobalt, and rare earths. Competition is moderate: established suppliers defend share through mergers and acquisitions and digital optimization, whereas smaller entrants deploy bio-based chemistries and dry-processing aids to tap under-served niches in the mining chemicals market.

Global Mining Chemicals Market Trends and Insights

Increasing Mining CAPEX in APAC and North America

United States is translating into brisk reagent demand in the mining chemicals market. Australia alone expects resource export earnings to reach USD 380 billion in 2024-25, and the pipeline of new copper, lithium, and nickel projects is widening reagent tenders for flotation, leaching, and water treatment packages. Copper smelter treatment charges turned negative in 2024, signaling tight concentrate supply and encouraging fresh hydrometallurgical investments that rely on high-purity solvent-extraction agents. Financial analysts estimate that the broader industrial capex cycle could inject USD 2.5-5 trillion annually into infrastructure, indirectly fortifying the mining chemicals market through higher demand for critical minerals. Suppliers capable of bundling digital dosing control with specialty formulations are winning long-term supply contracts as operators standardize plant chemistry across new assets.

Surging Mineral Demand from EV and Renewable-Energy Supply Chains

Battery gigafactories commissioned in 2024 catapulted United States cell output by 40%, accelerating the hunt for lithium, nickel, and cobalt units and inflating global mineral demand forecasts three-fold by 2030. Each incremental tonne of spodumene or laterite processed consumes 40-200% more chemical reagents than legacy base-metal flowsheets, lifting solvent-extraction and crystallization reagent volumes across the mining chemicals market. In parallel, cell makers pivoting to lithium iron phosphate and sodium-ion chemistries are creating fresh process-control challenges that require tailor-made chelating agents. Miners are locking in multi-year reagent contracts to de-risk supply as geopolitical friction raises the specter of critical mineral disruptions, reinforcing structural growth for the mining chemicals market.

Tightening Global Regulations on Toxic Reagents

Governments now compel cyanide, mercury, and xanthate users to register under stricter codes that demand continuous monitoring, emergency response plans, and financial assurance for post-closure water treatment. The International Cyanide Management Code and recent U.S. Bureau of Land Management rules on long-term treatment funds have escalated compliance costs. European regulators consider additional bans on PFAS-based frothers, accelerating the shift toward alternative surfactants across the mining chemicals market. Suppliers must either reformulate or face restricted market access, dampening near-term growth but catalyzing long-run innovation.

Other drivers and restraints analyzed in the detailed report include:

- Stricter Water-Recycling Norms in Large Mines

- Shift to Bio-Based Collectors for ESG Compliance

- Emerging Dry-Processing Technologies That Bypass Wet Reagents

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Flotation reagents captured 55.88% of the mining chemicals market share in 2024, underscoring their essential role in separating copper, zinc, and precious-metal sulfides from increasingly complex ores. Collectors account for the largest slice of this revenue, followed by depressants, flocculants, frothers, and dispersants that adjust pulp chemistry for optimum kinetics. Premium collectors such as Syensqo's AEROPHINE series deliver improved selectivity at doses up to 30% lower than legacy xanthates, a feature prized by miners seeking both cost savings and ESG compliance. Depressants eliminate iron sulfide dilution, while synthetic frothers stabilize bubble size in coarse-particle flotation circuits. The mining chemicals market size for flotation reagents is forecast to grow steadily on the back of declining ore grades, which force operators to grind finer and add more chemistries to maintain recovery.

Extraction reagents, diluents, extractants, and stripping solutions, are expanding at a 4.39% CAGR, the highest among functional segments. This trajectory stems from large-scale hydrometallurgical lines planned for lithium brines, nickel laterites, and polymetallic concentrates. BASF's hydrometallurgy platform consumes 40% less energy than smelting and yields high-purity metal salts, making solvent extraction an attractive decarbonization pathway.

The Mining Chemicals Report is Segmented by Function (Flotation Chemicals, Extraction Chemicals, and Grinding Aids), Application (Mineral Processing and Wastewater Treatment), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific maintained a 54.56% revenue hold on the mining chemicals market in 2024 thanks to China's dominant position in copper, nickel, and rare-earth processing as well as India's push to commercialize domestic mineral reserves. China's lithium and nickel refining clusters, coupled with state-backed investments in African and Latin American mines, underpin resilient demand even amid broader economic softening.

North America's market is growing as Washington pursues supply-chain security for advanced batteries and critical minerals. Federal incentives spurred more than USD 150 billion in announced cell and raw-material projects, reinforcing reagent demand in lithium, nickel, and cobalt extraction lines. Canada's exploration spend climbed to USD 4.1 billion in 2024, with junior players driving hydrometallurgy trials for rare-earth and critical-metal deposits.

Europe exhibits modest volume but intensive innovation. The EU Critical Raw Materials Act supports domestic refining and recycling, lifting specialty reagent uptake in battery material loops. BASF and Clariant supply PFAS-free frothers and bio-collectors from European plants, raising regional self-sufficiency and competitive differentiation. South America's lithium triangle and Chilean copper expansions secure a pivotal role, while Africa's mineral wealth offers upside for suppliers able to navigate infrastructure and governance complexities. Middle East demand is minor, yet vertically integrated mega-projects in phosphate fertilizers and aluminum point to selective growth pockets.

- BASF

- 3M

- AECI

- Arkema

- Betachem (Pty) Ltd

- Celanese Corporation

- Chevron Phillips Chemical Company LLC

- Clariant

- CTC (Tennant Consolidated Group)

- Ecolab

- FMC Corporation

- Indorama Ventures Public Limited

- Kemira

- NASACO

- Orica Limited

- Qingdao Ruchang Mining Industry Co. Ltd

- Sasol

- SNF Group

- Syensqo

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing Mining CAPEX in APAC and North America

- 4.2.2 Surging Mineral Demand from EV And Renewable-Energy Supply Chains

- 4.2.3 Stricter Water-Recycling Norms in Large Mines

- 4.2.4 Commodity-Price Rebound Sustaining Exploration Budgets

- 4.2.5 Shift to Bio-Based Collectors for ESG Compliance

- 4.3 Market Restraints

- 4.3.1 Tightening Global Regulations on Toxic Reagents

- 4.3.2 Volatile Crude-Derived Raw-Material Costs

- 4.3.3 Emerging Dry-Processing Technologies that Bypass Wet Reagents

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Function

- 5.1.1 Flotation Chemicals

- 5.1.1.1 Collectors

- 5.1.1.2 Depressants

- 5.1.1.3 Flocculants

- 5.1.1.4 Frothers

- 5.1.1.5 Dispersants

- 5.1.2 Extraction Chemicals

- 5.1.2.1 Diluents

- 5.1.2.2 Extractants

- 5.1.3 Grinding Aids

- 5.1.1 Flotation Chemicals

- 5.2 By Application

- 5.2.1 Mineral Processing

- 5.2.2 Wastewater Treatment

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Indonesia

- 5.3.1.6 Malaysia

- 5.3.1.7 Australia and New Zealand

- 5.3.1.8 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Russia

- 5.3.3.6 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 BASF

- 6.4.2 3M

- 6.4.3 AECI

- 6.4.4 Arkema

- 6.4.5 Betachem (Pty) Ltd

- 6.4.6 Celanese Corporation

- 6.4.7 Chevron Phillips Chemical Company LLC

- 6.4.8 Clariant

- 6.4.9 CTC (Tennant Consolidated Group)

- 6.4.10 Ecolab

- 6.4.11 FMC Corporation

- 6.4.12 Indorama Ventures Public Limited

- 6.4.13 Kemira

- 6.4.14 NASACO

- 6.4.15 Orica Limited

- 6.4.16 Qingdao Ruchang Mining Industry Co. Ltd

- 6.4.17 Sasol

- 6.4.18 SNF Group

- 6.4.19 Syensqo

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment