|

市场调查报告书

商品编码

1852038

亚太地区油漆涂料:市场份额分析、行业趋势、统计数据和成长预测(2025-2030 年)Asia-Pacific Paints And Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

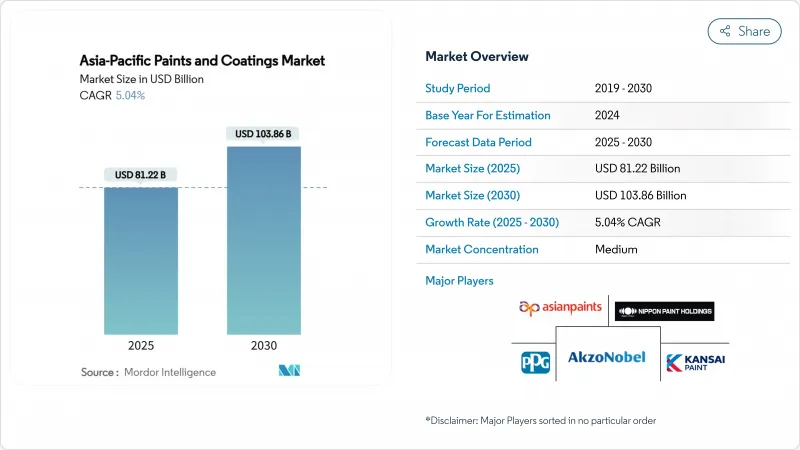

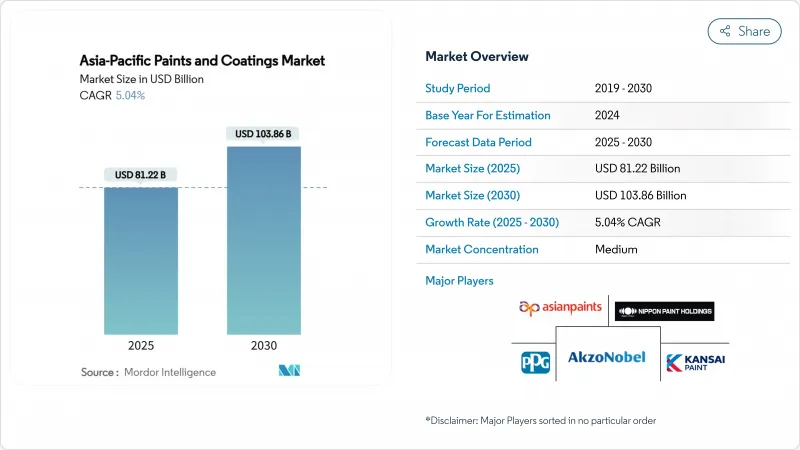

亚太地区油漆和涂料市场规模预计在 2025 年达到 812.2 亿美元,预计到 2030 年将达到 1,038.6 亿美元,预测期(2025-2030 年)复合年增长率为 5.04%。

日益严格的环境法规、加速的都市化以及汽车和工业生产的快速扩张支撑了持续的需求,而向水性平台的转型则使技术领先企业能够保持利润率的韧性。中国在2024年仍将保持其主导地位,市占率高达56.42%,但随着基础建设投资和房屋重建的加速发展,印度将在2030年之前主导成长。BASF和阿克苏诺贝尔等公司的策略调整表明,规模、产品组合平衡和地理深度将决定竞争优势。数位化色彩工具、高端都市区住宅更快的翻新週期以及政策支持的「绿色船舶」维修,都为亚太地区的涂料市场增添了新的需求,使其区别于更成熟的化工价值链。

亚太地区涂料市场趋势及洞察

新兴东协城市的建设热潮

印尼、泰国、越南、马来西亚和菲律宾的建筑业蓬勃发展,持续推动建筑和防护涂料的销售量。印尼预计在2025年成为全球第三大建筑市场,贡献9%的GDP,并维持13%的年增长率。大型交通走廊、工业和经济适用房专案为混凝土、钢骨和木材基材的涂料应用创造了更多机会。国际承包商通常会根据绿色建筑认证的要求指定低VOC涂料,这进一步推动了对水性涂料的需求。汽车和电子产业丛集的外商直接投资也带动了高性能OEM涂料、地板涂料和机械涂料的订单。虽然持续的资本流入取决于宏观经济稳定和地缘政治平静,但短期订单足以满足亚太地区涂料市场与建筑相关的销售成长需求。

缩短中国一流住宅大楼的重新粉刷週期

在中国成熟的房地产市场,随着业主优先考虑美观提升和资产保值,房屋重新粉刷的周期正在缩短。立邦涂料报告称,一、二线城市的市场成长显着,房屋重新粉刷的周期已从5-7年缩短至3-5年。能够确保色彩持久的高端品牌正抓住这一趋势,引导客户转向利润更高的产品。新屋开工量的结构性放缓,使得可支配收入更多地用于房屋维修,即使竣工量不高,也推高了每套房屋的价值。市场需求主要集中在符合GB/T 33372-2020排放标准的室内整理加工剂、水性底漆和无味面漆。虽然这一成长动能能否持续取决于家庭收入成长和整体房地产市场情绪,但亚太地区涂料市场的短期成长潜力已相当可观。

对挥发性有机化合物和甲醛的监管更加严格

中国GB/T 33372-2020标准将建筑涂料中VOC(挥发性有机化合物)的允许基准值降低至120克/公升,各地执法宣传活动正在加强审核。缺乏研发能力或水性分散基础设施的小型生产商将面临配方调整成本,并在合规期限过后面临供应链中断的风险。越南和马来西亚也正在推出类似的规定,迫使跨境供应商协调产品线、储备特定SKU或退出低利润的溶剂型产品类别。虽然从长远来看,这将促使市场需求转向更高价值的水性产品,但短期产能调整和转型成本将限制整体产量,从而抑制亚太地区涂料市场的成长动能。

细分市场分析

预计到2024年,水性涂料将占亚太地区涂料市场份额的57.05%,并在2030年之前以5.71%的复合年增长率成长。 2018年上海外墙溶剂禁令的实施,引发了广东、北京以及沿海工业一系列广泛的政策变革,促使建筑商转向低VOC、低气味的替代品。因此,亚太地区的涂料市场正从逐步采用转向系统性替换,这主要得益于新型丙烯酸乳化的出现,这些乳液具有与溶剂型醇酸涂料相媲美的抗粘连性、早期防水性和快速重涂性能。汽车原始设备製造商(OEM)正在检验能够承受东南亚常见湿度波动的水性底涂层和透明涂层组合,消除了以往的品质担忧。

粉状、紫外光固化、高固含量涂料系统是亚太地区涂料产业中一个规模虽小但成长迅速的细分市场,尤其适用于金属家具、家用电器和3C电子产品领域。粉末涂料的零VOC认证和超过95%的可回收性使其符合新加坡和澳洲以ESG主导的采购政策。然而,烘箱和预处理生产线的购买成本限制了资金紧张的中小企业丛集采用此类涂料。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 新兴东协城市的建设热潮

- 缩短中国一流住宅的重新粉刷週期

- 原始设备製造商转向水性汽车面漆

- 政府「绿色船舶」改造补贴(韩国、日本)

- 印度智慧城市计画强制要求使用冷屋顶涂料

- 市场限制

- 对挥发性有机化合物和甲醛的监管更加严格(例如,中国GB/T 33372-2020)

- 二氧化钛价格波动

- 印尼和越南缺乏合格的工业油漆工

- 价值链分析

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模与成长预测

- 透过技术

- 水系统

- 溶剂型

- 粉末涂装

- 其他技术(紫外线/电子束、高固含量等)

- 依树脂类型

- 丙烯酸纤维

- 醇酸

- 聚氨酯

- 环氧树脂

- 聚酯纤维

- 其他(酚类、酮类等)

- 按最终用户行业划分

- 建筑/装饰

- 车

- 木头

- 保护漆

- 一般工业用途

- 运输

- 包装

- 按地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲和纽西兰

- 印尼

- 泰国

- 马来西亚

- 越南

- 菲律宾

- 新加坡

- 亚太其他地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率(%)/排名分析

- 公司简介

- 3TREESGROUP

- Akzo Nobel NV

- Asian Paints

- Avian Brands

- Axalta Coating Systems, LLC

- BASF

- Berger Paints India

- Boysen Paints

- Chokwang Paint

- Davies Paints Philippines Inc.

- DuluxGroup Ltd

- Hempel A/S

- Jotun

- Kansai Paint Co., Ltd

- Nippon Paint Holdings Co., Ltd

- PPG Industries Inc.

- Propanraya

- The Sherwin-Williams Company

第七章 市场机会与未来展望

The Asia-Pacific Paints and Coatings Market size is estimated at USD 81.22 billion in 2025, and is expected to reach USD 103.86 billion by 2030, at a CAGR of 5.04% during the forecast period (2025-2030).

Tightening environmental regulations, accelerating urbanization, and the rapid scale-up of automotive and industrial production underpin sustained demand, while the shift to water-borne platforms positions technology leaders for margin resilience. China retained dominance with a 56.42% share in 2024, yet India is setting the growth pace through 2030 as infrastructure outlays and housing upgrades gain momentum. Raw-material volatility, especially in titanium-dioxide pricing, keeps margin management in sharp focus, and strategy realignments, such as divestitures by BASF and AkzoNobel, signal that scale, portfolio balance, and regional depth will define competitive advantage. Digitalized color tools, faster repaint cycles in premium urban housing, and policy-backed "green ship" retrofits add incremental layers of demand that distinguish the Asia-Pacific paints and coatings market from more mature chemical value chains.

Asia-Pacific Paints And Coatings Market Trends and Insights

Construction Boom in Emerging ASEAN Cities

Surging construction activity in Indonesia, Thailand, Vietnam, Malaysia, and the Philippines continues to lift architectural and protective coating volumes. Indonesia is on track to become the world's third-largest construction market by 2025, contributing 9% to national GDP while growing 13% year-on-year. Large transport corridors, industrial estates, and affordable-housing programs multiply coating touchpoints across concrete, steel, and wood substrates. International contractors typically specify low-VOC paints that align with green-building certifications, further tilting demand toward water-borne chemistry. Foreign direct investment in automotive and electronics clusters is also pushing orders for high-performance OEM, floor, and machinery coatings. Continued inflows hinge on macroeconomic stability and geopolitical calm, but near-term backlogs keep the Asia-Pacific paints and coatings market well supplied with construction-linked volume upside.

Re-painting Cycle Compression in Tier-1 Chinese Housing

China's mature property markets are experiencing shorter repaint intervals as owners prioritize aesthetic upgrades and asset preservation. Nippon Paint reported growth in Tier-1 and Tier-2 cities where repaint cycles have narrowed from 5-7 years to 3-5 years. Premium brands able to guarantee color retention for extended periods are exploiting the trend to trade customers up to higher-margin SKUs. Structural deceleration in new housing starts has redirected disposable incomes toward renovation outlays, raising value per dwelling even as unit completions soften. Demand is concentrated in interior finishes, water-borne primers and odor-free top-coats that meet GB/T 33372-2020 emission limits. Sustained momentum will depend on household income growth and sentiment in the broader real-estate market, yet the near-term uplift is already material for the Asia-Pacific paints and coatings market.

Tightening VOC and Formaldehyde Caps

China's GB/T 33372-2020 standard lowered permissible VOC thresholds for architectural coatings to 120 g/L, and provincial enforcement campaigns have intensified audit frequency. Smaller manufacturers lacking research and development and water-borne dispersion infrastructure face reformulation expenses and risk supply-chain disruptions if compliance deadlines lapse. Similar directives are taking shape in Vietnam and Malaysia, pushing cross-border suppliers to harmonize product lines, stock separate SKUs or exit low-margin solvent categories. While the long-term net effect channels demand into higher-value water-borne offerings, near-term capacity rationalization and transition costs suppress overall output, trimming Asia-Pacific paints and coatings market momentum.

Other drivers and restraints analyzed in the detailed report include:

- OEM Shift to Water-borne Auto Topcoats

- Mandated Cool-Roof Coatings in India's Smart-City Program

- Skills Deficit of Certified Industrial Coaters in Indonesia and Vietnam

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Water-borne formulations captured 57.05% of the Asia-Pacific paints and coatings market share in 2024 and are projected to record a 5.71% CAGR through 2030. Shanghai's 2018 exterior-wall solvent ban crystallized a wider policy wave across Guangdong, Beijing, and coastal industrial parks, steering builders toward low-VOC and low-odor alternatives. The Asia-Pacific paints and coatings market has therefore shifted from incremental adoption to systemic replacement, helped by new acrylic emulsions that deliver block resistance, early-water resistance, and rapid re-coat times comparable with solvent-borne alkyds. Automotive OEMs have validated water-borne base-coat clear-coat stacks that withstand humidity swings common to Southeast Asia, erasing previous quality concerns.

Powder, UV-curable, and high-solids systems together account for a smaller but fast-growing slice of the Asia-Pacific paints and coatings industry, particularly in metal furniture, appliances, and 3C electronics. Powder's zero-VOC credentials, plus reclamation efficiencies above 95%, appeal to ESG-driven procurement policies in Singapore and Australia. However, capital costs for ovens and pre-treatment lines limit penetration in cash-constrained SME clusters.

The Asia-Pacific Paints and Coatings Market Report is Segmented by Technology (Water-Borne, Solvent-Borne, Powder Coating, and Other Technologies), Resin Type (Acrylic, Alkyd, Polyurethane, and More), End-User Industry (Architectural/Decorative, Automotive, Wood, and More), and Geography (China, India, Japan, South Korea, Australia and New Zealand, Indonesia, and More). The Market Forecasts are Provided in Terms of Value (USD).

List of Companies Covered in this Report:

- 3TREESGROUP

- Akzo Nobel N.V.

- Asian Paints

- Avian Brands

- Axalta Coating Systems, LLC

- BASF

- Berger Paints India

- Boysen Paints

- Chokwang Paint

- Davies Paints Philippines Inc.

- DuluxGroup Ltd

- Hempel A/S

- Jotun

- Kansai Paint Co., Ltd

- Nippon Paint Holdings Co., Ltd

- PPG Industries Inc.

- Propanraya

- The Sherwin-Williams Company

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Construction Boom in Emerging ASEAN Cities

- 4.2.2 Re-Painting Cycle Compression in Tier-1 Chinese Housing

- 4.2.3 OEM Shift to Water-Borne Auto Topcoats

- 4.2.4 Government "Green Ship" Retro-Fit Subsidies (Korea, Japan)

- 4.2.5 Mandated Cool-Roof Coatings in India's Smart-City Program

- 4.3 Market Restraints

- 4.3.1 Tightening VOC and Formaldehyde Caps (China GB/T 33372-2020, Etc.)

- 4.3.2 Titanium-Dioxide Price Volatility

- 4.3.3 Skills Deficit of Certified Industrial Coaters in Indonesia and Vietnam

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 By Technology

- 5.1.1 Water-Borne

- 5.1.2 Solvent-Borne

- 5.1.3 Powder Coating

- 5.1.4 Other Technologies (UV/ EB, High-Solids, etc.)

- 5.2 By Resin Type

- 5.2.1 Acrylic

- 5.2.2 Alkyd

- 5.2.3 Polyurethane

- 5.2.4 Epoxy

- 5.2.5 Polyester

- 5.2.6 Others (Phenolic, Ketonic, etc.)

- 5.3 By End-user Industry

- 5.3.1 Architectural/ Decorative

- 5.3.2 Automotive

- 5.3.3 Wood

- 5.3.4 Protective Coatings

- 5.3.5 General Industrial

- 5.3.6 Transportation

- 5.3.7 Packaging

- 5.4 By Geography

- 5.4.1 China

- 5.4.2 India

- 5.4.3 Japan

- 5.4.4 South Korea

- 5.4.5 Australia and New Zealand

- 5.4.6 Indonesia

- 5.4.7 Thailand

- 5.4.8 Malaysia

- 5.4.9 Vietnam

- 5.4.10 Philippines

- 5.4.11 Singapore

- 5.4.12 Rest of Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 3TREESGROUP

- 6.4.2 Akzo Nobel N.V.

- 6.4.3 Asian Paints

- 6.4.4 Avian Brands

- 6.4.5 Axalta Coating Systems, LLC

- 6.4.6 BASF

- 6.4.7 Berger Paints India

- 6.4.8 Boysen Paints

- 6.4.9 Chokwang Paint

- 6.4.10 Davies Paints Philippines Inc.

- 6.4.11 DuluxGroup Ltd

- 6.4.12 Hempel A/S

- 6.4.13 Jotun

- 6.4.14 Kansai Paint Co., Ltd

- 6.4.15 Nippon Paint Holdings Co., Ltd

- 6.4.16 PPG Industries Inc.

- 6.4.17 Propanraya

- 6.4.18 The Sherwin-Williams Company

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment