|

市场调查报告书

商品编码

1910563

欧洲焊接设备市场:市场份额分析、行业趋势、统计数据和成长预测(2026-2031 年)Europe Welding Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

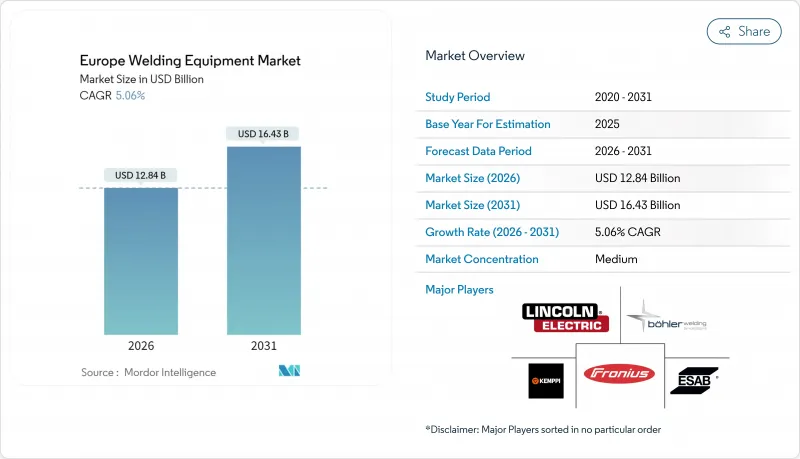

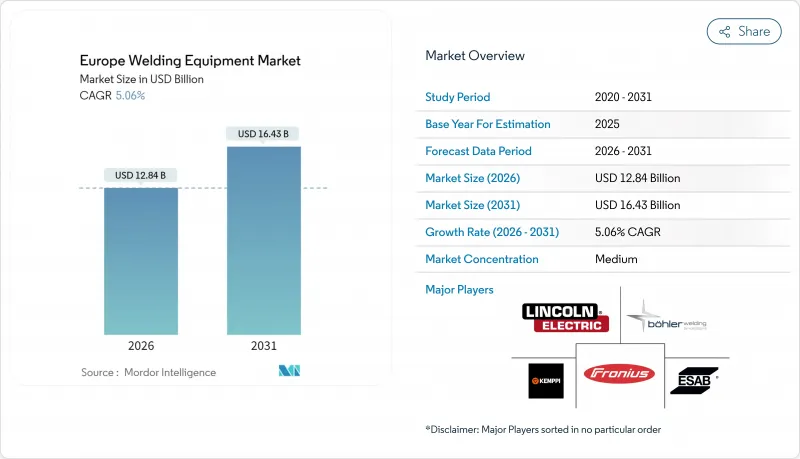

欧洲焊接设备市场预计到 2026 年将达到 128.4 亿美元,高于 2025 年的 122.2 亿美元。

预计到 2031 年将达到 164.3 亿美元,2026 年至 2031 年的复合年增长率为 5.06%。

市场扩张反映了设备现代化进程的加速,製造商正朝着整合感测器、软体和机器人技术的工业4.0生产单元迈进。电动车电池组组装和轻型铝材连接领域的需求成长尤为显着,而绿色交易基础设施计画也推动了公共部门大型焊接系统的采购。供应商不再仅仅在价格上竞争,而是致力于製程创新,例如高光束品质的雷射光源、低电磁辐射的逆变电源以及焊接数据分析平台。合格焊工的持续短缺正在推动自动化投资,中型企业纷纷部署协作机器人单元以应对劳动力波动。

欧洲焊接设备市场趋势与洞察

自动化和机器人技术在欧洲生产线中的渗透

欧洲各地的製造商正在部署机器人焊接单元,以填补30万焊工的缺口并满足ISO 3834品质要求。自适应控制演算法可即时调节电流和焊接速度,进而提高复杂接头几何形状的轮胎边缘一致性。一家德国汽车供应商报告称,在整合与人类操作员共用的协作机器人后,其生产週期缩短了40%。数位双胞胎模拟正在优化部署前的焊接路径,缩短试运行週期并提高整体设备效率(OEE)。随着模组化单元价格更加亲民,并透过三至五年的租赁协议资金筹措,其应用范围正从一级OEM厂商扩展到中级供应商。由此带来的生产力提升正在将劳动力短缺从瓶颈转变为现代化的催化剂。

电动车相关焊接需求快速成长

电池托盘和机壳的生产需要将铝材与钢材连接,同时限制热影响区。工作波长为 1030 奈米的光纤雷射可达到超过每分钟 10 公尺的穿透速度,取代电阻点焊,并省去了 6000 系列挤压件的后后处理工序。这项转变满足了联合国欧洲经济委员会 (UN ECE) R100 安全法规对电池组严格公差的要求。随着欧洲系统整合商扩大生产线以满足不断增长的电动车产量,通快 (TRUMPF) 延长了其多千瓦雷射系统的前置作业时间。製程监控模组可记录熔池尺寸和能量输入,产生车辆类型认证所需的可追溯性记录。因此,雷射焊接的投资能够同时应对生产效率和合规性的两大关键挑战。

对先进系统和雷射系统的大量资本投入

雷射焊接单元的单价可能在20万至200万欧元之间,而辅助设备(例如通风和防护设备)可能会使计划总成本翻倍。儘管雷射焊接单元能够提高生产效率,但超过五年的投资回收期阻碍了中小企业采用该技术。由于高功率雷射设备的残值不确定,租赁公司会收取高额风险溢价,导致资金筹措缺口进一步扩大。每年高达5万欧元的维护合约费用(用于光学元件、冷却系统和软体更新)也推高了总拥有成本。因此,即使精度要求更高,许多小规模製造商仍继续使用半自动的MAG设备,而忽略了雷射解决方案的优势。

细分市场分析

到2025年,电弧焊接将占据欧洲焊接设备市场56.12%的份额,并在2031年之前以4.94%的复合年增长率成长。电弧焊接市场规模的成长主要得益于土木工程、造船和工厂维护等领域,这些领域对电弧焊的便携性和厚壁加工能力的需求依然十分迫切。雷射和等离子焊接系统正经历最快的收入成长,这主要得益于使用者对铝製车身零件和薄板电子机壳所需的窄热影响区和高焊接速度的需求。其他焊接工艺,例如焊焊、硬焊和锻焊,在欧洲焊接设备市场规模方面呈现7.92%的复合年增长率,这主要受电子产品小型化和历史建筑修復的推动。耗材供应商正在推出用于异种金属连接的铝镍合金熔填材料,而监测Start-Ups则在产品中整合光学感测器,用于记录轮胎边缘形状并实现即时品质警报。日益严格的焊接烟尘排放法规进一步推动了从气焊到熔敷效率更高的逆变式MIG焊接机的转变。随着积层製造技术的普及,电弧沉积头可以螺栓固定到现有的机器人上,从而无需更换整个单元即可增加收入。

第二代电弧电源采用多进程韧体,可在MIG焊接、TIG焊接和手工电弧焊接模式之间无缝切换,从而提升了代工企业的设备柔软性。电阻点焊在汽车大批量生产线中仍将占据一席之地,但远端雷射焊接正逐渐取代铝製电池机壳的部分製程。等离子焊接的细分市场正在航太引擎专案中不断扩大,这些专案需要对镍基高温合金进行深熔和最小变形焊接。因此,製程多样化反映了欧洲多元化的製造业基础,其产品涵盖从重型钢结构到精密医疗设备的各个领域。

其他福利:

- Excel格式的市场预测(ME)表

- 分析师支持(3个月)

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 自动化和机器人技术在欧洲生产线的普及

- 电动车焊接需求(电池托盘和轻质铝材)快速成长

- 欧盟绿色交易下的基础设施更新支出

- 根据欧盟电磁场暴露指令 2013/35/EU 进行合规性维修

- 手持式光纤雷射焊接机在中小企业中越来越受欢迎。

- ESG审核可追溯性平台(焊接资料分析)

- 市场限制

- 先进雷射系统需要高资本投入

- 合格焊工和培训人员短缺

- 钢铁和铝价格波动

- 电磁场 (EMF) 和烟尘暴露限值的合规成本不断上升

- 价值/供应链分析

- 监管环境

- 技术展望

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模与成长预测

- 透过流程

- 电弧焊接

- 电阻焊接

- 雷射焊接

- 等离子焊接

- 气焊

- 其他焊接方法-焊焊、硬焊、锻焊等。

- 最终用户

- 建筑和基础设施

- 石油、天然气和石化

- 能源与发电

- 汽车/运输设备

- 重工业和工业设备

- 航太/国防

- 其他(特殊应用-小规模製造研讨会、维护和维修、客製化焊接服务)

- 按自动化级别

- 手动的

- 半自动

- 自动/机器人控制

- 按地区

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 比荷卢经济联盟(比利时、荷兰、卢森堡)

- 北欧国家(丹麦、芬兰、冰岛、挪威、瑞典)

- 其他欧洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Lincoln Electric Holdings Inc.

- ESAB Corp.

- Fronius International GmbH

- Kemppi Oy

- voestalpine Bohler Welding

- Carl Cloos SchweiBtechnik GmbH

- AMADA WELD TECH

- EWM AG

- Hobart Welders

- Denyo Co. Ltd

- WW Grainger Inc.

- Obara Corporation

- Polysoude SAS

- CEBORA SpA

- TRUMPF Group

- Air Liquide SA

- Panasonic Industry Europe GmbH

- Daihen Corp.

- IPG Photonics(EU operations)

- Plansee SE

第七章 市场机会与未来展望

The Europe Welding Equipment Market size in 2026 is estimated at USD 12.84 billion, growing from 2025 value of USD 12.22 billion with 2031 projections showing USD 16.43 billion, growing at 5.06% CAGR over 2026-2031.

Market expansion reflects accelerated equipment modernization as manufacturers migrate toward Industry 4.0 production cells that integrate sensors, software, and robotics Demand intensity rises most sharply in battery-pack assembly and lightweight aluminum joining for electric vehicles, while Green Deal infrastructure programs sustain public-sector procurement of heavy-duty welding systems. Suppliers compete on process innovations laser sources with higher beam quality, inverter-based power supplies with lower electromagnetic emissions, and weld-data analytics platforms rather than on pure pricing. Continued shortages of certified welders reinforce automation investments, and mid-sized enterprises adopt collaborative robot cells to hedge against labor volatility.

Europe Welding Equipment Market Trends and Insights

Automation & Robotics Penetration Across European Production Lines

Manufacturers across the continent install robot welding cells to offset the 300,000-worker welder gap and to meet ISO 3834 quality demands. Adaptive control algorithms adjust current and travel speed in real time, improving bead consistency on complex joint geometries. German automotive suppliers report 40% cycle-time reductions after integrating collaborative robots that share work zones with human operators. Digital twin simulations optimize weld paths before deployment, shrinking commissioning cycles and boosting overall equipment effectiveness. Adoption cascades from tier-one OEMs to mid-tier suppliers as modular cells become affordable and financeable on three- to five-year leases. The resulting productivity gains convert labor scarcity from a bottleneck into a catalyst for modernization.

Surge in EV-Related Welding Needs

Battery-tray and enclosure fabrication requires joining aluminum and steel while limiting heat-affected zones. Fiber-laser sources operating at 1,030 nm deliver penetration at speeds above 10 m/min, replacing resistance spot welding and eliminating post-processing on 6000-series extrusions. The transition supports tighter battery-pack tolerances demanded by UN ECE R100 safety rules. TRUMPF extended lead times for multi-kilowatt laser systems as European integrators ramp up lines to meet rising EV output. Process monitoring modules log melt-pool dimensions and energy input, generating traceability records essential for automotive homologation audits. Consequently, laser welding investments align with the twin imperatives of productivity and compliance.

High Capex for Advanced & Laser Systems

Laser welding cells cost EUR 200k - 2 million each, and ancillary ventilation or guarding can double project outlays. Payback horizons of five or more years deter SME buyers despite throughput benefits. Financing gaps widen as leasing companies apply higher risk premiums to high-power laser assets with uncertain residual values. Annual service contracts of EUR 50,000 for optics, chillers, and software updates inflate the total cost of ownership. Consequently, many small fabricators continue using semi-automatic MAG units even when precision demands favor laser solutions.

Other drivers and restraints analyzed in the detailed report include:

- EU Green Deal Infrastructure Spending

- Hand-Held Fiber-Laser Welders Gaining SME Adoption

- Shortage of Certified Welders & Trainers

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Arc welding held 56.12% of the Europe welding equipment market share in 2025, and the segment is forecast to advance at a 4.94% CAGR through 2031. The arc category's scale is anchored in civil construction, shipbuilding, and plant-maintenance jobs where portability and thick-section capability remain essential. Laser and plasma systems capture the fastest revenue acceleration as users pursue narrow heat-affected zones and higher line speeds for aluminum body components and thin-gauge electronics housings. The European welding equipment market size tied to "other" processes soldering, brazing, forge welding posts a 7.92% CAGR on the back of electronics miniaturization and heritage-structure restoration. Consumable vendors respond with aluminum-nickel fillers for dissimilar-metal joints, while monitoring start-ups embed optical sensors that log bead geometry for real-time quality alerts. Regulations curbing welding fumes further motivate a shift from gas welding toward inverter-based MIG units that offer higher deposition efficiency. As additive manufacturing gains traction, wire-arc deposition heads bolt onto existing robots, unlocking incremental revenue without replacing the entire cell.

Second-generation arc power sources ship with multiprocess firmware that toggles seamlessly between MIG, TIG, and stick modes, boosting asset flexibility for job shops. Resistance spot welding preserves share within high-volume automotive lines, though remote-seam lasers begin to replace some stations for aluminum battery enclosures. Plasma welding's niche expands inside aerospace engine programs that require deep penetration in nickel super-alloys with minimal distortion. Process diversification, therefore, mirrors Europe's multi-speed manufacturing base, stretching from heavy steel fabrication to precision medical devices.

The Europe Welding Equipment Market Report is Segmented by Process (Arc Welding, Resistance Welding and More), by End-User (Construction & Infrastructure, Oil Gas & Petrochemicals and More), by Automation Level (Manual, Semi-Automatic and More), and by Geography (United Kingdom, Germany, France and More). The Market Forecasts are Provided in Terms of Value (USD).

List of Companies Covered in this Report:

- Lincoln Electric Holdings Inc.

- ESAB Corp.

- Fronius International GmbH

- Kemppi Oy

- voestalpine Bohler Welding

- Carl Cloos SchweiBtechnik GmbH

- AMADA WELD TECH

- EWM AG

- Hobart Welders

- Denyo Co. Ltd

- W.W. Grainger Inc.

- Obara Corporation

- Polysoude SAS

- CEBORA S.p.A

- TRUMPF Group

- Air Liquide SA

- Panasonic Industry Europe GmbH

- Daihen Corp.

- IPG Photonics (EU operations)

- Plansee SE

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Automation & robotics penetration across European production lines

- 4.2.2 Surge in EV-related welding needs (battery trays & lightweight aluminium)

- 4.2.3 EU Green Deal infrastructure-renewal spending

- 4.2.4 Compliance retrofits triggered by EU EMF-exposure directive 2013/35/EU

- 4.2.5 Hand-held fibre-laser welders gaining SME adoption

- 4.2.6 Traceability platforms (weld-data analytics) aligned with ESG audits

- 4.3 Market Restraints

- 4.3.1 High capex for advanced & laser systems

- 4.3.2 Shortage of certified welders & trainers

- 4.3.3 Steel & aluminium price volatility

- 4.3.4 Rising compliance cost for EMF & fume-exposure limits

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Industry Attractiveness - Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Competitive Rivalry

5 Market Size & Growth Forecasts (Values, In USD Billion)

- 5.1 By Process

- 5.1.1 Arc Welding

- 5.1.2 Resistance Welding

- 5.1.3 Leser Welding

- 5.1.4 Plasma Welding

- 5.1.5 Gas Welding

- 5.1.6 Others - Soldering & Brazing, Forge Welding, etc.

- 5.2 By End-user

- 5.2.1 Construction & Infrastructure

- 5.2.2 Oil, Gas & Petrochemicals

- 5.2.3 Energy & Power Generation

- 5.2.4 Automotive & Transportation

- 5.2.5 Heavy Engineering & Industrial Equipment

- 5.2.6 Aerospace & Defence

- 5.2.7 Others (Specialized Applications - Small-scale fabrication workshops, maintenance & repair, and custom welding services)

- 5.3 By Automation Level

- 5.3.1 Manual

- 5.3.2 Semi-automatic

- 5.3.3 Automatic / Robotic

- 5.4 By Geography

- 5.4.1 United Kingdom

- 5.4.2 Germany

- 5.4.3 France

- 5.4.4 Italy

- 5.4.5 Spain

- 5.4.6 BENELUX (Belgium, Netherlands, and Luxembourg)

- 5.4.7 NORDICS (Denmark, Finland, Iceland, Norway, and Sweden)

- 5.4.8 Rest of Europe

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Products & Services, and Recent Developments)

- 6.4.1 Lincoln Electric Holdings Inc.

- 6.4.2 ESAB Corp.

- 6.4.3 Fronius International GmbH

- 6.4.4 Kemppi Oy

- 6.4.5 voestalpine Bohler Welding

- 6.4.6 Carl Cloos SchweiBtechnik GmbH

- 6.4.7 AMADA WELD TECH

- 6.4.8 EWM AG

- 6.4.9 Hobart Welders

- 6.4.10 Denyo Co. Ltd

- 6.4.11 W.W. Grainger Inc.

- 6.4.12 Obara Corporation

- 6.4.13 Polysoude SAS

- 6.4.14 CEBORA S.p.A

- 6.4.15 TRUMPF Group

- 6.4.16 Air Liquide SA

- 6.4.17 Panasonic Industry Europe GmbH

- 6.4.18 Daihen Corp.

- 6.4.19 IPG Photonics (EU operations)

- 6.4.20 Plansee SE

7 Market Opportunities & Future Outlook

- 7.1 White-space & Unmet-need Assessment