|

市场调查报告书

商品编码

1910709

热塑性淀粉(TPS):市占率分析、产业趋势与统计、成长预测(2026-2031)Thermoplastic Starch (TPS) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

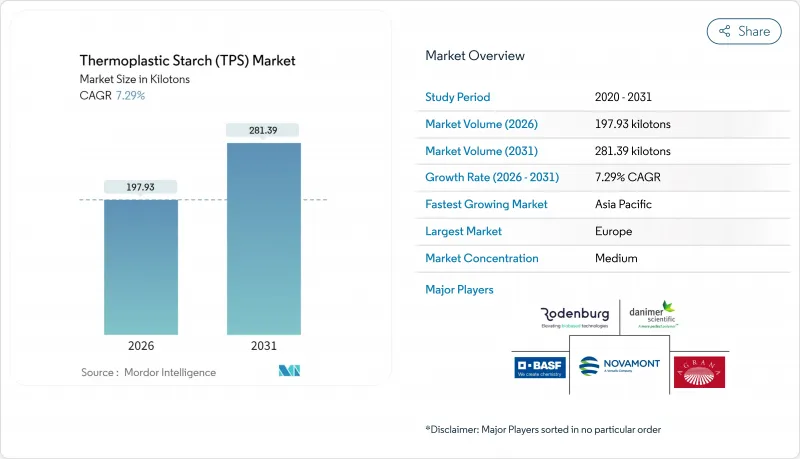

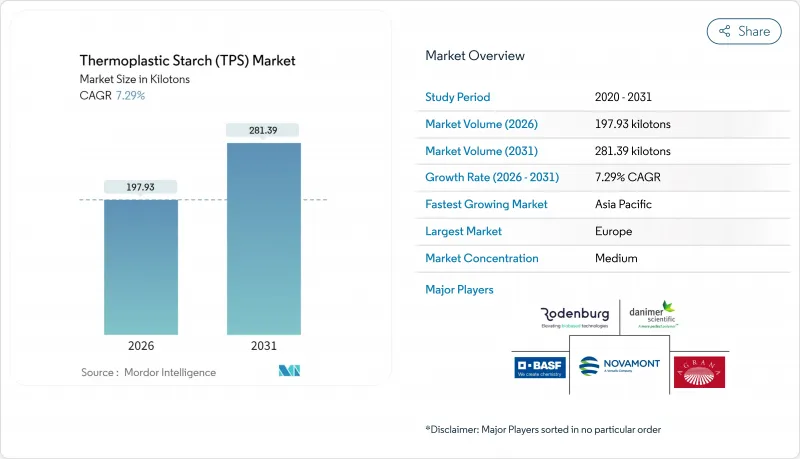

热塑性淀粉市场规模预计到 2026 年将达到 197.93 千吨,高于 2025 年的 184.49 千吨,预计到 2031 年将达到 281.39 千吨。

预计2026年至2031年年复合成长率(CAGR)为7.29%。

热塑性淀粉的防潮性能持续提升,加上相容剂和奈米复合材料技术带来的机械强度增强,长期以来存在的性能瓶颈正在被打破。欧洲优先考虑可堆肥性的法规、北美电子商务的需求以及亚太地区政府对生物基材料的支持,共同推动了热塑性淀粉市场规模的扩大。玉米和马铃薯淀粉原料价格的波动加剧了供应链风险,但木薯和农业残渣等非食品替代原料的同步发展则有助于降低成本风险。市场竞争依然激烈,但格局正趋于多元化:老牌化工巨头利用其规模优势,而专业製造商则拓展产品系列,以满足医疗、3D列印和高端包装等细分应用领域的需求。

全球热塑性淀粉(TPS)市场趋势及洞察

对可生物降解包装材料的需求不断增长

将于2025年2月生效的欧盟新包装及包装废弃物法规将强制要求包装可回收利用,同时鼓励使用工业和家庭可堆肥基材,这将立即扩大热塑性淀粉市场。同时,环氧大豆油塑化剂的技术创新已将水性降低了28.6%,且未影响其光学透明度。跨国品牌拥有者现在将可堆肥包装定位为高端差异化优势,已开发经济体中73%的消费者愿意为经认证的永续解决方案支付溢价。加工商和淀粉加工商之间建立的合作伙伴关係,剔除了中间环节,巩固了长期合约并支持了产能扩张。监管需求和商业性需求之间的协同作用正在加速食品、饮料和个人护理行业的规范核准,进一步巩固了热塑性淀粉市场的成长势头。

主要经济体禁止使用一次性塑胶製品

到2024年,已有超过67个国家实施了一次性塑胶法规,结束了现有石油基产品的合规期。中国的「竹子取代塑胶」政策和财政奖励正在推动国内对生物基材料的需求。欧盟的《一次性塑胶指令》要求大型速食连锁店使用可生物分解的刀叉餐具。同时,澳洲正日益严格地执行纯度标准,包括各州禁止使用淀粉-聚丙烯复合材料。监管的碎片化正在为符合严格生物降解标准的纯热塑性淀粉化合物创造一个高端利基市场。监管实施的加速表明,人们正在持续地从石油基塑胶转向其他材料,这将推动热塑性淀粉市场的成长。

水分敏感度会限制保存期限

淀粉的亲水性使其水蒸气透过率比低密度聚乙烯(LDPE)高出五倍,这限制了其在热带地区的应用。奈米晶纤维素的增强作用可降低40%的吸湿性,但会使生产成本增加25-35%,这给价格敏感型市场带来了挑战。保存期限12个月的食品,如果仅使用热塑性淀粉薄膜包装,通常会在30-60天内劣化。在潮湿的市场,温控物流可能会使分销成本增加高达15%。预计这些技术和物流方面的限制将暂时限制热塑性淀粉的市场渗透,直到新一代阻隔材料实现规模化商业化。

细分市场分析

预计到2025年,挤出成型将占据热塑性淀粉市场57.72%的份额,这主要得益于连续加工的经济性和其对高产能柔性薄膜生产线的适用性。此製程单位成本低,加之在线连续添加塑化剂和快速换料,已成功获得休閒食品和农产品包装袋加工商的订单。射出成型虽然规模较小,但预计其复合年增长率将达到7.73%,因为品牌商对尺寸公差较小的精密零件(例如药盖和化妆品罐)的需求日益增长。往復式螺桿设计的不断改进已将停留时间劣化降低了20%,提高了机械完整性,并拓展了薄壁产品的应用范围。

为了因应需求波动,製造商正在跨平台进行多元化发展。挤出系统仍然是通用薄膜的核心技术,但产能扩张的重点在于能够切换片材、吹膜和型材挤出的多功能生产线,从而最大限度地提高资产利用率。射出成型机製造商正在采用伺服马达驱动,以提高能源效率并缩小与液压机的成本差距。设备价格的下降吸引了更多中小企业,加剧了区域竞争,并加速了新兴经济体热塑性淀粉市场的深化。

热塑性淀粉市场报告按生产类型(挤出成型和射出成型)、应用领域(包装袋、薄膜、3D列印及其他应用)、终端用户行业(包装、农业园艺、消费品及其他)以及地区(亚太、北美、欧洲、南美以及中东和非洲)进行细分。市场预测以千吨为单位。

区域分析

预计到2025年,欧洲将占据热塑性淀粉市场39.32%的份额,这主要得益于清晰的法律体制、成熟的堆肥系统以及消费者的高度接受度。成员国的废弃物分类目标鼓励市政当局投资有机物收集,从而确保真正的循环经济,并支撑对淀粉基材料的需求。然而,玉米价格的急剧上涨导致原物料采购压力增大,AGRANA公司计划在2024年将其玉米加工量减少26%,凸显了供应链风险。

亚太地区预计将成为成长最快的地区,到2031年年均成长率将达到8.22%,主要得益于中国的生物材料补贴和印度不断扩大的生物聚合物产能。该地区的优势包括丰富的农业残余物以及国内对永续和柔性包装材料日益增长的需求。当地加工商正利用政府补贴增设反应挤出生产线,加速市场进入并加剧竞争。这正使热塑性淀粉市场从出口导向型转变为拥有广泛区域生产基地的市场。

在北美,电子商务的兴起和零售商日益提高的永续性标准正在推动成长。加州和华盛顿州的市政有机物处理计画为可堆肥废弃物创造了天然的出口管道,从而增强了直接面向消费者的品牌的需求。南美洲丰富的淀粉资源使其成为原料出口地区,但下游加工能力的不足正在减缓国内消费的成长。中东和非洲地区仍处于欠发达状态,其推广应用取决于未来的废弃物基础设施现代化和农业节水项目,这些项目有望推动可生物降解地膜的普及。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 可生物降解包装的需求不断增长

- 主要经济体禁止使用一次性塑胶製品

- 品牌所有者的永续性超越了监管义务。

- 改用可堆肥的电商信封

- 使用TPS复合材料测试替代药品泡壳包装

- 市场限制

- 水分敏感度会限制保存期限

- 与石油基塑胶相比,机械强度较差

- 围绕淀粉成分的食品与食材之争

- 价值链分析

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

第五章 市场规模与成长预测

- 按生产类型

- 挤出成型

- 射出成型

- 透过使用

- 包包

- 电影

- 3D列印

- 其他用途

- 按最终用户行业划分

- 包装

- 农业和园艺

- 消费品

- 医疗和药品

- 其他的

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- ASEAN

- 亚太其他地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 义大利

- 法国

- 北欧国家

- 其他欧洲地区

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率(%)/排名分析

- 公司简介

- AGRANA

- BASF

- BioLogiQ Inc.

- Biome Bioplastics

- BIOTEC Biologische Naturverpackungen GmbH & Co. KG.

- Danimer Scientific

- Great Wrap

- Grupa Azoty

- Kuraray Co., Ltd

- Novamont SpA(Versalis SpA)

- Rodenburg Biopolymers

第七章 市场机会与未来展望

Thermoplastic Starch market size in 2026 is estimated at 197.93 kilotons, growing from 2025 value of 184.49 kilotons with 2031 projections showing 281.39 kilotons, growing at 7.29% CAGR over 2026-2031.

Continuous improvements in moisture-barrier performance, coupled with mechanical-strength gains achieved through compatibilizer and nanocomposite technologies, are removing long-standing functional barriers. European legislation that prioritizes compostability, North American e-commerce fulfillment demands, and Asia-Pacific government stimulus for bio-based materials are jointly expanding the thermoplastic starch market's addressable applications. Price volatility in corn and potato starch feedstocks has raised supply-chain risk, yet parallel progress in non-food alternatives such as cassava and agricultural residues is buffering cost exposure. Competition remains intense but fragmented, with established chemical majors leveraging scale while specialists round out product portfolios for niche medical, 3-D printing, and premium packaging uses.

Global Thermoplastic Starch (TPS) Market Trends and Insights

Rising Demand for Biodegradable Packaging

New EU Packaging and Packaging Waste Regulation rules, effective February 2025, legally require recyclability while encouraging industrial and home-compostable substrates, instantly enlarging the thermoplastic starch market. Parallel breakthroughs in epoxidized soybean-oil plasticizers have lowered water sensitivity by 28.6% without losing optical clarity. Multinational brand owners now treat compostable packaging as a premium differentiator, and 73% of consumers in developed economies are willing to pay higher prices for verified sustainable solutions. Converter-starch-processor partnerships that cut intermediaries are cementing long-term contracts, thereby supporting capacity expansions. The combined regulatory and commercial pull is translating into faster specification approvals across food, beverage, and personal-care verticals, further solidifying thermoplastic starch market growth trajectories.

Ban on Single-Use Plastics in Major Economies

More than 67 nations enforced single-use plastic restrictions by 2024, closing the compliance window for incumbent petro-based products. China's bamboo-as-plastic-substitute policy and financial incentives have catalyzed domestic demand for bio-materials. The EU Single-Use Plastics Directive has pushed major quick-service restaurants to require biodegradable utensils, while Australia's state-level bans on starch-polypropylene blends illustrate tightening purity thresholds. Regulatory fragmentation creates a premium niche for pure thermoplastic starch formulations meeting strict biodegradability standards. The accelerated enforcement pace points to an enduring, structural shift away from petroleum plastics, thus feeding the thermoplastic starch market.

Moisture Sensitivity Limiting Shelf-Life

The hydrophilic nature of starch results in water-vapor transmission rates up to 5 times higher than LDPE, curbing adoption in tropical zones. Nanocrystalline-cellulose reinforcement can slash moisture uptake by 40%, yet production costs jump 25-35%, challenging price-sensitive segments. Food products that require 12-month shelf lives typically experience quality degradation in 30-60 days when packaged purely in thermoplastic starch films. Climate-controlled logistics add as much as 15% to distribution costs in humid markets. These technical and logistical penalties temporarily limit the thermoplastic starch market's penetration rate until next-generation barrier chemistries become commercial at scale.

Other drivers and restraints analyzed in the detailed report include:

- Brand-Owner Sustainability Pledges Beyond Regulatory Mandates

- Pharma Blister-Pack Replacement Trials with TPS Composites

- Inferior Mechanical Strength Vs. Petro-Plastics

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Extrusion molding delivered 57.72% of the thermoplastic starch market share in 2025, buoyed by its continuous processing economics and adaptability to high-volume flexible-film lines. The process allows inline plasticizer dosing and rapid order changeovers, keeping per-unit costs low and securing orders from snack-food and produce-bag converters. Injection molding, although smaller, is forecast at a 7.73% CAGR as brand owners pursue precision components such as pharmaceutical caps and cosmetic jars that demand tighter dimensional tolerances. Continuous enhancements in reciprocating-screw designs now reduce residence-time degradation by 20%, lifting mechanical integrity and widening the addressable range of thin-wall items.

Manufacturers diversify across both platforms to hedge demand swings. Extrusion systems remain the backbone for commodity films, but capacity additions tilt toward multi-purpose lines that switch between sheet, blown film, and profile extrusion to maximize asset utilization. Injection equipment suppliers embed servo-electric drives to enhance energy efficiency, narrowing the cost gap with hydraulic machines. As equipment prices fall, small and medium enterprises gain entry, expanding regional competition and deepening the thermoplastic starch market across emerging economies.

The Thermoplastic Starch Report is Segmented by Manufacturing Type (Extrusion Molding and Injection Molding), Application (Bags, Films, 3-D Printing, and Other Applications), End-User Industry (Packaging, Agriculture and Horticulture, Consumer Goods, and More), and Geography ( Asia-Pacific, North America, Europe, South America, and Middle-East and Africa). The Market Forecasts are Provided in Terms of Volume (Kilotons).

Geography Analysis

Europe's 39.32% share of the thermoplastic starch market in 2025 is rooted in clear legislative frameworks, mature composting systems, and strong consumer acceptance. Member-state waste-sorting targets incentivize municipal investments in organics collection, ensuring true circularity and validating demand for starch-based materials. Feedstock pressure, however, surfaced when corn prices spiked and AGRANA reported a 26% drop in corn processing volumes in 2024, highlighting supply-chain risk.

Asia-Pacific is forecast to deliver the fastest 8.22% CAGR through 2031, anchored by China's bio-material subsidies and India's widening biopolymer capacity. Regional advantages include abundant agricultural residues and growing domestic demand for sustainable, flexible packaging. Local processors leverage government grants to add reactive-extrusion lines, thereby accelerating market entry and intensifying competition. The thermoplastic starch market thus transitions from export-oriented pockets to a broad regional production base.

North America benefits from e-commerce penetration and rising retailer sustainability benchmarks. Municipal organics programs in California and Washington state create a natural outlet for compostable waste streams, reinforcing demand among direct-to-consumer brands. South America's starch abundance positions the region as a feedstock exporter, yet limited downstream processing capacity delays domestic consumption. Middle East and Africa remain nascent, with uptake tied to future waste-infrastructure modernization and agricultural water-conservation programs that could favor biodegradable mulch films.

- AGRANA

- BASF

- BioLogiQ Inc.

- Biome Bioplastics

- BIOTEC Biologische Naturverpackungen GmbH & Co. KG.

- Danimer Scientific

- Great Wrap

- Grupa Azoty

- Kuraray Co., Ltd

- Novamont S.p.A (Versalis S.p.A.)

- Rodenburg Biopolymers

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising Demand for Biodegradable Packaging

- 4.2.2 Ban on Single-Use Plastics in Major Economies

- 4.2.3 Brand-Owner Sustainability Pledges Beyond Regulatory Mandates

- 4.2.4 Shift Toward Home-Compostable E-Commerce Mailers

- 4.2.5 Pharma Blister-Pack Replacement Trials with TPS Composites

- 4.3 Market Restraints

- 4.3.1 Moisture Sensitivity Limiting Shelf-Life

- 4.3.2 Inferior Mechanical Strength Vs. Petro-Plastics

- 4.3.3 Food-Versus-Materials Debate around Starch Feedstock

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Manufacturing Type

- 5.1.1 Extrusion Molding

- 5.1.2 Injection Molding

- 5.2 By Application

- 5.2.1 Bags

- 5.2.2 Films

- 5.2.3 3-D Printing

- 5.2.4 Other Applications

- 5.3 By End-User Industry

- 5.3.1 Packaging

- 5.3.2 Agriculture and Horticulture

- 5.3.3 Consumer Goods

- 5.3.4 Medical and Pharmaceuticals

- 5.3.5 Others

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 ASEAN

- 5.4.1.6 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 Italy

- 5.4.3.4 France

- 5.4.3.5 Nordics

- 5.4.3.6 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 AGRANA

- 6.4.2 BASF

- 6.4.3 BioLogiQ Inc.

- 6.4.4 Biome Bioplastics

- 6.4.5 BIOTEC Biologische Naturverpackungen GmbH & Co. KG.

- 6.4.6 Danimer Scientific

- 6.4.7 Great Wrap

- 6.4.8 Grupa Azoty

- 6.4.9 Kuraray Co., Ltd

- 6.4.10 Novamont S.p.A (Versalis S.p.A.)

- 6.4.11 Rodenburg Biopolymers

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment