|

市场调查报告书

商品编码

1699277

可程式逻辑控制器 (PLC) 市场机会、成长动力、产业趋势分析及 2025-2034 年预测Programmable Logic Controller (PLC) Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025-2034 |

||||||

2024 年全球可程式逻辑控制器市场价值为 117 亿美元,预计 2025 年至 2034 年的复合年增长率为 10.4%。工业 4.0、数位孪生技术和自动化驱动解决方案的日益普及正在推动市场扩张。由于基于 PLC 的系统在自动化生产线和优化製造效率方面发挥关键作用,因此电动车 (EV) 的需求不断增长,进一步加速了成长。汽车製造商依靠 PLC 驱动的解决方案来简化电动车的生产、增强可扩展性并减少停机时间。此外,这些系统对于电池製造和复杂的组装过程至关重要,可确保最高的生产力。

工业 4.0 计画整合了人工智慧驱动的分析、机器通讯和云端运算,正在推动对先进 PLC 的巨大需求。这些系统促进了即时资料处理和无缝连接,使其成为智慧製造不可或缺的一部分。数位孪生技术与基于 PLC 的系统的整合使製造商能够创建虚拟模型来测试和优化效能,而不会中断实体操作。随着越来越多的公司采用数位孪生进行预测性维护和效率改进,PLC 製造商正专注于开发与这些进步一致的解决方案。各行各业对智慧自动化的需求日益增长,确保了对 PLC 的持续需求,使其成为现代工业生态系统的重要组成部分。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 117亿美元 |

| 预测值 | 314亿美元 |

| 复合年增长率 | 10.4% |

根据类型,市场分为模组化、紧凑型和机架式 PLC。其中,模组化 PLC 预计将实现最高成长,预测期内复合年增长率为 11.1%。这些 PLC 具有出色的可扩展性和灵活性,使其成为製造、能源、水处理和食品加工等行业的首选。它们能够在不中断整个系统的情况下更换故障模组,从而最大限度地减少停机时间,这推动了它们的广泛应用。

根据最终用途,市场分为航太和国防、汽车、化学品、能源和公用事业、食品和饮料、医疗保健、製造业、采矿和金属、石油和天然气以及运输业。受智慧工厂和自动化生产线中 PLC 部署日益增多的推动,製造业将在 2024 年占据总市场份额的 20.9% 以上。现代 PLC 系统透过即时资料处理、预测性维护和自适应自动化来提高效率,使其成为工业进步不可或缺的一部分。

市场也依组件分为软体、硬体和服务。在工业 4.0 快速应用和物联网整合的推动下,软体产业的规模到 2024 年将达到 41 亿美元。基于软体的 PLC 支援即时监控、预测分析和流程优化,帮助产业提高效率并最大限度地减少操作错误。随着智慧製造的发展势头强劲,它们在减少系统停机时间和简化生产流程方面的作用不断扩大。

从地理位置来看,由于对智慧基础设施和自动化技术的投资增加,北美在 2024 年占据了全球 PLC 市场的 34.4% 的份额。美国引领区域市场,2024 年创造 31 亿美元的收入,预计复合年增长率为 10.8%。工业 4.0 计划的扩展和对电动车生产的日益关注是推动该地区采用 PLC 的关键因素。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 产业衝击力

- 成长动力

- 采用工业 4.0 和数位孪生计划

- 各行各业对自动化的需求不断成长

- 工业机器人需求不断成长

- 老化基础设施升级

- 电动汽车(EV)产业的兴起

- 成长动力

- 产业陷阱与挑战

- 投资成本高

- 网路安全攻击的威胁

- 监管格局

- 技术格局

- 未来市场趋势

- 差距分析

- 波特的分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 策略仪表板

第五章:市场估计与预测:按类型,2021 年至 2034 年

- 主要趋势

- 模组化的

- 袖珍的

- 机架式

第六章:市场估计与预测:按组件,2021 年至 2034 年

- 主要趋势

- 硬体

- 中央处理器(CPU)

- 记忆体模组

- 输入模组

- 输出模组

- 通讯模组

- 电源单元

- 人机介面(HMI)

- 其他的

- 软体

- 服务

第七章:市场估计与预测:依最终用途,2021 年至 2034 年

- 主要趋势

- 航太和国防

- 汽车

- 化学

- 能源与公用事业

- 食品和饮料

- 卫生保健

- 製造业

- 采矿和金属

- 石油和天然气

- 运输

- 其他的

第八章:市场估计与预测:按地区,2021 年至 2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 西班牙

- 义大利

- 荷兰

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 韩国

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 阿联酋

第九章:公司简介

- ABB

- Bosch Rexroth

- Delta Electronics

- Eaton

- General Electric

- Honeywell International

- Keyence

- Mitsubishi Electric

- Omron

- Panasonic

- Phoenix Contact

- Rockwell Automation

- Schneider Electric

- Siemens

- Yokogawa Electric

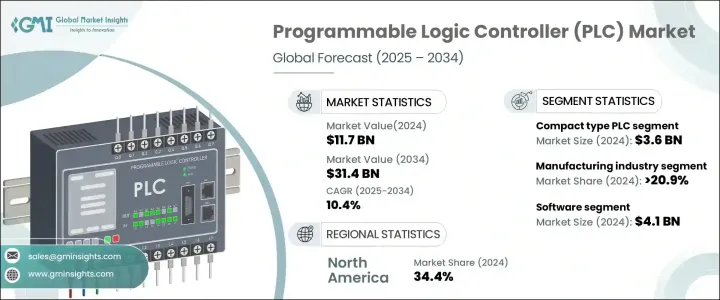

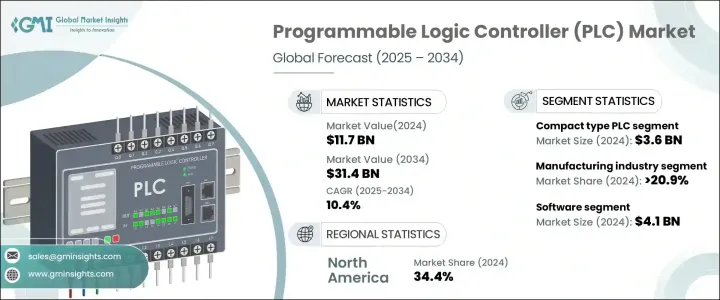

The Global Programmable Logic Controller Market was valued at USD 11.7 billion in 2024 and is projected to grow at a CAGR of 10.4% from 2025 to 2034. The increasing adoption of Industry 4.0, digital twin technology, and automation-driven solutions is fueling market expansion. The rising demand for electric vehicles (EVs) is further accelerating growth, as PLC-based systems play a critical role in automating production lines and optimizing manufacturing efficiency. Automakers rely on PLC-driven solutions to streamline EV production, enhance scalability, and reduce downtime. Additionally, these systems are essential for battery manufacturing and complex assembly processes, ensuring maximum productivity.

Industry 4.0 initiatives, which integrate AI-driven analytics, machine communication, and cloud computing, are driving significant demand for advanced PLCs. These systems facilitate real-time data processing and seamless connectivity, making them indispensable for smart manufacturing. The integration of digital twin technology with PLC-based systems enables manufacturers to create virtual models for testing and optimizing performance without disrupting physical operations. As companies increasingly adopt digital twins for predictive maintenance and efficiency improvements, PLC manufacturers are focusing on developing solutions that align with these advancements. The growing need for intelligent automation across various industries ensures sustained demand for PLCs, positioning them as essential components of modern industrial ecosystems.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $11.7 Billion |

| Forecast Value | $31.4 Billion |

| CAGR | 10.4% |

The market is segmented based on type into modular, compact, and rack-mounted PLCs. Among these, modular PLCs are expected to witness the highest growth, registering a CAGR of 11.1% during the forecast period. These PLCs offer superior scalability and flexibility, making them a preferred choice across industries, including manufacturing, energy, water treatment, and food processing. Their ability to minimize downtime by enabling faulty module replacements without disrupting entire systems drives their widespread adoption.

By end-use, the market is divided into aerospace and defense, automotive, chemicals, energy and utilities, food and beverages, healthcare, manufacturing, mining and metals, oil and gas, and transportation. The manufacturing sector accounted for over 20.9% of the total market share in 2024, driven by the increasing deployment of PLCs in smart factories and automated production lines. Modern PLC systems enhance efficiency through real-time data processing, predictive maintenance, and adaptive automation, making them integral to industrial advancements.

The market is also categorized by component into software, hardware, and services. The software segment accounted for USD 4.1 billion in 2024, driven by rapid Industry 4.0 adoption and IoT integration. Software-based PLCs support real-time monitoring, predictive analytics, and process optimization, helping industries improve efficiency and minimize operational errors. Their role in reducing system downtime and streamlining production processes continues to expand as smart manufacturing gains momentum.

Geographically, North America held a 34.4% share of the global PLC market in 2024, fueled by increased investments in smart infrastructure and automation technologies. The U.S. led the regional market, generating USD 3.1 billion in 2024, and is projected to grow at a CAGR of 10.8%. The expansion of Industry 4.0 initiatives and the rising focus on EV production are key factors driving PLC adoption in the region.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definitions

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Base estimates and calculations

- 1.3.1 Base year calculation

- 1.3.2 Key trends for market estimation

- 1.4 Forecast model

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.5.2 Data mining sources

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Adoption of industry 4.0 and digital twin initiatives

- 3.2.1.2 Growing demand for automation across industries

- 3.2.1.3 Rising demand for Industrial robotics

- 3.2.1.4 Upgradation of aging infrastructure

- 3.2.1.5 The rise of electric vehicles (EV) industry

- 3.2.1 Growth drivers

- 3.3 Industry pitfalls and challenges

- 3.3.1.1 High investment costs

- 3.3.1.2 Threats of cybersecurity attacks

- 3.4 Regulatory landscape

- 3.5 Technology landscape

- 3.6 Future market trends

- 3.7 Gap analysis

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive analysis of major market players

- 4.4 Competitive positioning matrix

- 4.5 Strategy dashboard

Chapter 5 Market Estimates and Forecast, By Type, 2021 – 2034 (USD Bn & Units)

- 5.1 Key trends

- 5.2 Modular

- 5.3 Compact

- 5.4 Rack mounted

Chapter 6 Market Estimates and Forecast, By Component, 2021 – 2034 (USD Bn & Units)

- 6.1 Key trends

- 6.2 Hardware

- 6.2.1 Central Processing Unit (CPU)

- 6.2.2 Memory modules

- 6.2.3 Input modules

- 6.2.4 Output modules

- 6.2.5 Communication modules

- 6.2.6 Power supply unit

- 6.2.7 Human Machine Interface (HMI)

- 6.2.8 Others

- 6.3 Software

- 6.4 Services

Chapter 7 Market Estimates and Forecast, By End Use, 2021 – 2034 (USD Bn & Units)

- 7.1 Key trends

- 7.2 Aerospace & defence

- 7.3 Automotive

- 7.4 Chemical

- 7.5 Energy & utilities

- 7.6 Food & beverages

- 7.7 Healthcare

- 7.8 Manufacturing

- 7.9 Mining & metal

- 7.10 Oil & gas

- 7.11 Transportation

- 7.12 Others

Chapter 8 Market Estimates and Forecast, By Region, 2021 – 2034 (USD Bn & Units)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Netherlands

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

Chapter 9 Company Profiles

- 9.1 ABB

- 9.2 Bosch Rexroth

- 9.3 Delta Electronics

- 9.4 Eaton

- 9.5 General Electric

- 9.6 Honeywell International

- 9.7 Keyence

- 9.8 Mitsubishi Electric

- 9.9 Omron

- 9.10 Panasonic

- 9.11 Phoenix Contact

- 9.12 Rockwell Automation

- 9.13 Schneider Electric

- 9.14 Siemens

- 9.15 Yokogawa Electric