|

市场调查报告书

商品编码

1740926

聚乙烯 (PE) 透明阻隔包装薄膜市场机会、成长动力、产业趋势分析及 2025 - 2034 年预测Polyethylene (PE) Transparent Barrier Packaging Films Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

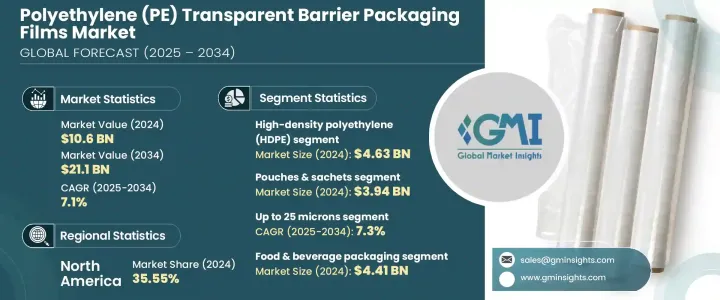

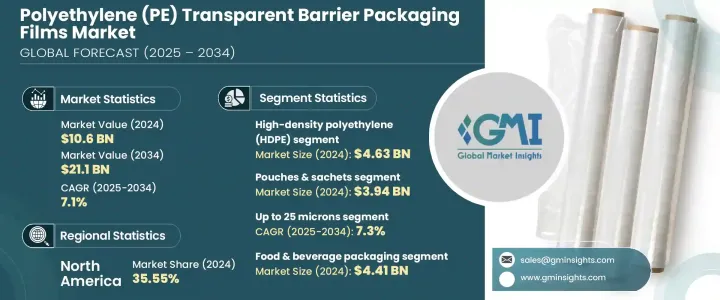

2024年,全球聚乙烯透明阻隔包装薄膜市场规模达106亿美元,预计到2034年将以7.1%的复合年增长率成长,达到211亿美元。这主要得益于对便利耐用包装商品日益增长的需求,这些商品需要高性能的包装解决方案。消费者对可持续、轻盈且经济高效的包装日益增长的偏好,正在加速各行各业向聚乙烯 (PE) 透明阻隔薄膜的转型。随着食品、化妆品和药品行业越来越重视延长保质期和产品完整性,对先进包装解决方案的需求也迅速增长。 PE透明阻隔薄膜能够出色地抵御潮湿、氧气和污染物,同时保持产品的可视性和柔韧性。

与金属和玻璃等传统材料不同,这些薄膜具有显着优势,例如运输成本更低、环境足迹更小、可回收性更高,使其成为前瞻性品牌的首选。此外,全球法规日益严格,提倡使用环保和可回收材料,这正推动各行各业根据循环经济目标创新包装设计。随着永续性继续成为企业议程的主导,製造商越来越注重提供高性能且易于回收的单一材料解决方案。消费者对环境议题的意识日益增强也是一个重要的催化剂,推动市场在预测期内保持强劲的成长轨迹。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 106亿美元 |

| 预测值 | 211亿美元 |

| 复合年增长率 | 7.1% |

市场按类型细分为茂金属聚乙烯 (mPE)、线性低密度聚乙烯 (LLDPE)、低密度聚乙烯 (LDPE) 和高密度聚乙烯 (HDPE)。 2024 年,HDPE 以 46.3 亿美元的市值领先该细分市场。 HDPE 以其卓越的耐用性和卓越的阻隔性而闻名,是包装敏感产品的首选材料,尤其是在食品和製药行业。其优异的化学和氧气阻隔性能使其对于提高食品安全和货架稳定性至关重要。随着市场日益重视永续性,采用共挤 HDPE 薄膜的趋势日益强劲,这种薄膜具有更高的可回收性,并有助于简化材料。

就厚度而言,市场涵盖100微米以上、50-100微米、25-50微米以及高达25微米的薄膜。预计2025年至2034年间,高达25微米的薄膜市场复合年增长率将达7.3%。这些超薄薄膜因其卓越的防潮和防气性能,越来越受到零食、烘焙食品和药品包装的青睐。企业正迅速转向采用这种厚度范围内的单一材料薄膜,以符合严格的环保标准,同时确保成本效益和产品新鲜度。

预计到2034年,德国聚乙烯透明阻隔包装薄膜市场将以惊人的32.77%的复合年增长率扩张,成为成长最快的区域市场之一。这项令人印象深刻的成长得益于德国《包装法》下不断完善的回收法规,该法规推动了单一材料聚乙烯薄膜的广泛应用,从而简化了分类和回收流程。德国在永续工业实践方面的领导地位以及强有力的监管推动力,正在为市场的未来发展奠定基础。

全球聚乙烯透明阻隔包装膜市场的领导企业包括Berry Global Inc.、Jindal Poly Films Ltd.、Sealed Air Corporation和Amcor Plc。这些公司正在大力投资先进製造技术,拓展可回收和可生物降解薄膜产品组合,并建立策略合作伙伴关係以推动创新。他们高度重视开发高性能单材料薄膜,并透过共挤技术优化生产工艺,这有助于他们巩固全球市场地位,同时满足不断变化的监管要求。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 产业衝击力

- 成长动力

- 永续包装需求不断成长

- 严格的环境法规

- 技术进步提高了阻隔性和可回收性

- 食品饮料、化妆品和製药业的采用率不断提高

- 提高对塑胶污染的认识。

- 产业陷阱与挑战

- 与传统塑胶相比,生产成本高且可扩展性有限

- 多层薄膜结构导致回收复杂性

- 成长动力

- 成长潜力分析

- 监管格局

- 技术格局

- 未来市场趋势

- 差距分析

- 波特的分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 策略仪表板

第五章:市场估计与预测:按类型,2021 - 2034 年

- 主要趋势

- 低密度聚乙烯(LDPE)

- 高密度聚乙烯(HDPE)

- 线性低密度聚乙烯(LLDPE)

- 茂金属聚乙烯(mPE)

第六章:市场估计与预测:依包装形式,2021 - 2034 年

- 主要趋势

- 小袋和小袋

- 包装膜和盖膜

- 袋子和内衬

- 收缩膜和伸展膜

- 蛤蜊壳包装和泡罩包装

- 真空和气调包装(MAP)薄膜

第七章:市场估计与预测:按厚度,2021 - 2034 年

- 高达 25 微米

- 25–50微米

- 50–100微米

- 100微米以上

第八章:市场估计与预测:按最终用途产业,2021 - 2034 年

- 主要趋势

- 食品和饮料包装

- 医药和医疗包装

- 个人护理和化妆品包装

- 工业包装

- 电子产品包装

第九章:市场估计与预测:按地区,2021 - 2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 西班牙

- 义大利

- 亚太地区

- 中国

- 印度

- 日本

- 澳新银行

- 韩国

- 拉丁美洲

- 巴西

- 墨西哥

- 中东和非洲

- 阿联酋

- 沙乌地阿拉伯

- 南非

第十章:公司简介

- Amcor Plc

- Arena Products, Inc.

- Berry Global Inc.

- BIO Packaging Films

- Celplast Metallized Products Ltd.

- Cosmo Films Ltd.

- Dai Nippon Printing Co., Ltd.

- DuPont Teijin Films USA

- Glenroy, Inc.

- Innovia Films

- Jindal Poly Films Ltd.

- Mondi Plc

- Plastissimo Film Co.

- ProAmpac

- Schur Flexibles Group

- Sealed Air Corporation

- SUDPACK Verpackungen GmbH & Co. KG

- Toray Plastics (America), Inc.

- UFlex Limited

- Winpak Ltd.

The Global Polyethylene Transparent Barrier Packaging Films Market was valued at USD 10.6 billion in 2024 and is estimated to grow at a CAGR of 7.1% to reach USD 21.1 billion by 2034, driven by the rising demand for convenient, durable packaged goods that require high-performance packaging solutions. Growing consumer preference for sustainable, lightweight, and cost-effective packaging is accelerating the transition toward polyethylene (PE) transparent barrier films across industries. With businesses across food, cosmetics, and pharmaceuticals placing a stronger emphasis on shelf life extension and product integrity, the demand for advanced packaging solutions is rapidly escalating. PE transparent barrier films deliver excellent protection against moisture, oxygen, and contaminants while maintaining product visibility and flexibility.

Unlike traditional materials like metal and glass, these films offer significant advantages such as lower transportation costs, reduced environmental footprint, and better recyclability, making them a top choice for forward-looking brands. In addition, stricter global regulations promoting the use of eco-friendly and recyclable materials are pushing industries to innovate packaging designs in line with circular economy goals. As sustainability continues to dominate corporate agendas, manufacturers are increasingly focused on delivering mono-material solutions that are both high-performing and easily recyclable. The growing awareness among consumers about environmental issues is also a major catalyst, propelling the market's robust growth trajectory through the forecast period.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $10.6 Billion |

| Forecast Value | $21.1 Billion |

| CAGR | 7.1% |

The market is segmented by type into metallocene polyethylene (mPE), linear low-density polyethylene (LLDPE), low-density polyethylene (LDPE), and high-density polyethylene (HDPE). HDPE led the segment in 2024 with a market value of USD 4.63 billion. Known for its excellent durability and superior barrier resistance, HDPE is a preferred material for packaging sensitive products, especially in the food and pharmaceutical sectors. Its chemical and oxygen barrier capabilities make it vital for enhancing food safety and shelf stability. As the market leans heavily toward sustainability, the trend of adopting co-extruded HDPE films is gaining momentum, offering better recyclability and supporting material simplification efforts.

In terms of thickness, the market includes above 100 microns, 50-100 microns, 25-50 microns, and up to 25 microns. The up to 25 microns category is projected to grow at a CAGR of 7.3% from 2025 to 2034. These ultra-thin films are increasingly favored for packaging snacks, baked goods, and pharmaceuticals due to their exceptional moisture and gas barrier properties. Companies are rapidly moving toward adopting mono-material films in this thickness range to align with strict environmental standards while ensuring cost-effectiveness and product freshness.

Germany's Polyethylene Transparent Barrier Packaging Films Market is projected to expand at a staggering CAGR of 32.77% by 2034, emerging as one of the fastest-growing regional markets. This impressive growth is fueled by the country's progressive recycling laws under the German Packaging Act, driving widespread adoption of mono-material polyethylene films that simplify sorting and recycling. Germany's leadership in sustainable industrial practices and strong regulatory push is setting the pace for the market's future.

Leading players in the Global Polyethylene Transparent Barrier Packaging Films Market include Berry Global Inc., Jindal Poly Films Ltd., Sealed Air Corporation, and Amcor Plc. These companies are investing heavily in advanced manufacturing technologies, expanding their portfolios with recyclable and biodegradable films, and forming strategic partnerships to drive innovation. A sharp focus on developing high-performance mono-material films and optimizing production processes through co-extrusion techniques is helping them strengthen global market positions while meeting evolving regulatory demands.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definitions

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Base estimates and calculations

- 1.3.1 Base year calculation

- 1.3.2 Key trends for market estimation

- 1.4 Forecast model

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.5.2 Data mining sources

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Rising demand for sustainable packaging

- 3.2.1.2 Stringent environmental regulations

- 3.2.1.3 Technological advancements improving barrier properties and recyclability

- 3.2.1.4 Increasing adoption of food & beverage, cosmetics, and pharmaceutical industries

- 3.2.1.5 Increasing awareness of plastic pollution.

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High production costs & limited scalability compared to traditional plastics

- 3.2.2.2 Recycling complexities due to multilayer film structures

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.5 Technology landscape

- 3.6 Future market trends

- 3.7 Gap analysis

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive analysis of major market players

- 4.4 Competitive positioning matrix

- 4.5 Strategy dashboard

Chapter 5 Market Estimates and Forecast, By Type, 2021 - 2034 ($ Mn & Kilo Tons)

- 5.1 Key trends

- 5.2 Low-density polyethylene (LDPE)

- 5.3 High-density polyethylene (HDPE)

- 5.4 Linear low-density polyethylene (LLDPE)

- 5.5 Metallocene polyethylene (mPE)

Chapter 6 Market Estimates and Forecast, By Packaging Format, 2021 - 2034 ($ Mn & Kilo Tons)

- 6.1 Key trends

- 6.2 Pouches & sachets

- 6.3 Wraps & lidding films

- 6.4 Bags & liners

- 6.5 Shrink & stretch films

- 6.6 Clamshells & blister packs

- 6.7 Vacuum & modified atmosphere packaging (MAP) films

Chapter 7 Market Estimates and Forecast, By Thickness, 2021 - 2034 ($ Mn & Kilo Tons)

- 7.1 Up to 25 microns

- 7.2 25–50 microns

- 7.3 50–100 microns

- 7.4 Above 100 microns

Chapter 8 Market Estimates and Forecast, By End Use Industry, 2021 - 2034 ($ Mn & Kilo Tons)

- 8.1 Key trends

- 8.2 Food & beverage packaging

- 8.3 Pharmaceutical & medical packaging

- 8.4 Personal care & cosmetics packaging

- 8.5 Industrial packaging

- 8.6 Electronics packaging

Chapter 9 Market Estimates and Forecast, By Region, 2021 - 2034 ($ Mn & Kilo Tons)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 UK

- 9.3.2 Germany

- 9.3.3 France

- 9.3.4 Spain

- 9.3.5 Italy

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 ANZ

- 9.4.5 South Korea

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.6 Middle East and Africa

- 9.6.1 UAE

- 9.6.2 Saudi Arabia

- 9.6.3 South Africa

Chapter 10 Company Profiles

- 10.1 Amcor Plc

- 10.2 Arena Products, Inc.

- 10.3 Berry Global Inc.

- 10.4 BIO Packaging Films

- 10.5 Celplast Metallized Products Ltd.

- 10.6 Cosmo Films Ltd.

- 10.7 Dai Nippon Printing Co., Ltd.

- 10.8 DuPont Teijin Films USA

- 10.9 Glenroy, Inc.

- 10.10 Innovia Films

- 10.11 Jindal Poly Films Ltd.

- 10.12 Mondi Plc

- 10.13 Plastissimo Film Co.

- 10.14 ProAmpac

- 10.15 Schur Flexibles Group

- 10.16 Sealed Air Corporation

- 10.17 SUDPACK Verpackungen GmbH & Co. KG

- 10.18 Toray Plastics (America), Inc.

- 10.19 UFlex Limited

- 10.20 Winpak Ltd.