|

市场调查报告书

商品编码

1750573

冷凝火管食品加工锅炉市场机会、成长动力、产业趋势分析及 2025 - 2034 年预测Condensing Fire-Tube Food Processing Boiler Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

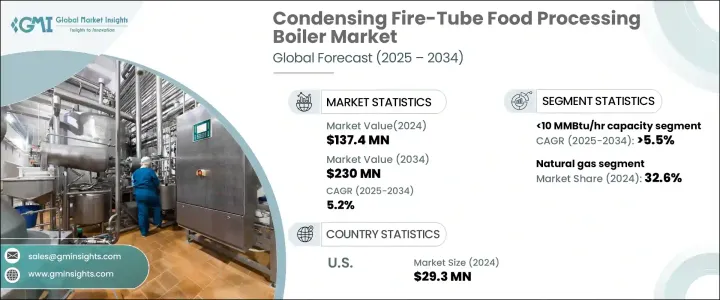

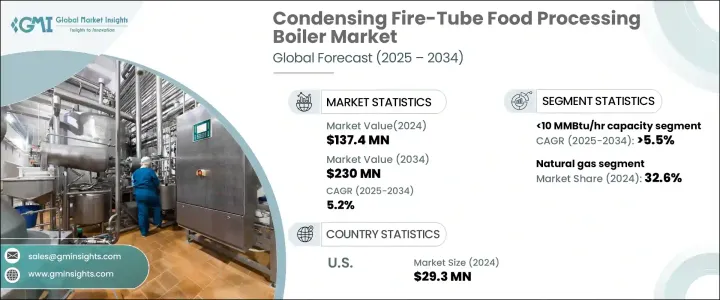

2024年,全球冷凝火管食品加工锅炉市场规模达1.374亿美元,预计到2034年将以5.2%的复合年增长率增长,达到2.3亿美元,这得益于对可持续供热技术日益增长的关注以及工业基础设施的现代化。随着对排放问题的日益关注以及对更清洁、更节能係统的需求,食品加工设施正纷纷采用高效的冷凝火管锅炉。这些系统的设计旨在优化能源利用,同时提供稳定的热输出,符合不断发展的环境规范和节能目标。

更严格的监管框架鼓励更换或升级老化的锅炉系统,进一步推动了市场的发展。这些法规促使製造商和工厂运营商投资于既合规又注重性能的先进加热装置。对可靠、连续的蒸汽生产(食品製造业的关键组成部分)的需求不断增长,也推动了对现代锅炉技术的需求。此外,随着工业设施的扩张和现代化,尤其是在城市和半城市地区,对紧凑、经济高效且节能的解决方案的需求日益增长——而冷凝火管锅炉正是满足这些需求的理想之选。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 1.374亿美元 |

| 预测值 | 2.3亿美元 |

| 复合年增长率 | 5.2% |

控制系统、远端监控和数位整合方面的创新在提高营运效率和最大程度减少停机时间方面发挥着至关重要的作用。智慧技术的融入使操作员能够即时追踪效能,快速识别问题并优化能耗。这些进步使冷凝火管锅炉成为那些希望在保持高生产力的同时减少碳足迹的企业的理想选择。

就容量而言,预计到2034年,容量为10 MMBtu/小时的冷凝火管食品加工锅炉的复合年增长率将超过5.5%。其占地面积小、安装简单、运作效率高,是老式非冷凝锅炉的理想替代品。它们能够提供可靠且稳定的性能,且不占用太多空间,这对于希望在不进行大规模空间重新配置的情况下进行升级的食品加工设施尤其具有吸引力。

按燃料类型细分,市场包括天然气、石油、煤炭和其他能源。 2024年,天然气燃料市场占总市占率的32.6%。由于其卓越的能源效率、更清洁的燃烧以及与再生能源的兼容性,预计未来几年该市场将显着增长。全球日益重视减少对煤炭和石油的依赖,这也推动了向天然气的转变,因为煤炭和石油的排放足迹都较高。

在美国,冷凝式火管食品加工锅炉市场近年来持续成长。 2022年,该市场规模达2,610万美元,2023年攀升至2,760万美元,2024年进一步升至2,930万美元。这一成长动能主要归功于一系列政策驱动的倡议,这些倡议旨在推动采用清洁技术和节能解决方案。联邦和州级计画持续鼓励安装高效设备,这进一步增强了食品生产企业对现代冷凝锅炉系统的需求。

预计到2034年,北美地区的市场复合年增长率将超过4.7%。气候变迁意识的增强,加上该地区对减少温室气体排放的坚定承诺,正在推动节能锅炉技术的广泛应用。食品加工产业尤其重视营运成本的节约和环保标准的合规性,而这两者恰好与冷凝火管锅炉的优势相契合。

市场格局略有巩固,前五名製造商合计占全球约40%的份额。这些关键参与者正专注于产品创新、策略伙伴关係和地理扩张,以在竞争激烈的环境中巩固立足点。随着食品加工领域对永续加热解决方案的需求持续增长,这些市场领导者在塑造未来趋势方面的作用将日益重要。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 川普政府关税分析

- 对贸易的影响

- 贸易量中断

- 报復措施

- 对产业的影响

- 供应方影响(原料)

- 主要材料价格波动

- 供应链重组

- 生产成本影响

- 需求面影响(售价)

- 价格传导至终端市场

- 市占率动态

- 消费者反应模式

- 供应方影响(原料)

- 受影响的主要公司

- 策略产业反应

- 供应链重组

- 定价和产品策略

- 政策参与

- 展望与未来考虑

- 对贸易的影响

- 监管格局

- 产业衝击力

- 成长动力

- 产业陷阱与挑战

- 成长潜力分析

- 波特的分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 战略仪表板

- 策略倡议

- 竞争基准测试

- 创新与永续发展格局

第五章:市场规模及预测:依产能,2021 - 2034 年

- 主要趋势

- < 10 百万英热单位/小时

- 10 - 25 百万英热单位/小时

- 25 - 50 百万英热单位/小时

- 50 - 75 百万英热单位/小时

- 75 - 100 百万英热单位/小时

- 100 - 175 百万英热单位/小时

- 175 - 250 百万英热单位/小时

- > 250 百万英热单位/小时

第六章:市场规模及预测:依燃料,2021 - 2034 年

- 主要趋势

- 天然气

- 油

- 煤炭

- 其他的

第七章:市场规模及预测:依地区,2021 - 2034

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 墨西哥

- 欧洲

- 英国

- 法国

- 德国

- 义大利

- 俄罗斯

- 西班牙

- 亚太地区

- 中国

- 澳洲

- 印度

- 日本

- 韩国

- 中东和非洲

- 沙乌地阿拉伯

- 阿联酋

- 土耳其

- 南非

- 埃及

- 拉丁美洲

- 巴西

- 阿根廷

第八章:公司简介

- Babcock and Wilcox

- Babcock Wanson

- BM GreenTech

- Bosch Industriekessel

- Clayton Industries

- Cleaver-Brooks

- Cochran

- Forbes Marshall

- Fulton

- Hoval

- Hurst Boiler

- Johnston Boiler

- Miura America

- Thermax

- Thermodyne Boilers

- Viessmann

The Global Condensing Fire-Tube Food Processing Boiler Market was valued at USD 137.4 million in 2024 and is estimated to grow at a CAGR of 5.2% to reach USD 230 million by 2034, driven by the increasing focus on sustainable heating technologies and the modernization of industrial infrastructure. Growing concerns over emissions and the need for cleaner, more energy-efficient systems are leading food processing facilities to adopt high-efficiency condensing fire-tube boilers. These systems are engineered to optimize energy use while delivering consistent thermal output, aligning with evolving environmental norms and energy conservation goals.

The market is further propelled by stricter regulatory frameworks that encourage the replacement or enhancement of aging boiler systems. These regulations are pushing manufacturers and plant operators to invest in advanced heating units that are both compliant and performance-focused. The rising demand for reliable and continuous steam production, a critical component in food manufacturing, is also fueling the demand for modern boiler technologies. In addition, as industrial setups expand and modernize, particularly in urban and semi-urban regions, there is a growing need for compact, cost-effective, and energy-saving solutions-needs that condensing fire-tube boilers are well-positioned to meet.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $137.4 Million |

| Forecast Value | $230 Million |

| CAGR | 5.2% |

Innovations in control systems, remote monitoring, and digital integration are playing a crucial role in enhancing operational efficiency and minimizing downtime. The incorporation of smart technologies allows operators to track performance in real time, identify issues quickly, and optimize energy consumption. These advancements are making condensing fire-tube boilers an attractive option for businesses aiming to reduce their carbon footprint while maintaining high productivity levels.

In terms of capacity, condensing fire-tube food processing boilers with a 10 MMBtu/hr capacity are anticipated to grow at a CAGR exceeding 5.5% by 2034. Their compact footprint, ease of installation, and high operational efficiency make them an ideal replacement for older, non-condensing units. Their ability to deliver reliable and consistent performance without occupying much space is particularly appealing to food processing facilities looking to upgrade without major spatial reconfigurations.

When segmented by fuel type, the market includes natural gas, oil, coal, and others. In 2024, the natural gas-fired segment accounted for 32.6% of the total market share. This segment is expected to witness significant growth over the coming years due to its superior energy efficiency, cleaner combustion, and compatibility with renewable energy sources. The shift toward natural gas is also supported by the rising global focus on reducing dependence on coal and oil, both of which have higher emission footprints.

In the United States, the condensing fire-tube food processing boiler market has shown consistent growth in recent years. It reached USD 26.1 million in 2022, climbed to USD 27.6 million in 2023, and further rose to USD 29.3 million in 2024. This upward trajectory is largely attributed to policy-driven initiatives promoting the adoption of cleaner technologies and energy-saving solutions. Federal and state-level programs continue to incentivize the installation of high-efficiency equipment, reinforcing the demand for modern condensing boiler systems across food manufacturing units.

Across the broader North American region, the market is set to grow at a CAGR of more than 4.7% through 2034. Factors such as growing awareness of climate change, coupled with strong regional commitments to reducing greenhouse gas emissions, are supporting the widespread implementation of energy-efficient boiler technologies. The food processing industry, in particular, is prioritizing operational cost savings and compliance with environmental standards, both of which align with the benefits offered by condensing fire-tube boilers.

The market landscape is moderately consolidated, with the top five manufacturers collectively holding around 40% of the global share. These key players are focusing on product innovation, strategic partnerships, and geographic expansion to strengthen their foothold in a highly competitive environment. As demand for sustainable heating solutions in food processing continues to rise, the role of these market leaders in shaping future trends will become increasingly significant.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.2 Market estimates & forecast parameters

- 1.3 Forecast calculation

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid

- 1.4.2.2 Public

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Trump administration tariffs analysis

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.2.1.1 Price volatility in key materials

- 3.2.2.1.2 Supply chain restructuring

- 3.2.2.1.3 Production cost implications

- 3.2.2.2 Demand-side impact (selling price)

- 3.2.2.2.1 Price transmission to end markets

- 3.2.2.2.2 Market share dynamics

- 3.2.2.2.3 Consumer response patterns

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Regulatory landscape

- 3.4 Industry impact forces

- 3.4.1 Growth drivers

- 3.4.2 Industry pitfalls & challenges

- 3.5 Growth potential analysis

- 3.6 Porter's analysis

- 3.6.1 Bargaining power of suppliers

- 3.6.2 Bargaining power of buyers

- 3.6.3 Threat of new entrants

- 3.6.4 Threat of substitutes

- 3.7 PESTEL analysis

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis, 2024

- 4.3 Strategic dashboard

- 4.4 Strategic initiatives

- 4.5 Competitive benchmarking

- 4.6 Innovation & sustainability landscape

Chapter 5 Market Size and Forecast, By Capacity, 2021 - 2034 (USD Million, MMBTU/hr & Units)

- 5.1 Key trends

- 5.2 < 10 MMBtu/hr

- 5.3 10 - 25 MMBtu/hr

- 5.4 25 - 50 MMBtu/hr

- 5.5 50 - 75 MMBtu/hr

- 5.6 75 - 100 MMBtu/hr

- 5.7 100 - 175 MMBtu/hr

- 5.8 175 - 250 MMBtu/hr

- 5.9 > 250 MMBtu/hr

Chapter 6 Market Size and Forecast, By Fuel, 2021 - 2034 (USD Million, MMBTU/hr & Units)

- 6.1 Key trends

- 6.2 Natural gas

- 6.3 Oil

- 6.4 Coal

- 6.5 Others

Chapter 7 Market Size and Forecast, By Region, 2021 - 2034 (USD Million, MMBTU/hr & Units)

- 7.1 Key trends

- 7.2 North America

- 7.2.1 U.S.

- 7.2.2 Canada

- 7.2.3 Mexico

- 7.3 Europe

- 7.3.1 UK

- 7.3.2 France

- 7.3.3 Germany

- 7.3.4 Italy

- 7.3.5 Russia

- 7.3.6 Spain

- 7.4 Asia Pacific

- 7.4.1 China

- 7.4.2 Australia

- 7.4.3 India

- 7.4.4 Japan

- 7.4.5 South Korea

- 7.5 Middle East & Africa

- 7.5.1 Saudi Arabia

- 7.5.2 UAE

- 7.5.3 Turkey

- 7.5.4 South Africa

- 7.5.5 Egypt

- 7.6 Latin America

- 7.6.1 Brazil

- 7.6.2 Argentina

Chapter 8 Company Profiles

- 8.1 Babcock and Wilcox

- 8.2 Babcock Wanson

- 8.3 BM GreenTech

- 8.4 Bosch Industriekessel

- 8.5 Clayton Industries

- 8.6 Cleaver-Brooks

- 8.7 Cochran

- 8.8 Forbes Marshall

- 8.9 Fulton

- 8.10 Hoval

- 8.11 Hurst Boiler

- 8.12 Johnston Boiler

- 8.13 Miura America

- 8.14 Thermax

- 8.15 Thermodyne Boilers

- 8.16 Viessmann