|

市场调查报告书

商品编码

1833622

半导体管材及配件市场机会、成长动力、产业趋势分析及 2025 - 2034 年预测Semiconductor Tubing and Fittings Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

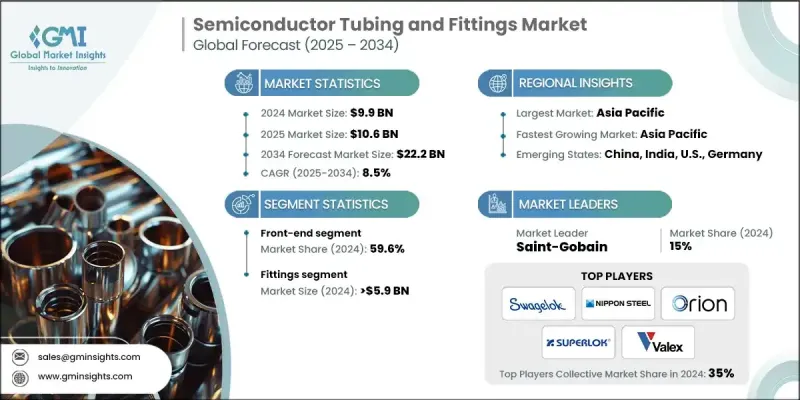

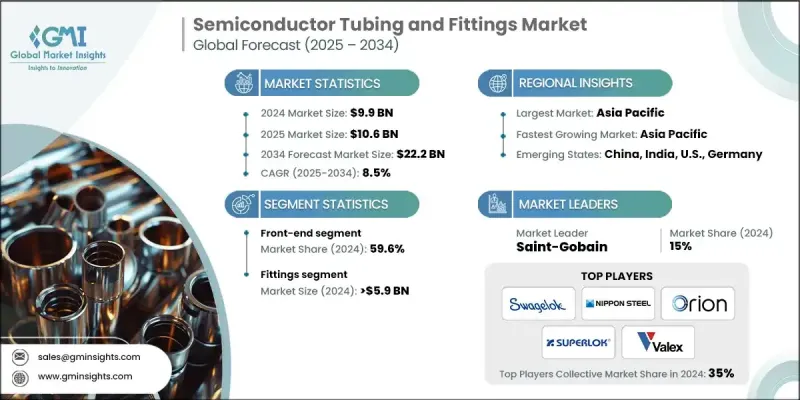

根据 Global Market Insights Inc. 发布的最新报告,全球半导体管道和配件市场规模在 2024 年估计为 99 亿美元,预计将从 2025 年的 106 亿美元增长到 2034 年的 222 亿美元,复合年增长率为 8.5%。

半导体製程使用腐蚀性化学品和特殊气体,必须安全、清洁地输送。这增加了对耐化学腐蚀、高纯度管道和配件的需求,例如由 PFA、PTFE 和 PVDF 製成的管道和配件。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 99亿美元 |

| 预测值 | 222亿美元 |

| 复合年增长率 | 8.5% |

前端半导体的采用率不断上升

2024年,前端市场将占据显着份额,这主要得益于晶圆製造工艺,因为工艺对纯度和精度的要求至关重要。此阶段涉及复杂的化学品输送系统,需要超洁净管道和耐腐蚀配件来维持製程的完整性。随着晶圆厂在极端的污染控制标准下运营,对前端流体处理组件的需求持续激增,尤其是在晶片製造商向更小节点和更复杂架构转型的情况下。

配件获得青睐

2024年,配件业务板块创造了可观的收入,因为即使是最轻微的洩漏或材料劣化,也可能危及整个半导体生产流程。配件需要能够耐受腐蚀性化学物质,在不同压力下保持防漏连接,并保持长期稳定性。市场对由高纯度金属和工程塑胶製成的精密工程、可焊接和快速连接的配件的需求日益增长。

亚太地区将成为利润丰厚的地区

2024年,亚太地区半导体管材及配件市场占有相当大的份额。台湾、韩国、中国大陆和日本等国家和地区拥有多家领先的晶圆代工厂和整合设备製造商 (IDM),对高纯度流体处理系统的需求庞大。政府支持的晶片製造投资以及本地和全球企业积极的产能扩张,正在推动对超级净管材及配件的需求。晶圆产量的提升、新晶圆厂的建设以及原始设备製造商 (OEM) 和零件供应商之间的战略合作伙伴关係,共同推动着市场的成长。

半导体管道和配件市场的主要参与者有 Rensa Tubes、Swagelok、Advance Fittings Corp、FITOK Group Co Ltd、Ihara Science Corporation、Valex Corp、Orion、FUJIKIN、Masterflex Group、Superlok、Dibert Valve & Fitting Co Inc、Saint-Gobain、APT、Superlok、Dibert Valve & Fitting Covanus、Saint-Gobain、APT、Nippon Corptics 和 HerNvanus Covanus Covanus。

为了巩固在半导体管材和配件市场的立足点,各公司正在采取创新、合作和区域扩张等一系列策略。领先的企业正在大力投资研发,以开发具有更强耐化学性、温度稳定性和零颗粒产生的下一代材料。许多企业也在关键客户所在地附近建造或扩大无尘室製造设施,以缩短交货时间并提高服务响应能力。与半导体原始设备製造商 (OEM) 和晶圆厂设备製造商的策略合作,使管材和配件供应商能够更无缝地融入系统级设计。此外,企业正在寻求併购,以多元化产品组合併进入新的区域市场,尤其是在半导体投资激增的亚洲和北美。这些积极主动的策略有助于企业在技术含量高且对品质要求高的市场中脱颖而出。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 供应商格局

- 利润率

- 每个阶段的增值

- 影响价值链的因素

- 产业衝击力

- 成长动力

- 半导体产业的成长

- 技术进步

- 增加研发活动

- 产业陷阱与挑战

- 专用材料成本高

- 製造和品质控制的复杂性

- 机会

- 先进材料的开发

- 客製化和模组化解决方案

- 成长动力

- 成长潜力分析

- 未来市场趋势

- 技术和创新格局

- 当前的技术趋势

- 新兴技术

- 价格趋势

- 按地区

- 依产品类型

- 监管格局

- 标准和合规性要求

- 区域监理框架

- 认证标准

- 波特的分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 按地区

- 公司矩阵分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 关键进展

- 併购

- 伙伴关係与合作

- 新产品发布

- 扩张计划

第五章:市场估计与预测:依产品类型,2021 - 2034 年

- 主要趋势

- 管道

- 金属管

- 氟聚合物管

- 石英管

- 复合管

- 特种聚合物管

- 配件

- 压缩配件

- 喇叭口配件

- 面密封配件

- 焊接配件

- 超高纯度(UHP)配件

- 快速连接配件

- 螺纹配件

- 其他的

第六章:市场估计与预测:按工艺,2021 - 2034 年

- 主要趋势

- 前端

- 后端

第七章:市场估计与预测:按设备类型,2021 - 2034 年

- 主要趋势

- 半导体设计

- 掩模版/光罩製造

- 晶圆製造/加工

- 表面处理

- 组装和包装

- 测试/检验

- 製造工厂

- 热处理

- 沉积

- 其他的

第 8 章:市场估计与预测:按配销通路,2021 年至 2034 年

- 主要趋势

- 直销

- 间接销售

第九章:市场估计与预测:按地区,2021 - 2034

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 亚太地区

- 中国

- 日本

- 印度

- 澳洲

- 韩国

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 中东和非洲

- 南非

- 沙乌地阿拉伯

- 阿联酋

第十章:公司简介

- Advance Fittings Corp

- APT

- Dibert Valve & Fitting Co Inc

- FITOK Group Co Ltd

- FUJIKIN

- Heraeus Covantics

- Ihara Science Corporation

- Masterflex Group

- Nippon Steel Corp

- Orion

- Rensa Tubes

- Saint-Gobain

- Superlok

- Swagelok

- Valex Corp

The global semiconductor tubing and fittings market was estimated at USD 9.9 billion in 2024 and is expected to grow from USD 10.6 billion in 2025 to USD 22.2 billion by 2034, at a CAGR of 8.5%, according to the latest report published by Global Market Insights Inc.

Semiconductor processes use aggressive chemicals and specialty gases that must be transported safely and cleanly. This increases demand for chemically resistant and high-purity tubing and fittings, such as those made from PFA, PTFE, and PVDF.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $9.9 Billion |

| Forecast Value | $22.2 Billion |

| CAGR | 8.5% |

Rising Adoption of Front-End Semiconductor

The front-end segment held a significant share in 2024, driven by wafer fabrication processes, where purity and precision are non-negotiable. This stage involves complex chemical delivery systems that require ultra-clean tubing and corrosion-resistant fittings to maintain process integrity. With fabs operating under extreme contamination control standards, demand for front-end fluid handling components continues to surge, particularly as chipmakers transition to smaller nodes and more complex architectures.

Fittings to Gain Traction

The fittings segment generated substantial revenues in 2024, as even the slightest leakage or material degradation can compromise the entire semiconductor production process. Fittings are expected to withstand aggressive chemicals, maintain leak-proof connections under varying pressures, and remain stable over time. The market is witnessing a growing preference for precision-engineered, weldable, and quick-connect fittings made from high-purity metals and engineered plastics.

Asia Pacific to Emerge as a Lucrative Region

Asia Pacific semiconductor tubing and fittings market held a sizeable share in 2024. Countries like Taiwan, South Korea, China, and Japan are home to several leading foundries and integrated device manufacturers (IDMs), demanding high-purity fluid handling systems. Government-backed investments in chip fabrication and aggressive capacity expansions by local and global players are fueling the need for ultra-clean tubing and fittings. The market growth is driven by rising wafer production, the construction of new fabs, and strategic partnerships between OEMs and component suppliers.

Major players in the semiconductor tubing and fittings market are Rensa Tubes, Swagelok, Advance Fittings Corp, FITOK Group Co Ltd, Ihara Science Corporation, Valex Corp, Orion, FUJIKIN, Masterflex Group, Superlok, Dibert Valve & Fitting Co Inc, Saint-Gobain, APT, Nippon Steel Corp, Heraeus Covantics.

To strengthen their foothold in the semiconductor tubing and fittings market, companies are adopting a mix of innovation, partnerships, and regional expansion strategies. Leading players are heavily investing in R&D to develop next-generation materials that offer enhanced chemical resistance, temperature stability, and zero particle generation. Many are also building or expanding cleanroom manufacturing facilities near key customer locations to shorten lead times and improve service responsiveness. Strategic collaborations with semiconductor OEMs and fab equipment manufacturers allow tubing and fittings suppliers to integrate more seamlessly into system-level designs. Additionally, businesses are pursuing mergers and acquisitions to diversify product portfolios and enter new regional markets, particularly in Asia and North America, where semiconductor investment is surging. These proactive strategies help firms differentiate themselves in a highly technical and quality-sensitive market.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Product type

- 2.2.3 Process

- 2.2.4 Equipment type

- 2.2.5 Distribution channel

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Growth of the semiconductor industry

- 3.2.1.2 Technological advancements

- 3.2.1.3 Increase in R&D activities

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High cost of specialized materials

- 3.2.2.2 Complexity of manufacturing and quality control

- 3.2.3 Opportunities

- 3.2.3.1 Development of advanced materials

- 3.2.3.2 Customization and modular solutions

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By product type

- 3.7 Regulatory landscape

- 3.7.1 Standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.7.3 Certification standards

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East and Africa

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Product Type, 2021 - 2034 (USD Billion) (Thousand Units)

- 5.1 Key trends

- 5.2 Tubing

- 5.2.1 Metal tubing

- 5.2.2 Fluoropolymer tubing

- 5.2.3 Quartz tubing

- 5.2.4 Composite tubing

- 5.2.5 Specialty polymer tubing

- 5.3 Fittings

- 5.3.1 Compression fittings

- 5.3.2 Flare fittings

- 5.3.3 Face seal fittings

- 5.3.4 Weld fittings

- 5.3.5 Ultra-high purity (UHP) fittings

- 5.3.6 Quick-connect fittings

- 5.3.7 Threaded fittings

- 5.3.8 Others

Chapter 6 Market Estimates and Forecast, By Process, 2021 - 2034 (USD Billion) (Thousand Units)

- 6.1 Key trends

- 6.2 Front-end

- 6.3 Back-end

Chapter 7 Market Estimates and Forecast, By Equipment Type, 2021 - 2034 (USD Billion) (Thousand Units)

- 7.1 Key trends

- 7.2 Semiconductor design

- 7.3 Mask/Reticle manufacturing

- 7.4 Wafer manufacturing/processing

- 7.5 Surface conditioning

- 7.6 Assembly & packaging

- 7.7 Test/Inspection

- 7.8 Fabrication facility

- 7.9 Thermal processing

- 7.10 Deposition

- 7.11 Others

Chapter 8 Market Estimates and Forecast, By Distribution Channel, 2021 - 2034 (USD Billion) (Thousand Units)

- 8.1 Key trends

- 8.2 Direct sales

- 8.3 Indirect sales

Chapter 9 Market Estimates and Forecast, By Region, 2021 - 2034 (USD Billion) (Thousand Units)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 Germany

- 9.3.2 UK

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 Japan

- 9.4.3 India

- 9.4.4 Australia

- 9.4.5 South Korea

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.6 Middle East and Africa

- 9.6.1 South Africa

- 9.6.2 Saudi Arabia

- 9.6.3 UAE

Chapter 10 Company Profiles

- 10.1 Advance Fittings Corp

- 10.2 APT

- 10.3 Dibert Valve & Fitting Co Inc

- 10.4 FITOK Group Co Ltd

- 10.5 FUJIKIN

- 10.6 Heraeus Covantics

- 10.7 Ihara Science Corporation

- 10.8 Masterflex Group

- 10.9 Nippon Steel Corp

- 10.10 Orion

- 10.11 Rensa Tubes

- 10.12 Saint-Gobain

- 10.13 Superlok

- 10.14 Swagelok

- 10.15 Valex Corp