|

市场调查报告书

商品编码

1871103

油气蒸气回收装置市场机会、成长驱动因素、产业趋势分析及预测(2025-2034年)Oil and Gas Vapor Recovery Units Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

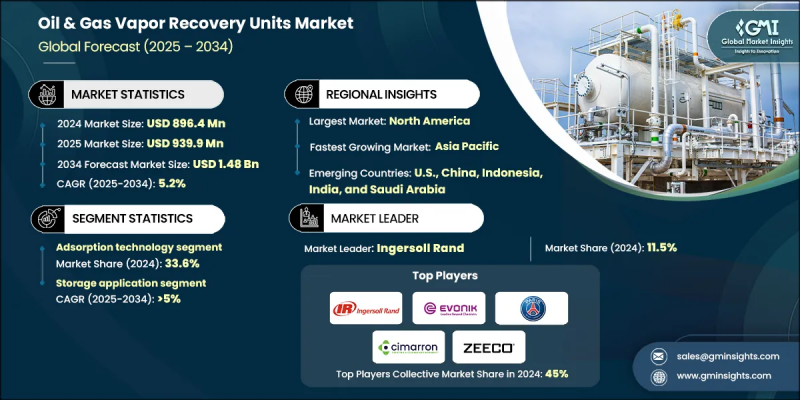

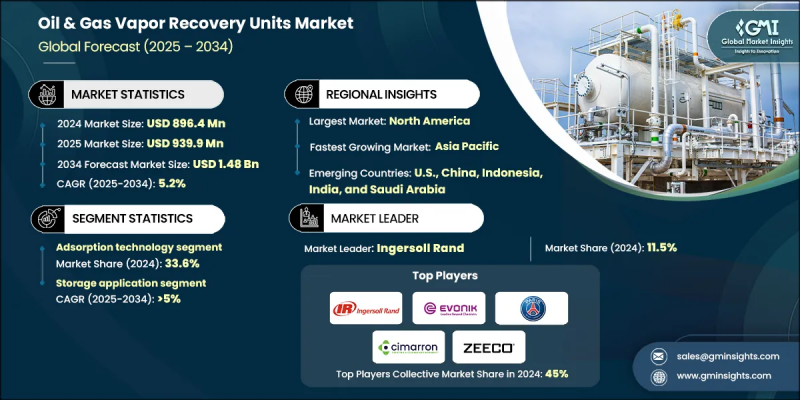

2024 年全球油气蒸气回收装置市值为 8.964 亿美元,预计到 2034 年将以 5.2% 的复合年增长率成长至 14.8 亿美元。

随着主要产油区日益严格的环保政策促使上游和下游业者采用油气回收装置(VRU)来减少挥发性有机化合物(VOC)的排放,市场需求正在不断增长。这些系统旨在捕获和回收原油和成品油等挥发性液体在储存、处理和加工过程中释放的碳氢化合物蒸气。炼油厂、码头和燃料储存场所对VRU的日益增长的需求反映了其在减少空气污染和回收宝贵碳氢化合物方面的双重优势,使其成为可持续油田作业的关键组成部分。发展中国家原油和燃料储存能力的扩张进一步推动了需求,而全球限制甲烷排放的倡议也推动了油井平台和压缩站对VRU的应用。分散式控制系统(DCS)和基于SCADA的自动化等智慧技术的集成,实现了即时监控、预测性维护和更高的性能可视性,使营运商能够提高效率并确保符合环保法规。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 8.964亿美元 |

| 预测值 | 14.8亿美元 |

| 复合年增长率 | 5.2% |

2024年,吸附技术市占率达到33.6%,预计2034年将以5%的复合年增长率成长。新一代吸附剂材料(包括高比表面积复合材料)的引入,正在提高严苛现场条件下的油气回收性能。向低维护和可再生吸附系统的转变,尤其有利于需要持续回收作业和可靠排放控制的上游和中游设施。

从2025年到2034年,储能应用领域将以5%的复合年增长率成长。对储槽作业中苯和挥发性有机化合物(VOCs)排放的日益严格审查,推动了储槽设施中蒸汽回收装置(VRU)的部署。在大型储槽区整合双级蒸汽回收系统,显着提高了碳氢化合物的回收效率,帮助营运商在满足严格排放标准的同时,最大限度地减少产品损失。

北美油气蒸气回收装置市场预计到2034年将以4.5%的复合年增长率成长。区域中游业者正越来越多地利用蒸汽回收装置来管理凝析油稳定和天然气加工活动中的蒸汽排放,从而提高营运的可持续性。联邦政府旨在减少甲烷排放的气候倡议进一步推动了上游生产商广泛采用该技术。对环境、社会和治理(ESG)目标的日益重视,正促使能源公司投资于先进的回收解决方案併升级现有基础设施,以满足不断变化的可持续发展标准。

油气蒸气回收装置市场的主要企业包括ALMA集团、Cimarron Energy、BORSIG、Cool Sorption、Ingersoll Rand、Flogistix、KAPPA GI、Koch Engineered Solutions、Kilburn Engineering、LeROI、Evonik、PETROGAS、PSG、SCS Technologies、Reynold India、SYMEX Technologies、Svonik、Tcam、SA&Vt、Reynold India、SYMEX Technologies、SA&Vt、St、Scoii、Scoon、Scoco,alcocon、BageBM、SG、Scoii、Scoon、Scoco,alcocon。为了巩固市场地位,油气蒸汽回收装置市场的企业正采取以创新、合作和全球扩张为核心的多角化成长策略。许多企业正在投资先进的排放控制技术和模组化蒸汽回收装置设计,以实现灵活部署于各种不同的运作环境。此外,各企业也与油田营运商和EPC承包商合作,提供符合国际环境标准的统包回收解决方案。策略联盟和併购正在增强全球分销能力,而透过物联网监控系统实现的数位整合则正在提高效率和可靠性。

目录

第一章:方法论与范围

第二章:执行概要

第三章:行业洞察

- 产业生态系分析

- 原物料供应及采购分析

- 製造能力评估

- 供应链韧性与风险因素

- 配电网路分析

- 监管环境

- 产业影响因素

- 成长驱动因素

- 产业陷阱与挑战

- 成长潜力分析

- 波特的分析

- PESTEL 分析

- 蒸汽回收装置的成本结构分析

- 新兴机会与趋势

- 数位化和物联网集成

- 投资分析及未来展望

第四章:竞争格局

- 介绍

- 按地区分類的公司市占率分析

- 北美洲

- 欧洲

- 亚太地区

- 中东和非洲

- 拉丁美洲

- 战略仪錶板

- Key partnerships & collaborations

- Major M&A activities

- Product innovations & launches

- Market expansion strategies

- 策略倡议

- 竞争性标竿分析

- 创新与技术格局

第五章:市场规模及预测:依技术划分,2021-2034年

- 主要趋势

- 缩合

- 吸附

- 吸收

- 压缩

第六章:市场规模及预测:依应用领域划分,2021-2034年

- 主要趋势

- 加工

- 贮存

- 运输

第七章:市场规模及预测:依地区划分,2021-2034年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 挪威

- 波兰

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 印尼

- 马来西亚

- 中东和非洲

- 沙乌地阿拉伯

- 阿联酋

- 卡达

- 埃及

- 阿曼

- 南非

- 奈及利亚

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

第八章:公司简介

- ALMA Group

- BORSIG

- Cimarron Energy

- Cool Sorption

- Evonik

- Flogistix

- Ingersoll Rand

- KAPPA GI

- Kilburn Engineering

- Koch Engineered Solutions

- LeROI

- PETROGAS

- PSG

- Reynold India

- S&S Technical

- SCS Technologies

- SYMEX Technologies

- Tecam

- VOCZero

- Zeeco

The Global Oil and Gas Vapor Recovery Units Market was valued at USD 896.4 million in 2024 and is estimated to grow at a CAGR of 5.2% to reach USD 1.48 Billion by 2034.

The market is gaining traction as stricter environmental policies across key oil-producing regions push operators in both upstream and downstream sectors to adopt vapor recovery units (VRUs) to curb emissions of volatile organic compounds (VOCs). These systems are designed to capture and recover hydrocarbon vapors released during the storage, handling, and processing of volatile liquids such as crude oil and refined fuels. Their growing installation in refineries, terminals, and fuel storage sites reflects their dual benefit of reducing air pollution while reclaiming valuable hydrocarbons, positioning them as a critical component of sustainable oilfield operations. The expansion of crude oil and fuel storage capacity in developing economies is further fueling demand, while global initiatives to limit methane emissions are driving adoption across well pads and compressor stations. Integration of smart technologies such as distributed control systems (DCS) and SCADA-based automation enables real-time monitoring, predictive maintenance, and improved performance visibility, allowing operators to enhance efficiency and maintain environmental compliance.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $896.4 Million |

| Forecast Value | $1.48 Billion |

| CAGR | 5.2% |

In 2024, the adsorption-based technology segment accounted for a 33.6% share and is expected to grow at a CAGR of 5% through 2034. The introduction of next-generation adsorbent materials, including high-surface-area composites, is improving vapor recovery performance under challenging field conditions. The shift toward low-maintenance and regenerative adsorption systems is especially beneficial for upstream and midstream facilities that require consistent recovery operations and reliable emission control.

The storage application segment will grow at a CAGR of 5% from 2025 to 2034. Heightened scrutiny over emissions of benzene and VOCs from tank storage operations is increasing the deployment of VRUs in storage facilities. The integration of dual-stage vapor recovery systems in larger tank farms is significantly enhancing hydrocarbon recovery efficiency, helping operators comply with stringent emission standards while minimizing product loss.

North America Oil and Gas Vapor Recovery Units Market will grow at a CAGR of 4.5% through 2034. Regional midstream operators are increasingly utilizing VRUs to manage vapor emissions from condensate stabilization and gas processing activities, improving operational sustainability. Federal climate initiatives focused on methane reduction are further encouraging widespread adoption among upstream producers. The growing emphasis on environmental, social, and governance (ESG) objectives is driving energy companies to invest in advanced recovery solutions and upgrade existing infrastructure to meet evolving sustainability benchmarks.

Leading companies operating in the Oil and Gas Vapor Recovery Units Market include ALMA Group, Cimarron Energy, BORSIG, Cool Sorption, Ingersoll Rand, Flogistix, KAPPA GI, Koch Engineered Solutions, Kilburn Engineering, LeROI, Evonik, PETROGAS, PSG, SCS Technologies, Reynold India, SYMEX Technologies, S&S Technical, Tecam, VOCZero, and Zeeco. To strengthen their market position, companies in the Oil and Gas Vapor Recovery Units Market are adopting diverse growth strategies centered on innovation, partnerships, and global expansion. Many are investing in advanced emission control technologies and modular VRU designs that enable flexible deployment across varied operating environments. Firms are also collaborating with oilfield operators and EPC contractors to deliver turnkey recovery solutions that comply with international environmental standards. Strategic alliances and mergers are enhancing global distribution capabilities, while digital integration through IoT-enabled monitoring systems is improving efficiency and reliability.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.1.1 Research approach

- 1.1.2 Data collection methods

- 1.2 Base estimates and calculations

- 1.2.1 Base year calculation

- 1.2.2 Market estimates & forecast parameters

- 1.3 Forecast

- 1.3.1 Key trends for market estimates

- 1.3.2 Quantified market impact analysis

- 1.3.2.1 Mathematical impact of growth parameters on forecast

- 1.3.3 Scenario analysis framework

- 1.4 Primary research and validation

- 1.4.1 Some of the primary sources (but not limited to)

- 1.5 Data mining sources

- 1.5.1 Paid Sources

- 1.5.2 Sources, by region

- 1.6 Research trail & scoring components

- 1.6.1 Research trail components

- 1.6.2 Scoring components

- 1.7 Research transparency addendum

- 1.7.1 Source attribution framework

- 1.7.2 Quality assurance metrics

- 1.7.3 Our commitment to trust

- 1.8 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

- 2.2 Business trends

- 2.3 Technology trends

- 2.4 Application trends

- 2.5 Regional trends

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Raw material availability & sourcing analysis

- 3.1.2 Manufacturing capacity assessment

- 3.1.3 Supply chain resilience & risk factors

- 3.1.4 Distribution network analysis

- 3.2 Regulatory landscape

- 3.3 Industry impact forces

- 3.3.1 Growth drivers

- 3.3.2 Industry pitfalls & challenges

- 3.4 Growth potential analysis

- 3.5 Porter's analysis

- 3.5.1 Bargaining power of suppliers

- 3.5.2 Bargaining power of buyers

- 3.5.3 Threat of new entrants

- 3.5.4 Threat of substitutes

- 3.6 PESTEL analysis

- 3.6.1 Political factors

- 3.6.2 Economic factors

- 3.6.3 Social factors

- 3.6.4 Technological factors

- 3.6.5 Legal factors

- 3.6.6 Environmental factors

- 3.7 Cost structure analysis of vapor recovery units

- 3.8 Emerging opportunities & trends

- 3.9 Digitalization and IoT integration

- 3.10 Investment analysis & future outlook

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis, by region, 2024

- 4.2.1 North America

- 4.2.2 Europe

- 4.2.3 Asia Pacific

- 4.2.4 Middle East & Africa

- 4.2.5 Latin America

- 4.3 Strategic dashboard

- 4.3.1 Key partnerships & collaborations

- 4.3.2 Major M&A activities

- 4.3.3 Product innovations & launches

- 4.3.4 Market expansion strategies

- 4.4 Strategic initiatives

- 4.5 Competitive benchmarking

- 4.6 Innovation & technology landscape

Chapter 5 Market Size and Forecast, By Technology, 2021 - 2034 (USD Million)

- 5.1 Key trends

- 5.2 Condensation

- 5.3 Adsorption

- 5.4 Absorption

- 5.5 Compression

Chapter 6 Market Size and Forecast, By Application, 2021 - 2034 (USD Million)

- 6.1 Key trends

- 6.2 Processing

- 6.3 Storage

- 6.4 Transportation

Chapter 7 Market Size and Forecast, By Region, 2021 - 2034 (USD Million)

- 7.1 Key trends

- 7.2 North America

- 7.2.1 U.S.

- 7.2.2 Canada

- 7.3 Europe

- 7.3.1 UK

- 7.3.2 Germany

- 7.3.3 France

- 7.3.4 Italy

- 7.3.5 Spain

- 7.3.6 Russia

- 7.3.7 Norway

- 7.3.8 Poland

- 7.4 Asia Pacific

- 7.4.1 China

- 7.4.2 India

- 7.4.3 Japan

- 7.4.4 South Korea

- 7.4.5 Indonesia

- 7.4.6 Malaysia

- 7.5 Middle East & Africa

- 7.5.1 Saudi Arabia

- 7.5.2 UAE

- 7.5.3 Qatar

- 7.5.4 Egypt

- 7.5.5 Oman

- 7.5.6 South Africa

- 7.5.7 Nigeria

- 7.6 Latin America

- 7.6.1 Brazil

- 7.6.2 Mexico

- 7.6.3 Argentina

Chapter 8 Company Profiles

- 8.1 ALMA Group

- 8.2 BORSIG

- 8.3 Cimarron Energy

- 8.4 Cool Sorption

- 8.5 Evonik

- 8.6 Flogistix

- 8.7 Ingersoll Rand

- 8.8 KAPPA GI

- 8.9 Kilburn Engineering

- 8.10 Koch Engineered Solutions

- 8.11 LeROI

- 8.12 PETROGAS

- 8.13 PSG

- 8.14 Reynold India

- 8.15 S&S Technical

- 8.16 SCS Technologies

- 8.17 SYMEX Technologies

- 8.18 Tecam

- 8.19 VOCZero

- 8.20 Zeeco