|

市场调查报告书

商品编码

1871132

电动车半导体市场机会、成长驱动因素、产业趋势分析及预测(2025-2034年)Electric Vehicle Semiconductors Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

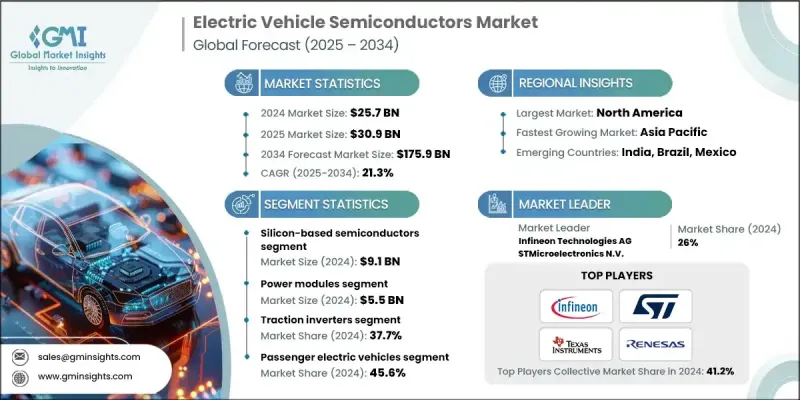

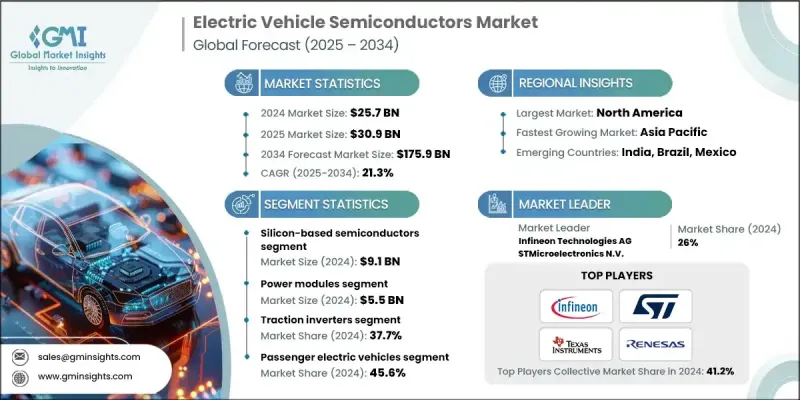

2024 年全球电动车半导体市场价值为 257 亿美元,预计到 2034 年将以 21.3% 的复合年增长率成长至 1,759 亿美元。

随着全球向碳中和和降低温室气体排放转型,电动车(EV)的普及推动了市场扩张。世界各国政府和监管机构在实施严格排放法规的同时,也推出了激励措施、退税和补贴,以促进电动车的使用。消费者越来越倾向于选择可持续的出行方式而非传统的燃油车,这进一步刺激了市场需求。电动车的快速普及也带动了对先进半导体的需求,而先进半导体正是电动车的技术支柱。它们能够实现高效的动力系统控制、能量优化、资讯娱乐系统和安全系统。永续发展要求已成为推动电动车生态系统中半导体创新发展的主要动力。整个产业正经历从传统硅基半导体向碳化硅(SiC)和氮化镓(GaN)等新一代材料的重大转型。这些宽频隙半导体具有更高的能量效率、更快的开关速度和更优异的热管理性能,对于电动车的高功率运作至关重要。它们能够使车辆动力系统更加紧凑、轻巧和高效,从而提升续航里程、充电速度和整体性能。汽车製造商和半导体公司正在迅速整合 SiC 和 GaN 技术来取代传统材料,从而提高自身的竞争优势,并满足不断变化的全球电动车需求。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 257亿美元 |

| 预测值 | 1759亿美元 |

| 复合年增长率 | 21.3% |

2024年,硅基半导体市场规模预计将达91亿美元。该市场的强劲表现得益于硅技术的成熟和成本效益,以及完善的全球製造能力。这些半导体装置性能可靠、可扩展,并与现有汽车系统相容,因此成为量产电动车的首选。随着电动车产业的规模化发展,它们在电源管理系统和车辆控制单元中的广泛应用也进一步巩固了其市场地位。

预计到2024年,功率模组市场规模将达到55亿美元。市场对功率模组的需求源自于其能够将多个功率元件整合到紧凑、高效的封装中,从而提升能量转换效率和散热性能。这项功能对于混合动力和纯电动车的动力传动系统、充电系统和逆变器至关重要。持续致力于提高系统可靠性和降低热损耗,使得功率模组始终处于电动车半导体创新领域的前沿。

到2034年,美国电动车半导体市场将以21.8%的复合年增长率成长。联邦和州政府的激励措施、电动车强制规定以及消费者对电动车日益增长的接受度,都为这一增长提供了强有力的支撑。美国本土汽车製造商越来越多地采用基于碳化硅(SiC)的功率晶片,以提高动力传动系统的效率、高性能运算能力以及自动驾驶系统的整合度。此外,美国也受惠于《晶片和半导体产业战略法案》(CHIPS Act)支持的本地半导体生产,从而促进了创新并增强了供应链的韧性。汽车製造商、半导体公司和技术供应商之间的合作正在推动电池管理系统、自动驾驶处理器和高性能充电模组等领域的下一代发展,确保电动车生态系统的持续竞争力。

电动车半导体市场的主要参与者包括 Wolfspeed, Inc.、NXP Semiconductors NV、STMicroelectronics NV、Texas Instruments Inc.、Infineon Technologies AG、Microchip Technology Inc.、Analog Devices, Inc.、Renesas Electronics Corporation、ON Semchip Technology Inc.、Analog Devices, Inc.、Renesas Electronics Corporation、ON Semiconductor 电话公司Co., Ltd.、Toshiba Electronic Devices & Storage、Allegro MicroSystems, Inc.、ams OSRAM AG、StarPower Semiconductor Ltd.、Samsung Semiconductor, Inc.、Sanken Electric Co., Ltd. 与 BYD Semiconductor Co., Ltd.。这些电动车半导体市场的领导者正在实施策略性倡议,以增强其竞争优势并扩大其技术影响力。他们正在加大研发投入,以加速碳化硅 (SiC) 和氮化镓 (GaN) 等宽禁带材料的研发,从而实现更高的性能和能源效率。各公司正与汽车原始设备製造商 (OEM) 建立长期供应合作伙伴关係,以确保半导体技术能够整合到新型电动车平台中。在政府政策的支持下,製造业在地化正在增强供应稳定性并提升成本竞争力。

目录

第一章:方法论与范围

第二章:执行概要

第三章:行业洞察

- 产业生态系分析

- 供应商格局

- 利润率

- 成本结构

- 每个阶段的价值增加

- 影响价值链的因素

- 中断

- 产业影响因素

- 成长驱动因素

- 全球永续发展目标推动电动车快速普及

- 电力电子技术的进步(SiC 和 GaN 技术)

- 政府对电气化的激励措施和监管要求

- 自动驾驶和连网电动车的需求日益增长

- 扩大电动车充电基础设施

- 产业陷阱与挑战

- 先进半导体的高製造成本与研发成本

- 全球供应链受限及晶片短缺

- 成长驱动因素

- 成长潜力分析

- 监管环境

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 波特的分析

- PESTEL 分析

- 技术与创新格局

- 当前技术趋势

- 新兴技术

- 价格趋势

- 历史价格分析(2021-2024)

- 价格趋势驱动因素

- 区域价格差异

- 价格预测(2025-2034)

- 定价策略

- 新兴商业模式

- 合规要求

- 永续性措施

- 永续材料评估

- 碳足迹分析

- 循环经济实施

- 永续性认证和标准

- 永续性投资报酬率分析

- 全球消费者情绪分析

- 专利分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 市场集中度分析

- 按地区

- 对主要参与者进行竞争基准分析

- 财务绩效比较

- 收入

- 利润率

- 研发

- 产品组合比较

- 产品范围广度

- 科技

- 创新

- 地理位置比较

- 全球足迹分析

- 服务网路覆盖

- 按地区分類的市场渗透率

- 竞争定位矩阵

- 领导人

- 挑战者

- 追踪者

- 小众玩家

- 战略展望矩阵

- 财务绩效比较

- 2021-2024 年主要发展动态

- 併购

- 伙伴关係与合作

- 技术进步

- 扩张和投资策略

- 永续发展倡议

- 数位转型计划

- 新兴/新创企业竞争对手格局

第五章:市场估算与预测:依技术类型划分,2021-2034年

- 主要趋势

- 硅基半导体

- 碳化硅(SiC)半导体

- 氮化镓(GaN)半导体

- 超宽频隙半导体

第六章:市场估算与预测:依产品类型划分,2021-2034年

- 主要趋势

- 电源模组

- 分离式功率元件

- 电源管理积体电路

- 微控制器和处理器

- 感测器积体电路

- 闸极驱动器积体电路

- 通讯与介面积体电路

- 记忆体和储存积体电路

- 其他的

第七章:市场估计与预测:依应用领域划分,2021-2034年

- 主要趋势

- 牵引逆变器

- 车用充电器(OBC)

- 直流-直流转换器

- 无线电力传输

- 超快速充电系统

- 其他的

第八章:市场估算与预测:依最终用途划分,2021-2034年

- 主要趋势

- 乘用电动车

- 商用电动车

- 专用电动车

- 电动车充电基础设施

- 其他的

第九章:市场估计与预测:依地区划分,2021-2034年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 西班牙

- 义大利

- 荷兰

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 韩国

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 阿联酋

第十章:公司简介

- Allegro MicroSystems, Inc.

- Alpha and Omega Semiconductor Ltd.

- ams OSRAM AG

- Analog Devices, Inc.

- BYD Semiconductor Co., Ltd.

- Diodes Incorporated

- Infineon Technologies AG

- IXYS Corporation

- Melexis NV

- Microchip Technology Inc.

- Monolithic Power Systems, Inc.

- NXP Semiconductors NV

- ON Semiconductor Corporation

- Power Integrations, Inc.

- Powerex, Inc.

- Qorvo, Inc.

- Renesas Electronics Corporation

- ROHM Co., Ltd.

- Samsung Semiconductor, Inc.

- Sanken Electric Co., Ltd.

- StarPower Semiconductor Ltd.

- STMicroelectronics NV

- Texas Instruments Inc.

- Toshiba Electronic Devices & Storage

- Wolfspeed, Inc.

The Global Electric Vehicle Semiconductors Market was valued at USD 25.7 Billion in 2024 and is estimated to grow at a CAGR of 21.3% to reach USD 175.9 Billion by 2034.

The market is expanding as the global shift toward carbon neutrality and lower greenhouse gas emissions drives widespread adoption of electric vehicles (EVs). Governments and regulatory authorities worldwide are enforcing strict emission regulations while introducing incentives, rebates, and subsidies to promote EV usage. Consumers increasingly prefer sustainable mobility alternatives over traditional combustion vehicles, further boosting demand. This surge in EV adoption has led to an accelerated requirement for advanced semiconductors, which serve as the technological backbone of electric vehicles. They enable efficient powertrain control, energy optimization, infotainment, and safety systems. Sustainability mandates have become a primary force shaping semiconductor innovation within the EV ecosystem. The industry is undergoing a major transition from conventional silicon-based semiconductors to next-generation materials such as silicon carbide (SiC) and gallium nitride (GaN). These wide-bandgap semiconductors provide superior energy efficiency, faster switching, and improved thermal management, essential for handling high-power operations in EVs. Their ability to make vehicle power systems more compact, lightweight, and efficient enhances range, charging speed, and overall performance. Automakers and semiconductor companies are rapidly integrating SiC and GaN technologies to replace legacy materials, increasing their competitive advantage and addressing the evolving global EV demand.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $25.7 Billion |

| Forecast Value | $175.9 Billion |

| CAGR | 21.3% |

The silicon-based semiconductors segment generated USD 9.1 Billion in 2024. The strong position of this segment is attributed to the maturity and cost-efficiency of silicon technology, supported by established global manufacturing capabilities. These semiconductors deliver reliable performance, scalability, and compatibility with current automotive systems, making them the preferred option for mass-produced EV models. Their extensive use in power management systems and vehicle control units continues to strengthen their market relevance as the EV industry scales.

The power modules segment generated USD 5.5 Billion in 2024. The demand for power modules stems from their ability to consolidate multiple power devices into compact, high-efficiency packages that enhance energy conversion and thermal regulation. This functionality is vital for powering electric drivetrains, charging systems, and inverters in both hybrid and fully electric vehicles. The continuous focus on achieving higher system reliability and reducing thermal losses keeps power modules at the forefront of EV semiconductor innovation.

U.S. Electric Vehicle Semiconductors Market will grow at a CAGR of 21.8% by 2034. Growth is strongly supported by federal and state-level incentives, EV mandates, and growing consumer adoption. Domestic automakers increasingly incorporate SiC-based power chips to enhance drivetrain efficiency, performance computing, and autonomous driving integration. The U.S. also benefits from local semiconductor production supported by the CHIPS Act, fostering innovation and supply chain resilience. Collaboration among automakers, semiconductor firms, and technology providers is driving next-generation developments in battery management systems, autonomous processors, and high-performance charging modules, ensuring sustained competitiveness within the EV ecosystem.

Key players active in the Electric Vehicle Semiconductors Market include Wolfspeed, Inc., NXP Semiconductors N.V., STMicroelectronics N.V., Texas Instruments Inc., Infineon Technologies AG, Microchip Technology Inc., Analog Devices, Inc., Renesas Electronics Corporation, ON Semiconductor Corporation, Power Integrations, Inc., Melexis N.V., Monolithic Power Systems, Inc., ROHM Co., Ltd., Toshiba Electronic Devices & Storage, Allegro MicroSystems, Inc., ams OSRAM AG, StarPower Semiconductor Ltd., Samsung Semiconductor, Inc., Sanken Electric Co., Ltd., and BYD Semiconductor Co., Ltd. Leading companies in the Electric Vehicle Semiconductors Market are implementing strategic initiatives to reinforce their competitive edge and expand their technological footprint. They are increasing R&D investment to accelerate advancements in wide-bandgap materials like SiC and GaN, targeting higher performance and energy efficiency. Firms are entering long-term supply partnerships with automotive OEMs to secure semiconductor integration across new EV platforms. Localization of manufacturing, supported by government policies, is enhancing supply stability and cost competitiveness.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry snapshot

- 2.2 Key market trends

- 2.2.1 Packaging type trends

- 2.2.2 Material trends

- 2.2.3 Application trends

- 2.2.4 Regional

- 2.3 TAM Analysis, 2025-2034 (USD Billion)

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 critical success factors

- 2.5 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Cost structure

- 3.1.4 Value addition at each stage

- 3.1.5 Factor affecting the value chain

- 3.1.6 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Rapid EV adoption driven by global sustainability goals

- 3.2.1.2 Advancements in power electronics (SiC & GaN technologies)

- 3.2.1.3 Government incentives and regulatory mandates for electrification

- 3.2.1.4 Growing demand for autonomous and connected EVs

- 3.2.1.5 Expansion of EV charging infrastructure

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High manufacturing and R&D costs of advanced semiconductors

- 3.2.2.2 Global supply chain constraints & chip shortages

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Technology and innovation landscape

- 3.7.1 Current technological trends

- 3.7.2 Emerging technologies

- 3.8 Price trends

- 3.8.1 Historical price analysis (2021-2024)

- 3.8.2 Price trend drivers

- 3.8.3 Regional price variations

- 3.8.4 Price forecast (2025-2034)

- 3.9 Pricing strategies

- 3.10 Emerging business models

- 3.11 Compliance requirements

- 3.12 Sustainability measures

- 3.12.1 Sustainable materials assessment

- 3.12.2 Carbon footprint analysis

- 3.12.3 Circular economy implementation

- 3.12.4 Sustainability certifications and standards

- 3.12.5 Sustainability ROI analysis

- 3.13 Global consumer sentiment analysis

- 3.14 Patent analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East & Africa

- 4.2.2 Market Concentration Analysis

- 4.2.1 By region

- 4.3 Competitive benchmarking of key players

- 4.3.1 Financial performance comparison

- 4.3.1.1 Revenue

- 4.3.1.2 Profit margin

- 4.3.1.3 R&D

- 4.3.2 Product portfolio comparison

- 4.3.2.1 Product range breadth

- 4.3.2.2 Technology

- 4.3.2.3 Innovation

- 4.3.3 Geographic presence comparison

- 4.3.3.1 Global footprint analysis

- 4.3.3.2 Service network coverage

- 4.3.3.3 Market penetration by region

- 4.3.4 Competitive positioning matrix

- 4.3.4.1 Leaders

- 4.3.4.2 Challengers

- 4.3.4.3 Followers

- 4.3.4.4 Niche players

- 4.3.5 Strategic outlook matrix

- 4.3.1 Financial performance comparison

- 4.4 Key developments, 2021-2024

- 4.4.1 Mergers and acquisitions

- 4.4.2 Partnerships and collaborations

- 4.4.3 Technological advancements

- 4.4.4 Expansion and investment strategies

- 4.4.5 Sustainability initiatives

- 4.4.6 Digital transformation initiatives

- 4.5 Emerging/ startup competitors landscape

Chapter 5 Market Estimates and Forecast, By Technology Type, 2021 - 2034 (USD Million)

- 5.1 Key trends

- 5.2 Silicon-based semiconductors

- 5.3 Silicon Carbide (SiC) semiconductors

- 5.4 Gallium Nitride (GaN) semiconductors

- 5.5 Ultra-wide bandgap semiconductors

Chapter 6 Market Estimates and Forecast, By Product Type, 2021 - 2034 (USD Million)

- 6.1 Key trends

- 6.2 Power modules

- 6.3 Discrete power devices

- 6.4 Power management ICs

- 6.5 Microcontrollers & processors

- 6.6 Sensor ICs

- 6.7 Gate driver ICs

- 6.8 Communication & interface ICs

- 6.9 Memory & storage ICs

- 6.10 Others

Chapter 7 Market Estimates and Forecast, By Application, 2021 - 2034 (USD Million)

- 7.1 Key trends

- 7.2 Traction inverters

- 7.3 Onboard Chargers (OBC)

- 7.4 DC-DC converters

- 7.5 Wireless power transfer

- 7.6 Ultra-fast charging systems

- 7.7 Others

Chapter 8 Market Estimates and Forecast, By End Use, 2021 - 2034 (USD Million)

- 8.1 Key trends

- 8.2 Passenger electric vehicles

- 8.3 Commercial electric vehicles

- 8.4 Specialized electric vehicles

- 8.5 EV charging infrastructure

- 8.6 Others

Chapter 9 Market Estimates and Forecast, By Region, 2021 - 2034 (USD Million)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 Germany

- 9.3.2 UK

- 9.3.3 France

- 9.3.4 Spain

- 9.3.5 Italy

- 9.3.6 Netherlands

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 Australia

- 9.4.5 South Korea

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.6 Middle East and Africa

- 9.6.1 Saudi Arabia

- 9.6.2 South Africa

- 9.6.3 UAE

Chapter 10 Company Profiles

- 10.1 Allegro MicroSystems, Inc.

- 10.2 Alpha and Omega Semiconductor Ltd.

- 10.3 ams OSRAM AG

- 10.4 Analog Devices, Inc.

- 10.5 BYD Semiconductor Co., Ltd.

- 10.6 Diodes Incorporated

- 10.7 Infineon Technologies AG

- 10.8 IXYS Corporation

- 10.9 Melexis N.V.

- 10.10 Microchip Technology Inc.

- 10.11 Monolithic Power Systems, Inc.

- 10.12 NXP Semiconductors N.V.

- 10.13 ON Semiconductor Corporation

- 10.14 Power Integrations, Inc.

- 10.15 Powerex, Inc.

- 10.16 Qorvo, Inc.

- 10.17 Renesas Electronics Corporation

- 10.18 ROHM Co., Ltd.

- 10.19 Samsung Semiconductor, Inc.

- 10.20 Sanken Electric Co., Ltd.

- 10.21 StarPower Semiconductor Ltd.

- 10.22 STMicroelectronics N.V.

- 10.23 Texas Instruments Inc.

- 10.24 Toshiba Electronic Devices & Storage

- 10.25 Wolfspeed, Inc.