|

市场调查报告书

商品编码

1438376

超音波无损检测 (NDT) 设备 - 市场占有率分析、产业趋势与统计、成长预测(2024 - 2029 年)Ultrasonic Non-Destructive Testing (NDT) Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

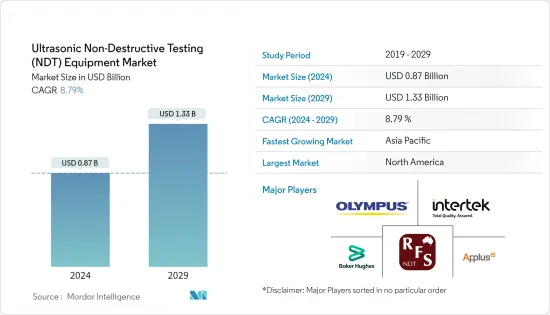

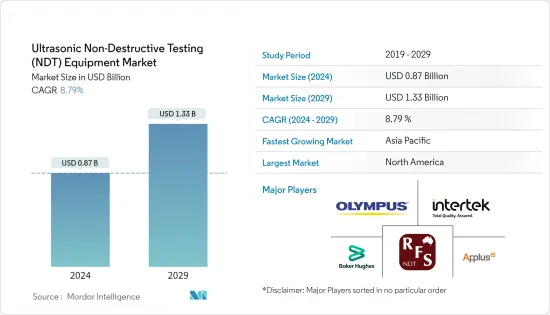

超音波无损检测设备市场规模预计到2024年为8.7亿美元,预计到2029年将达到13.3亿美元,在预测期内(2024-2029年)CAGR为8.79%。

发展中国家持续消耗大量天然气,而已开发国家的需求却在增加。需求的增加导致管道和炼油厂的扩建,从而导致超音波无损检测市场的激增。

主要亮点

- 根据许多国家的法律要求,定期无损检测被广泛用作主动安全措施。然而,与船舶检查中经常使用的目视检查相比,超音波检测越来越受欢迎,因为它可以创建更好的船舶腐蚀图,并且可以准确地确定船体厚度。透过超音波检测产生的影像可以显示肉眼检查无法侦测到的船体内部缺陷。定期超音波测试可确保在发生代价高昂的故障之前发现船体问题。预计这些趋势将为预测期内研究的市场创造显着的成长前景。

- 超音波检测设备是应用最广泛的无损检测设备,其结构简单、重量轻、便于携带、能承受温度、湿度、振动、灰尘,而且性价比高。超音波测试正在见证旨在填补现有市场产品组合空白的渐进式创新。在超音波测试中,相控阵超音波测试市场正在饱和,而导波超音波测试被称为最重要的技术之一。此外,超音波测试正在成为最终用户进行故障检测的首选,因为它对操作员或附近人员无害,并且不会影响正在测试的材料。它还提供即时结果。超音波测试已在发电行业和石油天然气行业中广泛应用。然而,随着行业技术的不断进步,技术也在其他行业中得到了重要的应用。

- 例如,超音波测试正在应用于船舶和航空业,因为测试活动定期在钢和铝容器上进行,以检测和量化腐蚀。它也可用于测量复合材料结构的厚度和完整性。 2021 年 4 月,Jet Aviation 获得瑞士联邦民航局批准,在其巴塞尔维修设施中使用红外线热成像技术进行无损检测 (NDT),以补充巴塞尔使用的其他 NDT 技术,例如液体渗透剂、X-射线、磁粉、涡流和超音波检测。

- 世界各地对超音波检测活动熟练技术人员以及熟练无损检测技术人员的需求不断增加。由于多种原因,目前需求超过供应。非破坏性检验只能由经过认证的专业人员执行,他们在主题专家在场的情况下接受详细培训,以获得分析资料所涉及的各种技术和技能的专业知识。

- 无损检测行业的技术进步使工人更难跟上当今的实践和技术。在加拿大、美国、中东和亚洲等一些地区,熟练劳动力严重短缺。加拿大和美国部分地区的页岩油气勘探导致对无损检测工人的需求突然激增。缺乏优质教师是新兴国家令人担忧的另一个问题。这种趋势加上市场上营运的公司由于缺乏现场访问和供应链中断而面临临时营运问题,可能会阻碍超音波无损检测设备市场的发展。

超音波无损检测 (NDT) 设备市场趋势

用于即时数据的便携式和连接设备的可用性预计将推动市场的成长

- 移动性是各公司持续监控关键资产的关键要求。超音波无损检测设备提供的便携性使无损检测技术人员能够处理多项现场任务。例如,技术人员可以在现场执行无损检测的准备、采集、分析和报告。测试设备需要定期往返于不同的管道、铁路和其他工作地点。便携式超音波无损检测设备使技术人员无需回到办公桌前即可执行所有此类活动,从而节省时间并加快流程。

- 此外,由于提供的灵活性,无线超音波检测设备的兴起和物联网等先进技术的渗透正在推动所研究的市场。物联网解决方案越来越多地被各行业采用,以优化营运、生产力和保护环境。製造业、石油和天然气、食品和饮料以及公用事业等行业面临激烈的竞争。因此,他们越来越多地投资于利用物联网、云端和大数据分析功能的新技术,以增强创新能力并最大限度地提高资产回报。

- 随着工业4.0的到来,工业物联网(IIoT)、智慧製造、智慧工厂、预测製造、工业机器人和感测器等趋势使物联网成为这些产业的核心支柱,实现设备上的远端监控、连续扫描功能工厂车间、即时分析以及支援新功能,例如预测性和持续维护。

- 工业 4.0 一直在帮助产业从遗留系统过渡到智慧组件和机器,促进数位工厂,以及后来的互联工厂和企业的生态系统。这种转型趋势预计将成为无损检测产业采用便携式和连网设备的主要驱动力。便携性和连接性等功能提供了无与伦比的功能,可以在远端位置定位不连续性和其他缺陷,而不会使携带设备成为限制因素。

- 随着智慧工厂概念的生效,企业专注于预测性和持续性维护和製造,预计这将降低和优化营运和维护成本并提高生产能力。此外,Wollenhaupt 表示,低维护策略可使公司的产能降低多达 20%。为了及早发现问题并预防问题,超音波检测是最有效的维护工具之一。

预计北美将占据主要市场份额

- 由于预测性维护测试技术的使用不断增加、石油和天然气行业的采用不断增加,以及该地区各行业安全法规的不断改进(尤其是来自国家的需求。越来越多地使用超音波无损检测设备来确定材料的厚度或管道中的任何裂缝,预计将推动其成长。因此,石油和炼油行业管道建设投资的不断增长预计将推动该国的研究市场。

- 例如,佩科斯小径管道项目、宾夕法尼亚东管道项目和大西洋海岸管道等管道建设项目预计将在未来几年内完成。预计这些项目将在未来几年内为该国创造对超音波无损检测设备的巨大需求。

- 超音波脉衝速度(UPV)是一种有效的无损检测方法,用于混凝土材料的品质控制和检测结构部件的损坏,过去几年美国建筑业的成长正在增加设备的销售。总统选举后,预计将特别重视建设新的基础设施和修復引起安全担忧的现有资本资产。此外,预计公私合作伙伴关係(PPP)将会增加,以开展大型基础设施项目。根据美国人口普查局的数据,新建商业建筑的价值已恢復至经济衰退前的水平,预计2020年将达799亿美元。2022年,美国新开工建筑价值预计将达到1350亿美元。私人办公室、仓库和购物/零售设施预计将在未来几年流行。建筑业的不断增长可能会推动美国无损检测检测设备市场的发展。

- 此外,加拿大经济正在復苏,过去几年持续成长。随着美国经济的走强和欧洲经济在衰退后的復苏,预计加拿大製造业在未来几年将表现得更好。

- 加拿大是全球重要的汽车生产国之一,该产业是该国製造业的最大贡献者。一段时间以来,车辆重量不断减轻,以提高燃油效率。使用更少或替代的复合材料来保持结构完整性和安全性,导致该地区需要更多和改进的超音波无损检测设备。

超音波无损检测(NDT)设备产业概况

由于初始投资增加,全球超音波无损检测 (NDT) 设备市场已整合。该市场由贝克休斯(Baker Hughes)、Intertek Group PKC、奥林巴斯公司(Olympus Corporation) 和Russell Fraser Sales Pty Ltd 等几家主要参与者主导。这些重要参与者在市场上占有显着份额,专注于扩大其在国外的客户群。这些公司正在利用策略合作计划来增加市场份额并提高盈利能力。然而,随着技术进步和产品创新,中小型公司正在透过获得新合约和开拓新市场来扩大其市场份额。

- 2021 年 10 月 - Intertek 位于英国德比的无损检测 (NDT) 专家为该公司庞大的先进技术实验室添加了一台 X 射线电脑断层扫描 (CT) 扫描仪。此扫描器具有 240 kV 微焦点和 450 kV 迷你焦点功能。 CT 扫描结合了随着被检物体缓慢旋转而从不同角度拍摄的多个 X 光影像。专用软体将这些影像结合起来创建一个三维模型,透过分析该模型可以识别内部特征和潜在缺陷,例如裂缝、孔隙和分层。

- 2021 年 9 月 - 必维国际检验集团 (Bureau Veritas) 收购了专门从事实验室测试、产品开发和永续测试的 AET France。此次收购增强了 BV 在欧洲消费品零售业的地位。

额外的好处:

- Excel 格式的市场估算 (ME) 表

- 3 个月的分析师支持

目录

第 1 章:简介

- 研究假设和市场定义

- 研究范围

第 2 章:研究方法

第 3 章:执行摘要

第 4 章:市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争激烈程度

- 产业价值链分析

- 评估 COVID-19 对市场的影响

第 5 章:市场动态

- 市场驱动因素

- 加强安全监管

- 更重视持续监控以防止突然故障

- 可携式和连接设备的即时数据可用性

- 市场限制

- 缺乏实施和进行检验服务所需的熟练劳动力

第 6 章:市场细分

- 按地理

- 北美洲

- 美国

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 西班牙

- 欧洲其他地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 亚太地区其他地区

- 拉丁美洲

- 巴西

- 阿根廷

- 拉丁美洲其他地区

- 中东和非洲

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 中东和非洲其他地区

- 北美洲

第 7 章:竞争格局

- 公司简介

- Baker Hughes

- MISTRAS Group

- Intertek Group PKC

- Olympus Corporation

- Russell Fraser Sales Pty Ltd

- Advanced NDT Ltd

- Johnson and Allen Ltd

- ROSEN Group

- OkoNDT group

- Bureau Veritas SA

- Applus Services SA

第 8 章:投资分析

第 9 章:市场的未来

The Ultrasonic Non-Destructive Testing Equipment Market size is estimated at USD 0.87 billion in 2024, and is expected to reach USD 1.33 billion by 2029, growing at a CAGR of 8.79% during the forecast period (2024-2029).

Developing countries continue to consume vast amounts of natural gas while the demand increases in developed countries. The increased demand is causing the expansion of pipelines and refineries, due to which there is a surge in the ultrasonic NDT testing market.

Key Highlights

- Regular non-destructive testing is widely used as a proactive safety measure, as it is required by law in many countries. However, ultrasonic testing is gaining popularity as it creates a better map of ship corrosion and can accurately determine hull thickness, as compared to visual inspection, which is frequently used in ship inspections. Images produced through ultrasonic testing can visualize defects inside the hull that visual inspection cannot detect. Regular ultrasonic testing ensures that hull issues are identified before a costly failure. Such trends are expected to create significant growth prospects for the market studied over the forecast period.

- Ultrasonic testing equipment is the most extensively used NDT equipment that is simple, lightweight, portable, can withstand temperature, humidity, vibration, and dust, and are also cost-effective in nature. Ultrasonic testing is witnessing incremental innovations aimed at filling gaps in the existing market product portfolio. Within ultrasonic testing, the market for phased array ultrasonic testing is witnessing saturation, while guided wave ultrasonic testing is being dubbed as one of the most significant techniques. Moreover, Ultrasonic testing is becoming a preferred choice amongst the end-users for fault detection, as it is non-hazardous to operators or nearby personnel and does not affect the material being tested. It also provides instantaneous results. Ultrasonic testing has witnessed the majority of applications in the power generation industry and the oil & gas industry. However, with the increasing technological advancements in the industry, technology is witnessing significant instances of applications in other industries as well.

- For instance, ultrasonic testing is being used in the marine and aviation industry, as the testing activity is regularly performed on steel and aluminum vessels to detect and quantify corrosion. It can also be used to measure the thickness and integrity of composite structures. In April 2021, Jet Aviation was approved by the Swiss Federal Office of Civil Aviation to use infrared thermography for non-destructive testing (NDT) at its Basel maintenance facility to add to other NDT techniques used in Basel, such as liquid penetrant, X-ray, magnetic particle, eddy current, and ultrasonic testing.

- There has been an incremental rise in the demand for skilled technicians in ultrasonic testing activities, along with skilled NDT technicians across the world. The demand currently outweighs supply due to many reasons. Non-destructive testing can only be performed by certified professionals who undergo detailed training in the presence of subject-matter experts to gain expertise on the various techniques and skills involved in analyzing the data.

- Technological advancements in the NDT industry have made it even tougher for workers to stay abreast of present-day practices and techniques. Acute shortage of skilled workforce can be seen in some regions, like Canada, the United States, the Middle East, and Asia. Shale oil and gas explorations in Canada and certain parts of the United States have led to a sudden surge in demand for NDT workers. The lack of quality instructors is another source of concern in emerging countries. Such trends coupled with companies operating in the market facing temporary operative issues due to the absence of site access and disruption in the supply chain might hamper the progression of the ultrasonic NDT testing equipment market.

Ultrasonic Non-Destructive Testing (NDT) Equipment Market Trends

Availability of Portable and Connected Devices for Real-time Data is Expected to Drive the Market's Growth

- Mobility is a key requirement for various companies to monitor critical assets continuously. The portability offered by ultrasonic NDT equipment allows NDT technicians to handle several on-site tasks. For instance, technicians can perform preparation, acquisition, analysis, and reporting of NDT on the site. The testing equipment is required to be transported to and from varying stretches of pipelines, rail, and other job sites regularly. The portable ultrasonic NDT equipment enables the technicians to perform all such activities without the need to go back to the desk, saving time and fastening the process.

- Furthermore, the rise of cordless ultrasonic testing equipment and the penetration of advanced technologies, like the Internet of Things, is driving the studied market, owing to the flexibility offered. IoT solutions are being increasingly adopted across industries for optimizing operations, productivity, and safeguarding the environment. Industries such as manufacturing, oil and gas, food and beverage, and utilities face intense competition. Thus, they are increasingly investing in new technologies that leverage the capabilities of IoT, cloud, and Big Data analytics to enhance their ability to innovate and maximize return on their assets.

- With the advent of Industry 4.0, trends like Industrial IoT (IIoT), smart manufacturing, smart factories, predictive manufacturing, industrial robots, and sensors have made IoT the central backbone of these industries, enabling remote monitoring, continuously scanning capabilities from the equipment on the factory floor, real-time analysis, and supporting new capabilities, such as predictive and continuous maintenance.

- Industry 4.0 has been aiding the industries' transition from legacy systems to smart components and machines, facilitating digital factories and, later, to an ecosystem of connected plants and enterprises. Such transformational trends are expected to act as a major driver for adopting portable and connected devices in the NDT industry. The features such as portability and connectivity provide unmatched capabilities for locating discontinuities and other flaws at remote locations without making carrying the device a restraining factor.

- With the smart factory concept coming into force, companies focus on predictive and continuous maintenance and manufacturing, which is anticipated to reduce and optimize operations and maintenance costs and enhance production capacities. Moreover, according to Wollenhaupt, low maintenance strategies can reduce a company's production capacity by as much as 20%. To identify the problems and prevent them at an early stage, ultrasonic testing is one of the most effective maintenance tools.

North America is Expected to Hold a Major Market Share

- The United States is expected to command a prominent share of the market demand owing to the increasing use of testing technology for predictive maintenance, growing adoption in the oil and gas sector, and growing safety regulations in the various industries in the region especially driven by the demand from the country. The increasing use of ultrasonic non-destructive testing equipment to determine a material's thickness or any cracks in a pipeline is expected to drive its growth. Therefore, the growing investment in the construction of pipelines in the oil and refinery sector is expected to drive the studied market in the country.

- For instance, Pipeline construction projects, such as Pecos trail Pipeline Project, Penn East Pipeline Project, and Atlantic Coast Pipeline, are some of the projects that are destined to be completed in the next few years. These projects are expected to create considerable demand for Ultrasonic non-destructive testing equipment in the country over the next few years.

- Ultrasonic Pulse Velocity (UPV) is an effective non-destructive testing method for quality control of concrete materials and detecting damages in structural components, and the growing construction sector in the United States over the past few years is augmenting the sales of equipment. After the presidential election, a particular emphasis on building new infrastructure and repairing existing capital assets that are raising safety concerns is expected to take place. Additionally, public-private partnerships (PPPs) are expected to increase to carry out large-scale infrastructure projects. According to the United States Census Bureau, the value of new commercial buildings has recovered to pre-recession levels, with USD 79.9 billion expected in 2020. In 2022, the value of construction starts in the United States is expected to reach USD 135 billion. Private offices, warehouses, and shopping/retail facilities are expected to be popular in the coming years. The increasing growth in the construction sector may boost the market for NDT testing equipment in the United States.

- Moreover, Canada is experiencing a resurging economy, with continuous growth over the last few years. With the strengthening of the American economy and the resurfacing of the European economy post-recession, the Canadian manufacturing sector is expected to perform better in the coming years.

- Canada is one of the significant vehicle producers globally, and this sector is the biggest contributor to the country's manufacturing industry. Over a period of time, vehicle weight has been reduced to increase fuel efficiency. Maintaining structural integrity and safety with less or alternative composite materials has created the need for more and improved ultrasonic non-destructive testing equipment in the region.

Ultrasonic Non-Destructive Testing (NDT) Equipment Industry Overview

The Global Ultrasonic Non-Destructive Testing (NDT) Equipment Market is consolidated due to higher initial investments. It is dominated by a few major players like Baker Hughes, Intertek Group PKC, Olympus Corporation, and Russell Fraser Sales Pty Ltd. These significant players, with a prominent share in the market, are focusing on expanding their customer base across foreign countries. These companies are leveraging strategic collaborative initiatives to increase their market share and increase their profitability. However, with technological advancements and product innovations, mid-size to smaller companies are growing their market presence by securing new contracts and tapping new markets.

- October 2021 - Intertek's non-destructive testing (NDT) experts in Derby, United Kingdom, added an X-ray computed tomography (CT) scanner to the company's extensive laboratory of advanced technology. The scanner has 240 kV microfocus and 450 kV mini focus capability. CT scanning combines multiple X-ray images taken from different angles as the inspected object is slowly rotated. Specialized software combines these images to create a three-dimensional model that can be analyzed to identify internal features and potential defects such as cracking, porosity, and delamination.

- September 2021 - Bureau Veritas acquired AET France, which is specialized in laboratory testing, product development, and sustainable testing. This acquisition has strengthened BV's position in the European consumer goods retail industry.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTs

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of the Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increased Safety Regulation

- 5.1.2 More Emphasis Toward Continuous Monitoring to Prevent Sudden Failure

- 5.1.3 Availability of Portable and Connected Devices for Real-time Data

- 5.2 Market Restraints

- 5.2.1 Lack of Skilled Labor Required to Implement and Carry Out Inspection Service

6 MARKET SEGMENTATION

- 6.1 By Geography

- 6.1.1 North America

- 6.1.1.1 United States

- 6.1.1.2 Canada

- 6.1.2 Europe

- 6.1.2.1 Germany

- 6.1.2.2 United Kingdom

- 6.1.2.3 France

- 6.1.2.4 Spain

- 6.1.2.5 Rest of Europe

- 6.1.3 Asia Pacific

- 6.1.3.1 China

- 6.1.3.2 Japan

- 6.1.3.3 India

- 6.1.3.4 South Korea

- 6.1.3.5 Rest of Asia Pacific

- 6.1.4 Latin America

- 6.1.4.1 Brazil

- 6.1.4.2 Argentina

- 6.1.4.3 Rest of Latin America

- 6.1.5 Middle East and Africa

- 6.1.5.1 United Arab Emirates

- 6.1.5.2 Saudi Arabia

- 6.1.5.3 Rest of Middle East and Africa

- 6.1.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles*

- 7.1.1 Baker Hughes

- 7.1.2 MISTRAS Group

- 7.1.3 Intertek Group PKC

- 7.1.4 Olympus Corporation

- 7.1.5 Russell Fraser Sales Pty Ltd

- 7.1.6 Advanced NDT Ltd

- 7.1.7 Johnson and Allen Ltd

- 7.1.8 ROSEN Group

- 7.1.9 OkoNDT group

- 7.1.10 Bureau Veritas SA

- 7.1.11 Applus Services SA