|

市场调查报告书

商品编码

1628827

北美 AMH 和储存系统:市场占有率分析、行业趋势和成长预测(2025-2030 年)NA AMH and Storage Systems - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

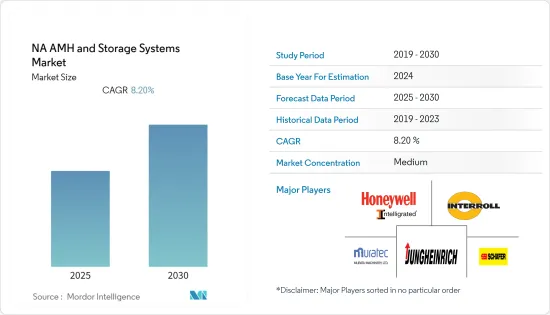

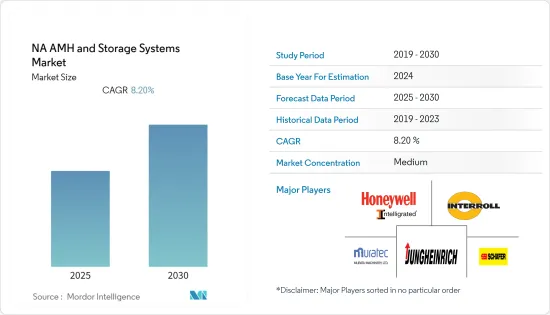

北美 AMH 和储存系统市场预计在预测期内复合年增长率为 8.2%

主要亮点

- 物料输送解决方案供应商透过製造可与其他系统无缝整合的灵活系统,作为整体物料输送计划的一部分,帮助最终用户专注于操作中的空间和时间的效用。此外,自动导引车和 AS/RS 已成为最具活力的物料输送设备和储存系统解决方案,主要部署在仓库、配送中心和机场。

- 此外,北美市场也建立了各种伙伴关係。例如,2021 年 2 月,美国着名电子产品量贩店百思买 (Best Buy) 宣布与 Bastian Solutions 合作,重新设计其区域配送中心。该计划涉及整合自动储存和搜寻技术、输送机和仓库执行软体,以最好地为每个设施提供服务。这种合作关係有助于百思买提供隔日送达服务并有效管理大量进货。

- 该地区各终端用户产业对工业 4.0 的日益关注也为市场创造了新的机会。根据美国BDO 的 2021 年工业 4.0 调查,约 50% 的製造商预计数位化投资将在未来 12 个月内带来收益增加。此外,43% 的受访者已经实施了机器人流程自动化 (RPA),47% 的受访者计划在未来这样做。改善供应链的重点包括客户订单週期(19%)、总交货成本(18%)、计画绩效(18%)和存货周转(16%)。

- 此外,该地区劳动力工资的上涨也增加了对新技术的需求,以减少对工人进行物料输送的依赖。加拿大统计局数据显示,加拿大企业单位产出人事费用继前两季小涨后,2021年第二季上涨2.7%。单位劳动成本的较快成长主要反映了平均时薪在经历了四分之三的下降后的回升(上涨3.2%)。

北美AMH和储存系统市场趋势

自动导引运输车有望获得显着的市场占有率

- AGV(自动导引自动导引运输车)的日益普及也是推动市场成长的因素。根据现代物料输送(MMH) 的数据,11% 的受访者将在 2021 年使用 AGV,18% 的受访者计划在未来 24 个月内使用 AGV。

- 市场上有许多关于自动牵引车和堆高机的创新。例如,2020年12月,丰田宣布推出一款用于仓库作业的新型中控骑士和核心牵引车自动堆高机。 AGV由丰田堆高机与丰田高级物流子公司Bastian Solutions合作开发,用于製造工厂和物流中心业务的高度重复性任务。丰田的新型堆高机还可以在需要时手动操作,并使用基于光检测和测距(LIDAR)的导航进行自主操作。

- 此外,该地区所有物流公司之间的竞争环境鼓励他们透过增加仓储设施或实现工作自动化来提高现有仓储设施的效率,从而导致市场上自动导引车的兴起,促进使用量的增长。

- 此外,大型仓库的增加也带来了对自动堆高机的需求,进一步推动了自动导引车市场的发展。例如,2020 年 11 月,DSV Global Transport Logistics 在多伦多附近开设了加拿大最大的多客户物流设施。该仓库提供 111,000 平方英尺的气候控制空间。

- 堆高机技术研发的扩大预计将与工业 4.0、人工智慧和机器学习的投资齐头并进,为 AGV 的蓬勃发展创造条件。此外,COVID-19 也提高了消费者对电子商务的采用和接受度,从而产生了各个最终用户行业对远端物料输送和储存系统的需求,这也为堆高机的自主或无人驾驶技术创造了新的机会。

美国预计将获得主要市场占有率

- 美国是世界上最重要的机器人市场之一,销售受到该地区汽车行业需求的推动。例如,根据国际机器人联合会(IFR)发布的《世界机器人2020工业机器人》报告,美国工厂运作的工业机器人数量约为29.3万台,与前一年同期比较增加7%。新型机器人销售量维持高位,2019 年出货量为 33,300 台。机器人技术的发展为市场创造了新的机会。

- 此外,该地区的仓库空间不断扩大,增加了对 AMH 和储存系统的需求。根据劳工统计局的数据,仓库将从 2019 年的 18,736 个增加到 2020 年的 19,190 个。此外,亚马逊和沃尔玛等公司正在透过建造新仓库来迅速扩大其足迹。 2021 年 5 月,亚马逊宣布将建造一座 380 万平方英尺的仓库,是美国最大的仓库之一。

- 对移动机器人、人工智慧和机器学习的投资也推动了该国的成长。例如,国家机器人计画3.0 2021重点在于加速美国机器人的开发和使用。

- 根据2020年Honeywell智慧自动化投资调查,超过一半的美国公司愿意投资自动化以在不断变化的市场环境中生存。最愿意投资自动化的产业是电子商务(60%)、食品饮料(59%)和物流(55%)。这为AMH和储存系统部署创造了新的机会。

- 仓库自动化程度的提高、AMH(自动物料输送)的采用增加以及熄灯自动化等趋势是推动美国的一些关键因素。

北美AMH和储存系统产业概况

北美 AMH 和储存系统市场与大量区域和全球参与者竞争中等。市占率较大的主要厂商都在註重技术创新、併购、伙伴关係、扩大海外基本客群。公司正在利用策略合作措施来提高盈利。

- 2020年8月,村田机械与Alpen株式会社签约,打造首个3D机器人仓库系统「Alphabot」。此外,阿尔彭集团的主要物流中心阿尔彭小牧物流中心将引进ALPHABOT,以补充储存容量,并将拣选、分类和包装作业减少约60%。

- 2020 年 7 月 - Interroll 完成了位于乔治亚海勒姆(亚特兰大)的第二家工厂的建设。 Interroll 投资 1,100 万美元,显着提高了在该地区的产能。英特诺在美洲地区的计划活动持续保持高水准。同时,该公司将创新解决方案快速推向市场。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争公司之间敌对关係的强度

- COVID-19 对工业生态系的影响

第五章市场动态

- 市场驱动因素

- 技术进步不断推动市场成长

- 电子商务的快速成长导致仓库自动化

- 工业 4.0 投资推动对 AMH 和储存系统的需求

- 市场挑战

- 缺乏技术纯熟劳工

- 高资本要求

第六章 市场细分

- 依产品类型

- 软体

- 硬体

- 服务

- 一体化

- 依设备类型

- 移动机器人

- 自动导引运输车(AGV)

- 自动堆高机

- 自动拖车/拖拉机/标籤

- 单元货载

- 组装

- 自主移动机器人(AMR)

- 自动化仓库系统(ASRS)

- 固定飞弹

- 旋转木马

- 垂直升降模组

- 自动输送机

- 腰带

- 滚筒

- 调色盘

- 开卖

- 堆垛机

- 传统的

- 机器人

- 分类系统

- 移动机器人

- 按最终用户

- 飞机场

- 车

- 饮食

- 零售/仓库/配送中心/物流中心

- 一般製造业

- 药品

- 小包裹

- 电子/半导体製造

- 其他最终用户

- 按国家/地区

- 美国

- 加拿大

第七章 竞争格局

- 公司简介

- JBT Corporation

- Honeywell Intelligrated(Honeywell International Inc.)

- SSI SCHEFER AG

- Daifuku Co. Limited

- Kardex Group

- Beumer Group GMBH & Co. KG

- Jungheinrich AG

- Murata Machinery Limited

- TGW Logistics Group GmbH

- Witron Logistik

- System Logistics

- Interroll Group

第八章投资分析

第9章 市场的未来

简介目录

Product Code: 55098

The NA AMH and Storage Systems Market is expected to register a CAGR of 8.2% during the forecast period.

Key Highlights

- Vendors of material handling solutions gradually veered toward the modern approach of helping end-users focus on their operations' space and time utility by manufacturing flexible systems that can seamlessly integrate with other systems as part of the overall material handling plan. Also, automated guided vehicles and AS/RS have emerged as the most dynamic material handling equipment and storage systems solutions and are mainly deployed in warehouses, distribution centers, and airports.

- Further, various partnerships are witnessing in the North American Market. For instance, In February 2021, Best Buy, a prominent US-based consumer electronics store, announced redesigning its regional distribution centers in partnership with Bastian Solutions. The project included integrating automated storage and retrieval technology, conveyor, and warehouse execution software to serve each facility best. The association has assisted Best Buy in offering next-day delivery and managing large inbound shipments effectively.

- The focus on Industry 4.0 across different end-user industries in the region also presents new opportunities for the market. According to the 2021 Industry 4.0 survey by the BDO United States, almost 50% of the manufacturers anticipate their digital investments may lead to revenue increases in the next 12 months. Also, 43% of the respondents have deployed robotic process automation (RPA), while 47% plan to deploy it in the future. Some of the crucial aspects for improving the supply chain include customer order cycle (19%), total delivery cost (18%), performance to plan (18%), and inventory turnover (16%).

- Additionally, the increasing labor rates in the region are also developing the need for new technologies that help reduce the dependency on laborers for material handling. According to Statistics Canada, Labour costs per unit of output of Canadian businesses increased by 2.7% in the second quarter of 2021, following slight increases in the previous two quarters. The more rapid growth in unit labor costs primarily reflects the rebound in the average compensation per hour worked (+3.2%), following three-quarters of the decline.

North America AMH & Storage Systems Market Trends

Automated Guided Vehicle Expected to Witness Significant Market Share

- The growing adoption of Automated Guided Vehicles (AGVs) is also a factor that is driving the growth of the market. According to the Modern Materials Handling (MMH), 11% of the respondents will use AGVs in 2021, while 18% plan to use them in the next 24 months.

- The market is witnessing various innovations for automated tow and forklifts. For instance, In December 2020, Toyota announced a new Center-Controlled Rider and CoreTow Tractor Automated Forklifts for warehouse operations. The AGVs were developed by Toyota Forklift, in collaboration with Bastian Solutions, a subsidiary of Toyota Advanced Logistics company, for applications in manufacturing facilities and distribution center operations to perform highly repetitive tasks. Also, the new forklifts by Toyota operate manually whenever required and can work autonomously by utilizing light detection and ranging (LIDAR) based navigation.

- Also, the competitive environment among all the logistics players in the region encourages them to either increase their warehouse establishments or increase the efficiency of current warehouses establishments by automating the operations, which drives the use of automated guided vehicle growth in the market.

- Furthermore, the growth of large-scale warehouses is also presenting a need for automated forklifts, further driving the automated guided vehicle market. For instance, In November 2020, DSV Global Transport Logistics opened the largest Multi-Client Logistics Facility in Canada Near Toronto. The warehouse offers 111,000 sq. ft of climate-controlled space.

- The growing R&D in forklift technology is expected to create a scope for AGV, which is in line with the investments in Industry 4.0, artificial intelligence, and machine learning. Furthermore, COVID-19 has also increased consumer adoption and acceptance of e-commerce and created a need for remote material handling and storage systems in different end-user industries, which is also expected to create new opportunities for autonomous or driverless technologies in forklifts.

United States Expected to Witness Significant Market Share

- The United States is one of the significant robot markets worldwide, with sales being influenced by the demand from the automotive industry in the region. For instance, According to the World Robotics 2020 Industrial Robots report presented by the International Federation of Robotics (IFR), a record of about 293,000 industrial robots operating in factories of the United States an increase of 7% compared with the previous year. Sales of new robots remain on a high level, with 33,300 units shipped in 2019. The growth in robotics technology creates new opportunities for the market.

- The growing warehouse space in the region is also developing a need for automated material handling and storage equipment. According to the Bureau of Labor Statistics, warehouses increased from 18,736 in 2019 to 19190 in 2020. Furthermore, companies such as Amazon and Walmart are expanding their footprint rapidly with new warehouses. In May 2021, Amazon announced a 3.8 million square feet warehouse, one of the country's largest warehouses.

- The investments in mobile robotics, artificial intelligence, and machine learning are also driving the country's growth. For instance, The National Robotics Initiative 3.0 2021 focuses on accelerating the development and use of robots in the United States.

- According to the 2020 Honeywell Intelligrated Automation Investment Study, more than half of the companies in the United States are increasingly open to investing in automation to survive changing market conditions. The industries that are most willing to invest in automation are e-commerce (60%), grocery, food, and beverage (59%), and logistics (55%). Thus, creating new opportunities for the adoption of automated material handling and storage systems.

- The increase in warehouse automation, rising adoption of automated material handling, and trends, like lights-out automation, are some of the major factors driving the United States.

North America AMH & Storage Systems Industry Overview

The North America Automated Material Handling and Storage Systems Market is moderately competitive, with a considerable number of regional and global players. The major vendors with a prominent share in the market are focusing on innovations, mergers and acquisitions, partnerships, and expanding customer base across foreign countries. The companies are leveraging on strategic collaborative initiatives to increase their profitability.

- August 2020 - Murata Machinery Ltd signed a contract with Alpen Co. Ltd to construct the first 3D robot warehousing system, ALPHABOT. Further, ALPHABOT will be introduced at the Alpen Komaki Distribution Center, one of Alpen Group's main distribution centers, to complement its storage capacity and reduce picking, sorting, and packaging operations by approximately 60%.

- July 2020 - Interroll completed construction of the second plant in Hiram (Atlanta), Georgia. The USD 11 million investment gives Interroll a substantial increase in capacity for the region. At Interroll, the Americas region continues to see a high level of project activities. At the same time, the company is quickly introducing innovative solutions to the markets.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Impact of COVID-19 on the Industry Ecosystem

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Technological Advancements Aiding Market Growth

- 5.1.2 Rapid Growth in E-commerce Leading to Warehouse Automation

- 5.1.3 Industry 4.0 Investments Driving the Demand for Automated Material Handling and Storage Systems

- 5.2 Market Challenges

- 5.2.1 Unavailability for Skilled Workforce

- 5.2.2 High Capital Requirements

6 MARKET SEGMENTATION

- 6.1 By Product Type

- 6.1.1 Software

- 6.1.2 Hardware

- 6.1.3 Services

- 6.1.4 Integration

- 6.2 By Equipment Type

- 6.2.1 Mobile Robots

- 6.2.1.1 Automated Guided Vehicle(AGV)

- 6.2.1.1.1 Automated Forklift

- 6.2.1.1.2 Automated Tow/Tractor/Tug

- 6.2.1.1.3 Unit Load

- 6.2.1.1.4 Assembly Line

- 6.2.1.2 Autonomous Mobile Robots(AMR)

- 6.2.2 Automated Storage and Retrieval System(ASRS)

- 6.2.2.1 Fixed Asile

- 6.2.2.2 Carousel

- 6.2.2.3 Vertical Lift Module

- 6.2.3 Automated Conveyor

- 6.2.3.1 Belt

- 6.2.3.2 Roller

- 6.2.3.3 Pallet

- 6.2.3.4 Overhead

- 6.2.4 Palletizer

- 6.2.4.1 Conventional

- 6.2.4.2 Robotic

- 6.2.5 Sortation System

- 6.2.1 Mobile Robots

- 6.3 By End-User

- 6.3.1 Airport

- 6.3.2 Automotive

- 6.3.3 Food and Beverage

- 6.3.4 Retail/Warehousing/Distribution Centers/Logistic Centers

- 6.3.5 General Manufacturing

- 6.3.6 Pharmaceuticals

- 6.3.7 Post and Parcel

- 6.3.8 Electronics and Semiconductor Manufacturing

- 6.3.9 Other End-Users

- 6.4 By Country

- 6.4.1 United States

- 6.4.2 Canada

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 JBT Corporation

- 7.1.2 Honeywell Intelligrated (Honeywell International Inc.)

- 7.1.3 SSI SCHEFER AG

- 7.1.4 Daifuku Co. Limited

- 7.1.5 Kardex Group

- 7.1.6 Beumer Group GMBH & Co. KG

- 7.1.7 Jungheinrich AG

- 7.1.8 Murata Machinery Limited

- 7.1.9 TGW Logistics Group GmbH

- 7.1.10 Witron Logistik

- 7.1.11 System Logistics

- 7.1.12 Interroll Group

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET

02-2729-4219

+886-2-2729-4219