|

市场调查报告书

商品编码

1629800

北美自动化物料输送:市场占有率分析、产业趋势与成长预测(2025-2030)North America Automated Material Handling - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

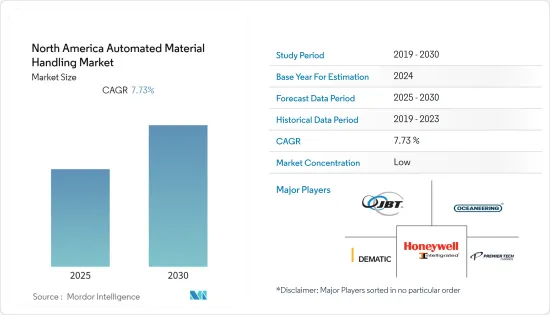

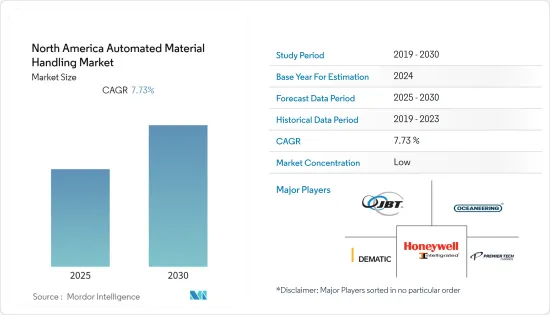

北美自动化物料输送市场预计在预测期内复合年增长率为 7.73%

主要亮点

- 随着越来越多的公司转向自动化来提高仓库效率、降低成本并保持市场竞争力,他们也在此过程中使员工的职场更加安全。自动化物料输送的主要动机之一是改善工作和安全条件。根据美国劳工统计局的数据,2021 年,在需要休假的非致命职业伤害中,有 27% 是由滑倒、绊倒和跌倒造成的。超过 235,000 人因接触设备或物体而不得不缺勤。透过自动化物料输送任务,製造商可以将工人从危险或重复性任务中解放出来。这可以将人才重新部署到职场的其他部分,使员工能够提高工作效率、安全性和成就感。

- 零售、汽车、食品和饮料以及製药等行业是该国自动化物料输送解决方案的最大需求来源。食品和饮料是最大的产业,占美国年度包装出货量的35%以上。

- 此外,由于仓库空置率较低和租金价格上涨,公司越来越多地寻找较小的空间来租用存放。我们预计公司很快就会部署更多自动化解决方案,以在如此狭小的空间中优化生产力。

- 此外,美国电商物流成本占美国物流总成本的6.9%以上。虽然供应链中的最后一英里仍然很重要,但製造商认识到,没有第一英里,就没有最后一英里。应用正确的物料输送技术可以节省可衡量的成本,同时带来即时的投资回报。

- COVID-19 大流行影响了许多公司,包括小型和大型製造商。全球范围内,自动物料输送系统市场的产品需求在一定程度上受到限制。产品开发生命週期受到劳动力少和营运限制的显着影响。停工限制放鬆后,需求在一定程度上稳定。公司已经创造了多种技术和方法来应对 COVID-19 带来的挑战。此外,2020 年 7 月,Honeywell发布的一项研究表明,超过 50% 的美国企业愿意投资自动化以应对不断变化的市场状况。 2020 年Honeywell整合自动化投资研究强调电子商务 (66%)、食品饮料 (59%) 和物流 (55%) 产业是增加自动化投资的先锋。

北美自动化物料输送市场趋势

零售/仓储/物流将占很大份额

- 美国拥有强大的电子商务生态系统。根据美国人口普查局数据,2022年1月至3月,美国零售电商销售额达到约2,500亿美元,较上季成长2.4%。快速发展的零售市场正在推动物流中心寻找并使用创新、灵活和自动化的方法来处理电子商务订单。

- 电子商务是自动化配送仓库需求的主要驱动力,因为消费者要求比以往更快的交货时间。消费者需求的变化和配送方式的创新预计也将推动美国零售市场的发展。随着电子商务市场的强劲成长,美国零售终端用户对 AMH 设备的需求也预计会增加。

- 当零售店的后台或配送中心易于操作和组织时,自动化物料输送设备可以帮助确保整体客户满意度,并提高库存和库存效率。例如,REB 等公司在美国供应、交付和安装物料输送和储存系统,并专注于满足客户满意度。

- 零售业是输送机和分类要求非常重要的主要产业之一。它帮助线上零售商对产品进行分类并提高交付效率。此外,零售公司还部署这种自动化物料输送设备进行最后一英里的交付。

- 自动化物料输送设备使零售后台和配送中心易于操作且井井有条,确保整体客户满意度并提高采购和库存效率。例如,REB 等公司为美国的零售企业供应、交付和安装物料输送和储存系统,并专注于满足客户满意度。

美国占有很大份额

- 美国是世界上最发达的经济体。该国的製造业是AMH市场的庞大需求来源,依赖主导的美国经济,美国经济占该地区经济产出的82%。

- 该国拥有强大的贸易和非常活跃的电子商务部门,增加了对仓库空间的需求。此外,北美机场业是世界上最大的机场业之一。它每年为大约 10.115 亿国内和国际乘客提供服务。它也是世界上最大的机场之一的所在地,预计将加强自动化的采用力度,以避免经营模式受到干扰。

- 美国拥有全球最大的汽车市场之一,是全球各类汽车製造商和汽车零件製造商的所在地。加上汽车需求的增加,美国作为最大的出口国和製造国(第二大)以及投资的增加,预计所研究的市场将见证美国汽车工业的强劲需求。

- 此外,由于製药业的变化和研发生产力的下降,美国製药业的成长正在放缓。该地区价值链各个阶段的数位化和自动化程度不断提高,帮助製药业更快地将药品从实验室送到患者手中。预计新的政策改革将影响预测期内的市场成长。以患者为中心的药物和生物相似药等趋势预计将对所研究市场的成长产生积极影响。

- 此外,该地区不断上涨的劳动力工资也催生了对新技术的需求,以帮助减少对物料输送工人的依赖。加拿大统计局数据显示,继前两季小涨后,2021年第二季加拿大企业每单位产出的人事费用上涨2.7%。这是去年以来最高的季度成长率。

北美自动化物料输送产业概况

自动化物料输送市场由各种硬体、软体和服务供应商适度整合。然而,大福、卡迪斯集团、凯傲集团和 JBT 公司等主要供应商作为自动物料输送产品/解决方案/服务供应商,已获得从中小型企业到大型企业的广泛认可。由于市场优势,这些公司正在更新与物料输送公司的伙伴关係。

- 2022 年 7 月 - JBT Corporation 收购 Alco-food-machines GmbH & Co.KG (Alco)。透过采用先进的自动化物料输送设备,您可以确保产品和员工的安全,而不会影响流程品质、时间或利润。 Alco 是 JBT 的理想选择,该品牌接触了广泛的食品和饮料平台,并为一家拥有关键技术和食品领域专业知识的公司描述了一个有吸引力的继任机会。

- 2021 年 11 月 - Westfalia 的自动储存/搜寻系统 (AS/RS) 和 Savanna.NET 仓库执行系统 (WES) 实现食品生产的完全自动化。 Kens Foods 选择 Westfalia Technologies 来实现亚特兰大地区新仓库的自动化。 Westfalia 的技术描述了一个可靠的温控仓库环境,为所有物料输送提供客製化解决方案,从收货到运输几乎实现零接触。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争公司之间敌对关係的强度

- COVID-19 对自动化物料输送市场的影响

第五章市场动态

- 市场驱动因素

- 技术进步不断推动市场成长

- 工业 4.0 投资推动自动化和物料输送的需求

- 电子商务快速成长

- 市场问题

- 初始成本高

- 缺乏技术纯熟劳工

第六章 市场细分

- 依产品类型

- 硬体

- 软体

- 服务

- 依设备类型

- 移动机器人

- 自动导引运输车(AGV)

- 自动堆高机

- 自动拖车/拖拉机/标籤

- 单元货载

- 组装

- 特殊用途

- 自主移动机器人(AMR)

- 雷射导引车

- 自动储存和搜寻系统(ASRS)

- 固定通道(堆垛机高机+穿梭系统)

- 轮播(水平轮播+垂直轮播)

- 垂直升降模组

- 自动输送机

- 腰带

- 滚筒

- 调色盘

- 开卖

- 堆垛机

- 常规型(高电位+低电位)

- 机器人

- 分类系统

- 移动机器人

- 按最终用户产业

- 飞机场

- 车

- 饮食

- 零售/仓库/配送中心/物流中心

- 一般製造业

- 药品

- 小包裹

- 其他的

- 按国家/地区

- 美国

- 加拿大

第七章 竞争格局

- 公司简介

- JBT Corporation

- Oceaneering International Inc.

- Dematic Corp.

- Honeywell Intelligrated

- Premier Tech Chronos

- DMW&H

- Westfalia Technologies Inc.

- OPUS Automation Inc.

- Creative Automation Inc.

- Remtec Automation

- Shuttleworth LLC

- Siggins

- Cornerstone Automation Systems LLC

第八章投资分析

第9章 市场的未来

The North America Automated Material Handling Market is expected to register a CAGR of 7.73% during the forecast period.

Key Highlights

- As more businesses turn to automation to boost efficiency in the warehouse, lower costs, and stay competitive in the market, they also make the workplace safer for employees in the process. One of the main motivations for automated material handling is improving working and safety conditions. According to the United States Bureau of Labor Statistics, in 2021, slips, stumbles, and falls were the cause of 27% of nonfatal occupational injuries that required days off from work. More than 235,000 people had to take time off work as a result of equipment or object contact. Automating material handling tasks allows manufacturers to remove workers from dangerous or repetitive work. This allows them to redeploy talent to other areas of the workplace where workers can be more productive, safe, and fulfilled.

- Sectors, including retail, automotive, food and beverage, and pharmaceutical, are the largest sources of demand for automated material handling solutions in the country. Food and beverage is the largest industry and represents more than 35% of US packaging shipments annually.

- Additionally, owing to low vacancy and a surge in the rental prices of warehouses, enterprises are progressively looking for smaller places to rent out for warehouse purposes. In order to optimize the productivity of these narrow spaces, they are expected to deploy more automated solutions soon.

- Moreover, the e-commerce logistics costs in the United States account for over 6.9% of the total US logistics costs. The importance of the last mile in the supply chain will never be lost; however, manufacturers realize that there is no last mile without the first. Applying the proper material handling technology produces measurable cost savings while bringing an immediate ROI.

- The COVID-19 pandemic had an impact on a variety of businesses, including small and big manufacturers. It limited the demand for products in the automated material handling system market on a global scale to some extent. The product development life cycle was significantly impacted by a small workforce and operational constraints. After the lockdown restrictions were later eased, demand stabilized to some extent. Companies created various technologies and methods to address issues caused by COVID-19. Further, in July 2020, a study released by Honeywell suggested that over 50% of U.S. companies have shown openness to investing in automation to survive changing market conditions. The 2020 Honeywell Integrated Automation Investment Study highlighted that the e-commerce (66%); grocery, food, and beverage (59%); and logistics (55%) industries are the forerunners in investing more in automation.

North America Automated Material Handling Market Trends

Retail/Warehousing/Logistics to Hold Significant Share

- The United States boasts a robust E-commerce ecosystem. According to the US Census Bureau, from January to March 2022, US retail e-commerce sales accounted for almost USD 250 billion, marking a 2.4% increase compared to the previous quarter. The rapidly evolving retail market is encouraging distribution centers to find and use innovative, flexible, and automated approaches to e-commerce order fulfillment.

- E-commerce is a significant driving factor for the demand from automated distribution warehouses, as consumers seek ever-shorter delivery times. Also, changing consumer needs and innovation in delivery methods are expected to drive the US retailing market. With the e-commerce market expected to witness robust growth, the demand for AMH equipment from the US retail end-user segment is also expected to increase.

- With a retail backroom or distribution center that is easy to steer and is well-organized, automated material handling equipment help ensure overall customer satisfaction and makes stocking and inventory more efficient. For instance, companies like REB furnish, deliver, and install material handling and storage systems nationwide in the United States, focusing on meeting customer satisfaction.

- Retail is one of the major industries in which the requirement for conveyors and sortation is important. It helps online retailers to sort goods and enhance delivery efficiency. Furthermore, retail companies are also adopting this automated material handling equipment to perform last-mile delivery.

- With a retail backroom or distribution center that is easy to steer and is well-organized, automated material handling equipment help ensure overall customer satisfaction and makes stocking and inventory more efficient. For instance, companies like REB furnish, deliver, and install material handling and storage systems for the retail sector nationwide in the United States, focusing on meeting customer satisfaction.

United States to Hold Major Share

- The United States is the most advanced economy in the world. The country's manufacturing sector, which is a huge source of demand for the AMH market, hinges on the dominant US economy, accounting for 82% of the region's economic output.

- The country has a high trading profile and a highly active e-commerce sector, which increases the demand for warehouse space. Moreover, the North American airport industry is one of the largest airport industries in the world. It provides services to about 1,011.5 million domestic and international passengers every year. It is also home to some of the world's biggest airports and is expected to bolster the adoption of automation to ensure no disruptions in the business model.

- The United States is home to one of the largest automotive markets in the world, with the presence of various global vehicle and auto part manufacturers. With the increasing demand for automotive vehicles and the United States being one of the largest exporters and manufacturers (second-largest), coupled with increasing investment, the market studied is expected to witness significant demand from the US automotive industry.

- Additionally, the US pharmaceutical industry is experiencing slow growth with the changing pharmaceutical landscape and diminished productivity in R&D. Digitalization and automation in the region, at every point along the value chain, help the pharmaceutical industry get pharmaceuticals from the lab to the patient more swiftly. New policy reforms are expected to influence market growth over the forecast period. Trends, such as patient-centric healthcare and biosimilars, is expected to positively impact the growth of the market studied.

- Furthermore, the increasing labor rates in the region are also developing the need for new technologies which help in reducing the dependency on laborers for material handling. According to Statistics Canada, Labour costs per unit of output of Canadian businesses rose 2.7% in the second quarter of 2021, following slight increases in the previous two quarters. This was the highest quarterly growth rate in a year.

North America Automated Material Handling Industry Overview

The automated material handling market is moderately consolidated, with a range of hardware, software, and service providers. However, major vendors such as Daifuku Co. Ltd, Kardex Group, KION Group, JBT Corporation, and many more are highly preferred automated material handling product/solution/service providers across small and large enterprises. The firms are renewing their partnership with material handling companies due to the benefits of the market.

- July 2022 - JBT Corporation acquired Alco-food-machines GmbH & Co. KG (Alco), a provider of other food processing solutions and production lines. The deployment of advanced and automated material handling equipment helps the company ensure the safety of products and employees without compromising process quality, time, and profits. Alco represents the ideal fit for JBT, where the brands approach the broad food and beverage platform and offer a compelling succession opportunity for companies with leading technology and food domain expertise.

- November 2021 - Westfalia's automated storage/retrieval system (AS/RS) and Savanna.NET Warehouse Execution System (WES) will fully automate food manufacturing. Kens foods chose Westfalia Technologies to automate the new Atlanta-area warehouse. Westfalia's technology will provide a reliable, temperature-controlled warehousing environment with a customized solution addressing all material handling while delivering almost zero touches from receiving to shipping.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Impact of COVID-19 on the Automated Material Handling Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Technological Advancments Aiding Market Growth

- 5.1.2 Industry 4.0 Investments Driving the Demand for Automation and Material Handling

- 5.1.3 Rapid Growth of E-Commerce

- 5.2 Market Challenges

- 5.2.1 High Initial Costs

- 5.2.2 Unavailability for Skilled Workforce

6 MARKET SEGMENTATION

- 6.1 By Product Type

- 6.1.1 Hardware

- 6.1.2 Software

- 6.1.3 Services

- 6.2 By Equipment Type

- 6.2.1 Mobile Robots

- 6.2.1.1 Automated Guided Vehicle (AGV)

- 6.2.1.1.1 Automated Forklift

- 6.2.1.1.2 Automated Tow/Tractor/Tug

- 6.2.1.1.3 Unit Load

- 6.2.1.1.4 Assembly Line

- 6.2.1.1.5 Special Purpose

- 6.2.1.2 Autonomous Mobile Robots (AMR)

- 6.2.1.3 Laser Guided Vehicle

- 6.2.2 Automated Storage and Retrieval System (ASRS)

- 6.2.2.1 Fixed Aisle (Stacker Crane + Shuttle System)

- 6.2.2.2 Carousel (Horizontal Carousel + Vertical Carousel)

- 6.2.2.3 Vertical Lift Module

- 6.2.3 Automated Conveyor

- 6.2.3.1 Belt

- 6.2.3.2 Roller

- 6.2.3.3 Pallet

- 6.2.3.4 Overhead

- 6.2.4 Palletizer

- 6.2.4.1 Conventional (High Level + Low Level)

- 6.2.4.2 Robotic

- 6.2.5 Sortation System

- 6.2.1 Mobile Robots

- 6.3 By End-user Vertical

- 6.3.1 Airport

- 6.3.2 Automotive

- 6.3.3 Food and Beverage

- 6.3.4 Retail/Warehousing/ Distribution Centers/Logistic Centers

- 6.3.5 General Manufacturing

- 6.3.6 Pharmaceuticals

- 6.3.7 Post and Parcel

- 6.3.8 Other End Users

- 6.4 By Country

- 6.4.1 United States

- 6.4.2 Canada

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 JBT Corporation

- 7.1.2 Oceaneering International Inc.

- 7.1.3 Dematic Corp.

- 7.1.4 Honeywell Intelligrated

- 7.1.5 Premier Tech Chronos

- 7.1.6 DMW&H

- 7.1.7 Westfalia Technologies Inc.

- 7.1.8 OPUS Automation Inc.

- 7.1.9 Creative Automation Inc.

- 7.1.10 Remtec Automation

- 7.1.11 Shuttleworth LLC

- 7.1.12 Siggins

- 7.1.13 Cornerstone Automation Systems LLC