|

市场调查报告书

商品编码

1631625

石油和天然气无损检测市场:市场占有率分析、产业趋势/统计、成长预测(2025-2030)Non-Destructive Testing in Oil and Gas Market - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

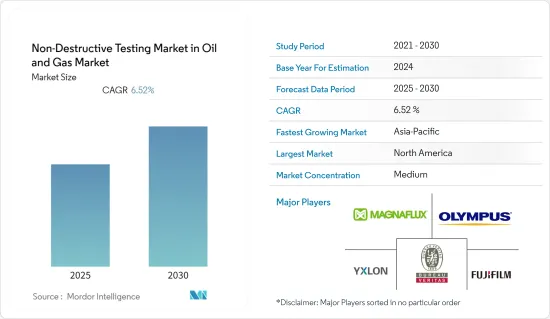

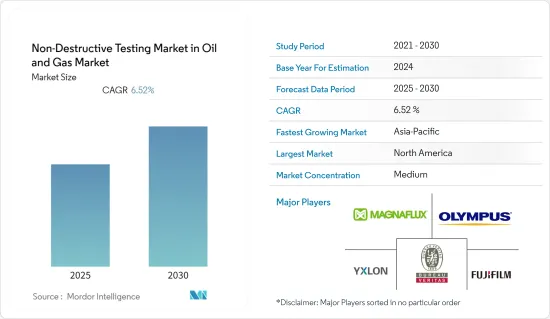

石油和天然气无损检测市场预计在预测期内复合年增长率为6.52%。

主要亮点

- 据英国无损检测协会称,英国工厂和现场每天都会进行超过 25,000 次测试,以发现各种产品、工厂和结构中的缺陷和损坏。据信,全球有超过 12 万名检查员在工作。

- 无损检测市场是由机械日益复杂、对产品精确使用规范的需求、严格执行政府法规以保护工人安全、需要更严格的品管等推动的。

- 由于过去发生的精油洩漏、管线爆炸和炼油厂爆炸事件,世界各国政府加强了有关无损检测的安全法规,这推动了市场的成长。

- 超音波检测预计将显着增长。它使用低频(20kHz 至 100kHz)广播来检测和识别材料属性的变化,通常表示组件的机械完整性已受到损害。它经常用于检测水下和埋地管道的腐蚀。

- COVID-19 大流行的爆发对全球几乎所有行业(包括汽车、建筑、航空和製造业)来说都是不利且意想不到的发展。作为预防措施,世界各地许多政府都采取了封锁措施,以阻止冠状病毒的传播及其负面影响。

- 全球供应链中断和工业生产力下降对全球经济造成压力。病毒的突然爆发也扰乱了企业的生产製造能力。

石油和天然气无损检测市场趋势

无人机在市场上的使用越来越多

- 近年来,配备摄影机的无人机已成为无损检测中收集视觉资料的另一种常用工具。由于技术限制,无人机只能在短时间内为检查人员提供补充视觉资料。儘管如此,无人机并不能取代检查人员亲自收集视觉资料。然而,无人机技术的改进使得检查人员可以使用无人机作为 RVI 工具,在某些情况下无需手动收集视觉资料。

- 无人机无需检查员进入危险区域收集视觉资料,从而提高职场安全性。对于炼油厂、管道和石油储备等资产的户外检查,无人机可以收集视觉资料,减少人们在塔和线路上花费的时间。

- 对于压力容器和锅炉等资产的室内检查,使用 FlyAbility 的 Elios 2 等无人机收集视觉资料可以透过消除检查员进入密闭空间的需要来显着降低风险。

- 到目前为止,无人机在无损检测中的主要用途是收集视觉资料。但近年来,无人机上的热感测器使检查人员能够从每架无人机收集热资料。随着时间的推移,为无人机开发的新感测器可能会出现,支援更多无损检测技术。

北美仍是最大市场

- 随着美国、加拿大和墨西哥等国家石油和天然气计划的增加,该地区未来几年可能会强劲成长。美国是最大的天然气和原油生产国之一。

- 美国拥有世界上最大的技术可采页岩气蕴藏量和第二大緻密油蕴藏量。水力压裂和损益平衡技术的新发展正在为陆上地区的上游石油和天然气提供支援。这意味着无损检测公司的需求量很大。

- 加拿大是世界领先的石油和天然气生产国之一。石油和天然气工业对国家经济至关重要。油砂仍是碳氢化合物生产的重要来源,占石油蕴藏量的90%以上。根据加拿大石油生产商协会(CAPP)预测,到2030年,该国石油产量预计将达到54亿桶/日,其中油砂占70.7%。

- 上述因素导致预测期内区域石油和天然气市场无损检测需求的增加。

石油和天然气无损检测概述

无损检测市场竞争激烈。越来越多的法规要求各个组织强制执行寿命评估程序作为安全措施,再加上需要定期检查以检查设备的任何损坏并采取必要的措施,这塑造了无损检测市场。因此,企业纷纷进入这个市场,将其视为一个巨大的机会。主要参与者包括 Magnaflux Corp.、Zetec Inc.、YXLON International Gmbh (COMET Group)、 FUJIFILM Corporation、 Olympus Corporation和 Bureau Veritas SA。近期趋势如下:

2022 年 9 月,Waygate Technologies 与 RINA 合作。此次合作将无损检测领域的数位专业知识和资料智慧相结合,为客户创造卓越的利益和附加价值。此接头解决方案有助于检测焊接期间和焊接后的潜在缺陷,优化生产过程,降低返工和报废风险,从而提高焊接接头的品质。

2022 年 5 月,TWI 与 Tech Eurolab Ltd. 签署了一份谅解备忘录,在各个行业和技术领域开展资助计划和无损检测计划,以实现产品和流程的最高品质和安全标准。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场动态

- 市场概况

- 产业相关人员分析

- 市场驱动因素

- 炼油厂资产运作营运的需求日益增加

- 上游产业预计将在主要市场获得动力

- 市场挑战

- 减产和技术纯熟劳工短缺

- COVID-19 市场影响评估

- 无损检测设备与服务业比较分析

- 市场机会

第五章市场区隔

- 按类型

- 装置

- 服务

- 按类型

- 上游

- 中游

- 下游

- 依技术

- 超音波

- 射线照相术

- 目视检查

- 液体液体渗透探伤剂

- 其他(磁粉探伤、涡流探伤)

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 世界其他地区

第六章 竞争状况

- 公司简介

- Magnaflux Corp

- YXLON International Gmbh(COMET Group)

- Fujifilm Corporation

- Olympus Corporation

- Bureau Veritas SA

- GE Measurement and Control(Baker Hughes)

- Karl Storz Ndtec Gmbh

- Intertek Group PLC

- Applus Services SA

- Magnetic Analysis Corporation

- Zetec Inc

第七章 投资分析

第八章市场的未来

The Non-Destructive Testing Market in Oil and Gas Market is expected to register a CAGR of 6.52% during the forecast period.

Key Highlights

- According to the British Institute of Non-Destructive Testing, more than 25,000 inspections are done every day in factories and on-site in the UK to find flaws and damage in a wide range of products, plants, and structures. It is thought that more than 120,000 inspectors are working around the world.

- The NDT market is driven by the increasing complexity of machines, the need for accurate product usage specifications, the strict enforcement of government rules to keep workers safe, and the need for tighter quality control.

- As a result of refinery leaks, pipeline explosions, and refinery explosions in the past, governments around the world have tightened safety rules for NDT, which has helped the market grow.

- Significant growth is expected in ultrasonic testing. This is where the broadcast of low-frequency waves (20 kHz to 100 kHz) can detect and identify changes in material properties, often indicating that the mechanical integrity of the part is compromised. This is frequently used to detect corrosion in underwater or buried pipelines.

- The COVID-19 pandemic outbreak turned out to be unfavorable and unforeseen for almost all industries globally, including automotive, construction, airlines, and manufacturing. As a precaution, many governments around the world put lockdowns in place to stop the spread of the new coronavirus and its bad effects.

- The disrupted global supply chain and decreased industrial productivity strained the global economy. The companies' production and manufacturing capabilities were also disrupted due to the sudden outbreak of the virus.

Non-Destructive Testing in Oil and Gas Market Trends

The Rising Usage of Drones in the Market

- Over the last few years, camera-equipped drones have become another commonly used tool in NDTs for collecting visual data. Due to technical limitations, drones could only provide inspectors with supplementary visual data for a short time. Still, they were not a substitute for inspectors who physically collect the visual data themselves. However, as drone technology has improved, inspectors can now use the drone as an RVI tool, eliminating the need to collect visual data manually in some cases.

- Drones improve workplace safety by eliminating the need for inspectors to enter dangerous areas to collect visual data. For outdoor inspections of assets like refineries, pipelines, and oil reserves, drones can collect visual data to reduce the amount of time a person needs to be on a tower or line.

- For indoor inspection of assets such as pressure vessels and boilers, using a drone like the Elios 2 from FlyAbility to collect visual data eliminates the need for inspectors to enter confined spaces and significantly reduces the risk.

- To date, the primary use of drones in NDT has been collecting visual data. However, thermal sensors mounted on drones have allowed inspectors to collect thermal data on a drone-by-drone basis over the past few years. Over time, new sensors developed for drones may emerge to support more NDT technologies.

North America to Remain the Largest Market

- With the rise of oil and gas projects in countries such as the United States, Canada, and Mexico, the region can grow strongly over the next few years. The United States is one of the largest producers of natural gas and crude oil.

- The United States has one of the world's largest technically recoverable shale gas reserves and the second-largest tight oil reserves. New developments in hydraulic fracturing and break-even technology support upstream oil and gas in the onshore region. This means that NDT companies are in high demand.

- Canada is one of the world's largest producers of gas and oil. The oil and gas industry is vital to the country's economy. Oil sands remain a significant source of hydrocarbon production, accounting for more than 90% of total oil reserves. According to the Canadian Oil Producers Association (CAPP), the country's oil production is projected to reach 5.4 billion barrels per day in 2030, with oil sands accounting for 70.7% of the total output.

- The factors mentioned earlier contribute to the increasing demand for Non-Destructive Testing in the oil & gas market in the region during the forecast period.

Non-Destructive Testing in Oil and Gas Industry Overview

The NDT market is competitive. The increasing regulations, which make it mandatory for different organizations to undergo a life assessment procedure as a safety measure, coupled with the regular inspection required to check for any damage in the equipment and take necessary action, create a market for NDT. Thus, companies are entering this market, seeing a huge opportunity. Some key players are Magnaflux Corp., Zetec Inc., YXLON International Gmbh (COMET Group), Fujifilm Corporation, Olympus Corporation, and Bureau Veritas SA, among others. Some recent developments are:

In September 2022, Waygate Technologies teams up with RINA. This collaboration combines digital expertise and data intelligence in non-destructive inspection to create exceptional customer benefits and added value. The joint solution will help detect potential defects during and after welding, optimize production processes, reduce the risk of rework and scrap, and eventually improve the quality of welded joints.

In May 2022, TWI signed an MoU with Tech Eurolab Ltd. for delivering funded projects and non-destructive testing programs across a range of industries and technologies for attaining the highest standards of quality and safety for products and processes.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Industry Stakehholder Analysis

- 4.3 Market Drivers

- 4.3.1 Rising need to run refinery assets at full cap

- 4.3.2 Upstream sector expected to gain momentum in key markets

- 4.4 Market Challenges

- 4.4.1 Production cuts and lack of skilled workforce

- 4.5 Assessment of the Impact of COVID-19 on the Market

- 4.6 Comparative Analysis of NDT Equipment VS Service Industry

- 4.7 Market Opportunities

5 MARKET SEGMENTATION

- 5.1 By Type

- 5.1.1 Equipment

- 5.1.2 Services

- 5.2 By Type

- 5.2.1 Upstream

- 5.2.2 Midstream

- 5.2.3 Downstream

- 5.3 By Technique

- 5.3.1 Ultrasonic

- 5.3.2 Radiography

- 5.3.3 Visual Inspection

- 5.3.4 Liquid Penetrant

- 5.3.5 Others (Magnetic Particle & Eddy Current)

- 5.4 By Geography

- 5.4.1 North America

- 5.4.2 Europe

- 5.4.3 Asia-Pacific

- 5.4.4 Rest of the World

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Magnaflux Corp

- 6.1.2 YXLON International Gmbh (COMET Group)

- 6.1.3 Fujifilm Corporation

- 6.1.4 Olympus Corporation

- 6.1.5 Bureau Veritas SA

- 6.1.6 GE Measurement and Control (Baker Hughes)

- 6.1.7 Karl Storz Ndtec Gmbh

- 6.1.8 Intertek Group PLC

- 6.1.9 Applus Services SA

- 6.1.10 Magnetic Analysis Corporation

- 6.1.11 Zetec Inc