|

市场调查报告书

商品编码

1635369

发电领域无损检测:市场占有率分析、产业趋势与统计、成长预测(2025-2030)NDT in Power Generation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

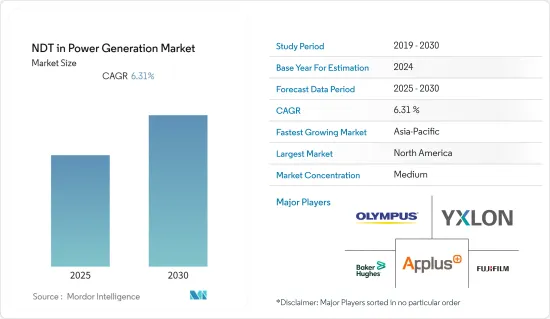

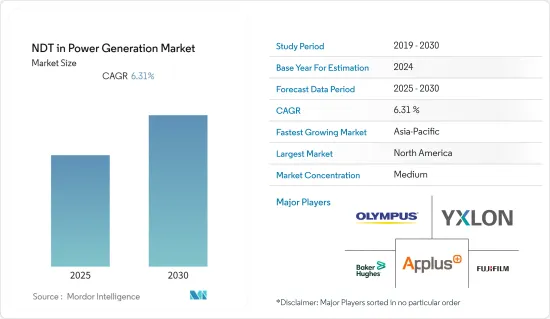

预计发电无损检测市场在预测期间的复合年增长率为 6.31%。

主要亮点

- 发电行业正在经历许多变化,包括整体效率的提高和所用材料品质的提高。暴露于操作或环境条件下可能会导致意外损坏。 NDT 可协助您检查此类缺陷并在它们成为更大问题之前解决它们。

- 无损检测在电力行业的主要应用范围是帮助确保工厂设备的安全性、完整性和可靠性,例如压力容器、锅炉、热交换器、管道和管道。水泥建筑物的检查是工厂寿命评估的一部分,因为这些材料通常构成工厂设备建造的一个组成部分。

- 北美是发电领域无损检测设备市场的旗手,并且继续拥有先进无损检测应用的机会。近年来,亚太地区尤其是中国、印度、日本和韩国的电力需求快速成长。这项变化为发电无损检测市场提供设备和服务的公司创造了巨大的市场机会。随着环保天然气发电厂的出现,亚太地区对非破坏性检测设备的需求预计将增加。

- 此外,数位成像技术日益提高的可用性和适应性也有望提高发电行业无损检测设备方法的成本效益。新的无损检测仪器技术还可以实现连续资料收集、储存、线上检测、高级即时资料模拟以及资讯解释。这些技术正在为市场创造重大机会。

- 此外,各种法规要求发电厂进行寿命评估程序作为安全措施。除此之外,还需要进行检查,检查设备是否有损坏,并采取必要的措施进行控制。这种情况可望扩大核能发电领域的商机。

- 美国机械工程师协会 (ASME) 和国际标准化组织 (ISO) 等多个政府机构和地区机构已製定严格的措施,以确保设备安全,同时监督工程服务测试过程。这对于获得相关机构的批准和证书至关重要,这将对无损检测市场产生积极影响。

发电无损检测的市场趋势

目视检查预计将显着成长

- 目视检查设备包括内视镜、高速摄影机、红外线摄影机和显微镜,用于检测检体表面的洩漏和裂缝。它们也用于发电行业的品质保证、维护和修理。目视检查在大量生产或最终检查过程中进行。

- 此外,目视检查设备包括用于两种类型检查的设备:直接检查和间接检查。直接检验设备是由一名检验员或检验员直接对材料进行检验和评估。

- 可使用管道镜、纤维内视镜和高清光学元件等工具进行直接目视检查。它们用于难以到达的区域,例如机器内部和锁后面。在间接目视检查中,用相机对要检查的区域进行拍照,显示在监视器上,并由大量人员进行检查。

- 由于技术进步和发电行业的数位化,公司正在创新自动视觉检测设备。例如,RNA 製造的电脑影像检查系统可以满足 100% 检测的高速品管要求。它可用于各行业的所有类型的自动化和机器人应用,包括系统整合、分类、生产、製造和发电产业。

- 此外,研究市场上的许多公司都提供远端视觉检测设备。例如,贝克休斯提供耐用的远端视觉检测设备,可以更轻鬆、更准确地收集和分析资料。该公司使用保证测量精度的Real3D和提供出色影像品质的TrueSight等技术。该公司的视觉检测设备旨在满足发电行业对安全、效率和准确性的现代需求。

亚太地区预计将出现显着成长

- 目前,中国是世界上最大的电力生产国。该国的能源需求预计将增加,从而推动能源生产的成长。无损检测在石化燃料领域的应用占据市场主导地位。该国的电力产业基础设施老化程度也不断增加,因此必须使用无损检测设备来识别并确保这些结构的完整性。因此,预计该国的无损检测服务在预测期内将快速成长。

- 2021年2月,中国运作燃煤发电量38.4吉瓦(GW)。中国也支持2020年新增煤电装置容量36.9GW,是2019年的三倍。目前,正在开发的燃煤发电容量为247吉瓦,足以供应整个德国。无损检测设备市场预计将从这些规划的发电厂中获得重大商机。

- 印度发电能力位居世界第五。发电量也高居世界第三。截至2021年3月,印度国家电网装置容量为382.15GW。这显示目前对无损检测设备的需求以石化燃料产业为主,核能无损检测设备正逐渐获得发展动能。

- 此外,截至年终,韩国有超过84座煤电厂(CPP)、27座燃气电厂(GPP)和23座核能发电厂(NPP)在运作。多项研究显示,韩国电力需求与前一年同期比较%,有4座核能发电厂、8座CPP在建,并宣布再建设6座CPP,增加了该地区无损检测机组的数量。 。

- 据日本核能工业论坛称,6个地点的12座核子反应炉已核准运作,两座新发电厂正在建设中,预计将在预测期内运作,发电领域的无损检测也已获得批准。 。

发电无损检测产业概况

发电领域的无损检测 (NDT) 市场竞争激烈,由几个主要企业组成。越来越多的法规要求各种组织进行寿命评估程序作为安全措施,再加上检查设备损坏情况所需的定期检查,正在塑造发电领域的无损检测市场。该市场的主要企业正在推出创新的新产品并建立伙伴关係和协作,以获得竞争优势。

- 2021 年 2 月 - Controle Mesure Systemes 开发了名为 Probus 的软体。它收集NDT设备提供的资讯、显示讯号、分析讯号、做出筛选决策并产生检查报告。 Probus是无损侦测线的决策中心。所有感测器资料都可以集中管理,并且可以控制测试台致动器。 Probus 软体的主要目的是产生单一产品或批次的检验报告,以确保可追溯性。它可以列出检测到的缺陷及其位置,并提供控制证明。

- 2021 年 1 月 -Olympus Corporation推出创新的 DP 系列相机,该系列相机共用智慧功能和精确的色彩精度,可简化工业显微镜的成像。 DP28相机提供4K解析度的高解析度影像。同时,DP23 相机的全高清解析度与有用的功能相平衡,使其对几乎所有工业影像处理应用(包括发电行业)具有出色的价值。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 买方议价能力

- 供应商的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争公司之间的敌对关係

- 产业价值链分析

- COVID-19 市场影响评估

第五章市场动态

- 市场驱动因素

- 严格的法规强制执行安全标准

- 缺陷检测的需求增加以降低维修成本

- 基础设施老化和维护需求增加

- 市场限制因素

- 熟练劳力短缺及培训规定

第六章 市场细分

- 按类型

- 服务

- 装置

- 透过检测技术

- 射线照相检查

- 超音波探伤检验

- 目视检查

- 涡流探伤

- 其他测试技术

- 按地区

- 北美洲

- 美国

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 其他欧洲国家

- 亚太地区

- 中国

- 日本

- 印度

- 其他亚太地区

- 拉丁美洲

- 中东/非洲

- 北美洲

第七章 竞争格局

- 公司简介

- Olympus Corporation

- Fujifilm Corporation

- Baker Hughes Company

- Yxlon International Gmbh(Comet Holding AG)

- Applus+Services Technologies, SL

- Mistras Group, Inc.

- SGS Group

- Bureau Veritas SA

- Zetec, Inc.

- Eddyfi

- Intertek Group Plc.

- Team Inc.

第八章投资分析

第9章 市场的未来

The NDT in Power Generation Market is expected to register a CAGR of 6.31% during the forecast period.

Key Highlights

- The power generation industry has undergone various changes, including enhanced overall efficiency and quality of the materials used. Exposure to operating and environmental conditions can cause damages to unforeseen. NDT serves that purpose to check any such flaws and help solve the problem before it elevates.

- The main scope of NDT applications in the power industry is to help ensure plant equipment's safety, integrity, and reliability, such as pressure vessels, boilers, heat exchangers, pipework, and pipelines. The inspection of concrete structures is a part of plant life assessment, as these materials often form an essential part of constructing such plant equipment.

- North America has been the flag bearer for the NDT equipment market in the power generation sector and still has opportunities for advanced NDT applications. Recently, Asia-Pacific has experienced an enormous boom in power demand, mainly from China, India, Japan, and South Korea. This shift has created significant market opportunities for companies providing equipment and services in the NDT market for electricity generation. Due to emerging eco-friendly natural gas power plants, the demand for NDT equipment is expected to be higher in the APAC region.

- Further, the increasing utilization and adaptability of digital imaging technology are also expected to increase the cost-effectiveness of the NDT equipment methods in the power generation industry. Continuous data collection, storage, online inspection, advanced simulation of data in real-time, and interpretation of the information are also possible with new NDT equipment techniques. These techniques are creating greater opportunities in the market.

- Moreover, various regulations make it mandatory for power plants to undergo a life assessment procedure as a safety measure. Apart from this, inspection is also required to check for any damages to the equipment and take necessary countermeasures to control them. This situation is expected to create increased opportunities in the nuclear power sector.

- Several governmental agencies and regional bodies, like the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO), have been instructed to formulate stringent measures for assuring the safety of instruments, while overseeing the process of engineering services testing. This is crucial for gaining clearances and certificates from the concerned authorities thereby creating a positive impact on the NDT market.

Non-Destructive Testing In Power Generation Market Trends

Visual Inspection Testing is Expected to Witness a Significant Growth

- Visual inspection equipment comprises a wide range of endoscopes, high-speed cameras, thermal imagers, and microscopes, which are used to detect leaks or cracks on the surface of the specimen. These are also used for quality assurance or maintenance and repair in the power generation industry. Visual inspections are carried out during series production or in the final inspection step.

- Also, visual inspection equipment comprises devices used for two different types of inspection, direct and indirect inspections. Direct equipment is employed to test and assess the material directly by one inspector or tester.

- Direct visual inspection can be carried out with tools such as borescopes, fiberscopes, and HD optics. These are used in difficult-to-reach places, such as the insides of machines, locks, etc. In indirect visual inspection, the area to be inspected is captured by a camera and displayed on a monitor by many people.

- Due to the advancement in technology and digitalization of the power generation sector, companies are innovating automated visual inspection equipment. For instance, RNA has manufactured a computerized vision inspection system to meet high-speed quality control requirements for 100% inspection. It can be used for system integrators, sorting, production, manufacturing, and all types of automation and robotic applications in various industries, including the power generation sector.

- Further, many companies offer remote visual inspection equipment in the studied market. For instance, Baker Hughes offers a range of durable remote visual inspection equipment that enable easier and more accurate data collection and analysis. The company uses technologies such as Real3D to ensure measurement accuracy, and TrueSight, for superior image quality. Its visual inspection equipment is built to meet the modern demands for safety, efficiency, and precision in the power generation industries.

Asia Pacific is Expected to Witness Significant Growth

- Currently, China is the world's largest producer of electricity. The country's energy demand is expected to increase, thereby provoking the growth in energy production. NDT application in the fossil fuel segment for power generation dominates the market. Also, there has been an increased count of aging infrastructure in the power industry in the country, making it essential to use NDT equipment to identify and secure the integrity of these structures. As a result, the NDT service in the country is expected to grow rapidly over the forecast period.

- In February 2021, China put a new 38.4 gigawatts (GW) of new coal-fired power capacity into operation. Also, China supported the construction of a further 36.9 GW of coal-fired capacity in 2020, three times more than in 2019. It now has 247 GW of coal power under development, enough to supply the whole of Germany. The NDT equipment market is expected to have tremendous opportunities with these planned power plants.

- India has the fifth-largest power generation capacity globally. Also, the country ranks third globally in terms of electricity production. The Indian national electric grid has an installed capacity of 382.15 GW as of March 2021. This implies that the current demand for NDT equipment is dominated by the fossil fuel sector, with nuclear energy-based NDT equipment slowly gaining momentum.

- Further, South Korea had more than 84 coal power plants (CPP), 27 gas power plants (GPP), and 23 nuclear power plants (NPP) operational at the end of 2016. According to several studies, the electricity demand increased approximately 0.7% Y-o-Y in the country, leading to 4 NPP, 8 CPP under construction, and 6 more CPP announced for the future, creating several opportunities for the NDT equipment market in the region.

- According to the Japan Atomic Industrial Forum, twelve other reactors at six sites have been approved for the restart, and two new powerplants are under construction, which is expected to be operational in the forecast period, increasing the need for NDT services in the power generation sector.

Non-Destructive Testing In Power Generation Industry Overview

Non-Destructive Testing (NDT) in Power Generation Market is competitive in nature and consists of several key players. The increasing regulations, which make it mandatory for different organizations to undergo a life assessment procedure as a safety measure, coupled with the regular inspection required to check for any damage in the equipment, create a market for NDT in the power generation industry. Key players in this market are introducing new innovative products and forming partnerships and collaborations to gain competitive advantages.

- February 2021 - Controle Mesure Systemes developed software called Probus. It collects information provided by NDT equipment to display signals, analyzes them, makes a sorting decision, and creates inspection reports. Probus is the decision-making center of the Non-destructive Testing line. It centralizes all the sensor data and can control the test bench's actuators. The main purpose of the Probus software is to ensure traceability by creating either an individual product or a batch inspection report. They can list the detected defects and their locations and provide proof of control.

- January 2021 - Olympus Corporation launched the innovative DP series cameras that share a suite of smart features and precise color accuracy to simplify industrial microscopy imaging. The DP28 camera offers 4K resolution to provide high-resolution images. In contrast, the DP23 camera's full HD resolution is balanced with convenient features, offering outstanding value for almost any industrial imaging application, including the power generation industry.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definitions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Buyers

- 4.2.2 Bargaining Power of Suppliers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of the Impact of COVID -19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Stringent Regulations Mandating Safety Standards

- 5.1.2 Increase in Demand for Flaw Detection to Reduce Repair Cost

- 5.1.3 Aging Infrastructure and Increasing Need for Maintenance

- 5.2 Market Restraints

- 5.2.1 Lack of Skilled Workforce and Training Regulations

6 MARKET SEGMENTATION

- 6.1 Type

- 6.1.1 Services

- 6.1.2 Equipment

- 6.2 Testing Technology

- 6.2.1 Radiography Testing

- 6.2.2 Ultrasonic Testing

- 6.2.3 Visual Inspection Testing

- 6.2.4 Eddy Current Testing

- 6.2.5 Other Testing Technologies

- 6.3 Geography

- 6.3.1 North America

- 6.3.1.1 United States

- 6.3.1.2 Canada

- 6.3.2 Europe

- 6.3.2.1 United Kingdom

- 6.3.2.2 Germany

- 6.3.2.3 France

- 6.3.2.4 Rest of Europe

- 6.3.3 Asia Pacific

- 6.3.3.1 China

- 6.3.3.2 Japan

- 6.3.3.3 India

- 6.3.3.4 Rest of Asia Pacific

- 6.3.4 Latin America

- 6.3.5 Middle East and Africa

- 6.3.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Olympus Corporation

- 7.1.2 Fujifilm Corporation

- 7.1.3 Baker Hughes Company

- 7.1.4 Yxlon International Gmbh (Comet Holding AG)

- 7.1.5 Applus+ Services Technologies, S.L

- 7.1.6 Mistras Group, Inc.

- 7.1.7 SGS Group

- 7.1.8 Bureau Veritas S.A.

- 7.1.9 Zetec, Inc.

- 7.1.10 Eddyfi

- 7.1.11 Intertek Group Plc.

- 7.1.12 Team Inc.