|

市场调查报告书

商品编码

1636591

欧洲堆垛机:市场占有率分析、产业趋势和成长预测(2025-2030 年)Europe Palletizer - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

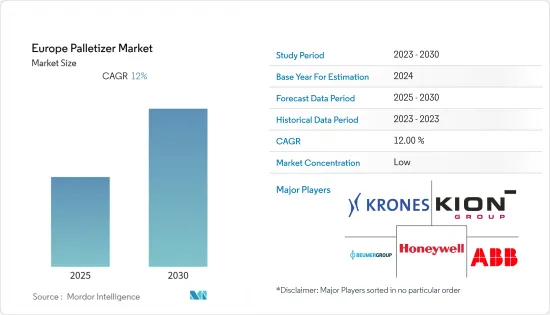

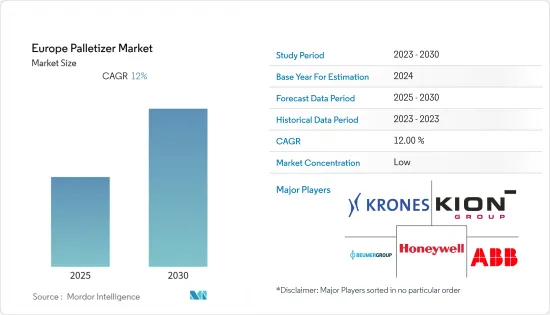

预计预测期内欧洲堆垛机市场复合年增长率将达到 12%。

主要亮点

- 堆垛机是任何先进的自动化物料输送系统中最重要的设备之一。企业对劳动力的灵活性和安全性的期望越来越高,营运也正在从手动转向自动化。

- 根据具体情况,物流中心、仓库和工业设施可以使用机器人或传统的堆垛机来自动化托盘堆迭过程。根据应用情况,整合不同的技术,使製造商能够打造完美的托盘。

- 此外,德国的工厂关闭也增加了对食品生产能力的需求,迫使製造工厂加快生产速度,预计这将提振堆垛机市场。提高生产能力也将增加对自动化和先进机械的需求。

- 製药业在堆垛机产业中也发挥着不可或缺的作用。全自动堆垛机用于药品的无人化生产。在欧洲製药业的支持下,该产业正在蓬勃发展。

- 欧洲对认证美容产品的兴趣和需求日益增长,推动了化妆品行业堆垛机的成长。个人护理领域的堆垛机发展受到韩国美容潮流及其异想天开和创新的包装的推动。

- 在研究期间,维护成本预计会限制机器人堆垛机的发展。机器人码堆垛机的采用,包括高昂的转换成本,以及维护和部署自动化系统的高成本,对堆垛机市场的成长构成了进一步的挑战。

- 新冠疫情的爆发使快速消费品产业的许多生产工厂面临越来越大的压力,迫使它们加快加工生产。根据Packaging Europe 进行的一项调查,87% 的受访者表示,他们已经开始以不同的方式转移生产,以保持供应链中的生产力和社交距离,而22% 的受访者已转向自动化来维持流程。这表明,疫情导致这个市场呈指数级增长。

欧洲堆垛机市场趋势

食品饮料业占比大

- 在食品和饮料包装行业,堆垛机由于成本低、吞吐率高、占地面积小而最受欢迎且效益最佳。堆垛机包装因重量轻且能长期保存食物而受到消费者和零售商的青睐。它服务于产品线的末端,因此对于所有行业都至关重要。

- 食品和饮料行业对堆垛机的需求正在上升,该行业可能会对市场收益产生重大影响。随着政府监管日益严格以及零售商在市场上的竞争力不断增强,食品和饮料行业对自动化和堆迭机器人的需求正在迅速增长。

- 此外,人们对环保包装的兴趣也越来越大。食品和非酒精饮料的消费者物价指数也在上涨,大大增加了食品和饮料产业对自动化机械的需求。

- 此外,ABB 还提供一系列测量产品、控制系统、驱动器、PLC 和电源调节器,以确保食品和饮料行业整个包装和堆迭操作的灵活性和协调性。 ABB持续专注于堆迭自动化解决方案中包装技术的开发。

- 製造业的成长增加了对自动化的需求,而这又需要灵活的机器。欧洲食品和饮料产业受到欧盟和国家关于食品营养、健康、安全、创新、进出口的各种法规的约束。该行业在吸引高技能员工方面也面临挑战。这些因素是食品和饮料行业采用自动化的驱动力。

- 这一领域的成长主要得益于对药品和食品的巨大需求,以及沿岸地区等新兴经济体政府对药品 CRP(儿童安全包装)的规定,例如食品饮料、乙酰胺酚、阿斯匹灵和避孕药等正在推动英国对堆垛机和食品包装器材的需求。

机器人堆垛机预计将占据很大份额

- 随着人事费用的上升、对安全工作环境的需求以及保持您的营运最尖端科技,机器人码垛系统是提高准确性、可靠性和效率的明智选择。机器人堆垛机有多种配置,以适应不同的产品类型、应用和不同的排放配置。

- 德国是工业 4.0 运动的关键市场之一,因为它跟随其他欧盟国家在其製造工厂中实施自动化技术以提高效率。该计划的目标是提供机器人码垛选项。此外,该国正在开发灵活的机器人堆垛机,可以从不同级别的输送机上挑选产品,并根据托盘的布置一次处理一个或多个产品。机器人堆迭技术可以轻鬆适应各种托盘模式和产品品种。

- 此外, 堆垛机还提供专为高速、低距离、重载负载容量而设计的机器人模型。各种软体选项允许使用者快速产生托盘模式并检查堆迭系统的状态。严格要求的应用包括将箱子、纸箱、袋子、瓶子、盒子等堆放于托盘上。

- 机器人堆垛机提供了一种实用的解决方案,可以节省营运成本并提高营运效率,帮助那些依赖人工进行装载、卸载、包装和堆迭货物等重复过程的部门。由于全球食品饮料、医疗保健等行业的需求激增,市场前景看好。

- 与其他包装相比,製药、化妆品、个人护理和化学品等行业也更喜欢使用机器人码垛。此外,多年来,机器人堆垛机市场一直由食品和饮料行业主导。

- 对食品和饮料产品日益增长的需求正在影响着全球运输货物的包装。这些堆堆垛机可以轻鬆平衡负载,不会发生任何损坏或溢出,并且食品的动态运输有望推动和增强市场对机器人堆垛机的需求。

欧洲堆垛机产业概况

欧洲堆垛机市场竞争激烈,有许多国内外公司参与。 Abb Ltd、Beumer Group GmbH &Co. KG、Honeywell International Inc.KG、Honeywell International Inc.、KION Group AG、Krones AG、Sidel、安川电机株式会社、Barry-wehmiller Companies Inc.

- 2022 年 8 月 - 在 POWTECH 上,BEUMER 集团将展示其在建材、水泥和(石油)化学产品的输送、装载、填充、码垛和包装方面的专业知识。 Beumer 集团近期更新了其码垛系列「paletpac」和拉伸罩包装机「BEUMER」。模组化设计减少了零件数量,这对备件和交货时间具有决定性的影响。

- 2022 年 6 月 - Aetna Group 透过其 Robopac 和 Ocme 业务部门收购了德国主要企业之一 Meypack。此次收购是安泰集团战略成长计画的一部分,该计画旨在在製造国建立生产基地并扩大其在食品和个人护理领域的产品范围。

- 2021 年 7 月-ABB 收购 ASTI 移动机器人集团 (ASTI)。 ASTI 是全球领先的自主移动机器人 (AMR) 製造商,其软体套件支援的所有主要应用领域均拥有广泛的产品组合。这扩大了 ABB 在机器人和自动化领域的足迹,使其成为唯一一家能够提供下一代弹性自动化完整产品组合的公司。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概况

- 产业价值链分析

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 竞争对手之间的竞争

- 替代品的威胁

- COVID-19 产业影响评估

第五章 市场动态

- 市场驱动因素

- 食品和饮料行业的需求不断增加

- 对高品质消费品的需求不断增长以及机器人堆垛机的采用

- 市场挑战

- 维护和设备成本高

第六章 市场细分

- 按类型

- 传统的

- 机器人

- 按行业

- 饮食

- 药品

- 个人护理及化妆品

- 化学产品

- 按国家

- 德国

- 义大利

- 法国

- 英国

- 其他的

第七章 竞争格局

- 公司简介

- Beumer Group GmbH & Co. KG

- Honeywell International Inc.

- ABB Ltd

- KION Group AG

- Krones AG

- Kuka AG

- Concetti SPA

- Aetnagroup Spa

- Fuji Robotics Americas

第八章投资分析

第九章 市场机会与未来趋势

简介目录

Product Code: 57297

The Europe Palletizer Market is expected to register a CAGR of 12% during the forecast period.

Key Highlights

- Palletizer is one of the significant pieces of equipment among the primary advanced automated material handling systems. Organizations are raising their expectations for workforce flexibility and safety; a shift is happening from manual to automation in operations.

- In distribution centers, warehouses, and industrial facilities, the pallet construction process is automated using robotic or traditional palletizers, depending on the situation. Different technologies are integrated according to usage, which enables manufacturers to create optimal pallets.

- Additionally, the lockdown in Germany is causing a rise in the demand for grocery capacity, which is anticipated to boost the palletizer market because manufacturing facilities were forced to speed up production. An increase in capacity will also increase the need for automation and sophisticated machinery.

- The pharmaceutical sector also plays an essential role in the palletizer industry. Fully automatic palletizers are used for unattended pharmaceutical production. Supported by the European pharmaceutical industries, the sector is booming.

- The growing interest and demand for certified beauty products in Europe drive the growth of palletizers in the cosmetic industry. The development of palletizers in the personal care sector is fueled by the K-beauty trends with its whimsical and innovative packaging.

- The maintenance cost is anticipated to constrain the development of robotic palletizers during the study period. The adoption of robotic palletizers, which includes high switching costs, and the high cost of maintaining and deploying automation systems, present further challenges to the growth of the palletizer market.

- Due to the breakout of the COVID-19 pandemic, many manufacturing facilities in the FMCG sector have undergone increased pressure, and they had to speed up their process production. According to a survey done by Packaging Europe, 87% of the respondents answered that to maintain the supply chain productivity and social distancing, they had started different shifts, and 22% claimed that they had to incorporate automation to keep the process. This shows that the pandemic helped this market to grow exponentially.

Europe Palletizer Market Trends

Food and Beverage Industry to Hold a Major Share

- In the food and beverage packaging industry, palletizers are most preferred and beneficial due to their low cost, high throughput rate, and small footprint. The packaging is preferred among consumers and retailers as it is less weight and can preserve food for a long; the perishable rate is relatively low in palletizer packaging. It is vital for every industry as it is helpful at the end of the product line.

- The need for palletizers in the food and beverage sector is growing, and this sector will significantly impact market revenue. As government regulations tighten over time and retailer rivalry in the market increases, the demand for automation and palletizing robots is rising quickly in the food and beverages industry.

- Additionally, people are now highly concerned about environmentally friendly packaging. The Consumer Price Index for food and non-alcoholic beverages is also increasing, significantly increasing the need for automation machinery in the food and beverage sector.

- Moreover, ABB provides various measurement products, control systems, drives, PLCs, and power conditioning to ensure flexibility and coordination throughout packaging and palletizing operations in the food and beverage industry. ABB has been continuously focusing on developing packaging technologies in palletizing automation solutions.

- The growth in the manufacturing industries is helping the demand for automation to increase, resulting in the need for flexible machinery. The European beverage and food industry is subjected to various EU and national regulations concerning food nutrition, health, safety, innovation, import, and export. The industry is also facing issues in getting high-skilled staff. These factors are responsible for adopting automation in the food and beverage industry.

- The growth of this segment is driven by emerging economies, i.e., Gulf Region, where the demand for pharmaceuticals and food is very high, moreover the government regulations regarding CRP (Child-resistant Packaging) for drugs. i.e., food and beverages, paracetamol, aspirin, and contraceptives are boosting the demand for palletizers and food packaging machinery in the United Kingdom.

Robotic Palletizers is Expected to Hold Significant Share

- A robotic palletizing system is a wise choice to improve accuracy, dependability, and efficiency in light of rising labor costs, the requirement for safe working environments, and maintaining operations with the most cutting-edge technology. Robotic palletizers can be configured in many ways to accommodate various product types and applications and different infeed and discharge configurations.

- Germany, following other EU Countries is one of the leading markets in the industry 4.0 trend due to their adoption of automation technologies in manufacturing facilities to increase efficiency. The goal of this project is to offer robotic palletizing options. Additionally, the nation is creating a flexible robotic palletizer that can pick products off a conveyor on various levels and handle one or more units simultaneously, depending on pallet arrangement. Robotic palletizing technologies can easily accommodate different pallet patterns and product varieties.

- Moreover, The country is very interested in automation, Palletizer offers robot models specially designed for high-speed, low-range, and heavy payload palletizing. A variety of software options helps the user to quickly generate pallet patterns and check the status of the palletizing systems. It is a demanding application for stacking cases, cartons, bags, bottles, and boxes into pallets.

- Robotic palletizers benefit sectors that use a manual labor for repetitive processes like loading/unloading items, packaging, and palletizing by offering a practical solution to save operational costs and enhance job productivity. The market's future potential is growing as a result of the rapid rise in demand in industries including food and beverage, healthcare, and others around the world.

- Industries like pharmaceuticals, cosmetics, personal care, and chemicals also prefer Robotic palletizing over other packaging. In addition, for several years, the market for robotic palletizers has been dominated by the food and beverage sector.

- The usage of packaging for goods that have been shipped around the world has been influenced by the growing demand for food and beverage products. Because these palletizers can readily balance the loads, the dynamic shipment of food products without damage or spills raises the demand for robotic palletizers in the market, which is anticipated to drive that demand.

Europe Palletizer Industry Overview

The Europe palletizer market is competitive because of the presence of many players running their businesses within national and international boundaries. The market is highly fragmented with the presence of major players like Abb Ltd, Beumer Group GmbH & Co. KG, Honeywell International Inc., KION Group AG, Krones AG, Sidel, Yaskawa Electric Corp., Barry-wehmiller Companies Inc., among others.

- August 2022 - At POWTECH, the BEUMER Group will demonstrate its expertise in conveying, loading, filling, palletizing, and packaging of building materials, cement, and (petro)chemical products. The BEUMER Group has now redesigned its paletpac palletizing series and the BEUMER stretch hood packaging machine. The modular design reduces the number of components, which has a decisive influence on spare parts and delivery times.

- June 2022 - Aetna Group, one of the leading companies in the production of end-of-line packaging machines and systems (through its Business Units Robopac and Ocme), has acquired the German company Meypack. This operation is part of Aetna Group's strategic plan to grow externally, to establish a production presence in countries with a manufacturing vocation, and to expand the product range in the food and personal care sector.

- July 2021- ABB to acquire ASTI Mobile Robotics Group (ASTI), a leading global autonomous mobile robot (AMR) manufacturer with a broad portfolio across all major applications enabled by the company's software suite. This will expand ABB's robotics and automation offering, making it the only company to offer a complete portfolio for the next generation of flexible automation.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Consumers

- 4.3.3 Threat of New Entrants

- 4.3.4 Intensity of Competitive Rivalry

- 4.3.5 Threat of Substitutes

- 4.4 Assessment of COVID-19 impact on the industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing demand from food and beverages Sector

- 5.1.2 Rising demand for high-quality consumer goods and adoption of robotic palletizers

- 5.2 Market Challenges

- 5.2.1 High maintenance and equipment costs

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Conventional

- 6.1.2 Robotic

- 6.2 By End-user Vertical

- 6.2.1 Food & Beverages

- 6.2.2 Pharmaceuticals

- 6.2.3 Personal Care & Cosmetics

- 6.2.4 Chemicals

- 6.3 By Country

- 6.3.1 Germany

- 6.3.2 Italy

- 6.3.3 France

- 6.3.4 United Kingdom

- 6.3.5 Others

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Beumer Group GmbH & Co. KG

- 7.1.2 Honeywell International Inc.

- 7.1.3 ABB Ltd

- 7.1.4 KION Group AG

- 7.1.5 Krones AG

- 7.1.6 Kuka AG

- 7.1.7 Concetti S.P.A

- 7.1.8 Aetnagroup Spa

- 7.1.9 Fuji Robotics Americas

8 INVESTMENT ANALYSIS

9 MARKET OPPORTUNITIES AND FUTURE TRENDS

02-2729-4219

+886-2-2729-4219