|

市场调查报告书

商品编码

1639485

欧洲包装检测:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Europe Package Testing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

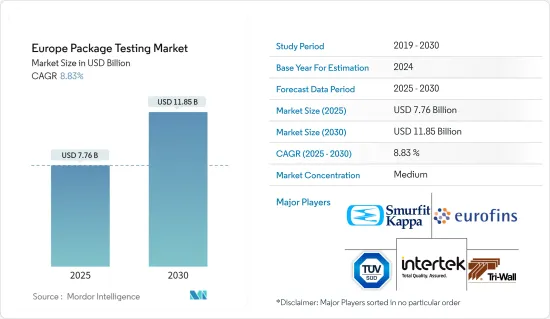

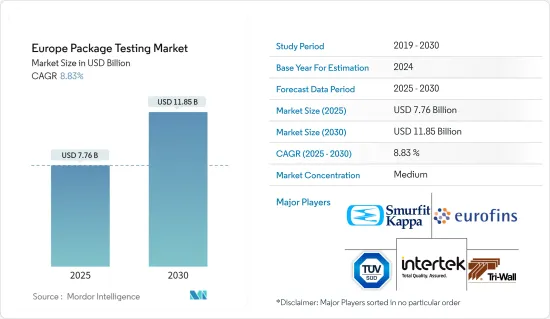

欧洲包装检测市场规模预计在 2025 年为 77.6 亿美元,预计到 2030 年将达到 118.5 亿美元,预测期内(2025-2030 年)的复合年增长率为 8.83%。

主要亮点

- 欧洲包装检测市场由于几个关键因素而不断增长。包装食品、食品和饮料以及加工食品的消费量增加是主要驱动因素。为确保包装商品的安全和质量,严格的法规和标准进一步推动了这一趋势。网路零售的快速扩张,尤其是食品和其他消费品的扩张,增加了对坚固包装的需求,以确保透过复杂的分销网路安全交付。此外,由于对能够承受运输过程中各种环境条件的创新包装解决方案的需求,市场也在不断增长。

- 包装检验对于评估产品品质和确保欧洲客户满意度至关重要。它涵盖了产品安全、法规遵循、改善客户体验、加强品牌、降低成本和产品开发创新等重要方面。有效的包装检验可确保产品符合安全标准、遵守法规并提供积极的客户体验。它还可以帮助您的品牌在竞争激烈的市场中脱颖而出,透过包装优化降低成本,并协助开发新产品和改进产品。

- 产品安全评估包装在运输和储存过程中保护内容物免受损坏、污染和篡改的能力。这包括评估材料强度、密封完整性、对湿度和温度变化等环境因素的抵抗力等等。法规合规性测试确保包装符合法律要求,例如标籤标准、材料限制和欧洲特定国家的环境法规。

- 改善客户经验包括测试包装的易用性、说明的清晰度和整体美观。这包括评估拆包体验、文字的可读性和可重新密封的封口等包装功能。透过包装测试进行品牌提升着重于保持整个产品线的包装品质的一致性,并确保包装有效地传达品牌价值和讯息。

- 包装测试节省成本的方面包括优化材料使用、提高生产效率和减少废弃物。这包括测试替代材料和设计,以在降低整体包装成本的同时保持产品保护。包装检测还透过评估新的包装概念、材料或技术来支援产品开发的创新。透过引入满足新消费者需求和环境问题的包装解决方案,此流程可帮助公司保持竞争力。

- 包装材料要经过各种测试,以评估其在不同条件下的性能。这些测试包括压力负荷、衝击、振动、敲击、湿度、温度变化等。已经开发出各种测试方法来评估包装质量,包括跌落测试、压缩测试和环境调节测试。包装对于在运输和储存过程中保持产品的品质和真实性至关重要。保护您的产品免受物理损坏、污染和环境因素的影响。随着消费者期望的不断提高,包装必须经受长时间的磨损,以确保产品以最佳状态到达消费者手中。

- 包装食品、食品和饮料以及加工食品的消费量不断增加,推动了欧洲包装测试市场的发展。为确保包装商品的安全和品质而製定的严格法规和标准进一步推动了这一成长。此外,网路零售(尤其是食品零售)的兴起,增加了精密包装的需求,以确保透过复杂的分销网路安全交付。对于能够承受运输过程中各种环境条件的创新包装解决方案的需求也促进了市场扩张。

- 随着基本客群的不断扩大,欧洲的包裹检查范围也不断扩大。这种扩张的推动因素包括日益严格的监管要求、消费者对更安全和更永续包装的需求以及公司在运输和储存过程中确保产品完整性的需求。 ASTM(美国材料与试验协会)、ISTA(国际安全运输协会)等权威机构会进行跌落测试、振动测试、衝击测试等标准测试。

- 这些测试模拟了包裹在运输和处理过程中可能遇到的真实环境。所有欧洲包装行业都遵守这些标准,以确保产品的安全和品质。在製药业,包装违规行为会受到美国FDA 等机构的严格审查和严厉处罚。这些措施对于维持药品的有效性和病人安全至关重要。包装材料包括玻璃、塑胶、纸/纸板和金属,每种材料都是根据特定的产品要求和环境考虑而选择的。

- 包裹检查费用昂贵,是市场拓展的一大限制因素。这些成本包括许多方面,例如专门的设备、训练有素的人员和耗时的程序。小型企业,尤其是在新兴市场营运的企业,可能需要协助分配资源进行全面的包装检查。这种经济障碍可能会抑制创新并减缓新包装解决方案的市场引入。因此,高昂的包装检查成本不仅影响个别企业,也影响整个包装产业的成长轨迹。

欧洲包裹检测市场趋势

食品和饮料预计将推动市场成长

- 预计食品和饮料行业将成为整个欧洲包装检测成长的主要动力。随着消费者对食品安全和品质的要求不断提高,製造商越来越多地投资于包装材料的严格测试程序。欧盟关于食品接触材料和包装完整性的严格规定进一步推动了这一趋势。

- 包装测试在食品和饮料行业的重要性日益增加,其背后有几个因素:法规合规性:欧洲食品安全法规要求对包装材料进行测试,以确保它们不会污染食品。广泛的测试消费者安全:包装检查有助于防止与包装故障和材料迁移相关的潜在健康危害。品质保证:严格的测试确保我们的包装保持产品的新鲜度并延长其保质期。品牌保护:经过测试检验的有效包装有助于维护您的品牌声誉和消费者信任。

- 此外,主动包装和智慧包装等创新包装解决方案的兴起需要更先进的测试方法来确保合规性和有效性。这些先进的包装技术通常包含去氧剂、湿度控制系统和温度指示器等功能,这些功能需要专门的测试通讯协定。

- 食品和饮料行业对永续性和环保包装的日益重视也导致了欧洲对包装测试服务的需求增加。随着製造商转向生物分解性、可堆肥和可回收材料,需要新的测试方法来检验这些替代包装解决方案的性能和安全性。

- 食品和饮料行业电子商务的扩张给包装带来了新的挑战,并导致对测试服务的需求增加。这些服务确保产品能够承受运输和处理的严格要求,同时保持其品质。包装测试变得至关重要,因为电子商务平台需要强大的包装解决方案来防止运输过程中的损坏并保持产品的完整性。

- 在英国,消费者在食品和非酒精饮料上的总支出正在增加。 2023年第三季度,消费者在食品和非酒精饮料上的支出将达到约435.1亿美元,高于2022年第四季的404.17亿美元。食品和饮料消费的成长趋势直接影响包装产业,推动了对更复杂和可靠的包装检测方法的需求。

- 消费者偏好和监管要求的变化也推动了包装检测服务需求的不断增长。随着消费者的环保意识增强,他们越来越关注永续的包装解决方案,这需要严格的测试以确保它们既符合性能又符合环保标准。此外,严格的食品安全法规要求进行全面的测试,以确保包装材料不会污染食品并在整个供应链中保持新鲜度。

英国占市场主导地位

- 各行各业对包装的应用日益广泛,推动了英国对包装测试的需求。推动这一趋势的是食品和饮料、製药和电子商务行业的成长,每个行业都需要专门的包装解决方案。随着公司努力确保产品安全、品质和法规遵循性,对全麵包装检验服务的需求显而易见。这些测试评估耐用性、阻隔性和环境影响,帮助公司优化包装设计并满足消费者的期望。

- 欧洲软性饮料、烈酒、葡萄酒和啤酒消费量的增加推动了饮料包装的成长,并促进了该地区包装检测市场的扩大。这一趋势在德国、法国、义大利等饮料产业蓬勃发展的国家尤其明显。随着消费者偏好的演变和新包装技术的出现,製造商越来越多地投资于严格的测试程序,以确保其产品安全、高品质并符合监管标准。这包括测试材料完整性、密封强度和阻隔性性能,这对于保持饮料的新鲜度和安全性至关重要。此外,欧洲市场越来越重视永续包装解决方案,推动对测试服务的需求,以检验新包装材料和设计的环境要求。

- 近年来,欧洲包装检测市场发生了重大变化,主要受零售商及其产品线扩张的推动。这种成长推动了对包装检测服务的需求,以确保产品安全、品质和法规遵循。零售公司透过更深层的垂直整合受益于更有效率的分销和物流,从而推动了对全麵包装检测解决方案的需求。这些发展促进了欧洲包装行业的整体成长。

- 在欧洲市场处于主要企业的英国,「包装活动」产业的收益呈现明显的成长趋势。产业资料显示,预计2023年收益将达到约55.05亿美元,较2021年的53.2亿美元大幅成长。这种成长反映了包装检测在零售和消费品领域日益增长的重要性,以及需要严格测试通讯协定的包装材料和技术的不断创新。

欧洲包装检测产业概况

欧洲包装检测市场是半静态的,由全球和地区参与者组成。主要企业包括 Intertek Group plc、TUV SUD AG、Smurfit Kappa 和 Tri-Wall UK Limited。该行业的特点是产品差异化程度低,产品扩散度高,市场参与企业之间的竞争激烈。

测试设备的技术进步、对永续包装的日益关注以及对电子商务解决方案的不断增长的需求进一步影响了竞争格局。该市场中的公司不断投资于研发,以增强其测试能力并保持领先地位,满足不断变化的行业需求。

随着市场的成长,公司正在透过策略联盟和收购来扩大其地理影响力和服务范围。这一趋势可能会加剧竞争,并在未来几年导致市场进一步整合。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场动态

- 市场驱动因素

- 严格的管理规定和管理/资格要求

- 各种条件下对产品长期储存的需求

- 市场限制

- 包裹检查限制市场相关高成本

- 技术简介

- 包装完整性测试

- 包装强度测试

- 包装有效期限测试

- 包裹验证

第六章 产业政策

- ASTM 标准

- ISO 标准

- ISTA 标准

第七章 市场区隔

- 按主要材料

- 玻璃

- 纸

- 塑胶

- 金属

- 按测试类型

- 体能表现测试

- 化学测试

- 环境检查

- 按最终用户产业

- 饮食

- 卫生保健

- 工业产品

- 个人及居家产品

- 其他最终用户产业

- 按国家

- 法国

- 德国

- 义大利

- 西班牙

第八章 竞争格局

- 公司简介

- Intertek Group plc

- TUV SUD AG

- Smurfit Kappa

- Tri-Wall UK Limited

- Eurofins Scientific(Ireland)Limited

- Stora Enso Oyj

- Bureau Veritas

第九章投资分析

第十章:市场的未来

The Europe Package Testing Market size is estimated at USD 7.76 billion in 2025, and is expected to reach USD 11.85 billion by 2030, at a CAGR of 8.83% during the forecast period (2025-2030).

Key Highlights

- The European Packaging Testing market is experiencing growth due to several key factors. The increasing consumption of packaged food, beverages, and processed food is a primary driver. Stringent regulations and standards further support this trend to ensure the safety and quality of packaged goods. The rapid expansion of online retail, particularly for food and other consumer items, has intensified the need for robust packaging to guarantee safe delivery through complex distribution networks. Additionally, the market is expanding due to the demand for innovative packaging solutions capable of withstanding various environmental conditions during transit.

- Package testing is crucial in assessing product quality and ensuring European customer satisfaction. It encompasses critical aspects such as product safety, regulatory compliance, customer experience enhancement, brand strengthening, cost reduction, and product development innovation. Effective package testing ensures products meet safety standards, comply with regulations, and deliver a positive customer experience. It also helps differentiate brands in competitive markets, reduces costs through optimised packaging, and supports the development of new and improved products.

- Regarding product safety, package testing evaluates the ability of packaging to protect contents from damage, contamination, or tampering during transportation and storage. This includes assessing the strength of materials, seal integrity, and resistance to environmental factors like moisture or temperature changes. Regulatory compliance testing ensures that packaging meets legal requirements, such as labelling standards, material restrictions, and environmental regulations specific to different European countries.

- Customer experience enhancement involves testing packaging for ease of use, clarity of instructions, and overall aesthetic appeal. This may include evaluating the unboxing experience, text readability, and packaging features' functionality, like resealable closures. Brand strengthening through package testing focuses on maintaining consistency in packaging quality across product lines and ensuring that packaging effectively communicates brand values and messaging.

- Package testing's cost-reduction aspects involve optimising material usage, improving production efficiency, and minimising waste. This may include testing alternative materials or designs that maintain product protection while reducing overall packaging costs. Package testing also supports innovation in product development by evaluating new packaging concepts, materials, or technologies. This process helps companies stay competitive by introducing packaging solutions that address emerging consumer needs or environmental concerns.

- Packaging materials undergo various tests to evaluate their performance under different conditions. These tests include pressure loads, shock, vibration, knocking, humidity, and temperature variations. Various testing methods, such as drop, compression, and environmental conditioning tests, have been developed to assess packaging quality. Packaging is crucial in maintaining product quality and reliability during transportation and storage. It protects products from physical damage, contamination, and environmental factors. Packaging must withstand extended wear and tear as consumer expectations increase to ensure products reach consumers in optimal condition.

- Increasing consumption of packaged food, beverages, and processed food propels the European Packaging Testing market. Stringent regulations and standards further support this growth to ensure the safety and quality of packaged goods. Furthermore, the rise of online retail, especially for food and other items, amplifies the need for precise packaging to ensure safe delivery through complex distribution networks. The demand for innovative packaging solutions that withstand various environmental conditions during transit also contributes to market expansion.

- Package testing in Europe is expanding alongside the growing customer base. This expansion is driven by increasing regulatory requirements, consumer demand for safer and more sustainable packaging, and the need for companies to ensure product integrity during transportation and storage. Authoritative bodies such as ASTM (American Society for Testing and Materials) and ISTA (International Safe Transit Association) conduct standard examinations, including drop, vibration, and shock testing.

- These tests simulate real-world conditions that packages may encounter during shipping and handling. All European packaging industries adhere to these standards to ensure product safety and quality. In the pharmaceutical industry, packaging violations are subject to high-level investigations by authorities such as the US FDA, resulting in stringent measures. These measures are crucial to maintaining drug efficacy and patient safety. Packaging materials include glass, plastic, paper and paperboard, metal, and others, each chosen based on specific product requirements and environmental considerations.

- The substantial expenses associated with package testing significantly constrain market expansion. These costs encompass various aspects, including specialised equipment, trained personnel, and time-intensive procedures. Companies, especially smaller ones or those operating in emerging markets, may need help to allocate resources for comprehensive package testing. This financial barrier could hinder innovation and slow down the introduction of new packaging solutions to the market. As a result, the high costs of package testing impact individual businesses and influence the overall growth trajectory of the packaging industry.

Europe Package Testing Market Trends

Food and Beverage Expected to Drive the Growth of the Market

- The food and beverage industry is expected to be a key driver of growth in package testing across Europe. As consumer demands for food safety and quality increase, manufacturers invest more in rigorous testing procedures for their packaging materials. This trend is further fueled by stringent regulations on food contact materials and packaging integrity in the European Union.

- Several factors contribute to the growing importance of package testing in the food and beverage sector: Regulatory compliance: European food safety regulations require extensive testing of packaging materials to ensure they do not contaminate food products. Consumer safety: Package testing helps prevent potential health hazards associated with packaging failures or material migrations. Quality assurance: Rigorous testing ensures that packaging maintains product freshness and extends shelf life. Brand protection: Effective packaging verified through testing helps maintain brand reputation and consumer trust.

- Additionally, the rise of innovative packaging solutions, such as active and intelligent packaging, requires more sophisticated testing methods to ensure compliance and effectiveness. These advanced packaging technologies often incorporate features like oxygen scavengers, moisture control systems, and temperature indicators, necessitating specialized testing protocols.

- The growing emphasis on sustainability and eco-friendly packaging in the food and beverage sector also contributes to the increased demand for package testing services in Europe. As manufacturers shift towards biodegradable, compostable, or recycled materials, new testing methodologies are required to verify the performance and safety of these alternative packaging solutions.

- The expansion of e-commerce in the food and beverage industry has created new challenges for packaging, leading to increased demand for testing services. These services ensure products can withstand the rigours of shipping and handling while maintaining quality. Package testing has become crucial as e-commerce platforms require robust packaging solutions to prevent damage during transit and maintain product integrity.

- In the United Kingdom (UK), total consumer spending on food and non-alcoholic beverages has gr. In the third quarter of 2023, consumer spending for food and non-alcoholic drinks reached approximately USD 43,501 million, an increase from USD 40,417 million in Q4 2022. This upward trend in food and beverage consumption directly impacts the packaging industry, driving the need for more sophisticated and reliable package testing methods.

- The growing demand for package testing services is also influenced by changing consumer preferences and regulatory requirements. As consumers become more environmentally conscious, there is an increased focus on sustainable packaging solutions, which require rigorous testing to ensure they meet both performance and eco-friendly standards. Additionally, stringent food safety regulations necessitate comprehensive testing to verify that packaging materials do not contaminate food products and maintain their freshness throughout the supply chain.

United Kingdom Occupies a Majority Share in the Market

- The increasing adoption of packaging across various industries drives the demand for package testing in the United Kingdom. This trend is fueled by the growth of food and beverage, pharmaceuticals, and e-commerce sectors, each requiring specialized packaging solutions. As companies strive to ensure product safety, quality, and regulation compliance, the need for comprehensive package testing services has become more pronounced. These tests evaluate durability, barrier properties, and environmental impact, helping businesses optimize their packaging designs and meet consumer expectations.

- The rising consumption of soft drinks, spirits, wine, and beer in Europe is driving growth in beverage packaging, contributing to expanding the package testing market in the region. This trend is particularly evident in countries with beverage industries, like Germany, France, and Italy. As consumer preferences evolve and new packaging technologies emerge, manufacturers increasingly invest in rigorous testing procedures to ensure product safety, quality, and compliance with regulatory standards. This includes tests for material integrity, seal strength, and barrier properties, which are crucial for maintaining the freshness and safety of beverages. Additionally, the growing emphasis on sustainable packaging solutions in the European market has increased demand for testing services to validate the environmental claims of new packaging materials and designs.

- The European package testing market has undergone significant changes in recent years, primarily driven by the expansion of retail companies and their product lines. This growth has increased demand for package testing services to ensure product safety, quality, and regulation compliance. Retailers have benefited from more efficient distribution and logistics through broader vertical integration, fueling the need for comprehensive package testing solutions. These developments have contributed to the overall growth of the packaging industry in Europe.

- In the United Kingdom, a key player in the European market, the revenue of the "packaging activities" industry has shown a notable upward trend. According to industry data, the revenue is expected to reach approximately USD 5.505 billion in 2023, a significant increase from USD 5.320 billion in 2021. This growth reflects the increasing importance of packaging and package testing in the retail and consumer goods sectors and the ongoing innovations in packaging materials and technologies that require rigorous testing protocols.

Europe Package Testing Industry Overview

The Europe package testing market is semi-consolidated, featuring a mix of global and regional players. Key companies such as Intertek Group plc, TUV SUD AG, Smurfit Kappa, and Tri-Wall UK Limited compete. The industry is characterized by low product differentiation, increasing product penetration, and intense competition among market participants.

The competitive landscape is further shaped by technological advancements in testing equipment, increasing emphasis on sustainable packaging, and growing demand for e-commerce solutions. Companies in this market continuously invest in research and development to enhance their testing capabilities and stay ahead of evolving industry requirements.

As the market grows, companies are expanding their geographical presence and service offerings through strategic partnerships and acquisitions. This trend will likely intensify competition and lead to further market consolidation in the coming years.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Rigorous Control Regulations and Administration and Qualification Demands

- 5.1.2 Demand for Longer Shelf Life of the Products Under Varying Conditions

- 5.2 Market Restraints

- 5.2.1 High Costs Associated with Package Testing Limits the Market

- 5.3 Technology Snapshot

- 5.3.1 Package Integrity Testing

- 5.3.2 Package Strength Testing

- 5.3.3 Package Shelf-life Studies

- 5.3.4 Package Validation

6 INDUSTRY POLICIES

- 6.1 ASTM Standards

- 6.2 ISO Standards

- 6.3 ISTA Standards

7 MARKET SEGMENTATION

- 7.1 By Primary Material

- 7.1.1 Glass

- 7.1.2 Paper

- 7.1.3 Plastic

- 7.1.4 Metal

- 7.2 By Type of Testing

- 7.2.1 Physical Performance Testing

- 7.2.2 Chemical Testing

- 7.2.3 Environmental Testing

- 7.3 By End-user Vertical

- 7.3.1 Food and Beverage

- 7.3.2 Healthcare

- 7.3.3 Industrial

- 7.3.4 Personal and Household Products

- 7.3.5 Other End-user Verticals

- 7.4 By Country

- 7.4.1 France

- 7.4.2 Germany

- 7.4.3 Italy

- 7.4.4 Spain

8 COMPETITIVE LANDSCAPE

- 8.1 Company Profiles

- 8.1.1 Intertek Group plc

- 8.1.2 TUV SUD AG

- 8.1.3 Smurfit Kappa

- 8.1.4 Tri-Wall UK Limited

- 8.1.5 Eurofins Scientific (Ireland) Limited

- 8.1.6 Stora Enso Oyj

- 8.1.7 Bureau Veritas