|

市场调查报告书

商品编码

1643201

转叶真空帮浦:市场占有率分析、产业趋势与统计、成长预测(2025-2030)Rotary Vane Vacuum Pump - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

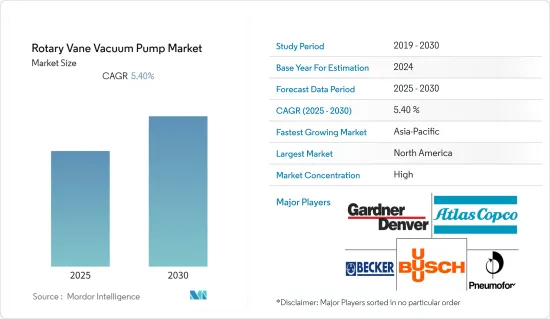

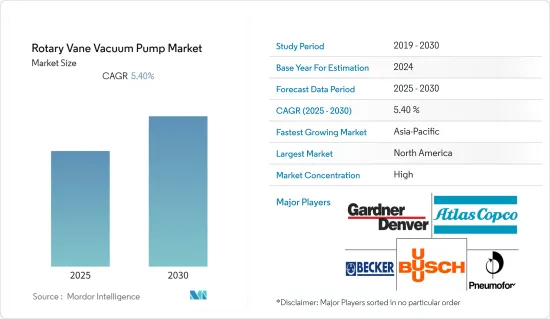

预测期内,转叶真空帮浦市场预期复合年增长率为 5.4%。

各终端用户垂直领域对真空帮浦的需求都很高。这些行业经常暴露在恶劣的环境中,这使它们极易受到腐蚀,因此更需要符合各种行业法规的真空帮浦。

关键亮点

- 转叶真空帮浦是油封旋转容积帮浦。该系统通常由一个外壳、一个偏心安装的转子、在弹簧力下径向移动的叶片、一个入口和一个出口组成。出口阀一般采用油封式。

- 电子和半导体产业的快速成长归因于智慧型手机、笔记型电脑和其他相关设备等消费性电子产品的日益普及。这些是推动旋转叶片泵市场成长的关键因素。

- 各公司即将开展的半导体製造计划可能会进一步推动对转叶真空帮浦的需求。例如,World Foundry在2021年3月宣布打算投资14亿美元建立全球製造能力。该公司每年投资数亿美元来提高生产能力。

- COVID-19 疫情对干式真空帮浦市场产生了不利影响。由于封锁和社交距离规定,一些地区的主要企业已经停止营运。由于都市化加快和对有效利用可用空间的需求,预计疫情过后该领域的需求和供应将大幅增加。

- 几十年来,油润滑转叶真空帮浦已在许多领域得到应用。目前,它是应用最广泛的机械真空帮浦。然而,无油真空帮浦的进入市场成为转叶真空帮浦普及的限制因素。

- 例如,2021 年 8 月,普发真空推出了 HiPace 80 Neo 涡轮帮浦。这些优势是透过为涡轮泵转子开发的新型先进雷射平衡方法实现的。

转叶真空帮浦的市场趋势

半导体产业预计将占很大份额

- 半导体产业是重点地区经济实力、国际竞争和技术领先地位的关键驱动力,特别是对于微处理器而言,对叶片真空帮浦的需求庞大。

- 半导体技术进步迅速,已开发出多代半导体装置。目前,半导体设备的製造和使用涉及多种化学元素等许多高新技术,技术整体性很强。

- 半导体设备技术正逐步将技术模组化融入设备之中,使其高度自动化、智慧化,并影响变化的材料和製程的自然分离。半导体製造流程出现了新的真空应用,主要受到智慧型手机、高亮度 LED 照明、光伏太阳能板和锂离子电池生产的推动。

- 例如,根据WSTS的数据,2021年半导体销售额为5,558.9亿美元。预计到 2022 年将达到 6,135.2 亿美元,高于全球整体的 4,403.9 亿美元。半导体销量的成长预计将推动转叶真空帮浦市场的发展。

- 半导体製程真空用于沉积、沉淀、PECVD 、真空干蚀刻、真空吸附、检查设备、真空清洗和其他键结製程。半导体製造过程会产生易燃、易爆和有毒气体,因此真空帮浦製造商必须遵守 CE、UL/CSA 等标准,以确保生产和人员安全。

- 例如干式蚀刻一般是透过物理和化学相结合的方法去除薄膜,因此蚀刻具有异向性,可以从根本上改善湿式製程固有的横向钻孔侵蚀问题,满足精细线路刻蚀的要求,转叶真空技术就是其中一种。此外,光是真空帮浦就占了半导体製造工厂总能耗的 25%。

预计北美将占很大份额

- 阿特拉斯·科普柯已收购多家泵浦业务以增强其基础。不过这些公司的收益与其国内收益接近。一些供应商正在北美、美国建立製造工厂,而其他海外供应商则在北美扩大其分销网络。由于半导体、太阳能和製程工业等各个终端用户产业的不断发展,转叶真空帮浦预计在美国将大幅成长。

- 2022 年 8 月,高通和 GlobalFoundries 宣布建立新的合作伙伴关係,其中包括斥资 42 亿美元扩建 GlobalFoundries 位于纽约州北部的工厂以生产晶片。全球领先的无晶圆厂半导体公司高通宣布,计划在未来五年内将其美国半导体产量提高至50%。由于转叶真空帮浦广泛应用于半导体,新兴市场的发展预计将对该地区的市场产生正面影响。

- 同样,2022年9月,美国总统签署了《晶片与科学法案》,授权政府为美国半导体生产和研究提供约520亿美元的补贴,以及为晶片工厂提供核准价值240亿美元的投资税额扣抵。

- 各公司即将开展的半导体製造计划预计将进一步推动对转叶真空帮浦的需求。例如,2021年3月,英特尔宣布将投资200亿美元在亚利桑那州钱德勒建造两家新工厂,以推动亚利桑那州蓬勃发展的半导体製造地。

- 该地区对半导体生产和研究的补贴和投资预计将推动转叶真空帮浦市场的发展。

转叶帮浦产业概况

转叶真空帮浦市场正在整合,少数参与企业占据大部分市场。产品线的技术进步为企业提供了可持续的竞争优势,市场也正在经历现有产品系列的升级。市场也出现了一系列併购活动。 Gardner Denver Inc.、Busch Holding GmbH、Atlas Copco Group、Gebr. Becker GmbH 和 Pneumofore SPA 是转叶真空帮浦市场的主要企业。

2021 年 10 月,HHV Pumps Pvt. Ltd 同意被阿特拉斯科普柯收购。该公司为各种行业设计和製造真空帮浦和真空系统。 HHV Pumps 总部位于印度班加罗尔,成立于 2009 年,拥有 151 名员工。 2020年公司收益约600万美元。

2021 年 8 月,普发真空推出了 HiPace 80 Neo 涡轮泵,该泵的使用寿命更长,振动和噪音更小。这些优势是透过为涡轮泵转子开发的新型先进雷射平衡方法实现的。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争强度

- COVID-19 市场影响评估

第五章 市场动态

- 市场驱动因素

- 工业物联网数位化推动电子产业成长

- 节能真空帮浦的需求

- 市场限制

- 市场参与企业整合

第六章 市场细分

- 按最终用户产业

- 製程工业

- 半导体

- 太阳能电池

- 测量仪器

- 其他的

- 按地区

- 美洲

- 中国

- 日本

- 韩国

- 亚洲其他地区

- 欧洲、中东和非洲

第七章 竞争格局

- 公司简介

- Gardner Denver Inc.

- Busch Holding GmbH

- Tuthill Corporation

- Gast Manufacturing Inc.(Idex Corporation)

- Atlas Copco Group

- ULVAC Technologies Inc.

- Pneumofore SpA

- Gebr. Becker GmbH

- The Kurt J. Lesker Company

第八章投资分析

第九章:市场的未来

The Rotary Vane Vacuum Pump Market is expected to register a CAGR of 5.4% during the forecast period.

Vacuum pumps have experienced a substantial demand from various end-user verticals. The operations in these verticals are extremely susceptible to corrosion due to constant exposure to harsh environments, emphasizing the need for vacuum pumps to comply with various industrial regulations.

Key Highlights

- The rotary vane vacuum pump is an oil-sealed rotary displacement pump. The system usually comprises a housing, an eccentrically installed rotor, vanes that move radially under spring force, and the inlet and outlet. The outlet valve is generally oil-sealed.

- The rapid growth of the electronics and semiconductor industries can be attributed to the increasing proliferation of consumer electronics like smartphones, laptops, and other relevant gadgets. It is a significant factor driving the rotary vane pump market growth.

- The upcoming semiconductor fabrication projects by different companies are likely to boost the rotary vane vacuum pump demand further. For instance, Global Foundries announced its intentions to invest USD 1.4 billion in its global manufacturing capacity in March 2021. The company invests hundreds of millions of dollars yearly to improve its production capacity.

- The COVID-19 pandemic had a detrimental impact on the Dry Vacuum Pumps Market. Due to the lockdown and social distancing norms, significant corporations halted operations in several areas. The sector anticipated a high level of demand and supply following the epidemic due to increased urbanization and the growing need for efficient use of available space.

- Oil-lubricated rotary vane vacuum pumps have been deployed across many fields for decades. Currently, they represent the most widely used mechanical vacuum pumps. However, oil-free vacuum pumps have been introduced in the market, which acts as a restraint towards adopting rotary vane vacuums.

- For instance, in August 2021, Pfeiffer Vacuum introduced the HiPace 80 Neo turbopump, which has a longer service life and lowers vibration and noise emissions. The novel, advanced Laser Balancing method developed for turbopump rotors enables these advantages.

Rotary Vane Vacuum Pump Market Trends

Semiconductor Industry is Expected to Hold Significant Share

- With the semiconductor industry being a key driver of the significant region's economic strength, global competitiveness, and technology leadership, especially in microprocessors, the demand for vane vacuum pumps has been substantial.

- Semiconductor technology has rapidly evolved, leading to the development of semiconductor devices over generations. Currently, the manufacture and use of semiconductor equipment involves many high and new techniques, such as various chemical elements, and has a robust technical comprehensiveness.

- Semiconductor equipment technology has gradually integrated technology modularization into equipment, making it highly automated and intelligent, affecting the natural separation of material and the process to change. New vacuum applications in the semiconductor manufacturing process have emerged, mainly fueled by the production of smartphones, high-brightness LED lighting, photovoltaic solar panels, and Li-ion batteries.

- For instance, according to WSTS, semiconductor sales in 2021 were USD 555.89 billion. It increased from USD 440.39 billion globally and was forecasted to rise to USD 613.52 billion in 2022. The increase in semiconductors sales will drive the rotary vane vacuum pump market.

- Semiconductor process vacuum is used across evaporation, sputtering, PECVD, vacuum dry etching, vacuum adsorption, testing equipment, vacuum cleaning, and other bonding processes. The flammable, explosive, and toxic substance gases in the manufacturing process of semiconductor, leads the manufacturer of vacuum pumps to adhere to compliances such as CE and UL/CSA standards for production and personnel safety.

- Dry etching, for instance, is generally used to remove the etched thin film through a combination of physical and chemical methods, so the etching has anisotropy, which can fundamentally improve the inherent problem of horizontal drilling erosion of wet process, to meet the requirements of fine line etching, rotary vane vacuum technology is one of them. Also, vacuum pumps alone represent up to 25% of the total energy consumed by a semiconductor manufacturing facility.

North America is Expected to Hold Significant Share

- Traditionally, European vendors dominated the rotary vane vacuum pump market, such as Atlas Copco, which acquired various pump businesses to increase its foothold. However, these companies reported revenues closer to their domestic revenues. While several vendors have established their manufacturing facilities in North America, in the United States, the other international vendors have increased their distributor networks in North America. The rotary vane vacuum pump is expected to grow significantly in the United States owing to the several developments taking place in various end-user industries, such as semiconductors, solar, and process industries.

- In August 2022, Qualcomm and GlobalFoundries announced a new partnership that included USD 4.2 billion to manufacture chips in an expansion of GlobalFoundries' upstate New York facility. Qualcomm, the leading fabless semiconductor company in the world, announced plans to increase semiconductor production in the US by up to 50% over the next five years. With the rotary vane vacuum pump significantly used in semiconductors, the developments are expected to impact the region's market positively.

- Similarly, in September 2022, the US President signed into law the Chips and Science Act, which authorized about USD 52 billion in government subsidies for US semiconductor production and research, as well as an investment tax credit for chip plants estimated to be worth USD 24 billion.

- The upcoming semiconductor fabrication projects by different companies will further boost the rotary vane vacuum pump demand. For instance, in March 2021, Intel stated that it would invest USD 20 billion in two new fabs in Chandler, Arizona, adding to Arizona's burgeoning semiconductor manufacturing base.

- Such subsidies and investments in semiconductor production and research in this region will drive the market for rotary vane vacuum pumps.

Rotary Vane Vacuum Pump Industry Overview

The rotary vane vacuum pump market is consolidated, with most of the market occupied by a few players. Technological advancements in their product line are bringing sustainable competitive advantage to the companies, and the market is also witnessing the upgradation of the existing product portfolio. The market is also witnessing various mergers and acquisitions. Gardner Denver Inc., Gardner Denver Inc., Busch Holding GmbH, Atlas Copco Group, Gebr. Becker GmbH, and Pneumofore SPA are the major players in the rotary vane vacuum pump market.

In October 2021, HHV Pumps Pvt. Ltd agreed to be acquired by Atlas Copco. Vacuum pumps and systems are designed and manufactured by the company for various industries. HHV Pumps, based in Bengaluru, India, was started in 2009 and employs 151 people. The company generated around USD 6 million in revenue in 2020.

In August 2021, Pfeiffer Vacuum introduced the HiPace 80 Neo turbopump, which has a longer service life, and lowers vibration and noise emissions. The novel, advanced Laser Balancing method developed for turbopump rotors enables these advantages.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Assessment of the Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Electronics Industry Driven by IIoT and Digitalization

- 5.1.2 Demand for Energy-Efficient Vacuum Pumps

- 5.2 Market Restraints

- 5.2.1 Consolidation of Market Participants

6 MARKET SEGMENTATION

- 6.1 By End-user Industry

- 6.1.1 Process Industry

- 6.1.2 Semiconductor

- 6.1.3 Solar

- 6.1.4 Instrumentation

- 6.1.5 Other End-user Industries

- 6.2 By Geography

- 6.2.1 Americas

- 6.2.2 China

- 6.2.3 Japan

- 6.2.4 South Korea

- 6.2.5 Rest of Asia

- 6.2.6 Europe, Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Gardner Denver Inc.

- 7.1.2 Busch Holding GmbH

- 7.1.3 Tuthill Corporation

- 7.1.4 Gast Manufacturing Inc. (Idex Corporation)

- 7.1.5 Atlas Copco Group

- 7.1.6 ULVAC Technologies Inc.

- 7.1.7 Pneumofore SpA

- 7.1.8 Gebr. Becker GmbH

- 7.1.9 The Kurt J. Lesker Company