|

市场调查报告书

商品编码

1683489

数位纺织印花:市场占有率分析、产业趋势与统计、2025-2030 年成长预测Digital Textile Printing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

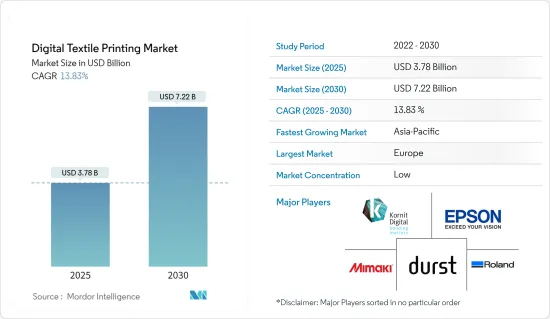

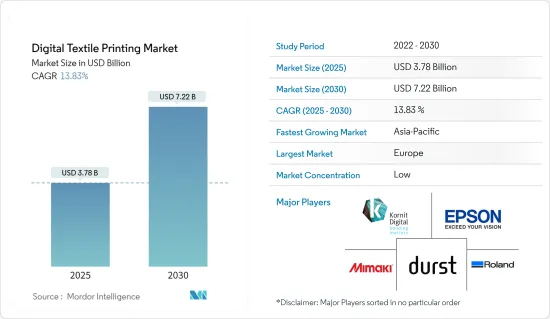

预计 2025 年数位纺织品印花市场规模为 37.8 亿美元,到 2030 年将达到 72.2 亿美元,预测期内(2025-2030 年)的复合年增长率为 13.83%。

主要亮点

- 使用喷墨技术的数位纺织品印花可以为材料装饰上鲜艳的图案。在纺织品设计软体的支援下,该方法满足了客自订T 恤印花日益增长的需求并提供了设计可能性。除了服装领域之外,数位纺织印花在商业和家居装饰市场也得到广泛的应用。

- 与胶印和固体油墨印刷等传统方法相比,数位印刷使用较温和的化学品和溶剂。在印染印花市场,环保方法和成本效益生产的双重关注正在推动对数位解决方案的需求激增。

- 此外,紫外线凝胶技术等进步正在推动产业创新。例如,2024 年 5 月,主要企业Canon美国公司透过韧体更新扩展了其 M 系列 UV 凝胶印表机的功能,以巩固其去年推出的科罗拉多 M 系列印表机的成功。此举旨在拓宽应用范围并开拓新的细分市场。

- 印花织物在车辆包装和室内装饰中的使用正日益成为市场成长的动力。数位印表机还存在墨水成本和维护成本高等挑战。这些因素,加上油墨和列印头等原料价格的波动,可能会阻碍市场扩张。然而,纺织品增材製造等有前景的技术支撑了市场的成长。

- 儘管前景光明,但障碍依然存在。油墨成本高、高速单一途径机器上需要多个印刷头以及昂贵的维护和更换费用使其难以在纺织市场上与轮转印花竞争。

数位纺织印花市场趋势

服饰和服饰领域预计将占据市场主要份额

- 服装和服饰印花技术自诞生以来已经取得了长足的进步。服装和配件的最新印花方法是数位纺织品印花。数位纺织品印花使用电脑控制的印表机将以数位格式储存的图案和图像传输到织物上。技术进步使得设计师和製造商能够快速、轻鬆地创造出复杂的图案。

- 印染市场传统上高度重视永续性和纺织废弃物。据联合国称,时尚产业严重依赖数位技术,造成全球温室气体排放的 10% 左右。

- 透过将纺织品设计流程转移到国内,数位纺织品印花提高了生产速度并降低了运输成本。

- 此外,随着尖端的数位纺织印花技术,中国大多数数位纺织印花企业已开始建造先进的数位纺织印花设施,以满足对无限色彩组合和色彩精度的需求。

- 此外,预计预测期内,消费行为的改变、都市化的加快、快速适应性、时装设计生命週期的缩短以及可支配收入的增加将增加服饰和服饰领域对数位纺织品印花解决方案的需求。

亚太地区预计将出现最高成长

- 亚太地区拥有众多纺织中心,可望引领全球成长。中国和印度是该地区的主要市场推动者,而越南和孟加拉正在成为纺织市场的主要企业。

- 中国和印度以其具有竞争力的人事费用而闻名,其纺织业正在快速扩张,从而推动了该地区的市场成长。中国数十年来一直是纺织强国,目前正致力于增强自身能力,投资无梭织机等先进技术来提高织物品质。

- 聚酯纤维因其抗皱、耐磨和经济高效等特性,已成为热昇华墨水的首选面料,尤其是在时尚领域。丝绸仍然是服装和家居装饰中备受青睐的材料,但其在该地区的应用受到高价格的限制,日本和海湾国家对丝绸纺织品的需求领先。

- 数位纺织印花和染料昇华技术彻底改变了纺织品生产的格局,开启了新的利润丰厚的市场领域。这一发展使大尺寸印染印表机和印刷服务提供者受益,为建筑物、零售指示牌和其他商业环境的软标誌铺平了道路。这些进步加上不断扩张的时尚产业预计将推动该地区的市场成长。

数位纺织印花产业细分

随着印花纺织品的需求不断增长,数位纺织品印花市场竞争也日益激烈。随着对永续产品的偏好日益增长,主要企业正将重点转向产品创新和策略合作伙伴关係。知名的市场参与者包括 Kornit Digital、Seiko Epson、Mimaki Engineering、Durst Group 和 Roland DG Corporation。

- 2024 年 8 月,领先的数位纺织品印花公司 Orange O Tec Pvt Ltd 在 Gartex 新德里展览会上推出了其革命性的「印度製造」数位纺织品印花机 Fabpro 1i。此举标誌着 Orange O Tec 的重大转变,该公司已进口数位纺织印刷机 15 年。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 纺织品印花概述

- 技术开发

- 产业价值链分析

- 产业吸引力-波特五力分析

- 新进入者的威胁

- 买家的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争强度

第五章 市场动态

- 市场驱动因素

- 时尚产业服饰个性化的成长

- 服装直接印刷

- 使用数位印表机降低列印成本

- 市场挑战

- 初期投资高

- 墨水和基板相容性

- 微观经济因素如何影响市场

第六章 市场细分

- 按印刷方式

- 卷对卷列印

- 服装直接印刷

- 按类型

- 昇华

- 颜料

- 反应性

- 其他类型(酸等)

- 按应用

- 服饰和服饰

- 适合家庭使用

- 展示和招牌

- 按基材分类

- 棉布

- 丝绸

- 聚酯纤维

- 其他基材

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

第七章 竞争格局

- 公司简介

- Kornit Digital

- Seiko Epson Corporation

- Mimaki Engineering

- Durst Group

- Electronics For Imaging Inc.

- D.Gen Inc.

- Aeoon Technologies GmbH

- Roland DG Corporation

- Ricoh Company Ltd

- ColorJet

- ATP Color

- SPG Prints

第八章投资分析

第九章:市场的未来

The Digital Textile Printing Market size is estimated at USD 3.78 billion in 2025, and is expected to reach USD 7.22 billion by 2030, at a CAGR of 13.83% during the forecast period (2025-2030).

Key Highlights

- Digital textile printing, powered by inkjet technology, embellishes materials with vibrant patterns. This method, bolstered by Textile Design Software, caters to the surging demand for custom t-shirt printing, offering an array of design possibilities. Beyond the apparel sector, digital textile printing has found extensive applications in commercial and home decor markets.

- Compared to conventional methods like offset and solid ink printing, digital printing employs gentler chemicals and solvents. The textile printing market is witnessing a surge in demand for digital solutions, driven by a dual focus on eco-friendly practices and cost-effective production.

- Furthermore, advancements such as UV gel technology are driving industry innovation. For example, in May 2024, Canon USA Inc., a prominent player in digital imaging, expanded its M-series UVgel Printer's capabilities through a firmware update, building on the success of its Colorado M-series launched the previous year. This move aims to broaden application horizons, potentially tapping into new market segments.

- The use of printed fabrics gains traction in vehicle wrapping and interior decoration as the market is poised for growth. Challenges, such as the high ink costs and maintenance expenses associated with digital printers, also exist. These factors, coupled with the volatility in raw material prices, notably ink and print heads, could impede the market's expansion. However, the market's growth is buoyed by promising technologies like textile additive manufacturing.

- Despite the promising landscape, hurdles remain. High ink costs and the need for multiple printing heads in high-speed single-pass machines, coupled with their pricey maintenance and replacement, render them less competitive against rotary printing in the textile market.

Digital Textile Printing Market Trends

The Garment and Apparel Segment is Expected to Hold Significant Share in the Market

- Since its inception, garment and clothing printing techniques have advanced significantly. The most recent printing method for apparel and accessories is digital textile printing. Digital fabric printing transfers designs or images kept in a digital format into the fabric using computer-controlled printers. Designers and makers may produce complex patterns quickly and simply due to technology.

- The market for textile printing has traditionally placed a high priority on sustainability and textile waste. According to the United Nations, the fashion industry is heavily reliant on digital technology, which contributes approximately 10% of global greenhouse gas emissions.

- Due to shifting the textile design process domestically, digital textile printing has increased the speed of production and lowered shipping expenses, which enables designers to make smaller fabric test runs and waste less while finalizing the fabric, which also reduces excessive waste in the design process.

- Moreover, with cutting-edge digital textile printing technology, most digital textile printing businesses in China have begun to build advanced digital textile printing equipment in response to the demand for limitless color combinations and color accuracy.

- Furthermore, demand for digital textile printing solutions in the garment and apparel segment is expected to be anticipated to increase due to changing consumer behavior, increased urbanization, faster adaptability, shorter life cycles of fashion designs, and higher disposable income during the forecast period.

Asia-Pacific is Expected to Witness the Highest Growth

- Asia-Pacific, driven by its numerous textile hubs, is poised to lead global growth. China and India stand out as the region's primary market drivers, with Vietnam and Bangladesh emerging as key players in the textile landscape.

- China and India, known for their competitive labor costs, have witnessed a surge in textile industry expansion, propelling the market's growth in the region. China, a textile powerhouse for decades, is now focusing on enhancing its capabilities, investing in advanced technologies like shuttle-less looms to elevate fabric quality.

- Polyester has emerged as the go-to fabric for sublimation ink, especially in the fashion realm, owing to its attributes such as wrinkle and abrasion resistance and cost-effectiveness. While silk remains a coveted choice for apparel and home decor, premium pricing limits its widespread adoption in the region, with Japan and Gulf nations leading in demand for silk textiles.

- Digital textile printing and dye-sublimation technologies have revolutionized the textile production landscape, carving out new, lucrative market niches. This evolution has benefitted large format textile printers and print service providers, opening up avenues in soft signage for buildings, retail displays, and other commercial settings. The expanding fashion industry, coupled with these advancements, is set to fuel the market's growth in the region.

Digital Textile Printing Industry Segmentation

The digital textile printing market is witnessing heightened competition as the demand for printed textiles surges, drawing new vendors enticed by the sector's stable profitability. With a mounting preference for sustainable goods, major players are pivoting toward product innovation and strategic collaborations. Notable market players encompass Kornit Digital, Seiko Epson Corporation, Mimaki Engineering, Durst Group, and Roland DG Corporation.

- August 2024: Orange O Tec Pvt Ltd, a leading player in digital textile printing, unveiled its revolutionary "Made in Bharat" digital textile printing machine, the Fabpro 1i, at the Gartex New Delhi exhibition. This launch signifies a significant shift for Orange O Tec, which, after 15 years of importing digital textile printing machines, emerges as a prominent manufacturer in the industry.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Overview of Textile Printing

- 4.2 Technology Developments

- 4.3 Industry Value Chain Analysis

- 4.4 Industry Attractiveness - Porter's Five Forces Analysis

- 4.4.1 Threat of New Entrants

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Bargaining Power of Suppliers

- 4.4.4 Threat of Substitute Products

- 4.4.5 Intensity of Competitive Rivalry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growth of Personalization of Clothing Items in the Fashion Industry

- 5.1.2 Direct to Garment Printing

- 5.1.3 Reduction in Per Unit Cost of Printing with Digital Printers

- 5.2 Market Challenges

- 5.2.1 High Initial Investments

- 5.2.2 Ink and Substrate Compatibility

- 5.3 Impact of Microeconomic Factors on the Market

6 MARKET SEGMENTATION

- 6.1 By Printing Method

- 6.1.1 Roll-to-Roll printing

- 6.1.2 Direct-to-Garment Printing

- 6.2 By Type

- 6.2.1 Sublimation

- 6.2.2 Pigment

- 6.2.3 Reactive

- 6.2.4 Other Types (Acid, etc.)

- 6.3 By Application

- 6.3.1 Garment and Apparel

- 6.3.2 Household

- 6.3.3 Display and Signage

- 6.4 By Substrate

- 6.4.1 Cotton

- 6.4.2 Silk

- 6.4.3 Polyester

- 6.4.4 Other Substrates

- 6.5 By Geography

- 6.5.1 North America

- 6.5.2 Europe

- 6.5.3 Asia-Pacific

- 6.5.4 Latin America

- 6.5.5 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Kornit Digital

- 7.1.2 Seiko Epson Corporation

- 7.1.3 Mimaki Engineering

- 7.1.4 Durst Group

- 7.1.5 Electronics For Imaging Inc.

- 7.1.6 D.Gen Inc.

- 7.1.7 Aeoon Technologies GmbH

- 7.1.8 Roland DG Corporation

- 7.1.9 Ricoh Company Ltd

- 7.1.10 ColorJet

- 7.1.11 ATP Color

- 7.1.12 SPG Prints