|

市场调查报告书

商品编码

1686552

压铸:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Die Casting - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

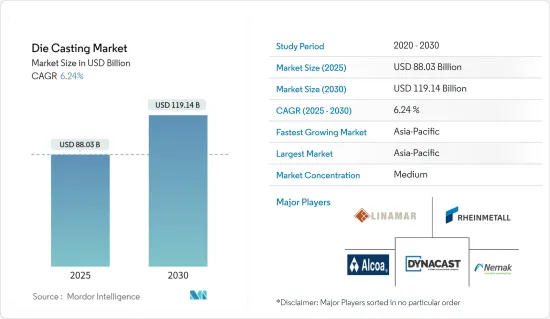

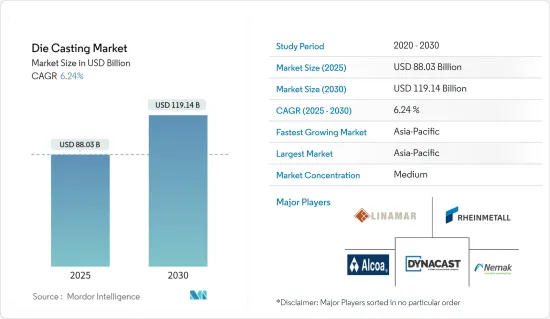

预计 2025 年压铸市场规模为 880.3 亿美元,到 2030 年将达到 1,191.4 亿美元,预测期内(2025-2030 年)的复合年增长率为 6.24%。

新冠疫情为製造业带来沉重打击。随着全球主要经济体进入封锁状态,供应链中断。在此期间,所有製造单位和OEM工厂被迫停止生产和运作。随着经济復苏,消费者偏好转向更轻的汽车,汽车产业对压铸件的需求也显着回升。预计这一趋势将持续并推动市场成长。

从中期来看,压铸行业供应链的日益复杂化、汽车市场的扩大、压铸件在工业机械中的渗透率的提高、建筑行业的增长以及电气和电子设备中铝铸件的采用将极大地推动所研究的市场。 CAFE 标准和 EPA 减少汽车排放气体、提高燃油经济性的政策正在鼓励汽车製造商透过使用轻质非铁金属来减轻汽车重量。因此,采用压铸件作为轻量化策略是汽车产业前者市场的主要驱动力。

由于铝压铸件具有较高的导热性,电气和电子产业对铝压铸件的需求不断增长,这可能会推动预测期内的成长。随后,采用压铸件作为轻量化策略已成为汽车领域前者市场的主要驱动力。然而,原物料供应紧张、原物料价格波动以及冶金业排放气体的环境法规是市场成长的主要障碍。

由于中国和印度等国家对汽车的需求不断增加,以及铝压铸在各种应用中的使用不断增加,预计亚太地区将占据压铸市场的最大市场占有率。由于建筑和汽车行业产量的增加,北美铝压铸市场预计也将显着成长。

压铸市场趋势

铝有望在压铸製程中发挥关键作用

多年来,许多工业应用对铝高压铸件的需求一直在增加,因为它可以生产重量轻的零件,并在复杂形状方面具有很高的灵活性。

近年来,随着新技术的发展,汽车零件不断进步和创新。其中,轻量化材料在汽车零件製造上的应用正受到各国的重视。

汽车受欢迎的主要原因之一是采用轻质汽车材料提高了汽车的燃油效率。

此外,必须在不损害安全性、品质或性能的情况下减轻车辆重量。铝压铸件耐用且可无限回收,由于其众多优点,铝已成为製造商的首选。

此外,大型公司不断增加收购和联盟活动,以进一步加强市场渗透。例如,

- 2022年8月,文灿集团宣布将在安徽省六安经济技术开发区兴建新能源汽车铝压铸件生产基地。

- 2021 年 10 月,我们成立了 Sandhar Engineering Private Limited 作为完全子公司,从事一系列锁定装置、电气、电子、机械、汽车和工业零件的製造和组装业务。

- 2021 年 4 月,Jaya Hind Industries 将与 KS Huayu Alutech GmbH (KSATAG) 的技术合作伙伴关係延长至 2027 年,用于製造汽车汽缸体和缸头。我们也将业务范围扩大到 Sunrise Industries 的新零件,包括电动车和底盘的结构件。

- 2021 年 3 月,Sandhar Technologies 与 Unicast Autotech 签署了一份不具约束力的谅解备忘录,以收购该公司的铝压铸业务。

预计铝压铸市场在预测期内将继续成长,以满足汽车和非汽车产业对轻质和高导电性金属零件日益增长的需求。

亚太地区将迎来显着成长

预计预测期内亚太地区将占据压铸市场的最大市场占有率。汽车行业的成长、工业领域的需求以及风力涡轮机和通讯应用的不断扩大预计将推动亚太地区压铸市场以更快的速度发展。

预计印度和中国的廉价劳动力和低製造成本将进一步推动亚太地区的市场成长。此外,对电动和混合动力汽车的需求不断增长,促使汽车製造商将注意力转向使用铝等轻质材料来取代所有类型车辆中较重的钢材和钢材。例如

- 2022年5月,泰米尔纳德邦小型工业发展公司投资5.8亿印度卢比,建立铝高压铸通用设备中心。

随着全国汽车製造业的扩张,汽车轻量材料的需求很有可能增加。例如

- 2021 年 2 月,MG Motors 宣布可能投资 150 亿印度卢比用于扩建和本地化运营,以提高其位于古吉拉突邦Halol 工厂的生产能力。

- 印度政府提案在预测期内将印度每辆电动车的铝使用量从 29 公斤增加到 160 公斤。

此外,电动车製造商也积极采购这些压铸机,因为他们采用这项技术来满足日益增长的消费者需求。

为了维持市场竞争力,许多公司正在采取扩大生产能力等成长策略。例如

- 2021年7月,伊之密将在美国和印度建立压铸技术服务中心(TSC),提供压铸单元、模具、压铸製程、产品调试一体化解决方案。

- 2021 年 2 月,Endurance Technologies 在位于泰米尔纳德邦 Kancheepuram 区 Vadagal 市 Vallam 的新工厂开始商业生产。该工厂生产铝压铸件、整合式碟式煞车组件和控制调变器,并向现代、起亚和皇家恩菲尔德供应机械加工铝铸件。

压铸业概况

压铸市场由几家主要企业主导,例如:其中包括 Neamk、Alcoa Corporation、Linamar Corporation 和 Dynacast。这些市场的关键参与者正致力于透过各种合併、联盟、合资和收购来扩大其全球影响力。例如,

- 2022 年 3 月,利纳马集团收购了 GF Casting Solutions (GF) 50% 的股份。透过此次收购,利纳马公司增强了产品系列。

- 2022 年 1 月,Gibbs Die Casting 的子公司 Koch Enterprises, Inc. 收购了 Amprod Holdings, LLC。透过此次收购,该公司扩大了在美国的产品系列。

- 2022 年 1 月,我们成立了完全子公司Sandhar Auto Electric Solutions Private Limited,并开始提供电动车业务和先进技术解决方案。 Sandhar Auto Electric Solutions Private Limited 主要从事电池电动车、氢燃料电池汽车、生质燃料技术汽车、全地形车 (ATV) 和其他先进汽车技术汽车的零件製造业务。

- 2021 年 8 月,利纳马集团宣布与荷兰 Innovative Mechatronic Systems BV(IMSystems)建立合作关係。此次伙伴关係将致力于将阿基米德驱动传动系统推向市场。

- 2021 年 4 月,Aludyne 宣布收购 Shiloh Industries CastLight 部门。该部门生产铝压铸件。

- 2021 年 2 月,Endurance Technologies 宣布已在位于印度泰米尔纳德邦 Kancheepuram 的新工厂开始商业生产。该工厂将生产铝压铸件并整合两轮车和四轮车的碟式煞车零件。

- 2020 年 4 月,Endurance Technologies 收购了位于义大利特伦蒂诺的 Adler SpA 99% 的股份。此次收购预计将整合义大利和德国的 10 家製造工厂,扩大该公司在欧洲的影响力。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 调查前提条件

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 市场驱动因素

- 市场限制

- 产业吸引力-波特五力分析

- 新进入者的威胁

- 买家/消费者的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争强度

第五章市场区隔

- 按应用

- 车

- 电气和电子

- 工业的

- 其他的

- 按工艺

- 压力铸造

- 真空压铸

- 挤压压铸

- 其他的

- 按原料

- 铝

- 镁

- 锌

- 按地区

- 北美洲

- 美国

- 加拿大

- 北美其他地区

- 欧洲

- 英国

- 法国

- 德国

- 义大利

- 俄罗斯

- 其他欧洲国家

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 泰国

- 马来西亚

- 印尼

- 韩国

- 其他亚太地区

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地区

- 中东和非洲

- 南非

- 土耳其

- 其他中东和非洲地区

- 北美洲

第六章竞争格局

- 供应商市场占有率

- 公司简介

- Form Technologies Inc.(Dynacast)

- Nemak

- Endurance Technologies Limited

- Sundaram Clayton Ltd

- Shiloh Industries

- Georg Fischer Limited

- Koch Enterprises(Gibbs Die Casting Group)

- Bocar Group

- Engtek Group

- 莱茵金属股份公司(莱茵金属汽车,原 KSPG AG)

- Rockman Industries

- Ryobi Die Casting Ltd

- Linamar Corporation

- Meridian Lightweight Technologies UK Ltd

- Sandhar Group

- Alcoa Corporation

第七章 市场机会与未来趋势

The Die Casting Market size is estimated at USD 88.03 billion in 2025, and is expected to reach USD 119.14 billion by 2030, at a CAGR of 6.24% during the forecast period (2025-2030).

The COVID-19 outbreak hit the manufacturing industry adversely. The disruptions were caused in the supply chain as several major economies of the world were in lockdown. All the manufacturing units and OEM plants were forced to halt production and operations during this period. With the recovery of economies, the demand returned to the market witnessing huge demand for die-cast parts in the automotive industry as the consumer preference changed to lightweight vehicles. The trend is expected to continue and drive market growth.

Over the medium term, the market studied is largely driven by supply chain complexities in the die-casting industry, expanding automotive market, increasing penetration of die-casting parts in industrial machinery, growing constructional sector, and employing aluminum casts in electrical and electronics. CAFE standards and EPA policies to cut down automobile emissions and increase fuel efficiency are driving the automakers to reduce the weight of the automobile by employing lightweight non-ferrous metals. Subsequently, employing die-cast parts as a weight reduction strategy is acting as a major driver for the former market in the automotive segment.

Rising demand for aluminum die-casting parts in the electrical and electronics industry owing to its high thermal conductivity is likely to drive growth during the forecast period. Subsequently, employing die-cast parts as a weight reduction strategy is acting as a major driver for the former market in the automotive segment. However, a crunch in raw material supply, volatility in raw material prices, and environmental regulations on emissions for the metallurgy industries are acting as major barriers to market growth.

The Asia-Pacific region is anticipated to hold the largest market share in the die-casting market due to the rise in demand for automobiles in countries such as China and India and the rise in the use of aluminum die-casting for various applications. North America is also expected to witness significant growth in the aluminum die-casting market due to growing output from the construction and automotive sectors.

Die Casting Market Trends

Aluminum Anticipated to Play Key Role in Die Casting Process

The demand for aluminum high-pressure die-casting parts has been increasing across numerous industrial applications over the years, as the process manufactures lightweight parts and provides high flexibility for complex shapes.

In recent years, automotive parts have witnessed advancements and innovations with the evolution of new technologies. Among them, the use of lightweight materials for the manufacturing of auto components has been gaining attention across the country.

One of the important reasons for this popularity is the enhanced fuel economy of automobiles with the adoption of lightweight automotive materials manufacturing crucial parts.

Additionally, the lightweight of vehicles must be done without compromising on safety, quality, and performance. Aluminum die-cast parts are durable and can be endlessly recycled therefore, aluminum is most preferred by manufacturers due to its varied advantages.

Moreover, there is a rising number of acquisitions and partnerships by the major players to further enhance development in the market. For instance,

- In August 2022, Wencan Group Co., Ltd. announced that it intends to build a production base of aluminum die-cast parts for New Energy Vehicles (NEVs) in Lu'an Economic and Technological Development Zone, Anhui Province.

- In October 2021, Sandhar Engineering Private Limited was incorporated as a wholly owned Subsidiary Company for carrying out the business of manufacturers, and assembling various Locking Devices, Electrical, Electronics, Mechanical, Automobile, and Industrial parts.

- In April 2021, Jaya Hind Industries extended its technical partnership with KS Huayu AlutechGmbH (KSATAG) for the manufacturing of automotive cylinder blocks and cylinder heads till 2027. The scope of the agreement has also been expanded to cover new parts from Sunrise Industries, such as Electric Vehicles, Structural parts for Chassis, etc.

- In March 2021, Sandhar Technologies entered a non-binding Memorandum of Understanding with Unicast Autotech to acquire its aluminum die-casting business

The growth of the aluminum die-casting market is likely to continue to increase during the forecast period to meet the increasing demand for lightweight components and high-conductivity metal parts from the automotive and non-automotive sectors.

Asia-Pacific Region Likely to Witness Significant Growth

The Asia-Pacific region is anticipated to hold the largest market share in the die-casting market during the forecast period. The growing automobile industry, demand from the industrial sector, and increased scope of application in windmills and telecommunications are expected to drive the die-casting market at a faster pace in the Asia-Pacific region.

Cheaper labor and low manufacturing costs in India and China are expected to further accelerate the market growth in the Asia-Pacific region. In addition, increased demand for electric and hybrid vehicles has turned automakers' focus to using lightweight materials like aluminum as a substitute for heavier steel and iron in all types of vehicles. For instance,

- In May 2022, Tamil Nadu Small Industries Development Corporation invested an amount of INR 5.8 Crore to establish a common facility center for aluminum high-pressure die casting.

The growing expansion of automotive manufacturing industries across the country is likely to increase the demand for lightweight materials for automotive applications. For instance,

- In February 2021, MG Motors announced that INR 1,500 crore may be invested in the expansion and localization of its business to increase its production capacity at the Halol plant in Gujarat.

- The government of India has proposed the use of aluminum per vehicle in India from 29 Kg to 160 Kg for the electric vehicle during the forecast period.

In addition, the companies manufacturing electric vehicles are also actively procuring these pressure diecasting machines and are adopting this technology to make themselves ready for growing consumer demand.

Several players adopt growth strategies, such as manufacturing capacity expansion, to stay competitive in this market. For instance,

- In July 2021, YIZUMI established the Die Casting Technical Service Center (TSC) in the United States and India that offers integrated solutions for die casting cells, dies, die casting process, and product debugging.

- In February 2021, Endurance Technologies commenced commercial production at its new plant in Vallam, Vadagal, Kancheepuram, Tamil Nadu. The plant manufactures aluminum die-castings and carries out the integration of disc brake components with control brake modulators for supplying machined aluminum castings to Hyundai, Kia, and Royal Enfield.

Die Casting Industry Overview

The Die Casting market is dominated by several key players such as Neamk, Alcoa Corporation, Linamar Corporation, Dynacast, and many others. These key players in the market are focusing on expanding their presence globally through various mergers, partnerships, joint ventures, and acquisitions. For instance,

- In March 2022, Linamar Corporation acquired a 50% interest in GF Casting Solutions (GF). Through this acquisition, Linamar Corporation enhanced its product portfolio in automotive applications.

- In January 2022, Koch Enterprises, Inc., a subsidiary of Gibbs Die Casting acquired Amprod Holdings, LLC. Through this acquisition, the company expanded its product portfolio across the United States.

- In January 2022, Sandhar Auto Electric Solutions Private Limited was incorporated as a wholly owned Subsidiary Company to undertake e-mobility business and to provide Advanced Technology Solutions. Sandhar Auto Electric Solutions Private Limited is primarily involved in the business of manufacturing parts/components for Battery Electric Vehicles, Hydrogen Fuel Cell Vehicles, Biofuel based technology Vehicle, All Terrain Vehicles (ATVs), and any other Advanced Automotive Technology Vehicles.

- In August 2021, Linamar Corporation announced the partnership with Netherlands-based Innovative Mechatronic Systems B.V. (IMSystems). The partnership focuses on bringing the Archimedes Drive transmission system to market.

- In April 2021, Aludyne announced that it had acquired Shiloh Industries CastLight division. This division manufactures aluminum die-casting parts.

- In February 2021, Endurance Technologies announced that it had started commercial production at the new plant in Kancheepuram, Tamil Nadu, India. The plant will manufacture aluminum die-castings and integration of disc brake components for two and four-wheelers.

- In April 2020, Endurance Technologies acquired a controlling equity stake of 99% in Adler SpA, based out of Trentino, Italy. The acquisition is expected to improve the company's reach across Europe, with the aid of ten manufacturing plants combined in Italy and Germany.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Drivers

- 4.2 Market Restraints

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Threat of New Entrants

- 4.3.2 Bargaining Power of Buyers/Consumers

- 4.3.3 Bargaining Power of Suppliers

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION (Market Size by Value - USD Billion)

- 5.1 By Application

- 5.1.1 Automotive

- 5.1.2 Electrical and Electronics

- 5.1.3 Industrial

- 5.1.4 Other Applications

- 5.2 By Process

- 5.2.1 Pressure Die Casting

- 5.2.2 Vacuum Die Casting

- 5.2.3 Squeeze Die Casting

- 5.2.4 Other Processes

- 5.3 By Raw Material

- 5.3.1 Aluminum

- 5.3.2 Maginesium

- 5.3.3 Zinc

- 5.4 Geography

- 5.4.1 North America

- 5.4.1.1 United States

- 5.4.1.2 Canada

- 5.4.1.3 Rest of North America

- 5.4.2 Europe

- 5.4.2.1 United Kingdom

- 5.4.2.2 France

- 5.4.2.3 Germany

- 5.4.2.4 Italy

- 5.4.2.5 Russia

- 5.4.2.6 Rest of Europe

- 5.4.3 Asia-Pacific

- 5.4.3.1 China

- 5.4.3.2 India

- 5.4.3.3 Japan

- 5.4.3.4 Australia

- 5.4.3.5 Thailand

- 5.4.3.6 Malaysia

- 5.4.3.7 Indonesia

- 5.4.3.8 South Korea

- 5.4.3.9 Rest of Asia-Pacific

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 South Africa

- 5.4.5.2 Turkey

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Vendor Market Share

- 6.2 Company Profiles

- 6.2.1 Form Technologies Inc. (Dynacast)

- 6.2.2 Nemak

- 6.2.3 Endurance Technologies Limited

- 6.2.4 Sundaram Clayton Ltd

- 6.2.5 Shiloh Industries

- 6.2.6 Georg Fischer Limited

- 6.2.7 Koch Enterprises (Gibbs Die Casting Group)

- 6.2.8 Bocar Group

- 6.2.9 Engtek Group

- 6.2.10 Rheinmetall AG (Rheinmetall Automotive, formerly KSPG AG)

- 6.2.11 Rockman Industries

- 6.2.12 Ryobi Die Casting Ltd

- 6.2.13 Linamar Corporation

- 6.2.14 Meridian Lightweight Technologies UK Ltd

- 6.2.15 Sandhar Group

- 6.2.16 Alcoa Corporation