|

市场调查报告书

商品编码

1690797

工业雷射系统-市场占有率分析、产业趋势与统计、成长预测(2025-2030)Industrial Laser System - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

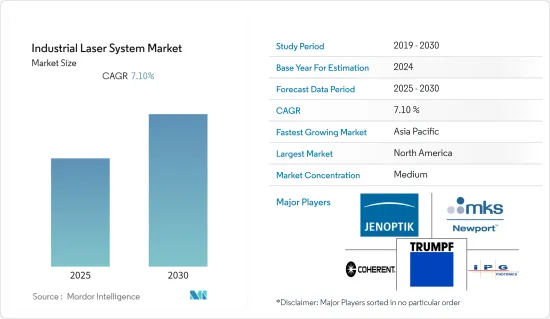

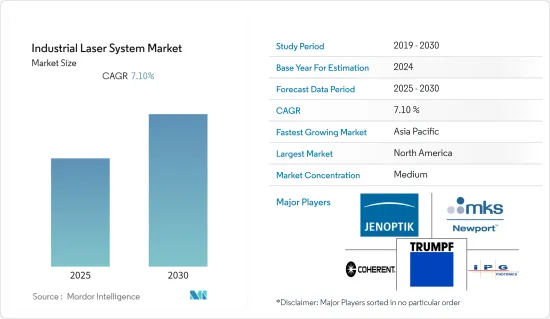

预计工业雷射系统市场在预测期内的复合年增长率将达到 7.1%

关键亮点

- 随着工业 4.0 和工业IoT的出现,工业环境中的各种技术进步,例如工业自动化、工业机器人和 3D 列印,预计将推动雷射系统在工业中的应用。製造业和其他产业对精度的需求也刺激了终端用户产业采用雷射解决方案。

- 雷射在各行各业中都有多种不同形式和类型的应用,但最大的应用领域是在材料加工领域。根据《Laser Focus World》报道,光纤雷射光源主要用于材料加工,其次是直接二极体雷射。

- 随着自动化程度的提高和精密製造需求的增加,雷射的应用和需求越来越高。该公司正在将现有的製造流程与雷射和雷射系统的多项技术进步相结合,以提高生产力并保持竞争优势。

- 此外,由于疫情增加了对数控系统和製程自动化的需求,推动了对用于钻孔、切割和打标的雷射机器的需求,预计全球对自动化的投资将进一步加速。根据瑞银预测,到2021年,流程自动化预计将占据全球自动化投资的很大份额,达到740亿美元。

- 对基于雷射的解决方案的需求不断增长,推动着各个供应商扩大其产品阵容。例如,MKS Instruments Inc. 推出了 Spectra-Physics Talon 355-45,这是一款高功率紫外线雷射器,可加快紫外线处理速度,同时显着降低每个零件的成本。非常适合 PC 板、电子元件、半导体、平板显示器、锂离子电池、家用电子电器、清洁能源和其他高要求应用的 LED 的工业製造。

- COVID-19 危机迫使企业遵守严格的要求,以确保其员工和客户的持续安全。因此,对自动化的需求呈指数级增长。这很可能成为不久的将来值得关注的趋势。

- 在此情况下,全球製造业收益和利润大幅下滑,导致员工和工人大幅减少,工业生产活动整体损失。

- 政府认为食品饮料和製药等行业很少是必要的。然而,製造业受到疫情严重影响,损失惨重,供应链和原物料采购面临前所未有的挑战。

- 然而,工业雷射系统应用于多个终端用户产业,包括航太和国防、汽车、医疗和半导体。在汽车领域,安装的雷射系统主要用于切割和焊接应用。这提高了生产力,减少了停机时间并显着降低了製造成本。此外,在航太和国防工业领域,我们广泛的製造能力涵盖金属加工、连接和涂层的所有环节。

工业雷射系统市场趋势

半导体电子领域预计将实现强劲成长

- 基于雷射的设备在半导体製造和加工中发挥着至关重要的作用。晶圆製造中常用的两种雷射是近红外线(NIR)雷射和绿光雷射。 NIR 雷射用途广泛,适用于半导体製造等许多机械应用。这些都是有效的,因为能量范围直接对应于执行晶圆所需标记所需的频谱场。

- 绿色雷射是二次谐波产生(也称为倍频)过程的结果。这项技术有助于将两张照片合併起来,创造一张能量增加一倍的新照片。这可以在保持雷射相干性的同时放大功率。雷射打标有助于整个市场的晶圆可追溯性和可读性,是晶圆製造的必要步骤。

- 全球对硅晶圆的需求正在快速增长,预计当前包括汽车在内的各行业的晶片短缺将推动需求成长。根据国际半导体设备与材料协会(SEMI)发布的资料,2020年全球硅片需求量为124.1亿平方英寸,高于上年的118.1亿平方英寸。继 2019 年需求低迷和市场整体波动之后,预计未来几年全球市场将因电子产品需求成长而加速成长。

- 雷射设备应用的很大一部分是半导体加工和PCB加工。该设备用于去除製程、黏附製程、检查、测量和修改製程。使用雷射可以提高产量比率和吞吐量,降低破损/晶粒品质的风险,避免无残留颗粒,并且具有成本效益。预计奈秒和皮秒型雷射将占据大部分市场,其次是二氧化碳、飞秒和准分子雷射。

- 在半导体产业之外,雷射设备在电子製造过程中有着广泛的应用。对于微钻孔等雷射应用,IPG Photonics 等知名供应商提供了重要的产品。随着物联网、工业物联网和智慧家庭解决方案的兴起,製造过程中对雷射的需求预计将快速增长。

- 随着技术创新降低智慧型手机更换率以及 5G 普及的加速,预计未来几年对 5G 智慧型手机和连网型设备的需求将会成长。

- 根据爱立信2021年6月的报告,目前已有超过160家通讯服务供应商推出了5G服务,超过300款5G智慧型手机型号已经发布或投入商用。报告预计,2021年底,全球将有5亿5G用户。截至2020年底,智慧型手机在行动电话合约的普及率将达到76%,智慧型手机用户数将达到60亿。预计未来四年内这一数字将达到 77 亿,其中智慧型手机在行动用户中的普及率将达到 88%。

- 预计电子产品需求的加速成长将增加对基于雷射的製造和检测设备的需求,从而影响对半导体设备的需求。

预计北美将占很大份额

- 由于製造业、航太和汽车等各领域的技术进步,预计市场将由北美主导。 IPG Photonics 和 Coherent Inc. 等供应商在北美都有业务。

- 预计北美公司产品推出将促进该地区的成长。例如,2021 年 8 月,Coherent Inc. 推出了其 ExactWeld IP 聚合物焊接技术。 ExactWeld IP 是一种聚合物焊接方法,可产生无变形和无颗粒的巨大焊接。该系统包括热感视觉检查、用于零件识别和偏移校正的内建视觉系统以及用于提高製程稳定性和一致性的自动雷射功率校准模组。

- 许多公司,尤其是中小型企业(SME)和新兴企业,已经开始资金筹措来创造尖端雷射技术解决方案。例如,致力于将亚利桑那大学的发现、产品、技术和服务商业化的 UAVenture Capital Fund 已投资 DeUVe Photonics Inc. 以推进技术,使该公司能够主导新兴和现有的深紫外线雷射市场。

- 为了提高生产力并保持竞争优势,该公司正在将当前的製造流程与雷射和雷射系统的技术进步相结合。例如,2020年1月,通快集团收购了专门从事中空光纤的法国雷射技术公司GLOphotonics。这种光纤可以使雷射更有效率、更快速地从光源传输到所需位置,且不会造成任何功率损失。

- 由于对高功率和紧凑功率的需求,光纤雷射业务预计将成长。光纤雷射器的出色可靠性有望推动北美工业雷射产业的发展。

工业雷射系统产业概况

工业雷射系统市场竞争激烈,供应商众多。市场似乎相当集中。除了最大的供应商外,还有各种迎合不同市场的小型本地供应商。市场上的供应商将研究、创新和产品开发作为其成长策略的优先事项。随着这些发展,各公司正在加强在这一领域的影响力。由于这是一个资本密集型市场,收益规模较小的公司退出门槛较高,几乎总是被收益更强的公司收购。适度的企业集中度和市场整合进一步加剧了竞争企业之间的敌意。

- 2022 年 1 月 - TRUMPF 与位于亚琛的 Fraunhofer Lab ILT 建立伙伴关係,后者是一家生产尖端雷射束源和领先光学元件系统的製造商。透过此次合作,两家公司将推动雷射材料沉积的研究,并加速该技术的引进。

- 2021 年 3 月-II-VI Incorporated 以 63 亿美元收购 Coherent Inc.。 II-VI 将透过现金和股票交易收购 Coherent Inc. 的所有已发行股。 Coherent Inc. 是全球领先的雷射、基于雷射的技术和基于雷射的系统解决方案提供商。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概览

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 竞争对手之间的竞争

- 替代品的威胁

- 产业价值链分析

- COVID-19 的市场评估

第五章市场动态

- 市场驱动因素

- 与传统替代方案相比,精度和准确度更高

- 组件小型化

- 市场限制

- 雷射合规性

第六章市场区隔

- 依雷射类型

- 纤维

- 固态

- CO2

- 其他雷射器

- 按应用

- 断开

- 焊接

- 标记

- 钻孔

- 其他应用(表面处理、积层製造)

- 按最终用户产业

- 半导体电子

- 车

- 航太和国防

- 医疗保健

- 其他的

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

第七章竞争格局

- 公司简介

- JENOPTIK AG

- Newport Corporation

- TRUMPF GmbH+Co. KG

- Coherent Inc.

- IPG Photonics Corporation

- ACSYS Lasertechnik US Inc.

- nLIGHT Inc.

- Han's Laser Technology Co. Ltd

- II-VI Incorporated

第八章投资分析

第九章:市场的未来

The Industrial Laser System Market is expected to register a CAGR of 7.1% during the forecast period.

Key Highlights

- The various technological advancements in an industrial environment, like industrial automation, industrial robots, 3D Printing, etc., due to the advent of Industry 4.0 and Industrial IoT, are expected to boost the adoption of laser systems in industries. The demand for precision in manufacturing and other industries is also adding to the adoption of laser solutions in the end-user industries.

- Lasers find applications in various industries in different forms and types, but a prominent share of their application lies in material processing. According to Laser Focus World, optical fiber laser sources are being used mainly for material processing, followed by Direct Diode Laser.

- With the proliferation of automation and growing demand for precision manufacturing, lasers are witnessing higher application and demand. Companies are integrating the existing manufacturing processes with several technological advancements across lasers and laser systems to enhance productivity and stay ahead of the competition.

- In addition, the global investment in automation is expected to accelerate even further due to the conditions created by the pandemic resulting in higher demand for CNC systems and process automation, where the demand for laser-based equipment for drilling, cutting, and marking is increasing. According to UBS, by 2021, the global automation investment specific to process automation was expected to command a prominent share at USD 74.0 billion.

- Due to the growing demand for laser-based solutions, various vendors are looking to expand their product offerings. For instance, MKS Instruments Inc. launched the spectra-physics Talon 355-45, a high-power UV laser that results in faster UV processing at a significantly lower cost per part. It is ideal for the industrial manufacturing of PC boards, electronic components, semiconductors, flat panel displays, lithium-ion batteries, and LEDs for consumer electronics, clean energy, and other demanding applications.

- The impact of the COVID-19 crisis has forced businesses to adhere to strict requirements to ensure the ongoing safety of their employees and customers alike. As a result, the need for automation has witnessed a sudden spike. This could be observed as a notable trend in the foreseeable future.

- Under these circumstances, manufacturing industries worldwide witnessed a significant decline in revenue and profits, leading to a significant cut down of employees and workers and an overall loss to industrial production activities.

- Few industries, such as food and beverage and pharmaceutical, were deemed essential by governments. However, the manufacturing industry shrunk significantly due to the pandemic as the industry faced unprecedented challenges in the supply chain and procurement of raw materials, which resulted in significant losses for manufacturers.

- However, industrial laser systems are being adopted in several end-user industries, such as aerospace and defense, automotive, medical, and semiconductor, amongst others. In the automotive sector, laser systems deployed are used mainly for cutting and welding applications. This enables higher productivity and reduction of downtime while substantially reducing manufacturing costs. Also, in the aerospace and defense industry, extensive manufacturing capabilities encompass all areas of metal fabrication, joining, and coating.

Industrial Laser Systems Market Trends

Semiconductor and Electronics Segment Is Expected To Grow Significantly

- Laser-based equipment plays a vital role in the manufacturing and processing of semiconductors; two of the widely used lasers in wafer manufacturing are near-infrared (NIR) and green lasers. NIR Lasers are versatile and suitable for many machine applications like semiconductor creation. They are effective because of the energy range that falls squarely within the spectral field needed to make wafers' necessary markings.

- Green lasers are the result of second-harmonic generation processes, also called frequency doubling. This technology helps combine two photos to make a new one with twice the energy. This amplifies the power while conserving the coherence of the laser. Laser marking helps in the traceability and readability of wafers across the market and is one of the necessary steps in wafer manufacturing.

- The global demand for silicon wafers is increasing at a rapid pace, with a shortage of chips in various industries currently, such as automotive, which is expected to fuel the demand. According to data published by Semiconductor Equipment and Materials International, in 2020, the global silicon wafer demand stood at 12.41 billion square inches, which was 11.81 billion square inches during the previous year. Since the slump in demand and overall market demand fluctuation faced in 2019, the global market is expected to witness accelerated growth in the coming years, augmented by growing demand for electronics.

- A prominent share of the application of laser equipment is in semiconductor processing and PCB processing. This equipment is used for the removal process, bonding process, inspection, metrology, and reforming process; the use of lasers results in higher yields and throughput, reduces the risk of breakage/die quality, avoids particles with no residue, and is cost-effective. Nanosecond and Picosecond types of lasers are expected to command a prominent share of the market, followed by CO2, Femtosecond, and Excimer, in that order.

- Apart from the semiconductor industry, the application of laser equipment in the electronics manufacturing process is significant. Laser applications like micro-drilling where prominent vendors, such as IPG Photonics, have significant product offerings. With the proliferation of IoT, IIoT, and smart home solutions, the demand for lasers is expected to increase rapidly in the manufacturing process.

- With the reduced replacement rate of smartphones due to innovation and the growing push toward the adoption of 5G, the demand for smartphones and connected devices capable of 5G connectivity are expected to witness high demand over the coming years.

- According to Ericsson's June 2021 report, over 160 communications service providers launched 5G services, and over 300 5G smartphone models were announced or launched commercially; the report estimated half a billion 5G users across the world by the end of 2021. At the end of 2020, smartphone penetration among mobile phone subscriptions stood at 76%, with 6 billion smartphone subscriptions, and it is expected to reach 7.7 billion within the next four years, with smartphones reaching 88% penetration among mobile users.

- Such accelerated demand in electronics is expected to increase the demand for laser-based manufacturing and inspection equipment and impact the demand for semiconductor equipment.

North America is Expected to Hold Significant Share

- The market is expected to be dominated by North America due to technological improvements in various sectors, including manufacturing, aerospace, and automotive. Similarly, the site is home to several significant vendors, including IPG Photonics and Coherent Inc.

- Increasing product launches by companies in the North American region are expected to contribute to the region's growth. For instance, in August 2021, the ExactWeld IP polymer welding technology was introduced by Coherent. ExactWeld IP is a polymer welding method that generates enormous volumes of distortion- and particle-free welds. A Thermal Vision Check, an incorporated vision system for component identification or offset correction, and an automated laser power calibration module for improved process stability and consistency are all included in the system.

- Many businesses, particularly small and medium-sized enterprises (SMEs) and startups, have started raising large sums of money to create cutting-edge laser technological solutions. For instance, UAVenture Capital Fund, based in Tuscan and committed to the commercialization of discoveries, products, technologies, and services from the University of Arizona, invested in DeUVe Photonics Inc. to advance its technology, allowing the business to dominate emerging and established deep UV laser markets.

- In order to increase productivity and remain ahead of the competition, businesses are fusing current manufacturing processes with technical advancements in lasers and laser systems. For instance, in January 2020, TRUMPF Group acquired GLOphotonics, a French laser technology company focused on hollow-core fibers. The fiber enables more efficient and quick laser light transportation from the source to the intended location without compromising power.

- The business of fiber lasers is expected to grow due to the requirement for high-output power and compact power. The great dependability of fiber lasers is expected to propel the industrial laser industry in North America.

Industrial Laser Systems Industry Overview

The Industrial Laser Systems Market is highly competitive, owing to the presence of multiple vendors. The market appears to be moderately concentrated. It is home to some of the largest vendors as well as various smaller regional vendors operating and catering to their markets. Vendors in the market are prioritizing research, innovation, and product development as their growth strategy. Such developments enabled the companies to increase their presence in the space. As it is a highly capital-intensive market, the smaller revenue companies are subjected to higher barriers to exit and, in most cases, get acquired by high-revenue companies. Moderate firm concentration and the consolidated state of the market further intensify the competitive rivalry.

- January 2022 - TRUMPF established a partnership with Fraunhofer Institute for Laser Technology ILT, an Aachen-based manufacturer of cutting-edge laser beam sources and superior optical parts and systems. Through this partnership, it hopes to advance laser material deposition research and hasten the technology's introduction.

- March 2021 - II-VI Incorporated acquired Coherent Inc. in a USD 6.3 billion deal. II-VI will acquire all outstanding Coherent shares in a cash and stock transaction. Coherent Inc. is one of the world's leading providers of lasers, laser-based technologies, and laser-based system solutions.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Intensity of Competitive Rivalry

- 4.2.5 Threat of Substitute Products

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Enhanced Precision and Accuracy over Conventional Alternatives

- 5.1.2 Miniaturization of Component Parts

- 5.2 Market Restraints

- 5.2.1 Regulation Compliance Associated with Laser Usage

6 MARKET SEGMENTATION

- 6.1 By Type of Laser

- 6.1.1 Fiber

- 6.1.2 Solid-state

- 6.1.3 CO2

- 6.1.4 Other Types of Lasers

- 6.2 By Application

- 6.2.1 Cutting

- 6.2.2 Welding

- 6.2.3 Marking

- 6.2.4 Drilling

- 6.2.5 Other Applications (Surface treatment, Additive manufacturing)

- 6.3 By End-user Industry

- 6.3.1 Semiconductor and Electronics

- 6.3.2 Automotive

- 6.3.3 Aerospace and Defense

- 6.3.4 Medical

- 6.3.5 Other End-user Industries

- 6.4 By Geography

- 6.4.1 North America

- 6.4.2 Europe

- 6.4.3 Asia-Pacific

- 6.4.4 Latin America

- 6.4.5 Middle East & Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 JENOPTIK AG

- 7.1.2 Newport Corporation

- 7.1.3 TRUMPF GmbH + Co. KG

- 7.1.4 Coherent Inc.

- 7.1.5 IPG Photonics Corporation

- 7.1.6 ACSYS Lasertechnik US Inc.

- 7.1.7 nLIGHT Inc.

- 7.1.8 Han's Laser Technology Co. Ltd

- 7.1.9 II-VI Incorporated