|

市场调查报告书

商品编码

1690849

雷射打标产业:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Laser Marking Industry - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

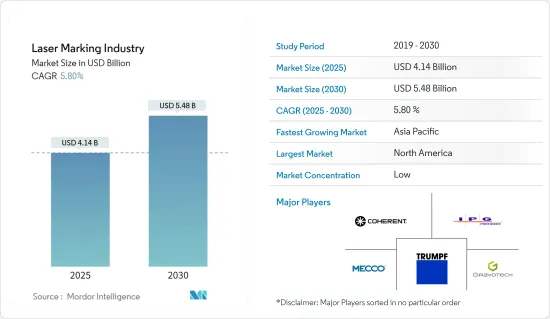

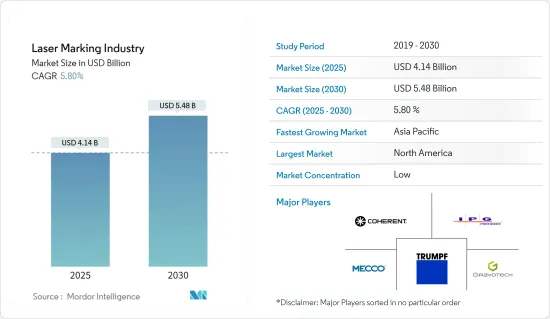

预计雷射打标产业规模将从 2025 年的 41.4 亿美元成长到 2030 年的 54.8 亿美元,预测期内(2025-2030 年)的复合年增长率为 5.8%。

雷射打标经常用于增强设备製造中的可追溯性、品管和製程改进。透过在生产线早期为每个零件分配一个标识,条码阅读器可以在生产的每个阶段追踪该零件。

主要亮点

- 传统的雷射打标机和一体机通常局限于平面视野,只能透过在打标时旋转或移动物体来调整倾斜或圆柱形表面。然而,随着製造业的发展,包括更复杂的字元形状,雷射打标机开始整合到编程机器人和先进的 5 轴机器中。

- 雷射打标是一种用途广泛的技术,广泛应用于各行各业。可以透过雷射蚀刻、雕刻或退火在多个表面上建立永久标记。这项卓越的技术可应用于医疗保健和製药、汽车、电子、工具机和包装领域。

- 市场受到各行业应用范围扩大和研发投入增加的影响,从而提高了雷射打标设备的功能。在设备製造过程中,经常采用雷射打标来辅助可追溯性、品管和製程改进。持续的研究和创新对于开发对环境负责的雷射打标流程至关重要,以确保卓越的操作和生态完整性。这将为永续的市场成长铺平道路。维持市场竞争力的关键是加大研发投入,创造创新产品。

- 高额的初始投资对于预算有限的小型企业和新兴企业来说是一个挑战。雷射打标机需要大量的初始投资,这会根据雷射位置、所需功率、打标区域大小和附加功能等因素而有所不同。因此,高昂的初始成本可能会阻碍市场扩张。

- 包括 COVID-19 在内的各种宏观经济因素对全球雷射打标市场产生了不利影响。世界各地实施的严格封锁措施导致供应链中断。美国、德国、英国和中国等主要製造业国家先前对设备和机械的需求很高,但受到疫情的严重影响,导致此类产品的市场陷入停滞。作为遏制病毒的努力的一部分,美国製造业蓬勃发展,因为公司允许非必要员工远端工作。中国面临经济成长放缓,亚洲市场暂停发展,而中国政府在最近的五年计画中瞄准的西方市场则因疫情復发而举步维艰。

雷射打标产业趋势

最大的终端用户是工具机。

- 汽车零件的雷射打标是一种灵活、永久性的过程,有助于在生产期间和生产后追踪和识别零件。以高精度和细节标记文字、徽标和其他图像。在汽车领域,零件必须完全可追溯,不仅出于安全原因,而且出于技术原因。汽车製造商在其车辆上使用独特的、防伪的、易于阅读的资料矩阵代码和字母数字标记。雷射打标机可用于将这些重要代码永久刻在几乎任何材料上,无论零件是由塑胶还是金属製成的。

- 许多汽车零件由塑胶、轻金属和钢製成,并带有标记以便于追溯和品管。这些标记必须耐用且能延长车辆或零件的使用寿命,即使暴露在高温和油气等液体中也是如此。因此,汽车零件的雷射打标可以在汽车製造中使用的大多数材料上提供持久的标记。

- 此外,雷射打标应用简单快捷,使其成为大规模生产中经济高效的解决方案,可简化零件缺陷控制并减少出错的机会。

- 雷射打标在汽车行业中具有许多优势,例如耐用性、防伪、最高精度、速度和高对比度。汽车製造商发现雷射技术是零件标记的理想方法。雷射打标还能抵抗热应力、酸、汽油、油和热,从而永久保证每个组件品质的最大可追溯性。雷射打标由于其易于使用和速度快而具有经济效益。

- 此外,中等收入阶层的扩大和庞大的人口数量正在创造全球对汽车的需求,从而支持市场成长。据IBEF称,印度汽车产业的目标是在2016年至2026年期间将汽车出口量增加五倍。 22财年印度的汽车出口数量为5,617,246辆。

- 许多汽车製造商正致力于扩大生产能力以满足日益增长的需求,并支持市场成长。例如,2023年10月,现代汽车与公共投资基金(PIF)宣布签署合资协议,在沙乌地阿拉伯建造高度自动化的汽车製造厂。

亚太地区:预计大幅成长

- 亚太地区有几个新兴经济体的製造业成长强劲。中国、印度、韩国、台湾和越南等新兴国家吸引了大量企业将其低技术和中等技术的生产设施从其他地区和国家迁移到这些新兴国家,而这些国家的生产成本较低,使得这些地区成为全球製造地。

- 此外,这些国家的政府正在采取措施改善该地区的外国投资环境。例如,印度政府最近推出了倡议,旨在吸引企业进入印度并鼓励对製造业的特定投资。中国政府也推出了进一步发展中国製造业的国家战略规划,名为「中国製造2025」。

- 此外,该地区的製造业支出大幅增加,预计未来将继续以相应的速度成长。推动该地区对雷射打标解决方案需求的关键因素是生产支出的快速成长和新技术的采用。此外,该地区有多个已开发国家,其製造业为雷射打标市场提供了巨大的成长机会。

- 雷射打标技术因其成本效益、可靠性和产品独特性而被广泛的工业领域采用。一些公司,特别是医疗和国防领域的公司,已经实施了通讯协定,对各种产品进行永久标记,以便进行原产地追踪、识别和记录。此外,该技术在航空和汽车领域的应用也日益广泛。汽车公司使用这项技术在不改变轮胎形状的情况下在轮胎上列印序号。与传统雕刻机相比,雷射打标因其高耐用性和识别许多不同飞机部件的能力而被认为是一种可行的选择。

- 雷射打标设备在电子设备的应用十分广泛。随着电子设备和半导体产品製造数量的不断增加,需要自动化标记和雕刻过程。零件上通常会刻有打标机雕刻的各种资讯。

雷射打标行业概况

雷射打标市场分散,主要参与者包括 Coherent Inc.、IPG Photonics Corporation、TRUMPF Group、Mecco Partners LLC 和 Gravotech Group。市场参与者正在采取合作和收购等策略来加强其产品供应并获得永续的竞争优势。

- 2023 年 9 月 - Videojet Technologies Inc. 宣布将在 2023 年包装博览会上展示其在标记、编码和印刷方面的工业 4.0 创新。该公司推出了新的 Videojet 3350 和 Videojet 3350 Smart Focus 雷射标记系统,旨在快速标记精确、复杂的代码,适用于食品和饮料、化妆品、製药和其他行业。这两种系统在其他行业中都提供了几乎无限的字体、程式码和图形选项。

- 2023 年 6 月 - Coherent 宣布推出 PowerLine PS 30,这是一款皮秒雷射打标机,用于医疗设备製造中的耐腐蚀黑色标记和精密微加工。 PowerLine PS 30 凭藉其高平均功率,可快速完成黑色标记和精细加工任务,同时保持极高的可靠性,显着提高生产效率和拥有成本。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

- 宏观趋势如何影响市场

第五章 市场动态

- 市场驱动因素

- 各种终端用户产业的应用日益增多

- 增加研发投入,提升功能性

- 市场挑战

- 实施成本高

第六章 市场细分

- 按设备

- 光纤雷射

- CO2雷射

- 固体雷射

- 其他设备

- 按产品

- 硬体

- 软体

- 按最终用户产业

- 卫生保健

- 车

- 电子产品

- 工具机

- 包装

- 其他最终用户产业

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 世界其他地区

第七章 竞争格局

- 公司简介

- Coherent Corporation

- IPG Photonics Corporation

- TRUMPF Group

- Mecco Partners LLC

- Gravotech Group

- Keyence Corporation

- Novanta Inc.

- Epilog Corporation

- Videojet Technologies Inc

- Han's Laser Group

第八章投资分析

第九章:市场的未来

The Laser Marking Industry is expected to grow from USD 4.14 billion in 2025 to USD 5.48 billion by 2030, at a CAGR of 5.8% during the forecast period (2025-2030).

Laser marking is frequently utilized to enhance traceability, quality control, and process improvement in equipment manufacturing. By assigning an identification to each component at the beginning of the production line, barcode readers may track parts at every manufacturing stage.

Key Highlights

- Traditional laser markers and integrated machines have typically been restricted to a flat planar field of view, which may be adjusted for inclined planes or cylindrical surfaces by rotating and moving the object during marking. However, as manufacturing has evolved to include more complex-shaped characters, laser markers have been integrated into programmed robotics or advanced 5-axis machines.

- Laser marking is an incredibly versatile technology used across various industries. It can create permanent marks on multiple surfaces through laser etching, engraving, or annealing. This remarkable technology is applied in healthcare and pharmaceuticals, automotive, electronics, machine tools, and packaging sectors.

- The market is influenced by the expanding usage in different industries and the rise in investment in research and development, which results in improved functionality of laser markers. Laser marking is frequently employed to aid in traceability, quality control, and process enhancement during the manufacturing process of equipment. Continuing research and innovation will be crucial in developing laser marking processes that are environmentally responsible, guaranteeing both operational excellence and ecological integrity. This will pave the way for sustainable market growth. The key to remaining competitive in the market is increasing investment in research and development and creating innovative products.

- The high initial investment can challenge small businesses or startups operating on limited budgets. Laser marking machines can entail a notable upfront expense, which can differ based on factors such as laser placement, power needs, marking area size, and additional functionalities. Consequently, the elevated initial cost may impede the expansion of the market.

- Various macroeconomic factors, including COVID-19, adversely impacted the global laser marking market. The strict lockdown measures implemented worldwide caused disruptions in the supply chain. Leading manufacturing countries like the United States, Germany, the United Kingdom, and China, which previously showed significant demand for equipment and machinery, were heavily affected by the pandemic, leading to a suspension in the market for such products. The manufacturing sector in the United States thrived because companies allowed nonessential employees to work remotely as part of their virus containment measures. China faced a slowdown in growth, while Asian markets paused, and the Western market, which the government had targeted in their recent five-year plan, struggled with a resurgence of the pandemic.

Laser Marking Industry Trends

Machine Tools to be the Largest End User

- Laser marking automotive parts is a flexible and permanent process that helps track and identify parts during and even after manufacturing. It marks text, logos, or other images with great precision and detail. In the automobile sector, components need to be fully traceable, not only for safety reasons but also for technical reasons. Automobile manufacturers use unique, forgery-proof, and easy-to-read data matrix codes and alphanumeric inscriptions in the vehicles. The laser markers are used to immortalize these important codes on almost any material, regardless of whether the components are made from plastic or metal.

- Many auto parts and components are made from plastics, light metals, and steel and are marked for traceability and quality control. These markings must be durable and last the car's or part's life, even when exposed to high temperatures and fluids such as oil and gas. Thus, laser marking of automotive parts offers lasting marks over time on most materials used in car manufacturing.

- Moreover, laser markings can be applied easily and quickly, making them a cost-effective solution for mass production, making it easier to manage component malfunctions, and lowering the possibility of errors.

- Laser marking in the automotive industry offers numerous benefits, such as durability, protection against forgery, maximum precision, speed, and high contrast. Automobile manufacturers make laser technology the ideal method for labeling components. Since laser marking is also resistant to thermal stress and exposure to acids, gasoline, oils, and heat, maximum traceability is permanently guaranteed for each component in terms of quality. Laser marking is also economically beneficial thanks to its ease of use and high speed.

- Moreover, the rising middle-class income and a huge population create global demand for automobiles, thus supporting market growth. According to IBEF, the Indian auto industry aims to increase car exports five times from 2016 to 2026. The total number of automobile exports from India in FY2022 was 5,617,246 units.

- Several automobile manufacturers focus on expanding their manufacturing capacity to meet the growing demand, thus supporting market growth. For instance, in October 2023, the Hyundai Motor Company and the Public Investment Fund (PIF) announced the signing of a joint venture agreement to construct a highly automated vehicle manufacturing plant in Saudi Arabia.

Asia-Pacific Expected to Witness Significant Growth

- The Asia-Pacific includes several developing countries with strong growth in their manufacturing sectors. The developing countries in the region, such as China, India, South Korea, Taiwan, and Vietnam, attract several businesses from other areas or countries to relocate their low-skilled and medium-skilled production facilities to these developing countries, which are working at lower costs, the region has become a global manufacturing hub.

- Furthermore, development to improve the foreign investment situation in the region has been made by the governments of these countries. For instance, the Indian government has recently launched an initiative called 'Make in India' aimed at promoting enterprises to set up shop in India and encouraging their specific investments into manufacturing. In addition, the Chinese Government has introduced a National Strategic Plan for Further Development of the Chinese Manufacturing Sector called 'Made in China 2025'.

- Moreover, manufacturing spending in the region has increased significantly and is expected to continue rising at a reasonable growth rate over the years. The key factors stimulating demand for laser marking solutions in that region are this sharp increase in production expenditures and the adoption of new technologies. In addition, it is characterized by several advanced countries whose manufacturing sectors have given rise to a significant growth opportunity for laser marking markets.

- Given its cost-effectiveness, reliability, and product uniqueness, laser marking technology is generally adopted across a wide range of industrial sectors. Several companies, especially in the health and defense sectors, are implementing protocols for permanently marking a wide range of products to trace their provenance, evidence of identity, or documentation purposes. Moreover, the aviation and automotive sectors are increasingly adopting this technology. Automobile companies use this technology to print serial numbers on tires without changing shape. It is believed that laser marking has been a helpful option in comparison to traditional engravers due to its high durability and the ability to distinguish many different aircraft parts.

- The use of laser marking equipment in electronic devices is extensive. Many electronics and semiconductor products are manufactured, making it necessary to perform an automatic marking and engraving process. The components are usually marked with various information engraved on the marking machines.

Laser Marking Industry Overview

The laser marking market is fragmented, with the presence of major players like Coherent Inc., IPG Photonics Corporation, TRUMPF Group, Mecco Partners LLC, and Gravotech Group. Players in the market are adopting strategies such as partnerships and acquisitions to enhance their product offerings and gain sustainable competitive advantage.

- September 2023 - Videojet Technologies Inc. announced that it would showcase Industry 4.0 innovations in marking, coding, and printing at Pack Expo 2023. The company introduced the new Videojet 3350 and Videojet 3350 Smart Focus laser marking systems, designed to mark precise, complex codes at high speed for the food, beverage, cosmetics, pharmaceutical, and other industries. Both systems offer virtually unlimited font, code, and graphics options in other industries.

- June 2023 - Coherent Corporation announced the launch of the PowerLine PS 30 picosecond laser marking machine for corrosion-resistant black marking and precision micromachining in medical device manufacturing. The PowerLine PS 30, with its high average power, quickly completes black marking and micro-machining tasks, significantly improving production productivity and cost of ownership while maintaining very high reliability.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porters Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Degree of Competition

- 4.3 Impact of Macro Trends on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Applications in Various End-User Industries

- 5.1.2 Increased Investment in R&D leading to better Functionality

- 5.2 Market Challenges

- 5.2.1 High Cost of Deployment

6 MARKET SEGMENTATION

- 6.1 By Equipment

- 6.1.1 Fiber Laser

- 6.1.2 CO2 Laser

- 6.1.3 Solid State Laser

- 6.1.4 Other Equipment

- 6.2 By Offering

- 6.2.1 Hardware

- 6.2.2 Software

- 6.3 By End-user Industry

- 6.3.1 Healthcare

- 6.3.2 Automotive

- 6.3.3 Electronics

- 6.3.4 Machine Tools

- 6.3.5 Packaging

- 6.3.6 Other End-User Industries

- 6.4 By Geography

- 6.4.1 North America

- 6.4.2 Europe

- 6.4.3 Asia-Pacific

- 6.4.4 Rest of the World

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Coherent Corporation

- 7.1.2 IPG Photonics Corporation

- 7.1.3 TRUMPF Group

- 7.1.4 Mecco Partners LLC

- 7.1.5 Gravotech Group

- 7.1.6 Keyence Corporation

- 7.1.7 Novanta Inc.

- 7.1.8 Epilog Corporation

- 7.1.9 Videojet Technologies Inc

- 7.1.10 Han's Laser Group