|

市场调查报告书

商品编码

1692475

中东和非洲正排量帮浦:市场占有率分析、产业趋势和统计数据、成长预测(2025-2030 年)MEA Positive Displacement Pumps - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

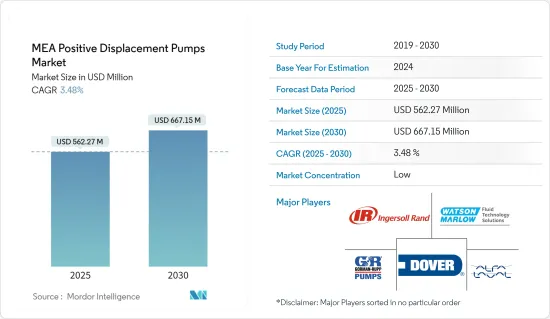

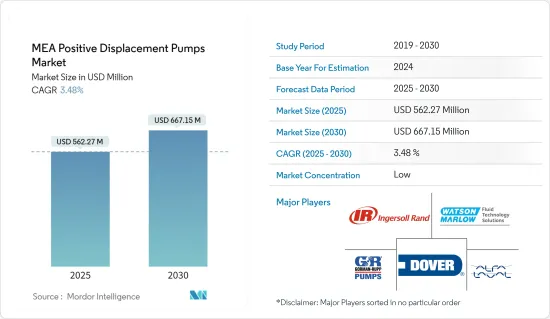

预计 2025 年中东和非洲正排量帮浦市场规模将达到 5.6227 亿美元,预计到 2030 年将达到 6.6715 亿美元,预测期内(2025-2030 年)的复合年增长率为 3.48%。

正排量帮浦用于泵送高黏度流体,例如油、油漆、树脂和食品。它是需要精确分配和高压输出的应用的首选。与离心式帮浦不同,容积泵的排气量不受压力的影响。因此,在供应不稳定的情况下,它们可能会更受青睐。

为了评估中东和非洲正排量帮浦市场的收入,我们追踪了中东和非洲地区正排量帮浦的收入。报告中考虑了各种类型的泵,包括隔膜泵、活塞泵、齿轮泵、叶片泵、蛇形泵、螺桿泵、叶片泵和蠕动泵,这些泵用于多个最终用户行业,包括石油和天然气、化学、食品和饮料、水和用水和污水、製药和发电。我们透过竞争格局来计算正排量泵的渗透率以及公司将如何参与有机和无机成长策略。

正排量帮浦的工作原理是捕获一定量的水并将其从排放管道中排出。容积泵也有吸入侧具有扩张腔、排出侧具有收缩腔的型号。众所周知,容积泵可以将一定量的流体困在腔体中,然后迫使流体从排放管流出。另一方面,离心式帮浦透过旋转的叶轮将马达的动能传递给液体,吸入液体并增加其速度以将其移动到排出口。

容积泵在石油和天然气作业的各个阶段都至关重要,包括探勘、开采、精製和分配。这些泵浦对于处理高黏度液体和提供一致的流速至关重要,使其适用于石油和天然气领域的关键应用。这些泵浦的运作速度较低,降低了处理高黏度油和浆体时损坏的风险,使其在工业中更加有用。

正排量帮浦所需的高额初始投资是市场成长的主要障碍。这些泵浦通常比其他类型的泵浦更昂贵,这可能会阻止潜在买家,尤其是小型企业。此外,泵浦的维护难题也推高了整体成本,影响了销售和市场渗透。

在中东和非洲等新兴地区,民用水利基础设施的快速成长对容积式帮浦的需求日益增加。公共和工业部门对废水处理的需求大幅增加,导致泵送设备的安装增加。海水淡化和零液体排放(ZLD)等技术的采用预计将进一步推动民用和工业领域的正排量泵市场的发展。

中东和非洲容积帮浦市场趋势

建筑业的成长将推动家具产品的需求

- 隔膜泵,也称为 AODD(气动双隔膜),是一种利用压缩空气运转的双隔膜容积泵。隔膜泵利用气动阀在泵浦的两侧之间交替压缩空气。隔膜泵擅长处理含有悬浮固体的各种黏度的液体。由于其设计配置和所用材料类型,这种类型的泵浦可以安全有效地处理特别腐蚀性的化学物质。

- 隔膜泵位于液面上方,即使内部没有液体且干燥时也可以吸液。帮浦和液位之间的距离会产生损耗负载。如果泵浦没有封装,其抽液最大高度不能超过6m,但如果泵浦封装,则可达到9.5m。

- 某些应用需要泵送两种流体,但没有足够的空间容纳两个独立的泵浦。各公司都提供透过分离输送和吸入来客製化泵浦的机会。这意味着同一个帮浦可以泵送两种不同颜色的流体。然而,流体必须具有相同的黏度和密度特性。

- 水和污水处理、石油和天然气、食品和饮料以及製药业的需求不断增长是市场成长的主要动力。例如,在科威特,碳氢化合物占GDP的50%,石油提供了约90%的出口和财政收入。科威特计画在2035年将石油产能提高到每天400万桶,到2040年将天然气产能提高到每天4,250万立方公尺。 KPC的目标是到2050年实现净零排放,这为能源转型带来了机会。科威特计划在未来五年内投资 480 亿美元用于探勘和钻探,以扩大现有成熟油田的石油产量。

预计亚太地区将占据主要市场占有率

- 沙乌地阿拉伯是世界上最大的石油和天然气生产国和出口国之一。沙乌地阿拉伯在塑造正排量帮浦市场需求方面发挥关键作用。在沙乌地阿拉伯丰富的蕴藏量和战略倡议的推动下,该国的石油和天然气产业需要广泛的设备和技术,包括正排量帮浦。

- 沙乌地阿拉伯政府正积极投资石油和天然气领域,发现新油田,扩大现有油田,并提高产量。这些投资促进了该地区石油和天然气工业的发展,从而推动了对正排量泵的需求。

- 2023 年 11 月,沙乌地阿美宣布在空白之地地区发现两处新的天然气田。已确认发现 Al Hiran天然气田,指示流量为每天 3000 万标准立方英尺,同时伴随每天 1600 桶冷凝油。同样,Al Mahakik天然气田的存在也得到证实,该气田生产85 万标准立方英尺的天然气。 2024年2月,沙乌地阿美在陆上Jafurah传统型油田又发现了15兆立方英尺天然气和20亿桶冷凝油。

- 沙乌地阿拉伯的2030愿景旨在利用该国的位置、战略伙伴关係、能源来源和物流,推动该国工业化和自动化达到新的水平。该国还计划在2030年实现国内生产一半的军事需求,并实现可再生能源和工业製造部门的自动化。

- 2023年,环境、水和农业部(MEWA)宣布将在未来几年内为计划拨款800亿美元。这符合联合国永续目标(SDG),旨在让全球人民平等获得清洁安全的水资源。

- MEWA 的目标是到 2030 年透过海水淡化满足沙乌地阿拉伯 90% 的用水需求,其余 10% 来自地下水和地表水。为了满足预计的每天450万立方公尺的缺水量,有必要建立一座新的都市区海水淡化厂,以满足当前的都市区用水需求并确保可靠的供水。

中东和非洲正排量帮浦产业概况

中东和非洲正排量帮浦市场高度分散,主要参与者包括 Dover Corporation、Ingersoll Rand Inc.、Watson-Marlow Fluid Technology Solutions(Spirax Group PLC)、Alfa Laval AB 和 Gorman-Rupp Corporation(Gorman-Rupp 旗下公司)。市场上的公司正在采取伙伴关係和收购等策略来加强其产品供应并获得永续的竞争优势。

2024 年 6 月 - 英格索兰公司成功收购 ILC Dover (ILC)。此外,该公司还透过收购 Complete Air and Power Solutions (CAPS)、Del PD Pumps &Gear Pvt 等公司,增强了其产品组合。 Ltd(Del Pumps)和 Fruvac Ltd(Fruitland Manufacturing)合计投资约 1.5 亿美元。

2023 年 9 月 - Busch 推出最新创新产品-节能的 R5 RA 真空帮浦。该泵浦具有时尚、卫生的设计、低发热量和简化的维护。可选的 Ecotorque 变速驱动器可提高 50% 的能源效率并将泵送速度提高 20%。此外,该配件还扩展了泵浦的电压范围,提高了全球可用性。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场洞察

- 市场概览

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买家的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

- 产业价值链分析

第五章市场动态

- 市场驱动因素

- 一次性水位严重短缺和地下水污染导致PD泵浦需求增加

- 石油和天然气产业的需求不断成长

- 市场挑战

- 高成本、相容性问题

第六章市场区隔

- 按泵类型

- 隔膜泵

- 活塞泵

- 齿轮泵浦

- LOBE泵

- 单轴螺旋泵浦

- 螺旋泵

- 叶片泵

- 蠕动帮浦

- 柱塞泵

- 按最终用户产业

- 石油和天然气

- 化学

- 食品和饮料

- 用水和污水

- 製药

- 发电

- 其他最终用户产业

- 按国家

- 沙乌地阿拉伯

- 阿拉伯聯合大公国

- 科威特

- 非洲

第七章竞争格局

- 公司简介

- Dover Corporation

- Ingersoll Rand Inc.

- Watson-Marlow Fluid Technology Solutions(Spirax Group PLC)

- Alfa Laval AB

- Gorman-Rupp Corporation(Gorman-Rupp Company)

- Busch Vacuum Solutions Inc.(Busch Group)

- Celeros Flow Technology Inc.

- Flowserve Corporation

- Atlas Copco AB

- Xylem Inc.

第八章 市场展望

The MEA Positive Displacement Pumps Market size is estimated at USD 562.27 million in 2025, and is expected to reach USD 667.15 million by 2030, at a CAGR of 3.48% during the forecast period (2025-2030).

Positive displacement pumps are used for pumping high-viscosity fluids, including oil, paints, resins, or foodstuffs. They are selected in applications where accurate dosing or high-pressure output is required. Unlike centrifugal pumps, the production of a positive displacement pump is not affected by pressure. Thus, they are also likely to be preferred in any situation where the supply is irregular.

To evaluate the market revenue for the Middle East & African positive displacement market, the sales of positive displacement pumps across the Middle East & Africa have been tracked. Different types of pumps are considered in the report, including diaphragm, piston, gear, lobe, progressive, screw, vane, and peristaltic, which are used in multiple end-user industries like oil and gas, chemicals, food and beverage, water and wastewater, pharmaceuticals, power generation, among others. The competitive landscape has been taken to calculate positive displacement pump penetration and how players involve themselves in organic and inorganic growth strategies.

A positive displacement pump operates by trapping a set amount of water and pushing it into the discharge piping. Some models of positive displacement pumps feature an expanding cavity on the suction side and a shrinking cavity on the discharge side. Positive displacement pumps are known for their operation of trapping a fixed volume of fluid in a cavity and then pushing that fluid into the discharge pipe. On the other hand, centrifugal pumps transfer the motor's kinetic energy to the liquid through a spinning impeller, which draws in fluid and increases velocity to move the liquid to the discharge point.

Positive displacement pumps are integral to various oil and gas operations stages, including exploration, extraction, refinement, and distribution. These pumps are crucial for handling high-viscosity fluids and providing consistent flow rates, which make them suitable for critical applications in the oil and gas sector. The ability of these pumps to work at lower speeds reduces the risk of damage when handling high-viscosity oils and slurries, further enhancing their utility in the industry.

The high initial investment required for positive displacement pumps is a significant barrier to market growth. These pumps are often more expensive than other types, which can deter potential buyers, especially small and medium-sized enterprises. In addition, the difficulty of maintaining these pumps further adds to the overall cost, affecting their sales and market penetration.

The swift growth of civic water utility infrastructure in emerging regions like the Middle East & Africa has resulted in a higher need for positive displacement pumps. There has been a significant rise in the demand for sewage treatment in both the public and industrial sectors, leading to an increased installation of pumping units. Implementing technologies such as desalination and zero-liquid discharge (ZLD) is anticipated to further drive the market for positive displacement pumps in civic and industrial sectors.

MEA Positive Displacement Pumps Market Trends

Growth in the Construction Sector Boosting the Demand for Furniture Products

- The diaphragm pump, also called an AODD (Air Operated Double Diaphragm), is a type of double diaphragm positive displacement pump operated using compressed air. Diaphragm pumps utilize a pneumatic valve to alternate compressed air between the pump's two sides. They excel at managing liquids of diverse viscosities, including those with suspended solids. This type of pump, due to its design configurations and type of materials used, is also capable of safely and efficiently handling particularly aggressive chemicals.

- The diaphragm pump is positioned above the fluid level and can aspirate it, even starting from dry when it has no liquid inside. The distance between the pump and the fluid level results in loss loads. If the pump is not potted, the maximum height at which the fluid can be aspirated cannot exceed 6 m, while if the pump is potted, we can reach 9.5 m.

- In some applications, two fluids need to be pumped, but there is not enough room to accommodate two separate pumps. Various companies offer the opportunity to customize their pumps by splitting both delivery and suction. This means that with the same pump, customers can pump two fluids, for example, of two different colors. The fluids, however, need to have similar viscosity and density characteristics.

- The growing demand in water and wastewater treatment, oil and gas, food and beverage, and pharmaceutical industries is a significant driver of market growth. For instance, in Kuwait, hydrocarbons contribute 50% of its GDP, with oil accounting for approximately 90% of export earnings and fiscal revenues. Kuwait planned to increase its oil production capacity to 4.0 million barrels per day by 2035 and gas capacity to 42.5 million cubic meters per day by 2040. KPC aims for net zero by 2050, presenting opportunities in the energy transition. Kuwait intends to invest USD 48 billion in exploration and drilling over the next five years to expand its oil production from existing and mature oil fields.

Asia-Pacific is Expected to Hold Significant Market Share

- Saudi Arabia is one of the world's largest producers and exporters of oil and gas. It plays a significant role in shaping the market's demand for positive displacement pumps. The country's oil and gas industry, driven by its vast reserves and strategic initiatives, demands various equipment and technologies, including positive displacement pumps.

- The Government of Saudi Arabia has been actively investing in the oil and gas sector, identifying new oil fields, expanding existing fields, and enhancing production. These investments contribute to the growth of the oil and gas industry in the region and subsequently drive the demand for PD pumps.

- In November 2023, Saudi Aramco unveiled two fresh natural gas finds in the Empty Quarter region. The Al-Hiran gas field's discovery was solidified as it exhibited a flow rate of 30 million standard cubic feet per day, accompanied by 1,600 barrels of condensate daily. Similarly, the Al-Mahakik gas field's presence was affirmed as gas emanating at 0.85 million standard cubic feet. In February 2024, Saudi Aramco found an additional 15 Tcf of natural gas and 2 billion barrels of condensate in the onshore Jafurah unconventional field as the world's biggest oil exporter pushes ahead with efforts to expand gas production.

- Saudi Arabia's 2030 Vision calls for leveraging the Kingdom's location, strategic partnerships, energy sources, and logistics to stimulate a new phase of industrialization and automation in the country. It also aims to bring manufacturing half of the Kingdom's military needs within the Kingdom by 2030 and to automate the Kingdom's renewable energy and industrial manufacturing sector.

- In 2023, the Ministry of Environment, Water and Agriculture (MEWA) announced that it would allocate USD 80 billion to water projects within the coming years. This aligns with the United Nations Sustainable Development Goals (SDGs), which aim to enable equal access to clean and safe water globally.

- MEWA aims to satisfy 90% of Saudi Arabia's water demand through desalination by 2030, with the remaining 10% sourced from ground and surface water. To bridge the projected water deficit of 4.5 million m3/day, new urban desalination facilities are deemed necessary, aligning with the current urban water needs and the assured water supply.

MEA Positive Displacement Pumps Industry Overview

The MEA positive displacement pumps market is highly fragmented, with the presence of major players like Dover Corporation, Ingersoll Rand Inc., Watson-Marlow Fluid Technology Solutions (Spirax Group PLC), Alfa Laval AB, and Gorman-Rupp Corporation (Gorman-Rupp Company). Players in the market are adopting strategies such as partnerships and acquisitions to enhance their product offerings and gain sustainable competitive advantage.

June 2024 - Ingersoll Rand Inc. successfully finalized its acquisition of ILC Dover (ILC). In addition, the company bolstered its portfolio by acquiring Complete Air and Power Solutions (CAPS), Del PD Pumps & Gear Pvt. Ltd (Del Pumps), and Fruvac Ltd (Fruitland Manufacturing) for a consolidated sum of around USD 150 million.

September 2023 - Busch unveiled its latest innovation, the energy-efficient R5 RA vacuum pump. This pump boasts a sleek, hygienic design, lower heat emissions, and streamlined maintenance. The Ecotorque variable speed drive, an optional feature, delivers an impressive 50% boost in energy efficiency and a 20% uptick in pumping speed. Moreover, this accessory expands the pump's voltage range, enhancing its global usability.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumption and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Demand for PD Pumps Due to Huge Scarcity in the Disposable Water Level and Groundwater Adulteration

- 5.1.2 Increasing Demand From the Oil and Gas Industry

- 5.2 Market Challenges

- 5.2.1 High Cost and Compatibility Issues

6 MARKET SEGMENTATION

- 6.1 By Type of Pump

- 6.1.1 Diaphragm Pump

- 6.1.2 Piston Pump

- 6.1.3 Gear Pump

- 6.1.4 LobePump

- 6.1.5 Progressive Cavity Pump

- 6.1.6 Screw Pump

- 6.1.7 Vane Pump

- 6.1.8 Peristaltic Pump

- 6.1.9 Plunger Pump

- 6.2 By End-user Industry

- 6.2.1 Oil and Gas

- 6.2.2 Chemicals

- 6.2.3 Food and Beverage

- 6.2.4 Water and Wastewater

- 6.2.5 Pharmaceutical

- 6.2.6 Power Generation

- 6.2.7 Other End-user Industries

- 6.3 By Country

- 6.3.1 Saudi Arabia

- 6.3.2 United Arab Emirates

- 6.3.3 Kuwait

- 6.3.4 Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Dover Corporation

- 7.1.2 Ingersoll Rand Inc.

- 7.1.3 Watson-Marlow Fluid Technology Solutions (Spirax Group PLC)

- 7.1.4 Alfa Laval AB

- 7.1.5 Gorman-Rupp Corporation (Gorman-Rupp Company)

- 7.1.6 Busch Vacuum Solutions Inc. (Busch Group)

- 7.1.7 Celeros Flow Technology Inc.

- 7.1.8 Flowserve Corporation

- 7.1.9 Atlas Copco AB

- 7.1.10 Xylem Inc.