|

市场调查报告书

商品编码

1693419

亚太地区氰基丙烯酸酯黏合剂-市场占有率分析、产业趋势与成长预测(2025-2030年)Asia-Pacific Cyanoacrylate Adhesives - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

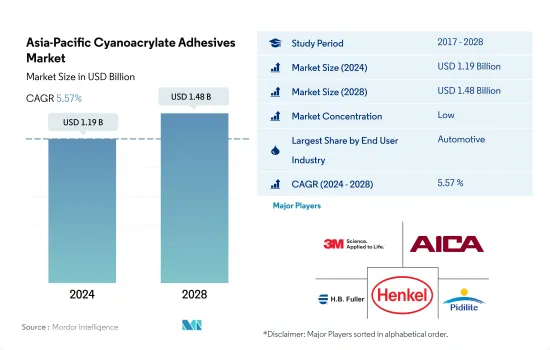

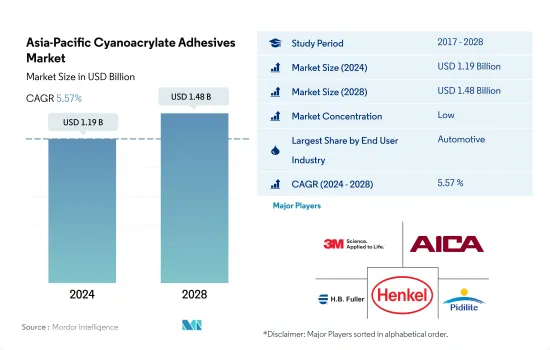

亚太地区氰基丙烯酸酯黏合剂市场规模预计在 2024 年为 11.9 亿美元,预计到 2028 年将达到 14.8 亿美元,预测期内(2024-2028 年)的复合年增长率为 5.57%。

氰基丙烯酸酯黏合剂在航太和医疗产业中的应用和需求不断增长是一个主要的成长要素。

- 由于预测期内 DIY 和电子应用的需求快速增长,亚太地区氰基丙烯酸酯黏合剂市场可能由其他终端用户产业主导。氰基丙烯酸酯具有独特的性能,能够在短时间内与木材、金属、塑胶、陶瓷和弹性体等各种基材形成优异的黏合力,适合 DIY 领域的专业人士使用。

- 由于氰基丙烯酸酯黏合剂在汽车等各行各业的关键组装作业中的应用不断增加,其消费量近期有所增加。氰基丙烯酸酯可提供永久性黏合,且在很宽的热度和温度范围内保持稳定。此外,汽车製造商正在努力生产轻量化零件,以在不牺牲安全性的情况下减轻车辆的整体重量。因此,预计未来几年汽车产业对氰基丙烯酸酯黏合剂的消费量将显着成长。

- 由于氰基丙烯酸酯具有不易燃、固化速度快、在机械和结构操作中应用方便等特点,航太业很可能成为氰基丙烯酸酯消费量成长最快的产业。此外,氰基丙烯酸酯正迅速被用作各种医疗外科应用中的组织黏合剂,以取代传统的缝合工艺。此外,氰基丙烯酸酯的口服使用在过去几年中也持续改善。这些因素将推动亚太地区氰基丙烯酸酯黏合剂的未来成长。

医疗产业推动印尼氰基丙烯酸酯黏合剂市场高速成长

- 亚太地区是全球最大的氰基丙烯酸酯胶黏剂消费地区,占2021年氰基丙烯酸酯胶黏剂总消费量的42.9%。氰基丙烯酸酯胶粘剂是该地区汽车、医疗、DIY和其他行业消费的瞬间胶粘剂。

- 中国是该地区乃至全球最大的氰基丙烯酸酯胶黏剂消费国。这些黏合剂主要用于该国的汽车和医疗行业。中国汽车产业约消耗23036吨氰基丙烯酸酯胶黏剂。预计到 2025 年,汽车产量将达到 3,420 万辆,高于 2021 年的 2,620 万辆。汽车行业日益增长的需求预计将推动该国对氰基丙烯酸酯黏合剂的需求。

- 航太是该地区氰基丙烯酸酯黏合剂成长最快的终端用户产业,预计在 2022-2028 年预测期内,其产量复合年增长率将达到 6.26%。中国正在实施「製造2025」计划,要求飞机製造商100%在中国采购和製造飞机,限制外国公司进入。同时,预计当地航太黏合剂和密封剂製造商将受益于政府计划。该地区其他国家正在实施的类似措施预计将促进该地区航太业的发展。

- 印尼是该地区乃至全球市场成长最快的国家,预计在 2022-2028 年预测期内,受医疗保健产业成长的推动,其复合年增长率将达到 7%。预计到 2027 年,印尼的医疗设备市场规模将达到 28.3 亿美元。这些因素预计将在预测期内推动亚太地区对氰基丙烯酸酯黏合剂的需求。

亚太地区氰基丙烯酸酯胶黏剂市场趋势

电动车的普及正在推动该产业

- 亚太地区的汽车产业是市场驱动力之一,因为汽车销量大幅成长。中国是最大的汽车生产国,约占该地区汽车产量的57%。其次是日本(17%)、印度(10%)和韩国(8%)。

- 该地区的汽车销售和产量均大幅下降,影响了黏合剂的使用。 2017- 与前一年同期比较变动为-1.8%,而2018-19年度则进一步下降-6.4%。 2019-20年度,受新冠疫情影响,该地区产量再次受到负面影响,较去年同期与前一年同期比较10.2%。由于製造工厂停工和供应链中断,汽车零件短缺,生产水准受到限制。然而,预计汽车需求将在 2021 年再次增加并持续增长,从而导致预测期内全部区域的黏合剂使用量增加。

- 亚太电动车市场为黏合剂市场带来了另一个成长机会。电动和混合动力汽车的产量和采用率的不断提高,推动了汽车电子组装中黏合剂的使用量。中国是世界上最大的电动车生产国,也是全部区域最大的电动车生产国。 2016年至2021年间,商用电动车数量从562,603辆增加到1,116,382辆,成长率约98%。预计这些因素将增加对黏合剂的需求,有助于预测期内的市场成长。

亚太地区家具製造商的强大影响力推动产业发展

- 在亚太地区,中国是最大的家具製造国、出口国和消费国。由于中国人口众多,都市区家庭可支配所得不断增加,家具消费量较高。全球超过35%的家具贸易来自中国,全球40%的金属家具出口以及超过60%的软体木质和金属座椅都来自中国。

- 儘管与美国存在利益衝突,但中国家具市场在2017年至2019年期间仍成长了约18%。在亚太地区,由于新冠疫情造成的营运、贸易和供应链限制,家具业在2020年下降了约7%。然而,由于中国、印度和日本等国家的需求增加,家具业已恢復到疫情前的水准。 2022年,中国向全球出口家具价值690亿美元。

- 印度是世界第五大家俱生产国。由于印度家庭可支配收入的增加、中产阶级的壮大以及都市化的稳步推进,家具製造业在 2017 年至 2019 年期间实现了健康成长。印度的家具製造业基本上是无组织的,印度政府已经认识到其潜力并将其命名为冠军产业。为确保国内家俱生产稳定成长,国家正大力组织、规范国内家俱生产。

- 受中国、印度和日本等国家木工和细木工行业显着增长的推动,预计预测期内(2022-2028 年)市场规模的复合年增长率约为 4.2%。

亚太地区氰基丙烯酸酯胶黏剂产业概况

亚太地区氰基丙烯酸酯胶黏剂市场细分化,前五大公司占31.95%的市占率。该市场的主要企业包括 3M、Aica Kogyo、HB Fuller Company、Henkel AG & Co. KGaA 和 Pidilite Industries Ltd.。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3个月的分析师支持

目录

第一章执行摘要和主要发现

第二章 报告要约

第三章 引言

- 研究假设和市场定义

- 研究范围

- 调查方法

第四章 产业主要趋势

- 最终用户趋势

- 航太

- 车

- 建筑与施工

- 鞋类皮革

- 木製品和配件

- 法律规范

- 澳洲

- 中国

- 印度

- 印尼

- 日本

- 马来西亚

- 新加坡

- 韩国

- 泰国

- 价值炼和通路分析

第五章市场区隔

- 最终用户产业

- 航太

- 车

- 建筑与施工

- 鞋类和皮革

- 医疗保健

- 木製品和配件

- 其他的

- 科技

- 反应性

- 紫外线固化胶合剂

- 国家

- 澳洲

- 中国

- 印度

- 印尼

- 日本

- 马来西亚

- 新加坡

- 韩国

- 泰国

- 其他亚太地区

第六章竞争格局

- 关键策略趋势

- 市场占有率分析

- 商业状况

- 公司简介

- 3M

- Aica Kogyo Co..Ltd.

- Arkema Group

- HB Fuller Company

- Henkel AG & Co. KGaA

- Hubei Huitian New Materials Co. Ltd

- Kangda New Materials(Group)Co., Ltd.

- NANPAO RESINS CHEMICAL GROUP

- Pidilite Industries Ltd.

- ThreeBond Holdings Co., Ltd.

第七章 CEO 的关键策略问题

第 8 章 附录

- 全球黏合剂和密封剂产业概况

- 概述

- 五力分析框架(产业吸引力分析)

- 全球价值链分析

- 驱动因素、限制因素和机会

- 资讯来源及延伸阅读

- 图片列表

- 关键见解

- 数据包

- 词彙表

简介目录

Product Code: 92478

The Asia-Pacific Cyanoacrylate Adhesives Market size is estimated at 1.19 billion USD in 2024, and is expected to reach 1.48 billion USD by 2028, growing at a CAGR of 5.57% during the forecast period (2024-2028).

The rising applications and demand for cyanoacrylate adhesives across the aerospace and healthcare industries are the major growth factors

- Asia-Pacific's cyanoacrylate adhesives market is likely to dominate by other end-user industries owing to rapidly increasing demand from DIY and electronics applications throughout the projected timeframe. Cyanoacrylates have unique characteristics to create an exceptional bond in a shorter time period with different substrates such as wood, metal, plastics, ceramics, and elastomers, which make them suitable to be used by professionals in the DIY sector.

- Cyanoacrylate adhesive consumption has recently increased for automotive due to rising applications of critical assembly operations across the industry. Cyanoacrylates offer a permanent bond that can be stable under a wide range of heat and temperature. Moreover, automotive manufacturers are engaging themselves in producing lightweight parts and components to reduce the overall vehicle's weight without sacrificing safety. Thus, cyanoacrylate adhesives consumption in the automotive industry will showcase significant growth in the upcoming years.

- The aerospace industry is likely to witness a fastest-growing sector in terms of cyanoacrylate consumption owing to its non-flammable, fast-curing ability, and hassle-free applications in mechanical and structural operations. In addition, cyanoacrylates are rapidly adopted as a tissue adhesive for a variety of medical and surgical applications to replace traditional suturing processes. Furthermore, oral applications of cyanoacrylates have exhibited continuous improvements over the last few years. These factors collectively impetus the growth of cyanoacrylate adhesives across the Asia-Pacific region in the upcoming years.

High value growth forecasted for the cyanoacrylate adhesives led by the Indonesian healthcare industry

- Asia-Pacific is the world's largest regional consumer of cyanoacrylate adhesives, accounting for 42.9% of total cyanoacrylate adhesive consumption in 2021. Cyanoacrylate adhesives are instant adhesives consumed in the region's automotive, healthcare, DIY, and other industries.

- China is the largest consumer of cyanoacrylate adhesives in the region and the world. These adhesives are majorly used in the country's automotive and healthcare industries. The Chinese automotive industry consumes about 23,036 tons of cyanoacrylate adhesives. Automotive production is expected to reach 34.2 million units by 2025 from 26.2 million units in 2021. Such growing demand from the automotive industry is expected to drive the demand for cyanoacrylate adhesives in the country.

- Aerospace is the fastest-growing end-user industry of cyanoacrylate adhesives in the region and is expected to record a CAGR of 6.26% in volume terms during the forecast period 2022-2028. China is implementing the 'Made in 2025' plan, which requires aircraft manufacturers to source and manufacture 100% of aircraft in China, restricting foreign players' entry. On the other hand, the local aerospace adhesives and sealants manufacturers are expected to benefit from this government scheme. Similar policies being implemented by other countries in the region are expected to boost the aerospace industry in the region.

- Indonesia is the fastest-growing country in the region and globally for the market and is expected to record a CAGR of 7% during the forecast period 2022-2028, owing to its growing healthcare industry. The medical device market in Indonesia is expected to reach USD 2.83 billion by 2027. These factors are expected to boost the demand for cyanoacrylate adhesives in the Asia-Pacific region over the forecast period.

Asia-Pacific Cyanoacrylate Adhesives Market Trends

Increasing adoption of electric vehicles to drive the industry

- The Asia-Pacific automotive industry is one of the leading industries in the market, as the sales of automotive vehicles are largely increasing. Among all the countries, China is the largest automotive producer, accounting for about 57% of the regional production, followed by Japan with 17%, India with 10%, and South Korea with 8%.

- Vehicle sales in the region have majorly declined along with production, owing to which the utilization of adhesives has been impacted. While the Y-o-Y variation in 2017-18 was -1.8%, it fell further by -6.4% in 2018-19. In 2019-20, regional production was again impacted negatively and recorded a -10.2% decline from the previous year due to the COVID-19 pandemic. The shutdown of manufacturing facilities and the shortage of vehicle components due to disruptions in the supply chain constrained the production level. However, in 2021, the demand for automobiles rose again and is expected to continue, thereby increasing the utilization of adhesives across the region over the forecast period.

- The EV market in Asia-Pacific offers another opportunity for the adhesives market to grow. The rising production and adoption of EVs and hybrid vehicles are boosting the usage of adhesives for electronic component assembly in vehicles. China is the largest producer of EVs globally as well as across the region. From 2016 to 2021, the volume of commercial electric vehicles increased from 562,603 to 1,116,382 units, recording a growth rate of about 98%. These factors are expected to increase the demand for adhesives and result in the higher market growth over the forecast period.

High presence of furniture manufacturers in the Asia-Pacific region will propel the industry

- In Asia-Pacific, China is the largest furniture manufacturer, exporter, and consumer. China's high furniture consumption is due to its large population and the growing disposable income of urban households. More than 35% of the world's furniture trade originates from China, and 40% of the world's metal furniture exports and over 60% of upholstered wooden and metal seats are produced in China.

- The Chinese furniture market grew by around 18% during 2017-19 despite the conflict of interests with the United States. In Asia-Pacific, the furniture industry witnessed a decline of around 7% in 2020 due to the operational, trade, and supply chain restrictions resulting from the COVID-19 pandemic. However, the furniture industry has bounced back to its pre-pandemic levels in line with the rising demand from countries such as China, India, and Japan. In 2022, China exported USD 69 billion worth of furniture globally.

- India is the fifth largest producer of furniture in the world. The furniture manufacturing industry witnessed healthy growth from 2017 to 2019 because of factors like rising disposable income in Indian households, increasing middle-income families, and steady growth in urbanization. The Indian furniture manufacturing industry is largely unorganized, and the Indian government has recognized its potential and named it a champion sector. Efforts are being made to organize and regulate it in a structured way to ensure steady growth in domestic furniture production.

- Owing to the significant growth in the woodworking and joinery sector in countries like China, India, and Japan, the market is expected to register a CAGR of around 4.2% in terms of volume during the forecast period (2022-2028).

Asia-Pacific Cyanoacrylate Adhesives Industry Overview

The Asia-Pacific Cyanoacrylate Adhesives Market is fragmented, with the top five companies occupying 31.95%. The major players in this market are 3M, Aica Kogyo Co..Ltd., H.B. Fuller Company, Henkel AG & Co. KGaA and Pidilite Industries Ltd. (sorted alphabetically).

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 EXECUTIVE SUMMARY & KEY FINDINGS

2 REPORT OFFERS

3 INTRODUCTION

- 3.1 Study Assumptions & Market Definition

- 3.2 Scope of the Study

- 3.3 Research Methodology

4 KEY INDUSTRY TRENDS

- 4.1 End User Trends

- 4.1.1 Aerospace

- 4.1.2 Automotive

- 4.1.3 Building and Construction

- 4.1.4 Footwear and Leather

- 4.1.5 Woodworking and Joinery

- 4.2 Regulatory Framework

- 4.2.1 Australia

- 4.2.2 China

- 4.2.3 India

- 4.2.4 Indonesia

- 4.2.5 Japan

- 4.2.6 Malaysia

- 4.2.7 Singapore

- 4.2.8 South Korea

- 4.2.9 Thailand

- 4.3 Value Chain & Distribution Channel Analysis

5 MARKET SEGMENTATION (includes market size in Value in USD and Volume, Forecasts up to 2028 and analysis of growth prospects)

- 5.1 End User Industry

- 5.1.1 Aerospace

- 5.1.2 Automotive

- 5.1.3 Building and Construction

- 5.1.4 Footwear and Leather

- 5.1.5 Healthcare

- 5.1.6 Woodworking and Joinery

- 5.1.7 Other End-user Industries

- 5.2 Technology

- 5.2.1 Reactive

- 5.2.2 UV Cured Adhesives

- 5.3 Country

- 5.3.1 Australia

- 5.3.2 China

- 5.3.3 India

- 5.3.4 Indonesia

- 5.3.5 Japan

- 5.3.6 Malaysia

- 5.3.7 Singapore

- 5.3.8 South Korea

- 5.3.9 Thailand

- 5.3.10 Rest of Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Key Strategic Moves

- 6.2 Market Share Analysis

- 6.3 Company Landscape

- 6.4 Company Profiles (includes Global Level Overview, Market Level Overview, Core Business Segments, Financials, Headcount, Key Information, Market Rank, Market Share, Products and Services, and Analysis of Recent Developments).

- 6.4.1 3M

- 6.4.2 Aica Kogyo Co..Ltd.

- 6.4.3 Arkema Group

- 6.4.4 H.B. Fuller Company

- 6.4.5 Henkel AG & Co. KGaA

- 6.4.6 Hubei Huitian New Materials Co. Ltd

- 6.4.7 Kangda New Materials (Group) Co., Ltd.

- 6.4.8 NANPAO RESINS CHEMICAL GROUP

- 6.4.9 Pidilite Industries Ltd.

- 6.4.10 ThreeBond Holdings Co., Ltd.

7 KEY STRATEGIC QUESTIONS FOR ADHESIVES AND SEALANTS CEOS

8 APPENDIX

- 8.1 Global Adhesives and Sealants Industry Overview

- 8.1.1 Overview

- 8.1.2 Porter's Five Forces Framework (Industry Attractiveness Analysis)

- 8.1.3 Global Value Chain Analysis

- 8.1.4 Drivers, Restraints, and Opportunities

- 8.2 Sources & References

- 8.3 List of Tables & Figures

- 8.4 Primary Insights

- 8.5 Data Pack

- 8.6 Glossary of Terms

02-2729-4219

+886-2-2729-4219