|

市场调查报告书

商品编码

1846212

缝纫机:市场占有率分析、产业趋势、统计数据和成长预测(2025-2030 年)Sewing Machines - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

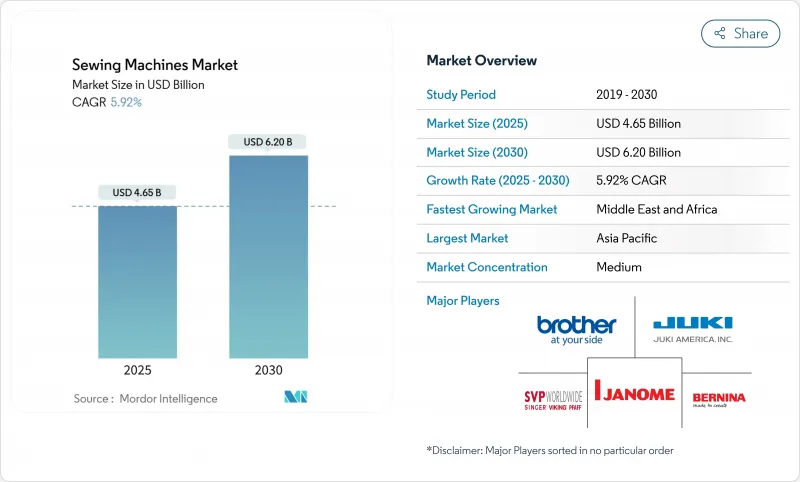

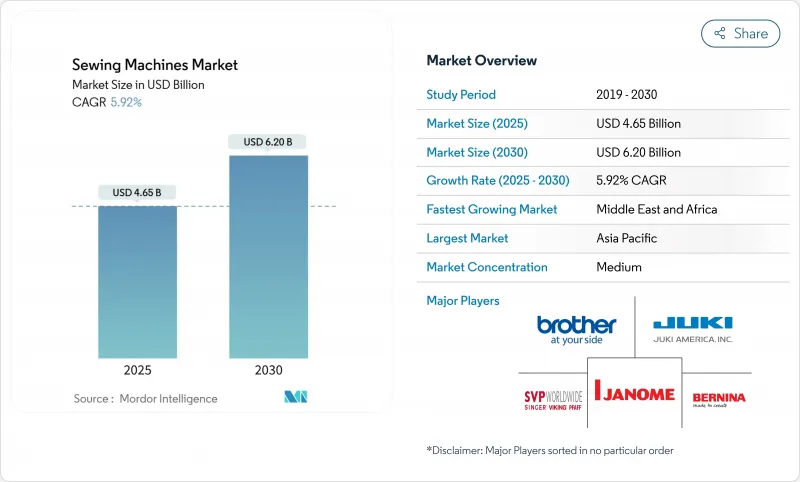

预计到 2025 年,缝纫机市场规模将达到 46.5 亿美元,到 2030 年将达到 62 亿美元,复合年增长率为 5.92%。

工业自动化需求正在推动成长,扩大创客机芯,而快速的技术升级则提高了生产效率,同时减少了工厂和家庭的浪费。製造商受惠于亚洲纺织品出口量庞大以及北美和欧洲的维修更换文化带来的双重优势。 Wi-Fi 连接、可下载的针迹库和可程式逻辑控制器等技术升级提高了平均售价,同时延长了更换週期,即使销量趋于稳定,也能保证收益。服饰生产回归美国和西欧的近岸外包模式,进一步扩大了灵活的小批量生产系统的可用基础,使款式变更无需漫长的换型过程。

全球缝纫机市场趋势与洞察

亚太地区服装製造业的快速扩张

在公共奖励和出口导向策略的推动下,亚洲服装生产持续领先其他地区。光是印度就计划在2030年实现3,500亿美元的纺织品出口额,这刺激了高产能缝纫生产线的大量采购。针对技术纺织品的生产连结计画缩短了无需人工干预即可处理多种布料重量的自动化机器的投资回收期。低成本传统中心不断上涨的工资促使製造商转向配备伺服马达和可程式设计缝纫模式的设备,以抵消人事费用。越南和孟加拉的工厂集群简化了售后物流,鼓励供应商建立区域服务中心。随着订单从基本款T恤转向高价值的休閒和正装,市场需求正转向具有复杂缝纫结构和数位压板调节功能的缝纫机。

在成熟经济中,DIY和手工艺文化的復兴

Z世代消费者将居家缝纫视为打造个人化时尚和减少纺织品废弃物的途径,而社群媒体上的教学则将这种兴趣转化为可观的硬体销售。零售商现在提供入门套装,将入门级缝纫机与可下载的纸样组合在一起,以降低学习难度。疫情期间兴起的爱好热潮在疫情结束后依然盛行,成为一种有效的减压方式,即使其他家居用品类别恢復正常,也依然保持着零售额的高位。外形规格和类似智慧型手机的触控萤幕深受数位原民原住民的喜爱,迫使品牌优先考虑直觉的用户体验而非机械的复杂性。 Etsy等手工製品二手交易平台的兴起进一步收益了这项爱好的商业化,并鼓励用户在掌握基本功能后升级设备。

工业机械的高资本支出

虽然有供应商融资方案,但这些方案仅涵盖硬件,培训和维护并不包含在融资范围内。银行通常要求提供抵押品,而小型作坊往往缺乏抵押品,这延缓了现代化进程,导致生产基地仍然使用十年前的锁式缝纫机。随着品牌对缝纫强度和数位化可追溯性的要求日益严格,延迟投资会降低企业的竞争力。 JUKI 于 2024 年推出的租赁计画在越南已率先实施,但在其他地区仍属新颖。

细分市场分析

到2024年,电动缝纫机将占总销售量的65.00%,凸显其在工厂和家庭中的多功能性。许多工业买家将这个细分市场视为迈向全面自动化的过渡阶段,他们会加装伺服驱动器和半自动剪线器来延长机器的使用寿命。同时,随着工厂追求缝纫品质的稳定性和减少返工,预计到2030年,自动化缝纫机的年复合成长率将达到6.89%。自动化系统的市场规模正在扩大,反映出运动服装和产业用纺织品工厂的需求不断增长。手动缝纫机仍然在电力不稳定的地区使用,并且越来越受到喜欢触感操控的工匠的欢迎。

由于备件供应充足且操作人员熟悉操作,电动缝纫机仍然占据主导地位,从而降低了培训需求。胜家(Singer)的M3330支援Wi-Fi功能,显示传统缝纫机类别正在吸收智慧功能,而无需采用复杂的数控系统。液压绗缝机属于「其他」类别,在床垫製造领域取得了成功,并正在将市场拓展到土耳其和波兰。电动缝纫机和入门级自动化系统之间的价格差距已缩小至18%,这是财务长开始批准升级的阈值。

2024年,服装销售额将占总销售额的58.30%,这主要得益于快时尚巨头和製服供应商的大订单。运动服装市场也日益增长,因为拉伸布料需要差动送布包缝机,而原始设备製造商(OEM)也开始捆绑销售专用压脚。窗帘和靠垫套等家纺产品是成长最快的细分市场,年复合成长率(CAGR)高达6.95%,主要得益于房主对个人化家居装饰的投入。 2023年至2024年,家用纺织品缝纫机的市占率将成长120个基点,这预示着家庭客家用纺织品趋势的持续发展。非服装领域还包括汽车内装、医疗耗材和工业过滤器,这些领域都需要高强度缝纫针和加固型工作檯面。

消费者对永续室内装潢的偏好推动了对优质纱线的需求,使供应环保染色纱线的子公司American & Efird受益。汽车座椅製造商要求缝纫机具备每秒40针的加固缝纫能力,这为能够整合高扭矩伺服马达的供应商创造了机会。虽然超音波缝纫在医疗防护装备领域也占有一席之地,但监管审核表明,对于关键的罩衣接缝,缝线仍然是首选。印度都市区可支配收益的成长正在扩大专用刺绣机的市场。这种多元化经营有助于缓解服饰製造业的週期性低迷,从而在服饰低迷时期为原始设备製造商(OEM)的利润提供缓衝。

区域分析

亚太地区2024年销售额成长51.00%,反映出其在纺织服装价值链中无可比拟的规模以及不断增长的中阶消费。印度持续推行与生产连结奖励计画,最高可报销15%的资本投资,鼓励工厂快速现代化。中国原始设备製造商(OEM)正增加对全球品牌伺服组件和人机介面的供应,缩短功能更新的前置作业时间。越南服装出口的成长促使供应商在胡志明市建造服务仓库,从而减少因更换备件而造成的停机时间。此外,该地区消费者对手工爱好的热情也日益高涨,雅加达和曼谷的零售连锁店报告称,入门级家用电器的销售额实现了两位数的增长。

中东和非洲地区,在埃及苏伊士运河经济区等基础设施走廊和免税工业网络的支持下,将成为成长最快的地区,预计年复合成长率将达到7.20%。埃塞俄比亚的哈瓦萨工业目前已拥有25家服装製造商,海关数据显示,到2024年,该总合将进口超过5,000台可程式设计包缝机。波湾合作理事会成员国正在其「2030愿景」计画下鼓励纺织业投资,沙乌地阿拉伯计划为综合工厂提供5亿美元的贷款。非洲消费市场也在日趋成熟,尼日利亚的电商平台销售的中阶手机在节庆期间经常售罄。培训仍然是一项挑战。原始设备製造商(OEM)正与内罗毕和阿克拉的职业学校合作,为操作人员提供基础维护认证。

北美本土製造业正在復苏,这主要得益于消费者对本地服饰的重视以及品牌面临的跨太平洋货运价格波动。耐吉等品牌正在奥勒冈州试点自动化生产线,这些生产线采用能够缝製多种材料的数控缝纫机头。北卡罗来纳州和南卡罗来纳州提供州级津贴,用于将传统工厂升级为智慧工厂。加拿大服装业的中小型企业正在采用线上配置器,允许终端用户设计定製图案,这间接提升了对可接收数位输入檔案的缝纫机的需求。随着美国买家为了适应快速反应的零售模式而选择就近采购,墨西哥正在确保产生连锁反应。

欧洲拥有成熟的工业基础和前沿的永续性政策,正在重新定义设备规格。将于2027年生效的生态设计指令将要求在机器层面提供精确的能耗指标,引导原始设备製造商(OEM)采用高效能伺服马达。德国在汽车和航太应用的技术纺织品领域持续保持领先地位,推动了对重型可程式打结机的需求。义大利奢侈时装品牌正在采用专业的手工刺绣机以及自动化设备,以保持「义大利製造」的纯正品质。由于物流不稳定,罗马尼亚和保加利亚的东欧工厂正在将部分订单从亚洲转移过来,这迫使它们迅速扩大机器规模。

在南美洲,巴西圣卡塔琳娜州的服饰丛集正稳步发展,透过现代化改造和引入伺服马达节能措施来应对不断上涨的电费。乌拉圭和巴拉圭正积极吸引中国投资者建立从棉花到服装的完整产业链,这有望实现设备需求的在地化。同时,智利日益增长的电子商务也促使业余爱好者使用专为小型公寓设计的紧凑型家用机器。外汇波动仍然是一个主要的阻力,往往导致进口机械设备的购买决策被推迟,直到外汇稳定下来。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 亚太地区服装製造业的快速扩张

- 成熟经济体中DIY与手工艺文化的復兴

- 物联网缝纫机和数控缝纫机的进步

- 推广工业自动化以提高生产力

- 透过近岸外包增加对小批量生产单位的需求

- 「维修与再利用」的消费运动促进了永续性。

- 市场限制

- 工业机械方面的高资本支出

- 低成本再生产品的普及

- 电子产品供应链中的瓶颈(MCU、伺服)

- 先进机型熟练操作人员短缺

- 产业价值链分析

- 波特五力分析

- 新进入者的威胁

- 供应商的议价能力

- 买方的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

- 洞察最新市场趋势与创新

- 深入了解市场近期发展动态(新产品发布、策略性倡议、投资、合作、合资、市场发展、併购等)

第五章 市场规模与成长预测

- 按机器类型

- 手动型

- 电的

- 自动的

- 其他机器类型

- 透过使用

- 服装与时尚

- 非服装纺织品(汽车、室内装潢)

- 鞋类和皮革製品

- 家用纺织品和工艺品

- 其他用途

- 最终用户

- 住宅

- 工业的

- 按分销管道

- B2C/零售

- 多品牌店

- 独家品牌经销店

- 在线的

- 其他分销管道

- B2B/製造商直销

- B2C/零售

- 按地区

- 北美洲

- 加拿大

- 美国

- 墨西哥

- 南美洲

- 巴西

- 秘鲁

- 智利

- 阿根廷

- 其他南美

- 欧洲

- 英国

- 德国

- 法国

- 西班牙

- 义大利

- 比荷卢经济联盟(比利时、荷兰、卢森堡)

- Nordix(丹麦、芬兰、冰岛、挪威、瑞典)

- 其他欧洲国家

- 亚太地区

- 印度

- 中国

- 日本

- 澳洲

- 韩国

- 东南亚(新加坡、马来西亚、泰国、印尼、越南、菲律宾)

- 其他亚太地区

- 中东和非洲

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 南非

- 奈及利亚

- 其他中东和非洲地区

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略倡议

- 市占率分析

- 公司简介

- Brother Industries, Ltd.

- JUKI Corporation

- SVP Worldwide(Singer(R), Husqvarna Viking(R), Pfaff(R))

- Janome Sewing Machine Co., Ltd.

- Bernina International AG

- Mitsubishi Electric Corp.(Industrial Sewing Machinery)

- Jack Sewing Machine Co., Ltd.

- Pegasus Sewing Machine Mfg. Co., Ltd.

- Toyota Industries Corp.(TACHINO)

- Baby Lock/Tacony Corporation

- Zoje Sewing Machine Co., Ltd.

- Feiyue Group Co., Ltd.

- Union Special LLC

- Rimoldi & CF

- SunStar Co., Ltd.

- Yamato Sewing Machine Mfg. Co., Ltd.

- Typical Sewing Machine Co., Ltd.

- Seiko Sewing Machine Co., Ltd.

- Merrow Sewing Machine Company

第七章 市场机会与未来展望

The sewing machine market attained a value of USD 4.65 billion in 2025 and is forecast to rise at a 5.92% CAGR to USD 6.20 billion in 2030.

Industrial automation requirements power growth, the widening maker movement, and rapid feature upgrades that allow both factories and households to boost productivity while reducing waste. Manufacturers benefit from dual exposure: large-volume textile exports in Asia and the repair-over-replace culture in North America and Europe. Technology upgrades toward Wi-Fi connectivity, downloadable stitch libraries, and programmable logic controllers lengthen replacement cycles yet raise average selling prices, supporting revenue even when unit volumes plateau. Near-shoring of garment production back to the United States and Western Europe further expands the addressable base for flexible, small-batch industrial systems that can switch styles without lengthy retooling.

Global Sewing Machines Market Trends and Insights

Rapid Apparel-Manufacturing Expansion in Asia-Pacific

Asia continues to outpace every other region in apparel output, fueled by public incentives and export-oriented strategies. India alone targets USD 350 billion in textile exports by 2030, stimulating bulk procurement of high-throughput sewing lines . Production-linked schemes covering technical textiles lower the payback period on automated machines that handle multiple fabric weights without manual intervention. Growing wages in legacy low-cost centers push manufacturers toward units with servo motors and programmable stitch patterns that offset labor costs. Factory clustering in Vietnam and Bangladesh simplifies after-sales logistics, encouraging suppliers to embed regional service hubs. As orders shift from basic tees to higher-value athleisure and formalwear, demand tilts toward machines capable of complex seam constructions and digital platen adjustments.

DIY & Craft Culture Revival in Mature Economies

Gen Z consumers view home sewing as a route to personalized fashion and lower textile waste, and social media tutorials convert that interest into measurable hardware sales. Retailers now curate starter bundles that pair entry-level machines with downloadable patterns, easing the learning curve. Pandemic-era hobby adoption has persisted post-lockdown as a stress-relief habit, keeping retail sell-through high even as other home-improvement categories normalize. Compact form factors that fit small apartments and smartphone-like touchscreens resonate with digital natives, forcing brands to prioritize intuitive UX over mechanical complexity. The rising tide of reseller platforms for handmade items, such as Etsy, further monetizes the hobby, reinforcing equipment upgrades once users outgrow basic functions.

High Capital Outlay for Industrial Machines

Vendor financing options exist yet cover only the hardware, leaving training and maintenance outside loan packages. Banks often require collateral that small workshops lack, delaying modernization cycles and leaving production stuck with 10-year-old lockstitch units. Deferred investment saps competitiveness when brands demand tight tolerances on seam strength and digital traceability. Leasing programs introduced by JUKI in 2024 showed early adoption in Vietnam but remain a novelty elsewhere, partly because operators fear long-term commitment to proprietary software ecosystems.

Other drivers and restraints analyzed in the detailed report include:

- Advancements in IoT-Enabled and CNC Sewing Machines

- Industrial Automation Push for Productivity

- Shortage of Skilled Operators

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Electric models accounted for 65.00% of revenue in 2024, underscoring their versatility for factories and households alike. Many industrial buyers regard the segment as an interim step toward full automation, adding servo drives and semi-automatic thread cutters to stretch machine life cycles. Automated units, meanwhile, are slated to expand at 6.89% CAGR through 2030 as factories chase consistent stitch quality and lower rework. The sewing machine market size for automated systems is growing, reflecting rising demand from sportswear and technical-textile plants. Manual machines linger in regions with unstable electricity grids, carving out a defensible niche among artisans who prize tactile control.

Continued dominance of the electric segment derives from abundant spare parts and universal familiarity among operators, decreasing training periods. Singer's Wi-Fi-ready M3330 illustrates how traditional categories absorb smart features without jumping to full CNC complexity. Hydraulically actuated quilting machines populate the "other" category and find success in mattress manufacturing, expanding geographic penetration into Turkey and Poland. Price gaps between electric and entry-level automated systems have narrowed to 18%, a threshold at which CFOs start green-lighting upgrades.

Apparel retained a commanding 58.30% slice of 2024 revenue due to vast order volumes from fast-fashion giants and uniform suppliers. Sportswear gains traction as stretch fabrics require differential-feed overlockers, prompting OEMs to bundle specialized presser feet. Home textiles, including curtains and cushion covers, represent the fastest-growing niche with a 6.95% CAGR as homeowners invest in personalized decor. The sewing machine market share for home-textile applications rose 120 basis points between 2023 and 2024, signaling a durable shift toward at-home customization. Automotive upholstery, medical disposables, and industrial filters round out the non-apparel group, each demanding heavy-duty needles and reinforced work tables.

Consumer preference for sustainable interiors boosts premium thread demand, benefiting subsidiaries like American & Efird that supply eco-dyed yarns. Car seat makers specify bar-tacking capabilities at 40 stitches per second, creating opportunities for providers that can integrate high-torque servo motors. In medical PPE, ultrasonic sewing alternatives compete, yet regulatory audits still favor stitched seams for critical gowns. Rising disposable income in urban India grows the market for embroidery-only machines that let users monetize home businesses. This diversification smooths cyclical dips in garment manufacturing, cushioning OEM revenue during apparel slowdowns.

The Sewing Machines Market Report is Segmented by Machine Type (Manual, Electric, and More), by Application (Apparel, Non-Apparel Textiles, and More), by End-User (Residential and Industrial), by Distribution Channel (B2C/Retail and B2B/Directly From the Manufacturers), and by Geography (North America, South America, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific's 51.00% revenue leadership in 2024 reflects its unmatched scale in fiber-to-fashion value chains and ascending middle-class consumption. India continues to roll out Production Linked Incentives that reimburse up to 15% of capital investment, prompting mills to modernize quickly . Chinese OEMs increasingly supply servo components and human-machine interfaces to global brands, shortening lead times for feature updates. Vietnam's apparel export growth encourages suppliers to build service warehouses in Ho Chi Minh City, reducing downtime for spare-part replacements. The region also witnesses swelling consumer enthusiasm for craft hobbies, as retail chains in Jakarta and Bangkok report double-digit sales lift for entry-level home units.

The Middle East and Africa grows the fastest, projected at 7.20% CAGR, supported by infrastructure corridors like Egypt's Suez Canal Economic Zone that bundle industrial parks with duty exemptions. Ethiopia's Hawassa Industrial Park already houses 25 apparel manufacturers that collectively imported more than 5,000 programmable lockstitch machines in 2024 according to customs data. Gulf Cooperation Council states encourage textile investments under Vision-2030 plans, with Saudi Arabia earmarking USD 500 million loans for integrated mills. African consumer markets also mature; Nigeria's e-commerce platforms now list mid-range portable models that sell out during festival seasons. The challenge lies in training; OEMs partner with vocational institutes in Nairobi and Accra to certify operators on basic maintenance.

North America experiences a revival in domestic making, powered by consumers who value locally produced garments and by brands facing unpredictable trans-Pacific freight. Brands such as Nike pilot automated lines in Oregon that rely on CNC sewing heads capable of multi-material stitching. State-level grants in North Carolina and South Carolina subsidize equipment purchases for legacy mills upgrading to smart factories. Canada's apparel SMEs embrace online configurators that allow end-users to design custom patterns, indirectly boosting demand for machines that accept digital input files. Mexico secures spill-over benefits as US buyers near-source to comply with quick-response retail models.

Europe blends mature industrial bases with avant-garde sustainability policies that redefine equipment specifications. Eco-design directives coming into force by 2027 will require precise energy-consumption metrics at the machine level, nudging OEMs toward high-efficiency servo motors. Germany continues to lead in technical textiles for automotive and aerospace, prompting demand for heavy-duty programmable bartackers. Italy's luxury fashion houses employ specialized hand-guided embroiderers alongside automated equipment to uphold "Made in Italy" authenticity. Eastern European factories in Romania and Bulgaria win orders redirected from Asia due to logistics volatility, necessitating rapid scale-up in machine fleets.

South America exhibits steady momentum as Brazil's garment cluster in Santa Catarina modernizes, deploying servo-motor retrofits to capture energy savings under rising electricity tariffs. Uruguay and Paraguay court Chinese investors for integrated cotton-to-apparel complexes that could localize equipment demand. Meanwhile, Chile's e-commerce penetration fosters hobbyist uptake of compact home machines designed for small apartments. Currency fluctuations remain the principal headwind, often delaying purchase decisions for imported machines until exchange rates stabilize.

- Brother Industries, Ltd.

- JUKI Corporation

- SVP Worldwide (Singer(R), Husqvarna Viking(R), Pfaff(R))

- Janome Sewing Machine Co., Ltd.

- Bernina International AG

- Mitsubishi Electric Corp. (Industrial Sewing Machinery)

- Jack Sewing Machine Co., Ltd.

- Pegasus Sewing Machine Mfg. Co., Ltd.

- Toyota Industries Corp. (TACHINO)

- Baby Lock / Tacony Corporation

- Zoje Sewing Machine Co., Ltd.

- Feiyue Group Co., Ltd.

- Union Special LLC

- Rimoldi & CF

- SunStar Co., Ltd.

- Yamato Sewing Machine Mfg. Co., Ltd.

- Typical Sewing Machine Co., Ltd.

- Seiko Sewing Machine Co., Ltd.

- Merrow Sewing Machine Company

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rapid apparel-manufacturing expansion in APAC

- 4.2.2 DIY & craft culture revival in mature economies

- 4.2.3 Advancements in IoT-enabled and CNC sewing machines

- 4.2.4 Industrial automation push for productivity

- 4.2.5 Near-shoring boosts demand for small-batch industrial units

- 4.2.6 Sustainability-driven "repair & reuse" consumer movement

- 4.3 Market Restraints

- 4.3.1 High capital outlay for industrial machines

- 4.3.2 Proliferation of low-cost refurbished units

- 4.3.3 Electronics supply-chain bottlenecks (MCUs, servos)

- 4.3.4 Shortage of skilled operators for advanced models

- 4.4 Industry Value Chain Analysis

- 4.5 Porter's Five Forces Analysis

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Suppliers

- 4.5.3 Bargaining Power of Buyers

- 4.5.4 Threat of Substitutes

- 4.5.5 Competitive Rivalry

- 4.6 Insights into the Latest Trends and Innovations in the Market

- 4.7 Insights on Recent Developments (New Product Launches, Strategic Initiatives, Investments, Partnerships, JVs, Expansion, M&As, etc.) in the Market

5 Market Size & Growth Forecasts

- 5.1 By Machine Type

- 5.1.1 Manual

- 5.1.2 Electric

- 5.1.3 Automated

- 5.1.4 Other Machine Types

- 5.2 By Application

- 5.2.1 Apparel & Fashion

- 5.2.2 Non-apparel Textiles (Automotive, Upholstery)

- 5.2.3 Footwear & Leather Goods

- 5.2.4 Home Textiles & Crafts

- 5.2.5 Other Applications

- 5.3 By End User

- 5.3.1 Residential

- 5.3.2 Industrial

- 5.4 By Distribution Channel

- 5.4.1 B2C/Retail

- 5.4.1.1 Multi-brand Stores

- 5.4.1.2 Exclusive Brand Outlets

- 5.4.1.3 Online

- 5.4.1.4 Other Distribution Channels

- 5.4.2 B2B/Directly from the Manufacturers

- 5.4.1 B2C/Retail

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 Canada

- 5.5.1.2 United States

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Peru

- 5.5.2.3 Chile

- 5.5.2.4 Argentina

- 5.5.2.5 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 United Kingdom

- 5.5.3.2 Germany

- 5.5.3.3 France

- 5.5.3.4 Spain

- 5.5.3.5 Italy

- 5.5.3.6 BENELUX (Belgium, Netherlands, Luxembourg)

- 5.5.3.7 NORDICS (Denmark, Finland, Iceland, Norway, Sweden)

- 5.5.3.8 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 India

- 5.5.4.2 China

- 5.5.4.3 Japan

- 5.5.4.4 Australia

- 5.5.4.5 South Korea

- 5.5.4.6 South-East Asia (Singapore, Malaysia, Thailand, Indonesia, Vietnam, Philippines)

- 5.5.4.7 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 United Arab Emirates

- 5.5.5.2 Saudi Arabia

- 5.5.5.3 South Africa

- 5.5.5.4 Nigeria

- 5.5.5.5 Rest of Middle East and Africa

- 5.5.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 Brother Industries, Ltd.

- 6.4.2 JUKI Corporation

- 6.4.3 SVP Worldwide (Singer(R), Husqvarna Viking(R), Pfaff(R))

- 6.4.4 Janome Sewing Machine Co., Ltd.

- 6.4.5 Bernina International AG

- 6.4.6 Mitsubishi Electric Corp. (Industrial Sewing Machinery)

- 6.4.7 Jack Sewing Machine Co., Ltd.

- 6.4.8 Pegasus Sewing Machine Mfg. Co., Ltd.

- 6.4.9 Toyota Industries Corp. (TACHINO)

- 6.4.10 Baby Lock / Tacony Corporation

- 6.4.11 Zoje Sewing Machine Co., Ltd.

- 6.4.12 Feiyue Group Co., Ltd.

- 6.4.13 Union Special LLC

- 6.4.14 Rimoldi & CF

- 6.4.15 SunStar Co., Ltd.

- 6.4.16 Yamato Sewing Machine Mfg. Co., Ltd.

- 6.4.17 Typical Sewing Machine Co., Ltd.

- 6.4.18 Seiko Sewing Machine Co., Ltd.

- 6.4.19 Merrow Sewing Machine Company

7 Market Opportunities & Future Outlook

- 7.1 Growing demand for compact and portable sewing machines

- 7.2 Increasing prevalence of smart (integration of IoT and AI) and computerized sewing machines