|

市场调查报告书

商品编码

1846215

中国工程机械:市场占有率分析、产业趋势、统计及成长预测(2025-2030)China Construction Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

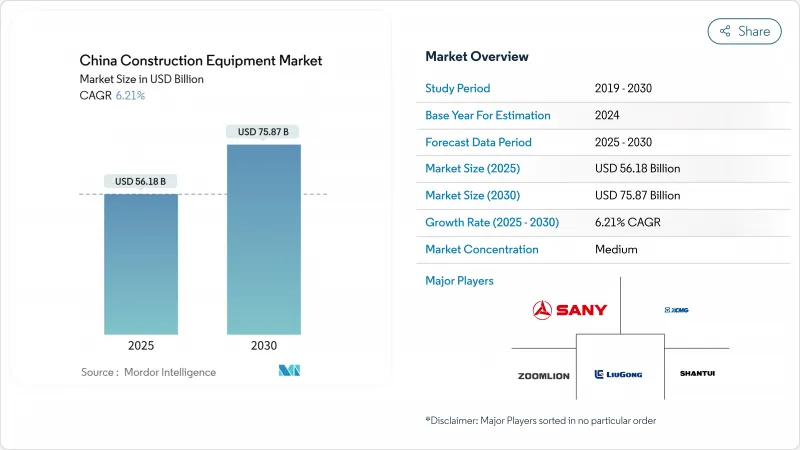

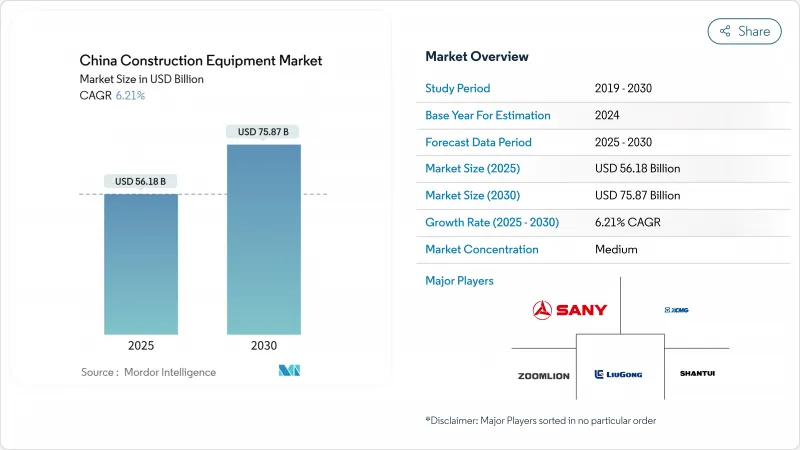

根据估计和预测,中国工程机械市场在 2025 年的价值为 561.8 亿美元,预计到 2030 年将成长至 758.7 亿美元,复合年增长率为 6.21%。

公共部门持续增加对铁路、公路和城市交通网络的投入,加上对电子机械和智慧机械的强力政策支持,即使住宅房地产市场降温,也支撑着市场需求。诸如计划于2025年建成18万公里国家铁路(总投资5900亿元人民币)等大型计划,保持了强劲的订单,并带动了大容量土方和起重设备的销售。同时,随着电气化与柴油的成本差距缩小,以及补贴抵消了部分资本支出,电气化正从试点计划转向大规模部署。海外出货量超过国内出货量,显示中国目标商标产品製造商(OEM)可以透过依靠海外基础设施建设週期来抵消国内经济放缓的影响。

中国工程机械市场趋势与洞察

政府基础建设投资和「一带一路」倡议

光是Delta地区,2024年铁路建设投入将达到创纪录的1,400亿元人民币,超过前一年的1,253亿元。国家发展和改革委员会的《2025年装备更新政策》将扩大对工业、能源、交通和农业等各领域的扶持力度,重点扶持高端、智慧、绿色技术,并加强贷款利息补贴以降低融资成本。由于基础设施计划通常需要三到五年的设备使用寿命,且更新换代模式可预测,此政策框架将创造超越传统建设週期的持续需求。 「一带一路」倡议的国际化维度将扩大国内製造商的出口机会,预计2022年中国70%的挖土机出口将销往「一带一路」沿线国家,从而形成良性循环,使国内生产规模能够带来具有国际竞争力的价格。预计到 2030 年,铁路网将扩展到 18 万公里,其中包括 6 万公里高速铁路,这将需要专门的施工设备进行隧道开挖、桥樑建设和轨道铺设,而中国製造商凭藉其在国内计划中的经验,在这些领域已经发展出了技术优势。

设施现代化和电气化政策

政府的设备现代化指令催生了独立于新建设的更新换代需求,而工业部发布的《2024年重点技术装备指导目录》也优先考虑了先进工程机械。直接补贴和营运成本优势推动了电动式工程机械的普及,中国製造商在某些应用领域实现了电动式和柴油机型的成本持平,从根本上改变了总拥有成本的计算方式。 《2024年绿色技术推广手册》列出了七大领域的112项尖端技术,其中工程机械在节能和环保类别中占据显着位置。随着营运商在寻求利用最新技术的同时尽可能降低资本支出,设备即服务(EaaS)模式正获得越来越多的支持,整合安装和拆除服务能够提高安全合规性和营运效率。这项政策催生了一个双轨制市场:高端电动和智慧设备净利率丰厚,而传统柴油设备则面临价格压力,这使得拥有强大研发能力和技术组合的製造商受益。

房地产业去槓桿化和建筑业放缓

房地产行业的去槓桿化将导致需求暂时中断,因为开发商会减少新计画开工和设备采购,尤其会影响小型机械和住宅建筑设备领域。然而,政府的都市更新计画和保障性住宅计画将提供替代需求来源,各大城市也优先考虑基础设施和公共建设,而非投机性开发。这将造成维持稳定的国有企业与面临资金限制的私人开发人员之间的市场分化,并为设备租赁和灵活的资金筹措模式创造机会,从而降低建设公司的资本需求。

细分市场分析

到2024年,挖土机和其他土木机械将占据中国工程机械市场55.28%的份额,巩固其在土方工程、采矿和地铁隧道计划中的重要地位。同时,由于补贴和电池成本下降削弱了柴油引擎的全生命週期成本优势,电动挖土机到2030年将以12.15%的复合年增长率成长。堆高机、伸缩臂操作车和高空作业平台将受惠于电商履约相关的仓库自动化,获得稳定的市场需求。道路施工设备将受益于不断扩展的17.7万公里国家高速公路网的维护週期缩短,其中自动压路机和摊舖机将成为高规格高速公路升级改造的关键设备。

技术融合将定义未来的竞争格局。如今,挖掘机标配远端资讯处理系统、半自动挖掘演算法和工厂预先安装的快速连接器,从而缩短了附件更换时间。混凝土搅拌机和泵浦车整合了物联网感测器,以优化坍落度和车辆物流,确保在人口密集的城市中心按时浇筑混凝土。预计到2030年,光是中国工程机械挖土机市场规模就将接近370亿美元,将为投资于专有电池组和控制软体的原始设备製造商(OEM)带来规模经济效益。随着互通性标准的日益成熟,拥有开放式架构控制器的零件供应商将获得更大的议价能力,将价值链再形成为以软体为中心的生态系统。

2024年,内燃机(柴油)仍将占据92.64%的销售份额,这得益于完善的加油基础设施、较长的作业週期以及较低的初始价格。然而,纯电动工程机械将带来决定性的变革,预计到2030年将以37.85%的复合年增长率成长。到2030年,中国纯电动工程机械市场规模预计将超过80亿美元,因为北京、上海和深圳的零排放法规限制了市政建设中柴油新车的采购。混合动力系统提供了一种过渡方案,在频繁怠速的作业週期中可降低20-25%的油耗。

成本平衡取决于电池密度、充电物流和转售价值。目前,原始设备製造商 (OEM) 的财务部门正将充电站和太阳能微电网纳入设备租赁合同,从而保证承包商在计划週期内收益固定的千瓦时价格。同时,国家电网营运商正在试点Vehicle-to-Grid)方案,将閒置的机器电池在非工作时间变现,增加额外的收益来源。在极端高温的矿场和无法连接电网的偏远「一带一路」沿线地区,柴油仍可能占据重要地位。然而,在噪音和排放法规最严格的大都市土木工程领域,柴油的市场份额可能会下降得最快。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 政府的「2025-30年新基础设施」规划

- 碳中和政策推动电子机械发展

- 透过整车製造商促进出口,将在国内实现规模经济。

- 「一带一路」倡议导致零件製造商订单积压。

- 当地碳信用市场青睐混合动力汽车

- 数位设备租赁平台刺激了中小企业的需求。

- 市场限制

- 房地产市场长期低迷

- 国内产能过剩引发的价格竞争

- 收紧对中小型承包商的信贷准入

- 电子设备逆变器和电池管理系统晶片短缺

- 价值/供应链分析

- 监管状况

- 技术展望

- 五力分析

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模与成长预测

- 按机器类型

- 土木机械

- 挖土机

- 装载机

- 推土机

- 物料输送机械

- 起重机

- 堆高机

- 伸缩臂操作车

- 道路施工设备

- 平土机机

- 压路机/压实机

- 铺路机

- 混凝土设备

- 混凝土搅拌机

- 混凝土泵

- 土木机械

- 按驱动类型

- 内燃机(柴油)

- 杂交种

- 纯电动

- 按销售管道

- OEM直销

- 由授权经销商出售

- 透过使用

- 建筑施工

- 基础设施建设

- 能源和自然资源

- 其他的

第六章 竞争情势

- 市场集中度

- 策略倡议

- 市占率分析

- 公司简介

- Sany Group

- Xuzhou Construction Machinery Group Co., Ltd.(XCMG)

- Caterpillar Inc.

- Zoomlion Heavy Industry

- LiuGong Machinery

- Komatsu Ltd.

- Hitachi Construction Machinery

- AB Volvo(Volvo CE)

- Liebherr Group

- Shantui Construction Machinery

- Tadano Ltd.

- JC Bamford Excavators Limited

- Doosan Bobcat Ltd.

- Hyundai Construction Equipment Ltd.

- Yanmar Holdings Co. Ltd.

- Terex Corporation

- China Railway Construction Heavy Industry Co., Ltd.

第七章 市场机会与未来展望

The China construction equipment market is estimated at USD 56.18 billion in 2025 and is forecast to advance to USD 75.87 billion by 2030, reflecting a 6.21% CAGR.

Sustained public-sector spending on railway, highway, and urban transit links, paired with a strong policy push for electric and smart machinery, underpins demand even as residential real-estate activity cools. Large-scale projects such as the 180,000 km national railway build-out, for which CNY 590 billion was earmarked in 2025, keep order books healthy and favor high-capacity earth-moving and lifting equipment. At the same time, electrification is moving from pilot projects to scaled deployment as cost parity with diesel narrows and subsidies offset capital outlays. Export momentum offers an additional cushion: overseas shipments have overtaken domestic deliveries, signaling that Chinese original-equipment manufacturers (OEMs) can lean on foreign infrastructure cycles to balance local slowdowns.

China Construction Equipment Market Trends and Insights

Government Infrastructure Investment and Belt Road Initiative

China's infrastructure investment surge represents the primary growth catalyst, with the Yangtze River Delta region alone allocating CNY 140 billion for railway construction in 2024, marking a record high that surpasses the previous year's CNY 125.3 billion. The National Development and Reform Commission's 2025 equipment update policy expands support across industrial, energy, transportation, and agricultural sectors, emphasizing high-end, intelligent, and green technologies with enhanced loan interest subsidies to reduce financing costs. This policy framework creates sustained demand beyond traditional construction cycles, as infrastructure projects typically require 3-5 year equipment lifecycles with predictable replacement patterns. The Belt and Road Initiative's international dimension amplifies domestic manufacturers' export opportunities, with 70% of Chinese excavator exports directed to BRI countries in 2022, creating a virtuous cycle where domestic production scale enables competitive international pricing. Railway network expansion to 180,000 km by 2030, including 60,000 km of high-speed rail, necessitates specialized construction equipment for tunneling, bridge construction, and track laying, segments where Chinese manufacturers have developed technological advantages through domestic project experience.

Equipment Modernization and Electrification Policies

The government's equipment modernization mandate creates replacement demand independent of new construction activity, with the Ministry of Industry and Information Technology's 2024 Major Technological Equipment Guidance Catalog prioritizing advanced construction machinery. Electric construction equipment adoption accelerates through direct subsidies and operational cost advantages, with Chinese manufacturers achieving cost parity between electric and diesel versions in certain applications, fundamentally altering total cost of ownership calculations. The Green Technology Promotion Directory (2024 Edition) includes 112 advanced technologies across seven sectors, with construction equipment featuring prominently in energy-efficient and environmental protection categories. Equipment-as-a-service models gain traction as operators seek to minimize capital expenditure while accessing latest technology, with integrated installation-dismantling services improving safety compliance and operational efficiency. The policy creates a two-tier market where premium electric and smart equipment commands higher margins while conventional diesel equipment faces pricing pressure, benefiting manufacturers with strong R&D capabilities and technology portfolios.

Real Estate Sector Deleveraging and Construction Slowdown

The real estate sector's deleveraging process creates temporary demand disruption as developers reduce new project starts and equipment purchases, particularly affecting compact machinery and residential construction equipment segments. However, government urban renewal initiatives and affordable housing programs provide alternative demand sources, with major cities prioritizing infrastructure upgrades and public facility construction over speculative development. Market differentiation emerges between state-owned enterprises maintaining stable operations and private developers facing financial constraints, creating opportunities for equipment leasing and flexible financing models that reduce capital requirements for construction firms.

Other drivers and restraints analyzed in the detailed report include:

- Export Market Expansion and International Competitiveness

- Digitalization and Smart Construction Technology Adoption

- Trade Tensions and Tariff Barriers in International Markets

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Earth-moving machinery such as excavators controlled 55.28% of China construction equipment market share in 2024, cementing their role across earthwork, mining and metro tunnelling projects. Rising infrastructure outlays and export demand keep delivery volumes elevated, while electric excavators record a 12.15% CAGR to 2030 as subsidies and falling battery costs erode diesel's lifetime cost advantage. Forklifts, telescopic handlers and aerial platforms gain steady traction from warehouse automation linked to e-commerce fulfilment. Road-building machines benefit from maintenance cycles for an expanding 177,000 km national highway grid, with autonomous rollers and pavers proving headline features on high-profile expressway upgrades.

Technology convergence defines future competition. Excavators now ship with standard telematics, semi-autonomous dig algorithms, and factory-installed quick couplers that cut attachment changeover time. Concrete mixers and pumps integrate IoT sensors to optimize slump quality and dispatch logistics, ensuring on-time pours in dense urban cores. China construction equipment market size for excavators alone is projected to approach USD 37 billion by 2030, providing scale economies for OEMs investing in proprietary battery packs and control software. As interoperability standards mature, component suppliers with open-architecture controllers will gain bargaining power, reshaping the value chain toward software-centric ecosystems.

Internal Combustion Engine (Diesel) still powered 92.64% of units sold in 2024, supported by established fueling infrastructure, long duty cycles, and lower upfront pricing. However, full-electric options post a 37.85% CAGR through 2030, signaling a decisive phase-change. The China construction equipment market size for battery-electric models is set to cross USD 8 billion by 2030, thanks to zero-emission mandates in Beijing, Shanghai, and Shenzhen that restrict new diesel purchases for municipal works. Hybrid drivetrains offer a bridge solution, trimming fuel burn by 20-25% on duty cycles involving frequent idling.

Cost parity hinges on battery density, charging logistics, and resale values. OEM finance arms now bundle charging depots and solar-powered micro-grids into equipment leases, giving contractors guaranteed kilowatt-hour pricing over project lifetimes. Meanwhile, state grid operators trial vehicle-to-grid schemes that monetize idle machinery batteries during off-shift hours, adding an ancillary revenue stream. Diesel's role will remain pronounced in extreme-temperature mines and remote Belt and Road corridors without grid access. Still, its share will erode fastest in metropolitan civil works segments where noise and emissions rules bite hardest.

The China Construction Equipment Market Report is Segmented by Machinery Type (Earth-Moving Machinery, Material-Handling Machinery, and More), Drive Type (Internal-Combustion, Hybrid, and More), Sales Channel (OEM Direct Sales, and Authorized Dealer Sales), and Application (Building Construction, Infrastructure Construction, and More). The Market Forecasts are Provided in Terms of Value (USD).

List of Companies Covered in this Report:

- Sany Group

- Xuzhou Construction Machinery Group Co., Ltd. (XCMG)

- Caterpillar Inc.

- Zoomlion Heavy Industry

- LiuGong Machinery

- Komatsu Ltd.

- Hitachi Construction Machinery

- AB Volvo (Volvo CE)

- Liebherr Group

- Shantui Construction Machinery

- Tadano Ltd.

- J.C. Bamford Excavators Limited

- Doosan Bobcat Ltd.

- Hyundai Construction Equipment Ltd.

- Yanmar Holdings Co. Ltd.

- Terex Corporation

- China Railway Construction Heavy Industry Co., Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Govt. 'New Infrastructure 2025-30' pipeline

- 4.2.2 Carbon-neutral mandate spurring electric machinery

- 4.2.3 OEM export push enables domestic economies of scale

- 4.2.4 Belt and Road back-orders for component suppliers

- 4.2.5 Provincial carbon-credit markets favouring hybrids

- 4.2.6 Digital equipment-rental platforms unlocking SME demand

- 4.3 Market Restraints

- 4.3.1 Prolonged real-estate downturn

- 4.3.2 Domestic price wars from over-capacity

- 4.3.3 Tight credit to SME contractors

- 4.3.4 Inverter and BMS chip shortages for e-equipment

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Competitive Rivalry

5 Market Size and Growth Forecasts (Value (USD))

- 5.1 By Machinery Type

- 5.1.1 Earth-moving Machinery

- 5.1.1.1 Excavators

- 5.1.1.2 Loaders

- 5.1.1.3 Dozers

- 5.1.2 Material-Handling Machinery

- 5.1.2.1 Cranes

- 5.1.2.2 Fork-lifts

- 5.1.2.3 Telescopic Handlers

- 5.1.3 Road-Construction Machinery

- 5.1.3.1 Motor Graders

- 5.1.3.2 Rollers/Compactors

- 5.1.3.3 Pavers

- 5.1.4 Concrete Equipment

- 5.1.4.1 Concrete Mixers

- 5.1.4.2 Concrete Pumps

- 5.1.1 Earth-moving Machinery

- 5.2 By Drive Type

- 5.2.1 Internal-Combustion (Diesel)

- 5.2.2 Hybrid

- 5.2.3 Full-Electric

- 5.3 By Sales Channel

- 5.3.1 OEM Direct Sales

- 5.3.2 Authorized Dealer Sales

- 5.4 By Application

- 5.4.1 Building Construction

- 5.4.2 Infrastructure Construction

- 5.4.3 Energy and Natural Resources

- 5.4.4 Others

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (Includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Sany Group

- 6.4.2 Xuzhou Construction Machinery Group Co., Ltd. (XCMG)

- 6.4.3 Caterpillar Inc.

- 6.4.4 Zoomlion Heavy Industry

- 6.4.5 LiuGong Machinery

- 6.4.6 Komatsu Ltd.

- 6.4.7 Hitachi Construction Machinery

- 6.4.8 AB Volvo (Volvo CE)

- 6.4.9 Liebherr Group

- 6.4.10 Shantui Construction Machinery

- 6.4.11 Tadano Ltd.

- 6.4.12 J.C. Bamford Excavators Limited

- 6.4.13 Doosan Bobcat Ltd.

- 6.4.14 Hyundai Construction Equipment Ltd.

- 6.4.15 Yanmar Holdings Co. Ltd.

- 6.4.16 Terex Corporation

- 6.4.17 China Railway Construction Heavy Industry Co., Ltd.

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment