|

市场调查报告书

商品编码

1852064

针状焦:市场占有率分析、产业趋势、统计数据、成长预测(2025-2030 年)Needle Coke - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

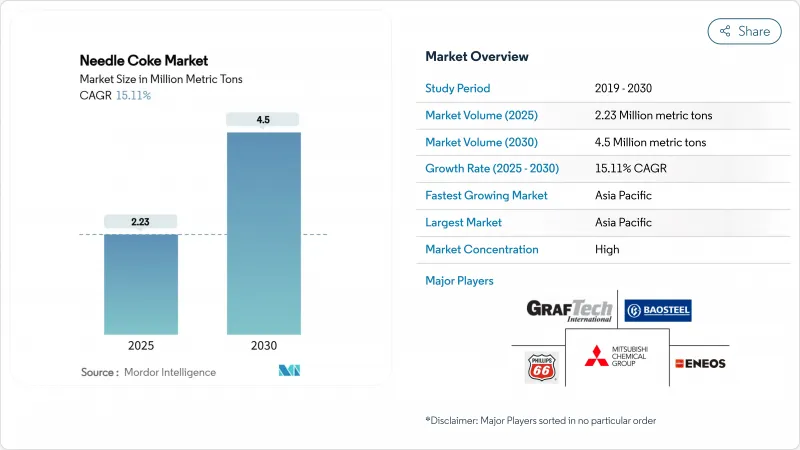

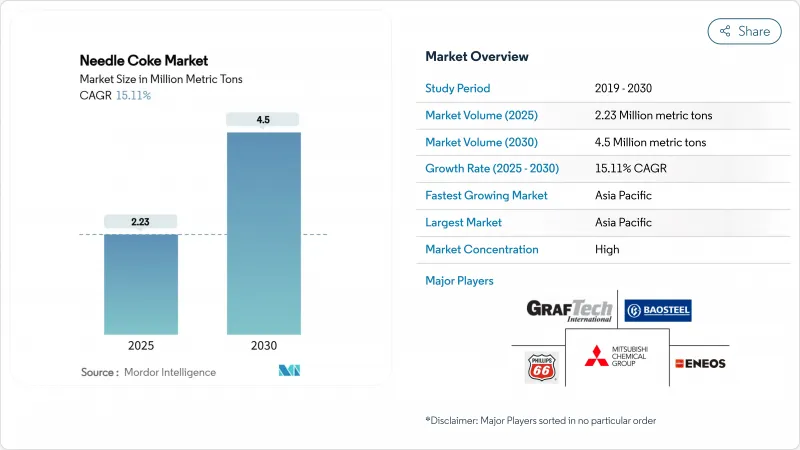

预计到 2025 年针状焦市场规模为 223 万吨,到 2030 年将达到 450 万吨,预测期(2025-2030 年)复合年增长率为 15.11%。

这项快速成长主要得益于电弧炉炼钢和锂离子电池製造的同步发展,这两个产业共同重塑了全球碳材料的需求模式。钢铁业向电弧炉技术的转型推动了对高功率石墨电极的需求,而电动车的蓬勃发展则扩大了对合成石墨负极的需求。原料供应紧张、生产集中在特定地区以及新的贸易限制,导致针状焦市场持续面临供应紧张,并加剧了价格上涨趋势。拥有稳定油源和先进延迟焦化设备的生产商仍然掌握定价权。

全球针焦市场趋势与洞察

增加对电弧炉炼钢产能的投资

全球钢铁生产商正加速从高炉炼钢转向电弧炉炼钢,以减少二氧化碳排放并提高原料灵活性。电弧炉炼钢目前已占全球钢铁产量的30%,并占2025年下半年计画新增产能的43%。印度的国家钢铁政策目标是到2030年将电弧炉炼钢的产量占比提高到40%,而中国则计划在2025年将这一比例提高到15%。因此,钢铁业的脱碳直接增加了整个市场对针状焦的需求。虽然电弧炉计划的资本投资主要集中在亚太地区,但北美钢铁生产商也在增建电弧炉,以实现永续性目标并利用丰富的废钢供应。这一趋势正促使综合焦炭生产商透过多年承购协议来扩大产能。

电动车用锂离子电池产量快速成长

锂离子电池的生产扩张速度远超预期。 2023年,全球电动车电池工厂将消耗超过63万吨石墨,预计到本世纪中期,随着新的超级工厂投入运营,这一数字将翻倍。合成石墨在快速充电稳定性和纯度方面具有显着的性能优势,从而推动了高能量密度负极材料的日益普及。为了确保供应,汽车製造商正与针状焦基合成石墨供应商签订长期合同,例如Panasonic能源与NOVONIX达成的协议,预计将于2025年开始交付。负极材料需求的激增正将石油基针状焦从传统的钢铁客户手中夺走,导致全球原材料供应趋紧,并提高了针状焦市场合格生产商的利润率。

延迟焦化中的劳工和环境危害。

美国环保署2024年焦炉新规强制要求使用零洩漏炉门并进行连续苯监测,迫使业者维修其排放法规。 40 CFR第63部分规定的类似措施将加强炼油厂焦炭槽的监测,增加遵循成本和停机风险。这些强制性规定可能会对近期产量造成压力,抑制产能扩张,并将新增产能转移到监管相对宽鬆的地区。供应限制的出现速度可能快于需求缓解速度,加剧针状焦市场的波动。

细分市场分析

2024年,石油基材料占针状焦市场份额的85.73%,预计到2030年将以16.34%的复合年增长率成长。此细分市场受益于完善的延迟焦化基础设施、可靠的FCC脱渣油供应以及优异的晶体取向,从而满足高功率电极的精度要求。预计到2025年,市场规模将成长至约191万吨,到2030年将超过380万吨,这印证了石油针状焦在更广泛的碳材料价值链中市场规模的不断扩大。儘管合成石墨阳极的采用将进一步推动市场成长,但美国和西欧炼油厂的合理化改造正在造成区域性原料短缺。亚洲炼油厂的柔性焦装置仍在运作,部分缓解了其他地区的供不应求。

煤焦油沥青基产品占据剩余市场份额,是电极和电池製造商实现多元化发展的重要途径。儘管面临技术挑战,两家商业化煤针焦工厂在2024年之前仍维持了稳定的产量。在钢铁週期有利的情况下,与冶金焦炉的上游整合可为营运商带来成本优势。沥青供应有限限制了成长潜力,但逐步消除瓶颈措施使该领域保持了重要性。对催化剂辅助石墨化的持续研究有望提高煤针焦的质量,并扩大其在针状焦市场的潜在份额。

针状焦市场报告按产品类型(石油基针状焦和煤焦油沥青基针状焦)、应用领域(石墨电极、锂离子电池及其他应用)和地区(亚太地区、北美地区、欧洲地区、南美地区以及中东和非洲地区)进行细分。市场预测以数量(公吨)为单位。

区域分析

亚太地区占针状焦市场88.31%的份额,预计到2030年将以15.72%的复合年增长率成长。中国预计2023年粗钢产量将超过9亿吨,并拥有全球最大的电池负极材料产能,在针状焦的供需两端都扮演重要角色。北京于2023年底推出高纯度石墨出口许可证制度,导致其海外出货量年减91%,引发了西方买家对供应链的担忧。印度计划在2035年实现年产2.4亿至2.6亿吨钢铁,并计划将电弧炉炼钢普及率提高到40%,这很可能成为推动针状焦需求成长的因素之一。

北美市场规模虽小,但正透过本地化策略提升其战略地位。美国提案对中国石墨征收93.5%的关税,凸显了华盛顿对自主研发的重视。欧洲市场维持温和的销售成长,这得益于支持循环经济钢铁生产和电池回收的政策。斯道拉恩索在芬兰的木质素石墨工厂体现了其对低碳负极材料的承诺。

其他地区,例如南美洲和中东及非洲,虽然仍处于应用初期,但对特种焦的兴趣日益浓厚。沙乌地阿拉伯已授予雪佛龙全球许可公司一份年产7.5万吨针状焦的生产许可证,该许可证将于2024年投产,标誌着中东首次大规模涉足特种焦领域。同时,埃及和巴西等新兴钢铁产业丛集正在寻求本地电极供应,以减少进口依赖。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 增加对电弧炉炼钢产能的投资

- 电动车用锂离子电池产量快速成长

- 中国和欧盟的废钢法规

- 炼油厂升级提升低硫卸油供应

- 闭合迴路石墨回收计划

- 市场限制

- 延迟焦化过程中的职业和环境危害。

- 原料价格波动(蒸馏油、煤焦油)

- 生物基硬碳阳极材料的前景

- 价值链分析

- 波特五力模型

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争程度

- 价格概览

第五章 市场规模与成长预测

- 依产品类型

- 石油基针状焦市场

- 煤焦油沥青基针状焦市场

- 透过使用

- 石墨电极

- 锂离子电池

- 其他用途

- 按地区

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 亚太其他地区

- 北美洲

- 美国

- 加拿大

- 墨西哥

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 俄罗斯

- 其他欧洲地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲国家

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 其他中东和非洲地区

- 亚太地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率(%)/排名分析

- 公司简介

- Baosteel Group

- China National Petroleum Corporation

- ENEOS Corporation

- GrafTech International

- Indian Oil Corporation

- Mitsubishi Chemical Group Corporation

- Nippon Steel Corporation

- PetroChina

- Phillips 66 Company

- POSCO Future M

- Shandong Yida New Materials Co., Ltd.

- Shanxi Hongte Coal Chemical Co Ltd

- Sinopec

- Tokai Carbon Co., Ltd

第七章 市场机会与未来展望

The Needle Coke Market size is estimated at 2.23 million metric tons in 2025, and is expected to reach 4.5 million metric tons by 2030, at a CAGR of 15.11% during the forecast period (2025-2030).

This rapid upswing stems from the parallel rise of electric-arc-furnace (EAF) steelmaking and lithium-ion battery manufacturing, two sectors that together reshape global carbon material demand. The steel industry's move toward EAF technology is intensifying the call for ultra-high-power graphite electrodes, while the electric-vehicle boom is expanding synthetic-graphite anode requirements. Tight feedstock availability, geographic concentration of production, and new trade controls are creating persistent supply tension that reinforces upward pricing trends across the needle coke market. Producers with secure decant-oil supply and advanced delayed-coking assets continue to control pricing power.

Global Needle Coke Market Trends and Insights

Increasing Investments in EAF Steel Capacity

Global steelmakers are accelerating the shift from blast furnaces to EAF technology to cut carbon emissions and improve raw-material flexibility. EAF installations already contribute 30% of world steel output and account for 43% of planned capacity additions slated for late 2025. India's National Steel Policy targets an EAF share of up to 40% by 2030, while China seeks a 15% EAF contribution by 2025. Each new furnace requires ultra-high-power electrodes that rely on premium petroleum-needle coke, so steel decarbonization directly enlarges overall needle coke market demand. Capital spending on EAF projects remains focused in Asia-Pacific, yet North American steel majors are also adding arc furnaces to meet sustainability goals and capitalize on abundant scrap supply. The trend locks in multi-year offtake commitments and encourages integrated coke producers to expand capacity.

Soaring Li-ion Battery Production for EVs

Lithium-ion battery manufacturing is scaling at a pace that exceeds earlier forecasts. Global EV battery plants consumed more than 630,000 tons of graphite in 2023, a figure expected to multiply by mid-decade as new giga-factories begin operations. Synthetic graphite holds critical performance advantages in fast-charge stability and purity, underpinning rising penetration rates within high-energy-density anodes. To secure supply, automotive OEMs have struck long-term agreements with needle-coke-based synthetic-graphite suppliers such as Panasonic Energy's pact with NOVONIX that commences deliveries in 2025. The surge in anode demand draws petroleum-based needle coke away from traditional steel customers, tightening the global feedstock pool and supporting elevated margins for qualified producers inside the needle coke market.

Occupational and Environmental Hazards in Delayed Coking

The U.S. Environmental Protection Agency's 2024 coke-oven rule mandates zero leaking doors and continuous benzene monitoring, pushing operators to retrofit emission controls. Similar measures under 40 CFR Part 63 tighten oversight of refinery coking drums, escalating compliance spend and downtime risk. These obligations strain output in the near term, curb expansion appetite, and may shift new capacity to regions with less stringent frameworks. For the needle coke market, supply constraints materialize faster than demand moderation, amplifying volatility.

Other drivers and restraints analyzed in the detailed report include:

- Scrap-Steel Mandates in China and EU

- Refinery Upgrades Boosting Low-Sulphur Decant-Oil Supply

- Raw-Material Price Volatility

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Petroleum-based material captured 85.73% of the needle coke market share in 2024 and is forecast to advance at a 16.34% CAGR to 2030. The segment benefits from established delayed-coking infrastructure, reliable FCC decant-oil supply, and superior crystalline orientation that meets ultra-high-power electrode tolerances. It grew to roughly 1.91 million tons in 2025 and should exceed 3.80 million tons by 2030, underscoring the rising petroleum needle coke market size within the larger carbon-materials value chain. Adoption of synthetic-graphite anodes injects additional momentum, but refinery rationalization in the United States and Western Europe introduces regional feed shortages. Asian refiners continue to commission flexi-coker units, offsetting partial supply loss elsewhere.

Coal-tar-pitch-based products occupy the remaining volume but supply an important diversification lever for electrode and battery producers. Despite technical hurdles, the two commercial coal-needle plants maintained stable output through 2024. Upstream integration with metallurgical coke ovens gives operators incremental cost advantages when steel cycles are favorable. Growth potential stays capped by limited pitch availability, yet incremental debottlenecking keeps the segment relevant. Ongoing research into catalyst-assisted graphitization may elevate coal-needle quality, broadening its addressable share in the needle coke market.

The Needle Coke Market Report is Segmented by Product Type (Petroleum-Based Needle Coke and Coal-Tar Pitch-Based Needle Coke), Application (Graphite Electrodes, Lithium-Ion Batteries, and Other Applications), and Geography (Asia-Pacific, North America, Europe, South America, and Middle-East and Africa). The Market Forecasts are Provided in Terms of Volume (Metric Tons).

Geography Analysis

Asia-Pacific leads with 88.31% of the needle coke market and is projected to preserve a 15.72% CAGR through 2030. China anchors both supply and demand, producing more than 900 million tons of crude steel in 2023 and operating the world's largest battery-anode capacity. Beijing's export license requirement for high-purity graphite introduced in late 2023 reduced outbound shipments by 91% year on year, a development that heightened supply-chain vigilance among Western buyers. India emerges as a demand multiplier as it targets 240-260 million tons of annual steel by 2035 and intends to lift EAF penetration to 40%.

North America accounts for a smaller base yet gains strategic relevance through localization. Tariff proposals of 93.5% on Chinese graphite underscore Washington's focus on self-reliance. Europe holds moderate volume growth as policy favors circular-economy steel production and battery recycling. Stora Enso's lignin-graphite plant in Finland signals commitment to lower-carbon anode material.

Other territories such as South America, the Middle East, and Africa are at earlier adoption stages but record growing interest. Saudi Arabia awarded Chevron Lummus Global a 75,000 TPA needle-coke complex license in 2024, marking the Middle East's first large-scale entry into specialty coke, while emerging steel clusters in Egypt and Brazil explore local electrode supply to reduce import exposure.

- Baosteel Group

- China National Petroleum Corporation

- ENEOS Corporation

- GrafTech International

- Indian Oil Corporation

- Mitsubishi Chemical Group Corporation

- Nippon Steel Corporation

- PetroChina

- Phillips 66 Company

- POSCO Future M

- Shandong Yida New Materials Co., Ltd.

- Shanxi Hongte Coal Chemical Co Ltd

- Sinopec

- Tokai Carbon Co., Ltd

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increasing Investments in EAF Steel Capacity

- 4.2.2 Soaring Li-Ion Battery Production for Evs

- 4.2.3 Scrap-Steel Mandates in China and EU

- 4.2.4 Refinery Upgrades Boosting Low-Sulphur Decant Oil Supply

- 4.2.5 Closed-Loop Graphite Recycling Initiatives

- 4.3 Market Restraints

- 4.3.1 Occupational and Environmental Hazards in Delayed Coking

- 4.3.2 Raw-Material Price Volatility (Decanter Oil, Coal Tar)

- 4.3.3 Prospect of Bio-Based Hard-Carbon Anode Materials

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

- 4.6 Price Overview

5 Market Size and Growth Forecasts (Volume)

- 5.1 By Product Type

- 5.1.1 Petroleum-based Needle Coke

- 5.1.2 Coal-tar Pitch-based Needle Coke

- 5.2 By Application

- 5.2.1 Graphite Electrodes

- 5.2.2 Lithium-ion Batteries

- 5.2.3 Other Applications

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Russia

- 5.3.3.6 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Baosteel Group

- 6.4.2 China National Petroleum Corporation

- 6.4.3 ENEOS Corporation

- 6.4.4 GrafTech International

- 6.4.5 Indian Oil Corporation

- 6.4.6 Mitsubishi Chemical Group Corporation

- 6.4.7 Nippon Steel Corporation

- 6.4.8 PetroChina

- 6.4.9 Phillips 66 Company

- 6.4.10 POSCO Future M

- 6.4.11 Shandong Yida New Materials Co., Ltd.

- 6.4.12 Shanxi Hongte Coal Chemical Co Ltd

- 6.4.13 Sinopec

- 6.4.14 Tokai Carbon Co., Ltd

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-need Assessment