|

市场调查报告书

商品编码

1907314

欧洲软包装市场:市场占有率分析、产业趋势与统计、成长预测(2026-2031年)Europe Flexible Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

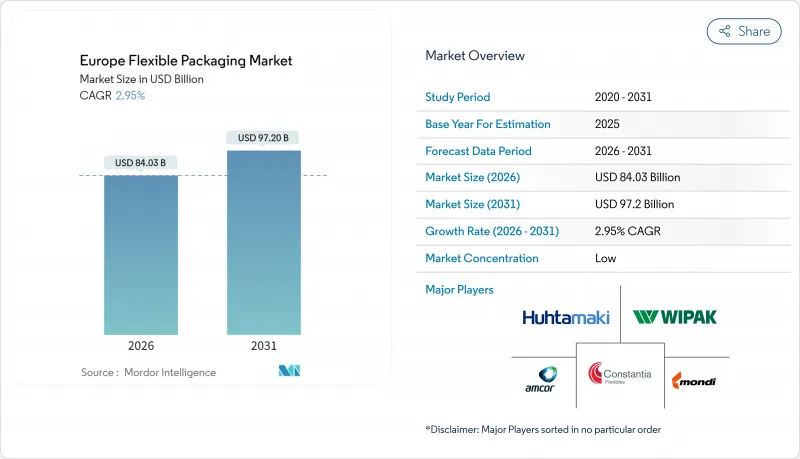

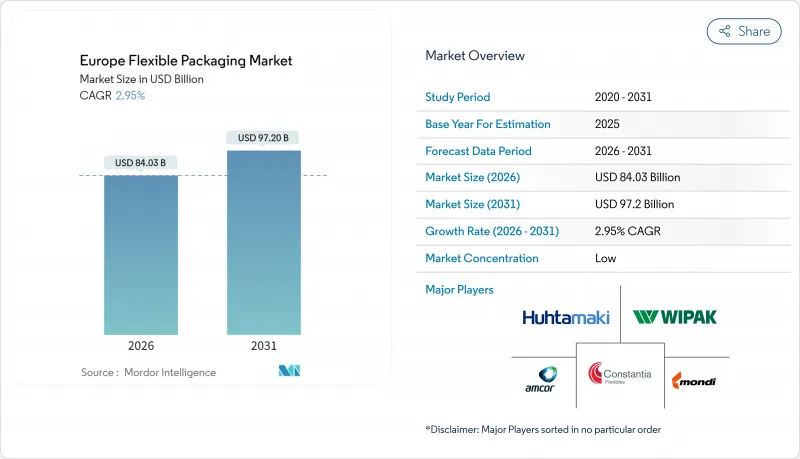

欧洲软包装市场预计到 2026 年价值将达到 840.3 亿美元,高于 2025 年的 816.2 亿美元。预计到 2031 年将达到 972 亿美元,2026 年至 2031 年的复合年增长率为 2.95%。

这一成长趋势主要受欧盟更严格的回收法规、不断增长的电子商务包裹量以及消费者对保质期长的便捷食品日益增长的需求所驱动。随着《包装和包装废弃物法规》(PPWR) 推动到2030年实现30%的再生塑胶含量,单一材料薄膜的创新正在加速,而可生物降解材料的选择也在小规模扩张。品牌所有者继续转向轻包装袋以降低物流成本,但由于薄膜和包装纸在食品和工业产品线中的广泛应用,它们仍然占据销售主导地位。市场竞争适中,前七大供应商的销售额仅占约四分之一,这为区域性专业企业在阻隔技术和数位印刷领域抓住利基市场机会创造了空间。

欧洲软包装市场趋势与洞察

欧盟循环经济目标推动对可再生单一材料薄膜的需求激增

包装废弃物指令 (PPWR) 要求到 2030 年,在欧洲销售的所有包装都必须可回收利用,这迫使加工商将多层结构重新设计为可机械回收的单一材料形式。雀巢公司报告称,其用于宠物食品的聚丙烯杀菌袋的碳足迹减少了 60%,而 Cycaflex 计划在 2025 年推出一系列完全可回收的产品,这些产品均采用消费后回收材料。由于纸张不受再生材料含量强制规定的约束,因此纸基替代品(例如科勒纸业的 NexPlus Barrier 系列)正日益受到青睐。为了弥补多层结构性能的下降,供应商正在测试无机涂层,例如 ORMOCER,它可以将聚丙烯基材上的氧气透过率降低 95%。对不可可再生材料征收生产者延伸责任成本加快了这一进程。

电子商务的快速成长推动了对柔性邮件包装和保护的需求。

在许多欧盟市场,线上零售持续保持两位数成长,推动了轻质邮寄袋和保护膜的普及,从而降低了每个小包裹的运输成本。像HP Indigo 200K这样的数位印刷机能够实现个性化的包装图案,用于季节性和区域性促销活动,并且与柔版印刷机相比,减少了设置废弃物。 Uteco的混合平台Sapphire Aqua采用符合食品接触法规的低迁移水性油墨,以1200 x 1200 dpi的分辨率和150米/分钟的速度进行列印。中小电商企业越来越多地将履约外包,并透过间接经销商进行发货,这些分销商更倾向于使用与自动化包装线相容的柔性包装形式。

欧盟更严格的塑胶和包装废弃物法规增加了合规成本。

中小型加工商被迫在可回收性认证、再生树脂整合和图形重新设计方面投入巨资,以满足统一的标籤标准。不合规包装的生产者延伸责任(EPR)费用可能使交付成本增加50%以上,在新的生产线投入运作之前,利润空间将被压缩。 2026年生效的PFAS禁令将迫使食品包装以防油涂层进行配方调整,而2028年生效的标籤规则将促使数千个SKU的图案设计改变。

细分市场分析

到2025年,塑胶将占欧洲软包装市场61.88%的份额,主要得益于聚乙烯在食品和电商领域的成本绩效优势。儘管石油基材仍主导,但随着品牌商追求生产者延伸责任(PPWR)合规性,欧洲软包装市场对生物基和可堆肥薄膜的兴趣日益浓厚,复合年增长率(CAGR)达到5.66%。纸张和纸板不受再生材料含量强制规定的约束,科勒纸业等供应商正在取得进展,其阻隔涂层等级的再生材料含量已达81.5%。金属化结构在医药和高端食品应用领域仍然很受欢迎,因为这些领域对绝对阻隔性很高,但由于其小众需求,受市场波动的影响较小。 PET的化学回收(包括解聚成与原生材料相当的原料)旨在确保到2027年食品级树脂的稳定供应,这可能是PET在日益严格的回收目标下稳定市场地位的关键里程碑。

欧洲软包装市场目前正在测试一种混合复合材料,将传统的聚烯层与可生物降解涂层结合。这种材料能够加速污垢降解,同时在整个保质期内保持密封完整性。虽然双向拉伸聚丙烯(BOPP)仍然是透明零食薄膜的主要材料,但聚丙烯(CPP)因其优异的密封性能而成为蒸馏罐盖的首选材料。儘管生质塑胶目前仅占总产量的一小部分,但它们正从可堆肥购物袋发展成为由聚乳酸(PLA)、聚丁二烯丙基三丙烯酸酯(PBAT)和淀粉混合物製成的高阻隔结构。加工商预测,在2028年或之后,随着相关法规的推出以推动需求和原料规模化生产,生物塑胶的成本竞争力将难以与化石基材料相提并论。

到2025年,薄膜和包装膜将占欧洲软包装市场43.92%的份额,主要面向烘焙产品、起司和工业零件等大众消费品类别。然而,在适应便利消费生活方式的产品(例如可蒸馏的蒸馏食品包装和微波炉即食食品)的推动下,软包装袋市场将持续成长,到2031年将维持6.55%的复合年增长率。自立式包装形式能更好地利用货架空间,提升品牌知名度,因此更受零售商青睐。雀巢的可回收高温杀菌杀菌袋展示了其如何在保持性能的同时,与传统包装相比减少60%的碳足迹(《包装摘要》)。

在农作物种子、肥料和DIY市场,由于重量限制,薄壁包装的应用受到限制,因此软包装袋仍占据主导地位。数位印刷技术的广泛应用使得加工商能够为5000件以下的小批量产品提供SKU级别的客製化服务,这鼓励了小众高端品牌在其产品生命週期的早期阶段就采用软包装袋,而不会影响单位经济效益。外包装和收缩膜套标作为防篡改解决方案在饮料和製药行业仍然十分重要,但其可回收性正受到越来越多的关注。欧洲PET塑胶拥有率的两位数成长进一步推动了对杀菌袋袋和立式袋能够确保产品的保鲜度和香气。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 为回应欧盟循环经济目标,对可再生单一材料薄膜的需求激增。

- 欧洲电子商务的加速成长正在推动对柔性邮寄袋和保护性包装的需求。

- 消费者对便利性和份量控制产品的偏好推动了柔软性袋的普及。

- 透过开发高阻隔共挤压技术延长蒸馏食品的保存期限

- 数位印刷和混合印刷技术的日益普及,使得小批量生产和大规模客製化成为可能。

- 欧洲宠物食品产业利用蒸馏和立式袋快速扩张

- 市场限制

- 欧盟更严格的塑胶和包装废弃物法规增加了合规成本。

- 多层薄膜回收基础设施有限,阻碍了循环经济目标的实现。

- 能源危机后聚烯和铝箔价格的波动将影响利润率。

- 来自永续性的品牌的来自严格的再生替代品的竞争压力

- 供应链分析

- 监理展望

- 技术展望

- 投资分析

- 波特五力分析

- 供应商的议价能力

- 买方的议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模与成长预测

- 依材料类型

- 塑胶

- 聚乙烯(PE)

- 双轴延伸聚丙烯(BOPP)

- 流延聚丙烯(CPP)

- 聚对苯二甲酸乙二醇酯(PET)

- 聚苯乙烯(PS)和发泡聚苯乙烯(EPS)

- 其他塑胶类型

- 纸和纸板

- 金属

- 可生物降解和可堆肥材料

- 塑胶

- 依产品类型

- 小袋

- 包包

- 薄膜和包装

- 其他产品类型

- 按最终用户行业划分

- 食物

- 饮料

- 医疗和药品

- 化妆品和个人护理

- 工业的

- 其他终端用户产业

- 按发行格式

- 直销

- 间接销售

- 按国家/地区

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 其他欧洲地区

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Amcor PLC

- Mondi Group

- Huhtamaki Oyj

- Constantia Flexibles GmbH

- Sealed Air Corporation

- Coveris Management GmbH

- ProAmpac LLC

- Novolex Holdings Inc.

- Sonoco Products Company

- Bischof+Klein SE & Co. KG

- Wipak Oy

- Schur International A/S

- Gualapack SpA

- ePac Holdings LLC

- Danaflex Group

- Cellografica Gerosa SpA

- Di Mauro Officine Grafiche SpA

- Bak Ambalaj Sanayi ve Ticaret AS

- Flextrus AB

- Sipospack Kft.

- Clondalkin Flexible Packaging

- Innovia Films Ltd.

- AR Packaging Group AB

- RKW Group

- Plastopil Hazorea Co. Ltd.

- Schur Flexibles Group

- Glenroy Inc.

- Leefung ASG Europe

第七章 市场机会与未来展望

Europe flexible packaging market size in 2026 is estimated at USD 84.03 billion, growing from 2025 value of USD 81.62 billion with 2031 projections showing USD 97.2 billion, growing at 2.95% CAGR over 2026-2031.

This trajectory follows tougher EU recycling mandates, expanding e-commerce parcel volumes, and accelerating demand for convenience foods that need extended shelf life. Mono-material film innovation is gathering pace as the Packaging and Packaging Waste Regulation (PPWR) pushes for 30% recycled plastic content by 2030, while biodegradable options are scaling from a small base. Brand owners continue to migrate toward lightweight pouches that cut logistics costs, yet films and wraps still dominate on volume thanks to their versatility in food and industrial lines. Moderate competitive intensity-as the seven largest suppliers together control only about one quarter of sales-creates room for regional specialists to capture niche opportunities in barrier technology and digital printing.

Europe Flexible Packaging Market Trends and Insights

Surge in Demand for Recyclable Mono-Material Films Driven by EU Circular Economy Targets

The PPWR obliges every package sold in Europe to be recyclable by 2030, prompting converters to redesign multilayer structures into mono-material formats that pass mechanical recycling streams. Nestle reports 60% carbon-footprint savings from polypropylene retort pouches for pet food, while Saica Flex plans a fully recyclable portfolio by 2025 that integrates post-consumer recyclate. Paper's exemption from recycled-content quotas gives a lift to paper-based alternatives such as Koehler Paper's NexPlus barrier line. To compensate for lost multilayer performance, suppliers are testing ORMOCER and other inorganic coatings that cut oxygen transmission rates by 95% on PP substrates. Extended Producer Responsibility fees now penalize non-recyclable materials, compressing timetables for adoption.

Accelerated Growth of E-Commerce Elevating Demand for Flexible Mailer & Protective Formats

Online retail continues to expand double-digit in many EU markets, spurring uptake of lightweight mailers and protective films that reduce freight cost per parcel. Digital presses such as HP Indigo 200K allow brands to personalize outer graphics for seasonal or regional promotions, while cutting set-up waste versus flexography. Uteco's SapphireAQUA hybrid platform prints 1,200 X 1,200 DPI at 150 mpm using low-migration, water-based inks that fulfil food-contact rules. Smaller e-commerce brands increasingly outsource fulfillment, channeling more volume through indirect distributors who favor flexible formats compatible with automated packing lines.

Stringent EU Plastics & Packaging-Waste Regulations Increasing Compliance Costs

Smaller converters face steep investments to certify recyclability, integrate recycled resin, and redesign graphics to meet harmonized labeling. Extended Producer Responsibility fees for non-compliant packs can add 50% or more to delivered cost, squeezing margins until new lines come on-stream. PFAS bans hitting in 2026 will force reformulation of grease-resistant coatings for food wraps, while labeling rules effective 2028 drive artwork changeovers across thousands of SKUs.

Other drivers and restraints analyzed in the detailed report include:

- Consumer Shift Toward Convenience & Portion-Control Products Boosting Flexible Pouch Adoption

- Technological Advances in High-Barrier Co-Extrusion Enhancing Shelf-Life for Ready Meals

- Limited Recycling Infrastructure for Multi-Layer Films Hampering Circularity Goals

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Plastics contributed 61.88% of Europe flexible packaging market share in 2025, powered by polyethylene's cost-to-performance edge in food and e-commerce lines. Petro-based substrates maintain leadership today, yet the Europe flexible packaging market is witnessing brisk interest in bio-based and compostable films expanding at a 5.66% CAGR as brand owners chase PPWR alignment. Paper and paperboard enjoy an exemption from recycled-content quotas, and suppliers such as Koehler Paper are making headway with barrier-coated grades that hit 81.5% recycling rates. Metalized structures still serve pharma and premium food where absolute barrier rules, but stand largely insulated from volume swings thanks to niche demand. Chemical recycling initiatives for PET, including depolymerization to virgin-like feedstock, aim to secure food-grade resin streams by 2027, a milestone that could stabilise PET's position amid rising recycled-content targets.

Europe flexible packaging market players are trialing hybrid laminates that pair traditional polyolefin layers with biodegradable coatings to accelerate soil decomposition while preserving seal integrity during shelf life. BOPP remains the workhorse for transparent snack films, whereas CPP is favoured for retortable lidding thanks to its sealability. Bioplastics, currently a sliver of overall tonnage, are moving beyond compostable shopping bags into high-barrier structures with blending of PLA, PBAT, and starch. Converters anticipate cost parity with fossil-based grades only after 2028, pending feedstock scale-up and mandates that spur demand.

Films and wraps carried 43.92% of Europe flexible packaging market share in 2025 because they serve high-volume categories such as bakery, cheese, and industrial components. Nonetheless, pouches are clocking a 6.55% CAGR through 2031, buoyed by retortable pet-food packs and microwaveable ready meals that fit on-the-go consumer lifestyles. Stand-up formats improve shelf utilisation and brand visibility, which retailers reward with premium placement. Nestle's recyclable retort pouch illustrates how brands can cut carbon footprints by 60% versus legacy structures while maintaining performance Packaging Digest.

Bag formats continue to dominate agricultural seeds, fertilizers, and DIY markets, where bulk weight limits the appeal of thin-wall alternatives. Digital printing's rise allows converters to offer SKU-level customisation in lot sizes below 5,000 units without compromising unit economics, encouraging niche gourmet brands to adopt pouch packaging earlier in their lifecycle. Overwraps and shrink sleeves remain relevant as tamper-evidence solutions in beverages and pharmaceuticals but face scrutiny over recyclability. Double-digit growth in European pet ownership further underpins demand for retort and stand-up pouches that guarantee product freshness and aroma protection.

The Europe Flexible Packaging Market Report is Segmented by Material Type (Plastics, Paper and Paperboard, and More), Product Type (Pouches, Bags, and More), End-User Industry (Food, Beverage, Healthcare and Pharmaceuticals, and More), Distribution (Direct Sales, Indirect Sales), and Country (Germany, United Kingdom, France, Italy, Spain, Rest of Europe). The Market Forecasts are Provided in Terms of Value (USD).

List of Companies Covered in this Report:

- Amcor PLC

- Mondi Group

- Huhtamaki Oyj

- Constantia Flexibles GmbH

- Sealed Air Corporation

- Coveris Management GmbH

- ProAmpac LLC

- Novolex Holdings Inc.

- Sonoco Products Company

- Bischof + Klein SE & Co. KG

- Wipak Oy

- Schur International A/S

- Gualapack SpA

- ePac Holdings LLC

- Danaflex Group

- Cellografica Gerosa SpA

- Di Mauro Officine Grafiche SpA

- Bak Ambalaj Sanayi ve Ticaret AS

- Flextrus AB

- Sipospack Kft.

- Clondalkin Flexible Packaging

- Innovia Films Ltd.

- AR Packaging Group AB

- RKW Group

- Plastopil Hazorea Co. Ltd.

- Schur Flexibles Group

- Glenroy Inc.

- Leefung ASG Europe

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surge in Demand for Recyclable Mono-Material Films Driven by EU Circular Economy Targets

- 4.2.2 Accelerated Growth of E-Commerce Elevating Demand for Flexible Mailer & Protective Formats in Europe

- 4.2.3 Consumer Shift Toward Convenience & Portion-Control Products Boosting Flexible Pouch Adoption

- 4.2.4 Technological Advances in High-Barrier Co-Extrusion Enhancing Shelf-Life for Ready Meals

- 4.2.5 Rising Penetration of Digital & Hybrid Printing Enabling Short Runs and Mass Personalisation

- 4.2.6 Rapid Expansion of European Pet-Food Industry Using Retort & Stand-Up Pouches

- 4.3 Market Restraints

- 4.3.1 Stringent EU Plastics & Packaging-Waste Regulations Increasing Compliance Costs

- 4.3.2 Limited Recycling Infrastructure for Multi-Layer Films Hampering Circularity Goals

- 4.3.3 Volatile Polyolefin & Aluminium-Foil Prices Post-Energy Crisis Impacting Margins

- 4.3.4 Competitive Pressure from Rigid Recyclable Alternatives Among Sustainability-Minded Brands

- 4.4 Supply-Chain Analysis

- 4.5 Regulatory Outlook

- 4.6 Technological Outlook

- 4.7 Investment Analysis

- 4.8 Porter's Five Forces Analysis

- 4.8.1 Bargaining Power of Suppliers

- 4.8.2 Bargaining Power of Buyers

- 4.8.3 Threat of New Entrants

- 4.8.4 Threat of Substitute Products

- 4.8.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material Type

- 5.1.1 Plastics

- 5.1.1.1 Polyethylene (PE)

- 5.1.1.2 Bi-orientated Polypropylene (BOPP)

- 5.1.1.3 Cast Polypropylene (CPP)

- 5.1.1.4 Polyethylene Terephthalate (PET)

- 5.1.1.5 Polystyrene (PS) and Expanded Polystyrene (EPS)

- 5.1.1.6 Other Plastics Types

- 5.1.2 Paper and Paperboard

- 5.1.3 Metal

- 5.1.4 Biodegradable and Compostable Materials

- 5.1.1 Plastics

- 5.2 By Product Type

- 5.2.1 Pouches

- 5.2.2 Bags

- 5.2.3 Films and Wraps

- 5.2.4 Other Product Type

- 5.3 By End-User Industry

- 5.3.1 Food

- 5.3.2 Beverage

- 5.3.3 Healthcare and Pharmaceuticals

- 5.3.4 Cosmetics and Personal Care

- 5.3.5 Industrial

- 5.3.6 Other End-Use Industries

- 5.4 By Distribution

- 5.4.1 Direct Sales

- 5.4.2 Indirect Sales

- 5.5 By Country

- 5.5.1 Germany

- 5.5.2 United Kingdom

- 5.5.3 France

- 5.5.4 Italy

- 5.5.5 Spain

- 5.5.6 Rest of Europe

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products & Services, and Recent Developments)

- 6.4.1 Amcor PLC

- 6.4.2 Mondi Group

- 6.4.3 Huhtamaki Oyj

- 6.4.4 Constantia Flexibles GmbH

- 6.4.5 Sealed Air Corporation

- 6.4.6 Coveris Management GmbH

- 6.4.7 ProAmpac LLC

- 6.4.8 Novolex Holdings Inc.

- 6.4.9 Sonoco Products Company

- 6.4.10 Bischof + Klein SE & Co. KG

- 6.4.11 Wipak Oy

- 6.4.12 Schur International A/S

- 6.4.13 Gualapack SpA

- 6.4.14 ePac Holdings LLC

- 6.4.15 Danaflex Group

- 6.4.16 Cellografica Gerosa SpA

- 6.4.17 Di Mauro Officine Grafiche SpA

- 6.4.18 Bak Ambalaj Sanayi ve Ticaret AS

- 6.4.19 Flextrus AB

- 6.4.20 Sipospack Kft.

- 6.4.21 Clondalkin Flexible Packaging

- 6.4.22 Innovia Films Ltd.

- 6.4.23 AR Packaging Group AB

- 6.4.24 RKW Group

- 6.4.25 Plastopil Hazorea Co. Ltd.

- 6.4.26 Schur Flexibles Group

- 6.4.27 Glenroy Inc.

- 6.4.28 Leefung ASG Europe

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-Space and Unmet-Need Assessment