|

市场调查报告书

商品编码

1911321

电动自行车马达:市场占有率分析、产业趋势与统计、成长预测(2026-2031)E-bike Motor - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

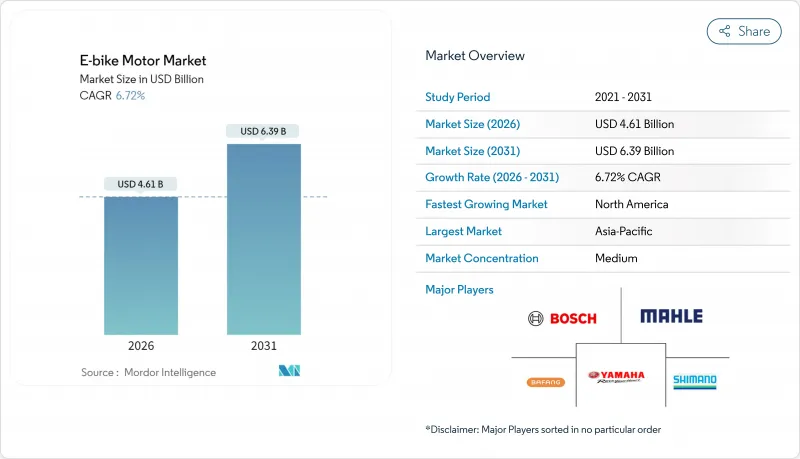

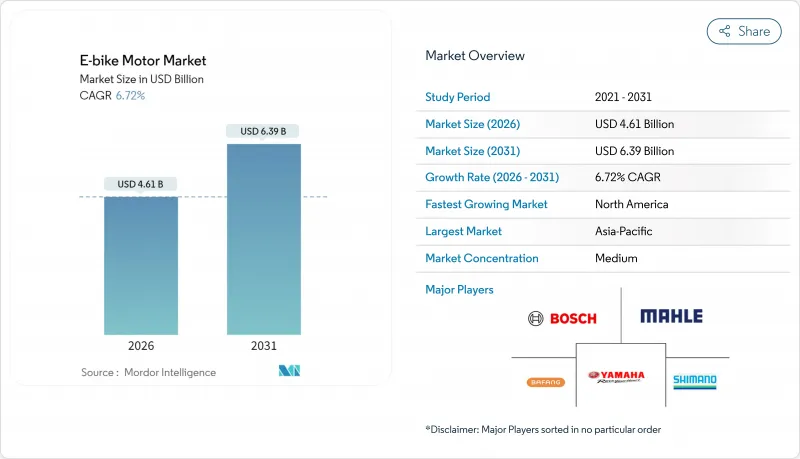

2025年电动自行车马达市场价值为43.2亿美元,预计到2031年将达到63.9亿美元,高于2026年的46.1亿美元。

预计在预测期(2026-2031 年)内,复合年增长率将达到 6.72%。

随着都市区碳减量法规日益严格、物流公司车辆电气化程度不断提高以及原始设备製造商 (OEM) 越来越多地采用软体定义驱动单元,市场需求正在加速成长。虽然电动自行车马达市场受益于电池价格的下降,但由于稀土元素磁铁价格波动,其利润率面临压力,迫使供应商考虑使用氮化铁和铁氧体等替代材料。产业整合的加速,例如Yamaha与 Bros 的合作以及博世智慧系统产品组合的扩展,标誌着产业正向垂直整合解决方案转型,这种解决方案结合了硬体和空中软体更新 (OTA)。儘管亚太地区仍然是主要的生产中心,但北美对高功率、带油门控制功能的车型的需求正在推动对当地组装的新投资。

全球电动自行车马达市场趋势与洞察

城市通勤者的需求迅速成长

企业自行车租赁专案正在创造巨大且可预测的需求,并提高马达供应商的最低品质标准。税收优惠政策使终端用户成本降低高达 40%,并促使消费者偏好配备车载互联功能的优质驱动单元。随着租赁业务在法国和北欧国家的扩张,电动自行车马达市场基于 3-4 年的车队更新週期,拥有稳定且类似年金的销售量。马达製造商正利用这种稳定性来证明增加研发投入的合理性,尤其是在能够减少停机时间的基于人工智慧的诊断技术方面。主要城市通勤专用电动自行车道的普及进一步巩固了市场需求。

欧盟和中国收紧二氧化碳排放目标

欧洲车辆排放气体法规和中国GB 17761-2024标准的变更迫使供应商将重点放在提高每公斤效率而非峰值功率。博世镁合金机壳的Performance Line CX Gen 5马达在保持85牛顿米扭矩的同时,重量减轻了100克。中国现在要求整合电池管理系统、防篡改硬体和卫星定位系统,这为拥有先进软体技术的企业提供了激励,同时也对价格分布组装提出了惩罚。这些法规正在加速产业从铅酸电池向锂电池的转型,并巩固了对相应马达电子产品的需求。虽然合规成本增加,但领先采用者获得了领先优势,并能进入高度监管的市场,从而提升了其在电动自行车马达市场的品牌价值。

依赖钕磁铁

中国加工了全球约85%的稀土元素产量,这使得电机整车製造商极易受到出口限制和现货价格飙升的影响。在中国境外建立加工设施需要多年的资本投资和环境审批,进一步延长了这种脆弱性。此外,应对复杂的法规结构和确保永续的供应链也加剧了这项挑战。由于磁铁供应波动带来的利润风险,电动自行车马达市场正翘首期盼氮化铁和铁氧体等替代材料的规模化应用,这些材料有望在长期内提供更稳定、更具成本效益的解决方案。

细分市场分析

到2025年,轮毂式马达将凭藉低成本、即插即用安装便利性和广泛普及等优势,保持其在电动自行车马达市场67.58%的份额。然而,中置马达预计将以8.36%的复合年增长率成长,并凭藉更优化的重量分配和传动系统协同效应,重塑高端市场格局。轮毂式马达创新者正积极应对,推出诸如无离合器滑行和密封多速变速箱等创新功能,以期在经济型城市自行车市场继续保持竞争力。

零件采购方式的变化凸显了这个趋势。汽车级供应商正在引入专有的扭矩感测器堆迭和基于ASIC的控制器,以提高中置马达的效率。韧体更新将使用户能够选择功率映射,进一步提升个人化程度。轮毂马达系统将在入门级市场和共享出行车队中占据主导地位,而高利润的中置马达平台将攫取巨额利润,加剧电动自行车马达市场的分化。

到2025年,城市通勤自行车将占电动自行车总销量的42.86%,并将持续到2020年代中期,成为电动自行车马达市场规模的支柱。地方政府建造专用车道以及提高对雇主的税收优惠政策,是推动市场基本需求的主要因素。同时,电动山地自行车(e-MTB)的出货量将以8.02%的复合年增长率(CAGR)实现最快成长,这主要得益于其高牵引扭力、自适应悬吊以及29吋底盘标准。专为山地自行车设计的马达配备了气压感测器,可根据坡度调节功率输出,从而提高电池效率。城市车队车型则强调耐候性和预测性维护警报功能,有助于减少配送公司的停机时间。

这两个细分市场的价格弹性不同,电动山地自行车的平均售价约为通勤车型的1.7倍,证明了高性能马达的必要性。城市平台推动了大规模生产,降低了电子元件的单位成本,进而对高性能电动山地自行车产生了积极影响。这种良性循环维持了两个细分市场的销售成长,并增强了电动自行车马达市场的整体实力。

区域分析

亚太地区将在2025年占据全球市场78.05%的份额,这主要得益于中国从稀土元素矿开采到最终组装的完整供应链。预计到2024年,中国电动两轮车出口额将超过400亿元人民币(约55亿美元),充分展现了该地区强大的生产能力。日本提供高品质的动力传动系统技术,而印度则透过与武藏精密等公司的合资企业,迅速崛起为组装中心。区域性优惠政策(例如降低增值税和都市区拥堵附加税)正在推动国内市场的发展,提升出口竞争力,巩固亚太地区作为电动自行车动力传动系统市场基地的地位。

到2031年,北美将维持9.14%的最高成长率,这主要得益于消费者偏好转向高功率、油门控制的车型。联邦政府的奖励策略和各州政府的补贴计画支持国内製造业,推动了产能扩张,例如eBliss Global在纽约的工厂。各州监管政策的差异为可自订韧体和模组化控制器设计创造了利基市场。企业车队的电气化和不断扩大的越野车道进一步丰富了需求结构,提升了该地区在电动自行车马达市场的重要性。

欧洲是一个成熟且充满创新活力的市场。儘管受宏观经济不利因素影响,预计2024年销量将有所下降,但凭藉其严格的EN 15194认证要求,该地区仍保持着技术主导。德国的租赁计划正在整个地区扩展,推动了对高规格驱动系统的稳定订单。供应链本地化倡议,包括在匈牙利建立电池工厂和在波兰建立驱动单元工厂,旨在减少对亚洲的依赖。在政策制定者讨论统一限速标准之际,欧洲原始设备製造商(OEM)正在提升250W功率范围内的马达效率,从而巩固其在全球电动自行车马达市场的高端品牌地位。

其他福利:

- Excel格式的市场预测(ME)表

- 3个月的分析师支持

目录

第一章 引言

- 研究假设和市场定义

- 调查范围

第二章调查方法

第三章执行摘要

第四章 市场情势

- 市场概览

- 市场驱动因素

- 城市通勤者迅速接受电动自行车

- 欧盟和中国严格的二氧化碳排放目标推动轻型电动推进系统的发展

- 披萨外送和小包裹配送车队迅速转向电动自行车

- OEM厂商对整合智慧马达和感测器组件的需求

- 为货运和山地自行车Start-Ups创业融资

- 创新磁性材料可减少稀土元素用量40%

- 市场限制

- 马达和电池组合的初始成本较高

- 钕铁硼磁铁供应链中的脆弱性

- 消防安全召回导致保费上涨

- 各国电动自行车限速政策的差异导致平台推出延迟。

- 价值/供应链分析

- 监管环境

- 技术展望

- 波特五力分析

- 新进入者的威胁

- 买方的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争

第五章 市场规模与成长预测

- 依马达类型

- 轮毂式马达

- 中置马达

- 电动自行车

- 城市/都市区

- 电动山地自行车/EMTB

- E-Cargo

- 按额定输出

- 小于250瓦

- 250~500 W

- 500瓦或以上

- 按销售管道

- 原始设备製造商/工厂设备

- 售后市场/维修

- 按地区

- 北美洲

- 美国

- 加拿大

- 北美其他地区

- 南美洲

- 巴西

- 阿根廷

- 其他南美洲

- 欧洲

- 德国

- 英国

- 法国

- 义大利

- 西班牙

- 荷兰

- 俄罗斯

- 其他欧洲地区

- 亚太地区

- 中国

- 日本

- 印度

- 韩国

- 澳洲

- 亚太其他地区

- 中东和非洲

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 土耳其

- 埃及

- 南非

- 其他中东和非洲地区

- 北美洲

第六章 竞争情势

- 市场集中度

- 策略趋势

- 市占率分析

- 公司简介

- Bafang Electric(Suzhou)Co., Ltd.

- Robert Bosch GmbH

- Shimano Inc.

- Yamaha Motor Co., Ltd.

- TDCM Corporation Limited

- Panasonic Holdings Corporation

- Nidec Corporation

- Mahle GmbH

- Suzhou Xiongda Electric Machine Co., Ltd.

- Jiangsu Dapu Motor Co., Ltd.

- TranzX

- Ananda Drive Techniques(Shanghai)Co., Ltd.

- Yadea Technology Group Co., Ltd.

- SportTech GmbH

- Valeo SA

- Polini Motori SpA

- Fazua GmbH

- TQ-Systems GmbH

- Wuxi Truckrun Motor Co., Ltd.

第七章 市场机会与未来展望

The e-bike motor market was valued at USD 4.32 billion in 2025 and estimated to grow from USD 4.61 billion in 2026 to reach USD 6.39 billion by 2031, at a CAGR of 6.72% during the forecast period (2026-2031).

Demand accelerates as cities tighten carbon-reduction mandates, logistics firms electrify fleets, and OEMs roll out software-defined drive units. The e-bike motor market benefits from falling battery prices, yet faces margin pressure from rare-earth magnet volatility that prompts suppliers to explore iron-nitride and ferrite alternatives. Intensifying consolidation-the Yamaha-Brose deal and Bosch's expanding smart-system portfolio-signals a shift toward vertically integrated offerings that blend hardware with over-the-air software. Asia-Pacific remains the primary production hub, but North America's appetite for high-power, throttle-enabled models drives fresh investment in local assembly lines.

Global E-bike Motor Market Trends and Insights

Soaring Urban-Commuter Uptake

Corporate bike-leasing programs fuel predictable, bulk demand that raises minimum quality thresholds for motor suppliers. Tax incentives lower end-user costs by up to 40%, channeling consumer preference toward premium drive units with onboard connectivity. As leasing spreads to France and the Nordics, the e-bike motor market secures an annuity-like volume stream anchored by fleet replacement cycles of three to four years. Motor makers leverage this stability to justify higher R&D outlays, especially for AI-based diagnostics that cut downtime. The growth of commuter e-bike lanes in major cities further reinforces baseline demand.

Stricter EU and China CO2 Targets

Revised European vehicle-emission rules and China's GB 17761-2024 standard press suppliers to maximize efficiency per kilogram, rather than peak wattage. Bosch's magnesium-housing Performance Line CX Gen 5 trims 100 g in weight yet maintains 85 Nm torque. China now mandates embedded battery-management systems, anti-tamper hardware, and satellite positioning, rewarding firms with advanced software stacks and penalizing low-end assemblers. These rulebooks also accelerate the industry's shift from lead-acid to lithium packs, cementing demand for compatible motor electronics. Compliance costs rise, but early movers gain a head start and access to high-regulation markets, reinforcing their brand equity in the e-bike motor market.

Dependence on NdFeB Magnets

China processes roughly 85% of global rare-earth output, leaving motor OEMs vulnerable to export restrictions and spot-price spikes. Setting up processing facilities beyond China's borders demands years of capital investment and environmental approvals, extending the period of vulnerability. This challenge is compounded by the complexities of navigating regulatory frameworks and securing sustainable supply chains. As the e-bike motor market grapples with margin risks linked to magnet supply fluctuations, it awaits the scaling of iron-nitride or ferrite alternatives, which could provide a more stable and cost-effective solution in the long term.

Other drivers and restraints analyzed in the detailed report include:

- OEM Push for Smart Integrated Systems

- Electrification of Delivery Fleets

- Speed-Cap Policy Divergence

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Hub motors retained a 67.58% e-bike motor market share in 2025, underpinned by low cost, plug-and-play installation, and widespread availability. Yet mid-drive units, projected to register an 8.36% CAGR, are reshaping premium categories through improved weight distribution and drivetrain synergy. Hub innovators answer back with features such as clutch-free coasting and sealed multi-speed gearboxes, prolonging their relevance in budget city bikes.

Shifts in component sourcing underscore the trajectory. Automotive-grade suppliers bring in IP-protected torque-sensor stacks and ASIC-based controllers that elevate mid-drive efficiency. Firmware updates enable user-selectable power maps, furthering personalization. While hub systems will dominate volume for entry-level and shared-mobility fleets, margin-rich mid-drive platforms will capture outsized profit pools, reinforcing the two-tier structure within the e-bike motor market.

Urban commuting bikes accounted for 42.86% of sales in 2025 and remain the anchor of the e-bike motor market size through mid-decade. City authorities add protected lanes and extend employer tax perks, magnifying baseline demand. At the same time, e-MTB shipments exhibit the fastest 8.02% CAGR as high-traction torque and adaptive suspension merge with 29-inch chassis standards. Motors designed for mountain bikes integrate barometric sensors to modulate power based on gradient, improving battery utilization. Fleet urban models emphasize weather sealing and predictive maintenance alerts that cut downtime for couriers.

The two segments differ on price elasticity; e-MTBs command ASPs approximately 1.7 times that of commuter units, justifying richer motor features. Urban platforms drive scale production, pushing down per-unit electronics cost, which then trickles into performance-oriented e-MTBs. This virtuous loop helps sustain volume growth across both segments, reinforcing the the overall robustness of the e-bike motor market.

The E-Bike Motor Market Report is Segmented by Motor Type (Hub Motor and Mid-Drive Motor), E-Bike Type (Urban/City, E-Mountain/EMTB, and E-Cargo), Power Rating (Below 250W, 250-500W, and Above 500W), Sales Channel (OEM/Factory-fit and Aftermarket/Retrofit), and Geography (North America, South America, Europe, Asia-Pacific, and the Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific dominated with 78.05% share in 2025 due to China's end-to-end supply chain that spans rare-earth mining to final assembly. Chinese electric two-wheeler exports exceeded CNY 40 billion (USD 5.5 billion) in 2024, underscoring regional capacity. Japan contributes premium drivetrain engineering, and India emerges as a fast-growing assembly node via joint ventures such as Musashi Seimitsu's partnership for integrated powertrains. Regional incentives-reduced VAT and urban congestion levies-bolster domestic ownership and export competitiveness, solidifying Asia-Pacific as the cornerstone of the e-bike motor market.

North America exhibits the fastest 9.14% CAGR through 2031 as consumer preferences tilt toward high-power, throttle-enabled models. Federal stimulus for domestic manufacturing and state-level rebates spur capacity additions like eBliss Global's New York plant. Regulatory heterogeneity across states creates niches for adaptable firmware and modular controller designs. Corporate fleet conversions and expanding trail access further diversify demand profiles, enhancing regional significance to the e-bike motor market.

Europe presents a mature but innovation-rich arena. Although unit sales tapered in 2024 amid macro headwinds, the continent remains technology-leading due to rigorous EN 15194 certification requirements. German leasing programs expand across the bloc, funneling steady orders for high-spec drive systems. Supply-chain localization efforts, notably battery-cell plants in Hungary and drive-unit factories in Poland, aim to offset Asian dependencies. As policymakers debate speed-cap harmonization, European OEMs refine motor efficiency within 250 W boundaries, reinforcing their premium brand cachet in the global e-bike motor market.

- Bafang Electric (Suzhou) Co., Ltd.

- Robert Bosch GmbH

- Shimano Inc.

- Yamaha Motor Co., Ltd.

- TDCM Corporation Limited

- Panasonic Holdings Corporation

- Nidec Corporation

- Mahle GmbH

- Suzhou Xiongda Electric Machine Co., Ltd.

- Jiangsu Dapu Motor Co., Ltd.

- TranzX

- Ananda Drive Techniques (Shanghai) Co., Ltd.

- Yadea Technology Group Co., Ltd.

- SportTech GmbH

- Valeo S.A.

- Polini Motori S.p.A.

- Fazua GmbH

- TQ-Systems GmbH

- Wuxi Truckrun Motor Co., Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Soaring Urban-Commuter Adoption of E-Bikes

- 4.2.2 Stricter EU and China CO2 Targets Favoring Lightweight Electric Propulsion

- 4.2.3 Rapid Transition of Pizza/Parcel Delivery Fleets To E-Bikes

- 4.2.4 OEM Demand for Integrated Smart-Motor and Sensor Packages

- 4.2.5 Venture Funding into Mid-Drive Start-Ups for Cargo and MTB Niches

- 4.2.6 Magnet-Material Breakthroughs Cut Rare-Earth Use by 40%

- 4.3 Market Restraints

- 4.3.1 High Upfront Motor/Battery Pairing Cost

- 4.3.2 Supply-Chain Vulnerability for NdFeB Magnets

- 4.3.3 Fire-Safety Recalls Triggering Insurance Premium Hikes

- 4.3.4 National E-Bike Speed-Cap Policy Divergence Delaying Platform Launches

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

5 Market Size & Growth Forecasts (Value, USD)

- 5.1 By Motor Type

- 5.1.1 Hub Motor

- 5.1.2 Mid-drive Motor

- 5.2 By E-Bike Type

- 5.2.1 Urban / City

- 5.2.2 E-Mountain / EMTB

- 5.2.3 E-Cargo

- 5.3 By Power Rating

- 5.3.1 Below 250 W

- 5.3.2 250 - 500 W

- 5.3.3 Above 500 W

- 5.4 By Sales Channel

- 5.4.1 OEM / Factory-fit

- 5.4.2 Aftermarket / Retrofit

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Rest of North America

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Netherlands

- 5.5.3.7 Russia

- 5.5.3.8 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 India

- 5.5.4.4 South Korea

- 5.5.4.5 Australia

- 5.5.4.6 Rest of Asia-Pacific

- 5.5.5 Middle-East and Africa

- 5.5.5.1 United Arab Emirates

- 5.5.5.2 Saudi Arabia

- 5.5.5.3 Turkey

- 5.5.5.4 Egypt

- 5.5.5.5 South Africa

- 5.5.5.6 Rest of Middle-East and Africa

- 5.5.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (Includes Global Level Overview, Market Level Overview, Core Segments, Financials as Available, Strategic Information, Market Rank/Share for Key Companies, Products & Services, and Recent Developments)

- 6.4.1 Bafang Electric (Suzhou) Co., Ltd.

- 6.4.2 Robert Bosch GmbH

- 6.4.3 Shimano Inc.

- 6.4.4 Yamaha Motor Co., Ltd.

- 6.4.5 TDCM Corporation Limited

- 6.4.6 Panasonic Holdings Corporation

- 6.4.7 Nidec Corporation

- 6.4.8 Mahle GmbH

- 6.4.9 Suzhou Xiongda Electric Machine Co., Ltd.

- 6.4.10 Jiangsu Dapu Motor Co., Ltd.

- 6.4.11 TranzX

- 6.4.12 Ananda Drive Techniques (Shanghai) Co., Ltd.

- 6.4.13 Yadea Technology Group Co., Ltd.

- 6.4.14 SportTech GmbH

- 6.4.15 Valeo S.A.

- 6.4.16 Polini Motori S.p.A.

- 6.4.17 Fazua GmbH

- 6.4.18 TQ-Systems GmbH

- 6.4.19 Wuxi Truckrun Motor Co., Ltd.