|

市场调查报告书

商品编码

1740872

替代蛋白质生产设备市场机会、成长动力、产业趋势分析及 2025 - 2034 年预测Alternative Protein Production Equipment Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

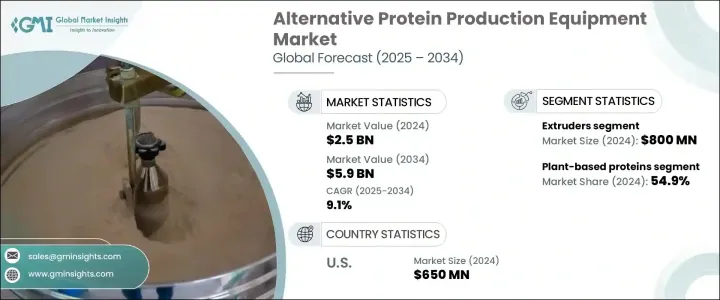

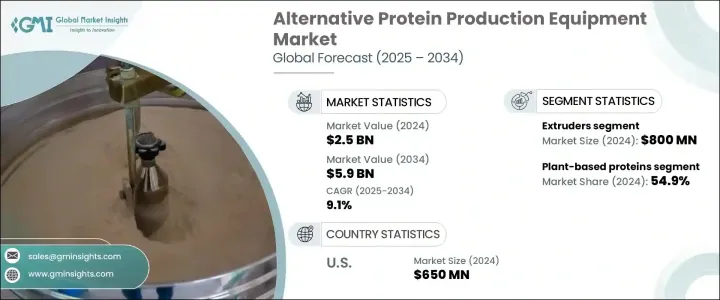

2024年,全球替代蛋白质生产设备市场价值为25亿美元,预计到2034年将以9.1%的复合年增长率成长,达到59亿美元。这一增长主要源于全球饮食习惯的重大转变,消费者越来越多地寻求符合健康、永续性和道德消费等现代价值观的食品替代品。随着人口成长加速和主要市场收入水准的提高,对可扩展、可靠且清洁的食品生产技术的需求日益增长。传统食品体系面临压力,促使该产业投资支持替代蛋白质的先进加工设备。这些解决方案对于改变食品生产方式至关重要,它们在不影响营养和口味的情况下,为传统肉类提供可行的替代品。

健康生活意识的不断增强,是推动非传统蛋白质生产设备需求成长的另一个驱动力。现今的消费者对饮食更加挑剔,主动避免食用与慢性疾病相关的食物,同时选择那些能够促进更健康生活方式的食品。这种思维模式的转变正促使食品製造商探索更精简、富含纤维且不含激素或抗生素等添加剂的蛋白质替代品。因此,生产商面临越来越大的压力,需要投资于能够高效生产这些高需求蛋白质产品的先进设备。这正在重塑产业格局,并为食品生产和设备设计树立新的标准。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 25亿美元 |

| 预测值 | 59亿美元 |

| 复合年增长率 | 9.1% |

就设备类型而言,挤压机引领市场,2024年创造了8亿美元的收入。预计到2034年,该细分市场的复合年增长率将达到约9.4%。这些机器对于将蛋白质成分塑造成吸引寻求传统肉类替代品的消费者的口感至关重要。尤其是高水分挤压技术,它被用来复製动物组织中的纤维结构,提升植物蛋白消费者的食用体验,并有助于推动替代食品的更广泛普及。

从应用角度来看,植物蛋白在2024年占据了总市场份额的54.9%,预计在预测期内的复合年增长率约为9.6%。由于其成本优势、市场成熟度和消费者接受度,该领域早期就吸引了市场的注意。各种植物来源的产品在食品杂货货架和餐饮服务菜单中占据了重要地位,吸引了越来越多注重健康的消费者和对更永续食品系统感兴趣的消费者。对加工能力提升的追求促使人们在分离机、搅拌机、干燥机和挤出机等设备上进行新的投资,这些设备专门用于处理植物来源的原料并优化产出品质。

就最终用途而言,食品业继续占据市场主导地位,在2024年占据最大份额,预计到2034年仍将保持这一领先地位。随着企业竞相迎合不断变化的消费者偏好,它们正在大力投资精密工程设备,以支持替代蛋白质产品的大规模生产。无论是老牌食品品牌或新兴企业,都在投入资金升级生产线,以保持竞争力。由于满足品质标准和生产可扩展性的需求,对发酵槽、料斗、生物反应器和大容量挤出机的需求正在增长。零售兴趣的增强以及消费者对健康和环保产品的支出增加,进一步加速了这一趋势。

从区域来看,美国以2024年6.5亿美元的估值领先北美市场,预计2034年复合年增长率将达到9.5%。人们对永续饮食习惯和植物性饮食的关注,正促使製造商建立或扩大用于替代蛋白质生产的设施。消费者偏好的转变推动了对创新食品加工技术的需求,并强化了先进自动化机械在该领域的重要性。需求的成长为设备製造商创造了新的机会,使其能够提供更专业的解决方案,以满足食品生产商的需求。

积极影响替代蛋白质生产设备市场的关键参与者包括安德里茨股份公司 (ANDRITZ AG)、阿法拉伐公司 (Alfa Laval AB)、比克食品设备公司 (BAK Food Equipment)、布勒股份公司 (Buhler AG)、FAM STUMABO、毕派克斯国际有限公司 (Bepex International LLC)、基伊埃比 (BTGEA)、Mengers International Corporation、JerGEA. Marel 公司、莫迪维克 (MULTIVAC Sepp Haggenmuller SE & Co. KG)、罗伯特·赖泽公司 (Robert Reiser & Co., Inc.)、罗克韦尔自动化公司 (Rockwell Automation)、保罗·穆勒公司 (Paul Mueller Company)、Scansteel Foodtech A/S 和斯必克流体技术公司 (SPX FLOW)。这些公司在设计和交付先进机械系统方面处于领先地位,以满足现代蛋白质生产不断变化的需求。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 影响价值链的因素

- 利润率分析

- 中断

- 未来展望

- 製造商

- 经销商

- 川普政府关税分析

- 对贸易的影响

- 贸易量中断

- 报復措施

- 对产业的影响

- 供应方影响(原料)

- 主要材料价格波动

- 供应链重组

- 生产成本影响

- 需求面影响(销售价格)

- 价格传导至终端市场

- 市占率动态

- 消费者反应模式

- 受影响的主要公司

- 策略产业反应

- 供应链重组

- 定价和产品策略

- 政策参与

- 展望与未来考虑

- 对贸易的影响

- 供应商格局

- 交易分析

- 利润率分析

- 技术概述

- 重要新闻和倡议

- 监管格局

- 衝击力

- 成长动力

- 全球人口快速成长

- 越来越重视健康和保健

- 消费者对永续蛋白质的需求不断增长

- 扩大植物蛋白生产

- 产业陷阱与挑战

- 初始资本投入高

- 与现有系统整合的复杂性

- 成长动力

- 成长潜力分析

- 波特的分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 公司市占率分析

- 竞争定位矩阵

- 战略展望矩阵

第五章:市场估计与预测:依设备类型,2021 - 2034 年

- 主要趋势

- 挤出机

- 均质机

- 搅拌机

- 烘干机

- 过滤装置

第六章:市场估计与预测:依营运模式,2021 年至 2034 年

- 主要趋势

- 半自动

- 自动的

第七章:市场估计与预测:按应用,2021 - 2034 年

- 主要趋势

- 植物蛋白

- 培养肉

- 昆虫蛋白

- 蛋替代品

第八章:市场估计与预测:依最终用途,2021 - 2034 年

- 主要趋势

- 食品工业

- 动物饲料

- 营养保健品

- 其他的

第九章:市场估计与预测:按加工技术,2021 - 2034 年

- 主要趋势

- 纹理化

- 发酵

- 乳化

- 喷雾干燥

第十章:市场估计与预测:按地区,2021 - 2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- MEA

- 南非

- 沙乌地阿拉伯

- 阿联酋

第 11 章:公司简介

- Alfa Laval AB

- ANDRITZ AG

- BAK Food Equipment

- Bepex International LLC

- Buhler AG

- FAM STUMABO

- GEA Group Aktiengesellschaft

- JBT Marel Corporation

- Middleby Corporation

- MULTIVAC Sepp Haggenmuller SE & Co. KG

- Paul Mueller Company

- Robert Reiser & Co., Inc.

- Rockwell Automation

- Scansteel Foodtech A/S.

- SPX FLOW

The Global Alternative Protein Production Equipment Market was valued at USD 2.5 billion in 2024 and is estimated to grow at a CAGR of 9.1% to reach USD 5.9 billion by 2034. This growth is largely driven by a major shift in global eating habits as consumers increasingly seek food alternatives that align with modern values around health, sustainability, and ethical consumption. With population growth accelerating and income levels rising across key markets, the demand for scalable, reliable, and clean food production technologies is gaining momentum. Traditional food systems are under pressure, prompting the industry to invest in advanced processing equipment that supports alternative proteins. These solutions are becoming critical in transforming how food is produced, offering a viable substitute to conventional meat without compromising on nutrition or taste.

The growing awareness around healthy living is another driving force behind the rise in demand for equipment capable of producing non-traditional protein sources. Consumers today are far more selective about what they eat, actively avoiding foods linked to chronic diseases while embracing options that fuel a more energetic lifestyle. This shift in mindset is encouraging food manufacturers to explore protein alternatives that are leaner, richer in fiber, and free from additives like hormones or antibiotics. As a result, there is increased pressure on producers to invest in advanced machinery capable of efficiently manufacturing these high-demand protein formats. This is reshaping the industry landscape and establishing new standards in food production and equipment design.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $2.5 Billion |

| Forecast Value | $5.9 Billion |

| CAGR | 9.1% |

In terms of equipment types, extruders led the market by generating USD 800 million in revenue in 2024. This segment is expected to grow at a CAGR of approximately 9.4% through 2034. These machines are essential for shaping protein ingredients into textures that appeal to consumers seeking substitutes for conventional meat. High-moisture extrusion technology, in particular, is being used to replicate the fibrous structure found in animal tissue, enhancing the eating experience for plant-based protein consumers and helping to drive broader adoption of alternative food products.

Application-wise, plant-based proteins accounted for 54.9% of the total market share in 2024 and are projected to grow at a CAGR of about 9.6% during the forecast period. This segment has captured early market attention thanks to its cost advantages, market readiness, and consumer acceptance. Products derived from various plant sources are finding a strong foothold in grocery aisles and foodservice menus, appealing to a growing group of health-conscious consumers and those interested in more sustainable food systems. The push for improved processing capabilities has led to new investments in equipment such as separators, mixers, dryers, and extruders, tailored to handle plant-derived inputs and optimize output quality.

The food industry continues to dominate the market in terms of end use, holding the largest share in 2024, and is expected to maintain this lead through 2034. As companies race to cater to evolving consumer preferences, they are investing heavily in precision-engineered equipment that supports large-scale production of alternative protein products. Both established food brands and emerging companies are directing capital toward upgrading their manufacturing lines to stay competitive. Demand for fermenters, hoppers, bioreactors, and high-volume extruders is rising, driven by the need to meet quality standards and production scalability. Enhanced retail interest and increased consumer spending on health-driven and environmentally friendly products are further accelerating this trend.

Regionally, the United States led the North American market with a valuation of USD 650 million in 2024 and is set to grow at a CAGR of 9.5% through 2034. Interest in sustainable eating practices and plant-forward diets is encouraging manufacturers to set up or expand facilities geared toward alternative protein production. The shift in consumer preferences is pushing demand for innovative food processing technologies and reinforcing the importance of advanced, automated machinery in this space. This rise in demand has created new opportunities for equipment manufacturers to offer more specialized solutions tailored to the needs of food producers.

Key players actively shaping the alternative protein production equipment market include ANDRITZ AG, Alfa Laval AB, BAK Food Equipment, Buhler AG, FAM STUMABO, Bepex International LLC, GEA Group Aktiengesellschaft, Middleby Corporation, JBT Marel Corporation, MULTIVAC Sepp Haggenmuller SE & Co. KG, Robert Reiser & Co., Inc., Rockwell Automation, Paul Mueller Company, Scansteel Foodtech A/S, and SPX FLOW. These companies are at the forefront of designing and delivering advanced machinery systems that meet the evolving needs of modern protein production.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definitions

- 1.2 Base estimates & calculations

- 1.3 Forecast calculations

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factor affecting the value chain

- 3.1.2 Profit margin analysis

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.2 Trump administration tariffs analysis

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-Side impact (Raw Materials)

- 3.2.2.2 Price volatility in key materials

- 3.2.2.3 Supply chain restructuring

- 3.2.2.4 Production cost implications

- 3.2.2.5 Demand-Side impact (Selling Price)

- 3.2.2.6 Price transmission to end markets

- 3.2.2.7 Market share dynamics

- 3.2.2.8 Consumer response patterns

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Supplier landscape

- 3.4 Trade analysis

- 3.5 Profit margin analysis

- 3.6 Technological overview

- 3.7 Key news & initiatives

- 3.8 Regulatory landscape

- 3.9 Impact forces

- 3.9.1 Growth drivers

- 3.9.1.1 Rapidly growing global population

- 3.9.1.2 Growing emphasis on health and wellness

- 3.9.1.3 Rising consumer demand for sustainable proteins

- 3.9.1.4 Expansion of plant-based protein production

- 3.9.2 Industry pitfalls & challenges

- 3.9.2.1 High initial capital investment

- 3.9.2.2 Complexity of integration with existing systems

- 3.9.1 Growth drivers

- 3.10 Growth potential analysis

- 3.11 Porter's analysis

- 3.12 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Equipment Type, 2021 - 2034 (USD Billion) (Thousand Units)

- 5.1 Key trends

- 5.2 Extruders

- 5.3 Homogenizers

- 5.4 Mixers

- 5.5 Dryers

- 5.6 Filtration units

Chapter 6 Market Estimates & Forecast, By Mode of Operation, 2021 - 2034 (USD Billion) (Thousand Units)

- 6.1 Key trends

- 6.2 Semi-automatic

- 6.3 Automatic

Chapter 7 Market Estimates & Forecast, By Application, 2021 - 2034 (USD Billion) (Thousand Units)

- 7.1 Key trends

- 7.2 Plant-Based proteins

- 7.3 Cultured meat

- 7.4 Insect proteins

- 7.5 Egg replacements

Chapter 8 Market Estimates & Forecast, By End Use, 2021 - 2034 (USD Billion) (Thousand Units)

- 8.1 Key trends

- 8.2 Food industry

- 8.3 Animal feed

- 8.4 Nutraceuticals

- 8.5 Others

Chapter 9 Market Estimates & Forecast, By Processing Technology, 2021 - 2034 (USD Billion) (Thousand Units)

- 9.1 Key trends

- 9.2 Texturization

- 9.3 Fermentation

- 9.4 Emulsification

- 9.5 Spray drying

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034 (USD Billion) (Thousand Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 UK

- 10.3.2 Germany

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.3.6 Russia

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 South Korea

- 10.4.5 Australia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.6 MEA

- 10.6.1 South Africa

- 10.6.2 Saudi Arabia

- 10.6.3 UAE

Chapter 11 Company Profiles

- 11.1 Alfa Laval AB

- 11.2 ANDRITZ AG

- 11.3 BAK Food Equipment

- 11.4 Bepex International LLC

- 11.5 Buhler AG

- 11.6 FAM STUMABO

- 11.7 GEA Group Aktiengesellschaft

- 11.8 JBT Marel Corporation

- 11.9 Middleby Corporation

- 11.10 MULTIVAC Sepp Haggenmuller SE & Co. KG

- 11.11 Paul Mueller Company

- 11.12 Robert Reiser & Co., Inc.

- 11.13 Rockwell Automation

- 11.14 Scansteel Foodtech A/S.

- 11.15 SPX FLOW