|

市场调查报告书

商品编码

1755193

技术纺织品生产设备市场机会、成长动力、产业趋势分析及 2025 - 2034 年预测Technical Textile Production Equipment Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

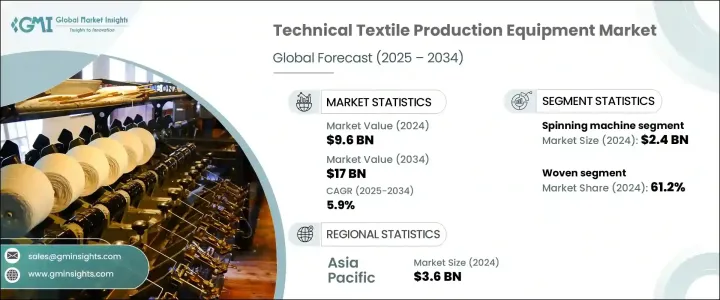

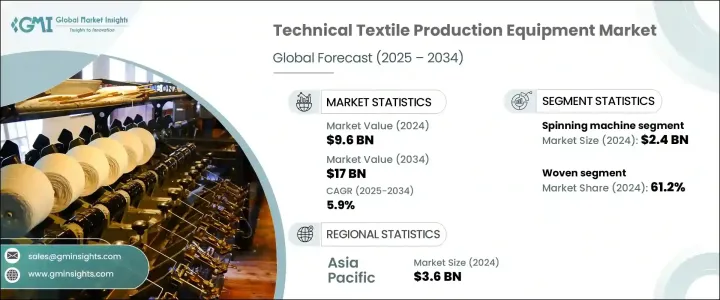

2024 年全球技术纺织品生产设备市场价值为 96 亿美元,预计到 2034 年将以 5.9% 的复合年增长率成长,达到 170 亿美元。市场成长很大程度上是由汽车、医疗保健、国防、农业和建筑等领域对专用纺织品日益增长的需求所驱动。随着各行各业寻找具有阻燃性、耐用性、高抗拉强度和生物相容性的高性能材料,对先进纺织生产机械的需求也日益增长。芳纶纤维、碳纤维和超高分子量聚乙烯纤维等纤维技术的兴起,大大拓宽了技术纺织品的应用范围。此外,对环保和可回收纺织品的需求不断增长,推动了对更先进製造设备的需求。生产过程中自动化和数位控制系统的发展有助于提高效率、客製化和整体生产力。

2024年,纺纱机市场规模达24亿美元,这得益于其在将原纤维转化为高性能应用所需纱线方面发挥的关键作用。这些机器在生产医疗、国防和汽车等关键产业所需的纺织品专用纱线方面发挥关键作用。随着碳纤维和芳纶等先进材料需求的不断增长,对纺纱机的需求也在不断增长,因为这些机器能够确保纤维混合、加捻和纱线生产的高精度,从而满足技术纺织品的严格规格要求。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 96亿美元 |

| 预测值 | 170亿美元 |

| 复合年增长率 | 5.9% |

2024年,机织布料领域以61.2%的份额领先市场。机织织物因其优异的机械强度、结构完整性以及适应各种高性能应用的能力而备受青睐。其高抗拉强度、耐用性和尺寸稳定性使其成为製造工业过滤器、防弹装备、安全带和土工布等产品的理想选择。机织织物能够透过各种编织图案和纤维取向进行定制,使其用途广泛,并可高度定制,适用于各种应用。由于机织织物在汽车、航太和建筑等行业的广泛应用,其市场正在不断扩大。

2024年,亚太地区技术纺织品生产设备市场规模达36亿美元,占37%。该地区的成长得益于工业能力的提升、技术进步以及政府的优惠政策。中国凭藉其发达的基础设施、较低的劳动力成本以及对纺织自动化的持续投入,在这一增长中发挥着重要作用。此外,印度的进步也受到「生产挂钩激励计画」(PLI)和「国家技术纺织品计画」(NTTM)等措施的推动,这些措施旨在促进技术纺织品的生产和创新。日本、韩国和越南等国家也为该地区的成长做出了贡献,推动了技术创新和出口成长。

全球技术纺织品生产设备市场的领导者包括:Andritz、Itema SpA、Dilo Group、BRUCKNER、Trutzschler Group SE、Staubli International AG、Reifenhauser Reicofil、Graute GmbH、Voith GmbH & Co. KGaA、Santex Rimarg、KARL MAYER、Koeith GmbH & Co. KGaA、Santex 烧、KARL MAYER、Koeelcle ZAYER、KoePEer、Kokia、KARL MAYER、Koeelf ZAY、APHA、KJA、K.Ater ZAYER为巩固市场地位,技术纺织品生产设备产业的公司专注于多种策略。这些包括投资尖端技术和提高生产流程效率,以满足对先进材料日益增长的需求。企业还与纺织和製造业的主要参与者建立合作伙伴关係,以扩大分销网络并提高市场渗透率。另一个关键方法是投资自动化和数位化,以提高精度、降低成本并为客户提供高度可自订的解决方案。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 影响价值链的因素

- 利润率分析

- 中断

- 未来展望

- 製造商

- 经销商

- 衝击力

- 成长动力

- 技术纺织品需求不断成长

- 製造技术的进步

- 汽车产业的成长

- 医疗级纺织品需求增加

- 产业陷阱与挑战

- 初期投资高

- 原料成本波动

- 成长动力

- 成长潜力分析

- 技术概述

- 定价分析

- 监管格局

- 波特的分析

- PESTEL分析

第四章:竞争格局

- 介绍

- 产业结构与集中度

- 竞争强度评估

- 公司市占率分析

- 竞争定位矩阵

- 产品定位

- 性价比定位

- 地理分布

- 创新能力

- 战略仪表板

- Competitive benchmarking

- Strategic initiatives assessment

- SWOT analysis of key players

- Future competitive outlook

第五章:市场估计与预测:按机器类型,2021 - 2034 年

- 主要趋势

- 挤压机

- 纺纱机

- 针织机

- 织布机

- 不织布机械

- 涂布机

- 覆膜机

- 复合及黏合设备

- 其他的

第六章:市场估计与预测:依製程类型,2021 - 2034 年

- 主要趋势

- 编织

- 针织

- 不织布

- 合成的

- 其他的

第七章:市场估计与预测:按应用,2021 - 2034 年

- 主要趋势

- 汽车纺织品

- 建筑纺织品

- 医用纺织品

- 运动纺织品

- 工业纺织品

- 农业纺织品

- 防护纺织品

- 其他的

第八章:市场估计与预测:按配销通路,2021 - 2034 年

- 主要趋势

- 直销

- 间接销售

第九章:市场估计与预测:按地区,2021-2034

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 英国

- 德国

- 法国

- 义大利

- 西班牙

- 俄罗斯

- 亚太地区

- 中国

- 印度

- 日本

- 韩国

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- MEA

- 阿联酋

- 沙乌地阿拉伯

- 南非

第十章:公司简介

- Andritz

- BRUCKNER

- Dilo Group

- Graute GmbH

- Itema SpA

- KARL MAYER

- Kawanoe Zoki Co Ltd

- Kusters Calico

- Reifenhauser Reicofil

- Santex Rimar Group

- SINCILON

- Staubli International AG

- Trutzschler Group SE

- UMPESL

- Voith GmbH & Co. KGaA

The Global Technical Textile Production Equipment Market was valued at USD 9.6 billion in 2024 and is estimated to grow at a CAGR of 5.9% to reach USD 17 billion by 2034. The growth of the market is largely driven by the increasing demand for specialized textiles in sectors like automotive, healthcare, defense, agriculture, and construction. As industries look for high-performance materials that offer flame resistance, durability, high tensile strength, and biocompatibility, there is a growing need for advanced textile production machinery. The rise of fiber technologies, including aramid fiber, carbon fiber, and ultra-high molecular weight polyethylene fibers, is significantly broadening the scope for technical textiles. Furthermore, the growing demand for eco-friendly and recyclable textiles pushes for more sophisticated manufacturing equipment. The development of automation and digital control systems in production processes has helped improve efficiency, customization, and overall productivity.

The spinning machine segment generated USD 2.4 billion in 2024, driven by its crucial role in converting raw fibers into yarns needed for high-performance applications. These machines play a pivotal role in the production of specialized yarns that are required for textiles used in critical sectors such as medical, defense, and automotive industries. With the growing need for advanced materials like carbon and aramid fibers, the demand for spinning machines is rising, as these machines ensure high precision in fiber blending, twisting, and producing yarns that meet the stringent specifications of technical textiles.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $9.6 Billion |

| Forecast Value | $17 Billion |

| CAGR | 5.9% |

In 2024, the woven fabric segment led the market with a share of 61.2%. Woven fabrics are favored for their mechanical strength, structural integrity, and ability to adapt to a wide range of high-performance applications. Their high tensile strength, durability, and dimensional stability make them ideal for manufacturing products such as industrial filters, ballistic gear, seat belts, and geotextiles. The ability to tailor woven textiles through various weave patterns and fiber orientations makes them versatile and highly customizable for diverse applications. The market for woven fabrics is expanding due to their broad usage in industries like automotive, aerospace, and construction.

Asia Pacific Technical Textile Production Equipment Market generated USD 3.6 billion in 2024, holding a 37% share. The region's growth can be attributed to expanding industrial capabilities, technological advancements, and favorable government policies. China plays a significant role in this growth due to its developed infrastructure, lower labor costs, and increased investments in textile automation. Additionally, India's progress is being propelled by initiatives such as the Production Linked Incentive (PLI) Scheme and the National Technical Textiles Mission (NTTM), which focus on boosting production and innovation in technical textiles. Countries like Japan, South Korea, and Vietnam also contribute to this regional growth, helping drive both technological innovation and export growth.

Leading players in the Global Technical Textile Production Equipment Market include: Andritz, Itema SpA, Dilo Group, BRUCKNER, Trutzschler Group SE, Staubli International AG, Reifenhauser Reicofil, Graute GmbH, Voith GmbH & Co. KGaA, Santex Rimar Group, KARL MAYER, Kawanoe Zoki Co Ltd, SINCILON, Kusters Calico, and UMPESL. To strengthen their market position, companies in the technical textile production equipment industry focus on several strategies. These include investing in cutting-edge technology and enhancing the efficiency of production processes to meet the growing demand for advanced materials. Firms are also forming partnerships with key players in the textile and manufacturing sectors to expand their distribution networks and increase market penetration. Another critical approach is investing in automation and digitalization to improve precision, reduce costs, and offer highly customizable solutions for their customers.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.1.1 Research approach

- 1.1.2 Data collection methods

- 1.2 Base estimates and calculations

- 1.2.1 Base year calculation

- 1.2.2 Key trends for market estimates

- 1.3 Forecast model

- 1.4 Primary research & validation

- 1.4.1 Primary sources

- 1.4.2 Data mining sources

- 1.4.2.1 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factors affecting the value chain

- 3.1.2 Profit margin analysis

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.2 Impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Rising demand for technical textiles

- 3.2.1.2 Advancements in manufacturing technologies

- 3.2.1.3 Growth in the automotive industry

- 3.2.1.4 Increased demand for medical-grade textiles

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High initial investment

- 3.2.2.2 Fluctuating raw material costs

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Technological overview

- 3.5 Pricing analysis

- 3.6 Regulatory landscape

- 3.7 Porter's analysis

- 3.8 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Industry structure and concentration

- 4.3 Competitive intensity assessment

- 4.4 Company market share analysis

- 4.5 Competitive positioning matrix

- 4.5.1 Product positioning

- 4.5.2 Price-performance positioning

- 4.5.3 Geographic presence

- 4.5.4 Innovation capabilities

- 4.6 Strategic dashboard

- 4.6.1 Competitive benchmarking

- 4.6.1.1 Manufacturing capabilities

- 4.6.1.2 Product portfolio strength

- 4.6.1.3 Distribution network

- 4.6.1.4 R&D investments

- 4.6.2 Strategic initiatives assessment

- 4.6.3 SWOT analysis of key players

- 4.6.4 Future competitive outlook

- 4.6.1 Competitive benchmarking

Chapter 5 Market Estimates & Forecast, By Machine Type, 2021 - 2034 (USD Billion) (Thousand Units)

- 5.1 Key trends

- 5.2 Extrusion machine

- 5.3 Spinning machine

- 5.4 Knitting machine

- 5.5 Weaving machine

- 5.6 Nonwoven machinery

- 5.7 Coating machine

- 5.8 Laminating machine

- 5.9 Composite and bonding equipment

- 5.10 Others

Chapter 6 Market Estimates & Forecast, By Process Type, 2021 - 2034 (USD Billion) (Thousand Units)

- 6.1 Key trends

- 6.2 Woven

- 6.3 Knitted

- 6.4 Nonwoven

- 6.5 Composite

- 6.6 Others

Chapter 7 Market Estimates & Forecast, By Application, 2021 - 2034 (USD Billion) (Thousand Units)

- 7.1 Key trends

- 7.2 Automotive textiles

- 7.3 Construction textiles

- 7.4 Medical textiles

- 7.5 Sports textiles

- 7.6 Industrial textiles

- 7.7 Agro textiles

- 7.8 Protective textiles

- 7.9 Others

Chapter 8 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034 (USD Billion) (Thousand Units)

- 8.1 Key trends

- 8.2 Direct sales

- 8.3 Indirect sales

Chapter 9 Market Estimates & Forecast, By Region, 2021-2034 (USD Billion) (Thousand Units)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 UK

- 9.3.2 Germany

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.3.6 Russia

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 South Korea

- 9.4.5 Australia

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.6 MEA

- 9.6.1 UAE

- 9.6.2 Saudi Arabia

- 9.6.3 South Africa

Chapter 10 Company Profiles

- 10.1 Andritz

- 10.2 BRUCKNER

- 10.3 Dilo Group

- 10.4 Graute GmbH

- 10.5 Itema SpA

- 10.6 KARL MAYER

- 10.7 Kawanoe Zoki Co Ltd

- 10.8 Kusters Calico

- 10.9 Reifenhauser Reicofil

- 10.10 Santex Rimar Group

- 10.11 SINCILON

- 10.12 Staubli International AG

- 10.13 Trutzschler Group SE

- 10.14 UMPESL

- 10.15 Voith GmbH & Co. KGaA