|

市场调查报告书

商品编码

1773462

改质沥青市场机会、成长动力、产业趋势分析及2025-2034年预测Modified Bitumen Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

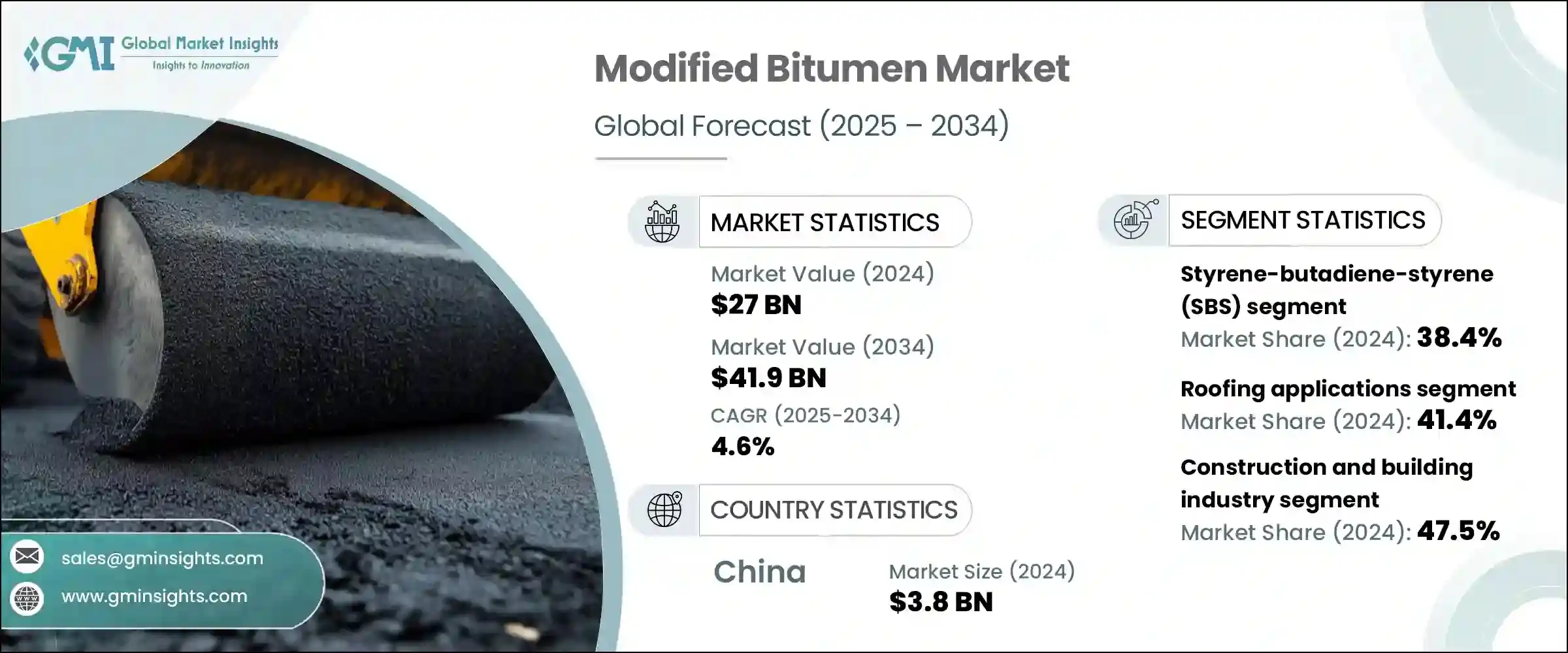

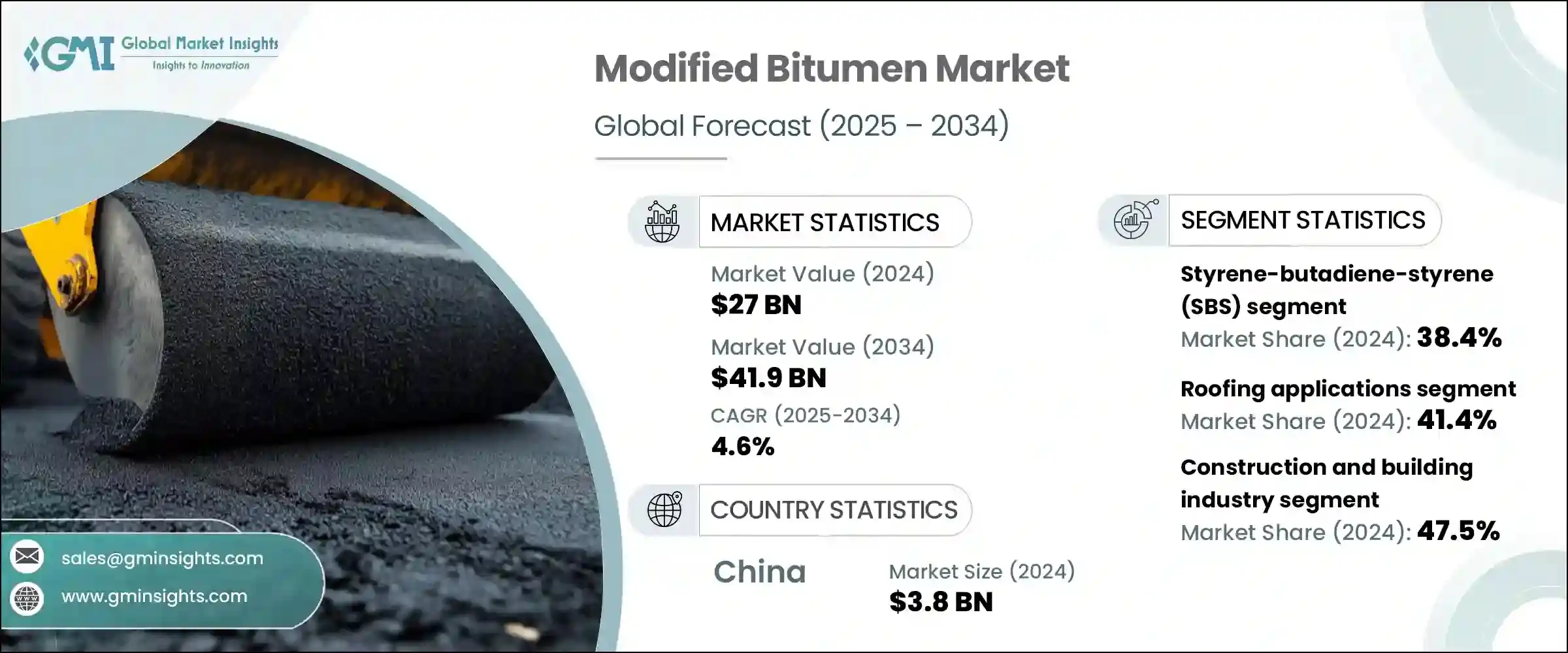

2024 年全球改质沥青市场价值为 270 亿美元,预计到 2034 年将以 4.6% 的复合年增长率成长至 419 亿美元。随着全球建筑业将重点转向高性能、耐用的屋顶和路面材料,对增强沥青配方的需求正在稳步增长。对能够承受恶劣环境条件的道路和基础设施的需求日益增长,推动了具有更高弹性和耐久性的改性沥青黏合剂的应用。对气候适应性的日益重视也促使人们使用具有更好抗热波动、开裂和氧化性能的沥青变体。行业运营商越来越多地选择聚合物改性替代品,以满足高流量区域和恶劣天气区域的性能要求。此外,人们对永续基础设施发展的认识不断提高,促使製造商生产符合环境标准并减少建筑活动碳影响的材料。

世界许多地方的政府都在追求雄心勃勃的基础设施建设目标,这促使炼油厂和沥青生产商扩大其高性能沥青的产能。公共和私营部门专案的材料选择越来越多地受到气候意识工程标准和生命週期成本评估的指导。改质沥青在极端条件下保持性能的能力使其成为要求长期价值和低维护成本项目的首选。黏合剂化学领域的创新促进了聚合物配方的开发,这些配方具有更高的弹性、卓越的温度稳定性和更高的抗紫外线性能。这些特性延长了路面和屋顶系统的使用寿命,并有助于提高基础设施投资的整体成本效益。因此,在对现代永续建筑实践不断增加的投资的支持下,改质沥青正成为长期交通和城市发展规划中不可或缺的一部分。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 270亿美元 |

| 预测值 | 419亿美元 |

| 复合年增长率 | 4.6% |

旨在减少排放和促进建筑投入循环利用的严格监管转变也推动了市场的成长。随着各国政府加强绿建筑认证并鼓励气候适应型城镇化,掺入再生橡胶或低排放聚合物等环保材料的改质沥青混合料正日益受到青睐。聚合物改质品种特别突出,对兼顾性能与永续性目标的方案的需求激增。研究工作持续关注混合相容性、低温铺路解决方案和减碳添加剂,所有这些都反映了环境因素对材料选择日益增长的影响。在这种不断变化的情况下,製造商正在透过重新设计兼具高性能和环保性的配方来应对,使其能够在符合永续性框架的同时满足更广泛的基础设施需求。

在市面上使用的各种改质剂中,苯乙烯-丁二烯-苯乙烯 (SBS) 因其增强弹性、抗疲劳性和耐温性而继续占据主导地位。这些特性使 SBS 改质黏合剂特别适用于温度变化频繁或车辆负载较重的严苛环境。 SBS 改质可显着提高表面耐久性,减少变形和开裂,最终延长道路和屋顶系统的使用寿命。其优异的机械性能使其成为新建和翻新项目的首选,这也解释了其在不同区域市场中占据的强劲地位。

改质沥青依应用领域可分为道路建设和铺路、屋顶、防水和密封以及工业和特殊用途。受耐候节能建筑材料需求不断增长的推动,2024年屋顶应用占据全球市场份额的41.4%。 SBS和无规聚丙烯(APP)在屋顶防水卷材中的使用增强了其柔韧性和抗紫外线降解性能,使其成为现代城市建筑的理想选择。商业和住宅建筑的稳定成长,尤其是在快速城市化地区,推动了屋顶系统向这些先进材料的转变。增强的隔热性能和对更严格建筑规范的合规性,使得改性屋顶防水卷材在已开发经济体和发展中经济体都越来越受欢迎。

生产技术也会影响产品品质和适应性。间歇式製程仍广泛用于生产聚合物改质沥青,尤其适用于客製化量或配方,这些配方必须符合特定的性能标准(例如黏度或弹性)。这种方法使生产商能够更灵活地回应不同的区域要求和特殊专案需求。对于需要调整配方的研发应用或小批量专案尤其有利。

亚太地区在全球改性沥青市场持续保持领先地位,这得益于强劲的建筑活动、不断增长的交通投资以及不断扩张的城市扩张。该地区各国正大力投资基础设施升级和新开发项目,推动对性能改质路面材料的持续需求。政府支持的措施以及越来越多的大型交通和住房计画进一步增强了该地区市场的成长势头,而这些计画都依赖高品质、高韧性的投入。

全球市场的主要参与者包括壳牌全球、道达尔能源公司、埃克森美孚公司、尼纳斯公司和科腾公司。这些公司凭藉其丰富的SBS、APP和混合改质产品组合,保持着强大的市场地位,这些产品专为不同的环境和交通状况而设计。他们在产品配方、技术支援和供应可靠性方面的专业知识,使其成为大型基础设施和工业项目的首选供应商。这些公司还透过开发生物基因改造剂、再生材料相容性以及旨在减少环境影响的下一代黏合剂,引领着永续发展的转变。透过持续的研发和对低碳创新的关注,这些公司持续塑造改质沥青技术的未来,同时满足全球对耐用、耐气候材料的需求。

目录

第一章:方法论与范围

第二章:执行摘要

第三章:行业洞察

- 产业生态系统分析

- 供应商概况

- 利润率

- 每个阶段的增值

- 影响价值链的因素

- 中断

- 产业衝击力

- 成长动力

- 基础建设和城市化成长

- 气候适应力和极端天气适应

- 永续发展要求和环境法规

- 效能增强和生命週期成本优化

- 产业陷阱与挑战

- 初始成本高且经济障碍多(溢价 60-70%)

- 储存稳定性和处理复杂性

- 熟练的安装劳动力有限

- 原物料价格波动和供应链依赖性

- 市场机会

- 新兴市场和基础设施投资计划

- 生物基和再生聚合物集成

- 智慧基础设施和物联网集成

- 抗灾建设要求

- 成长动力

- 成长潜力分析

- 监管格局

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 波特的分析

- PESTEL分析

- 价格趋势

- 按地区

- 按产品

- 未来市场趋势

- 技术和创新格局

- 当前的技术趋势

- 新兴技术

- 专利态势

- 贸易统计(HS编码)(註:仅提供重点国家的贸易统计资料)

- 主要进口国

- 主要出口国

- 永续性和环境方面

- 永续实践

- 减少废弃物的策略

- 生产中的能源效率

- 环保倡议

- 碳足迹考量

第四章:竞争格局

- 介绍

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- MEA

- 按地区

- 公司矩阵分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 关键进展

- 併购

- 伙伴关係与合作

- 新产品发布

- 扩张计划

第五章:市场估计与预测:按聚合物改质剂类型,2021 - 2034 年

- 主要趋势

- 苯乙烯-丁二烯-苯乙烯(SBS)改质沥青

- SBS聚合物等级和规格

- 无规聚丙烯(APP)改质沥青

- 乙烯醋酸乙烯酯 (EVA) 改质沥青

- 热塑性弹性体 (TPE) 和其他改质剂

- 生物基和再生聚合物改质剂

- 混合和多聚合物体系

- SBS-APP组合产品

- 聚合物-橡胶混合改质

第六章:市场估计与预测:按应用,2021 - 2034 年

- 主要趋势

- 屋顶应用

- 低坡度和平屋顶系统

- 商业和工业建筑应用

- 多层系统配置和效能

- 陡坡屋顶应用

- 住宅屋顶

- 底层和冰坝保护

- 木瓦和瓷砖整合系统

- 低坡度和平屋顶系统

- 道路建设和铺设

- 高速公路和州际应用

- 城市和市政道路系统

- 城市街道和主干道应用

- 交叉口和高应力区解决方案

- 维护和修復项目

- 机场和工业铺路

- 防水和密封应用

- 地下防水系统

- 地基和地下室应用

- 隧道及地下结构防护

- 桥面及基础设施防水

- 地上防水解决方案

- 广场甲板和阳台系统

- 绿色屋顶和花园应用

- 停车结构与平台保护

- 地下防水系统

- 工业和专业应用

- 黏合剂和密封剂

- 涂层和保护系统

- 管道涂层和防腐保护

第七章:市场估计与预测:按最终用途产业,2021 - 2034 年

- 主要趋势

- 建筑业

- 住宅建筑市场

- 单户住宅及多户住宅

- 翻新和改造项目

- 能源效率和绿建筑要求

- 商业建筑领域

- 办公大楼和零售中心

- 医疗保健和教育设施

- 饭店及娱乐场所

- 工业建筑应用

- 製造和加工设施

- 仓储和配送中心

- 资料中心和技术基础设施

- 住宅建筑市场

- 交通基础设施

- 公路和道路基础设施

- 州际公路系统维护

- 州和地方公路网

- 桥樑和立体交叉建设

- 机场基础建设发展

- 跑道和航站楼扩建项目

- 货运设施开发

- 港口和海洋基础设施

- 货柜码头及码头建设

- 海岸防护和海堤项目

- 公路和道路基础设施

- 能源和公用事业部门

- 发电设施

- 太阳能发电场和风能基础设施

- 传统发电厂维护

- 石油和天然气基础设施

- 炼油厂及加工设施应用

- 管道和储罐保护

- 水和废水处理

- 处理厂基础设施

- 水库及储存设施防水

- 发电设施

- 政府和公共基础设施

- 联邦和州政府项目

- 市政和地方政府申请

- 军事和国防基础设施

- 私人和专业市场

- 体育和娱乐设施

- 农业和农村基础设施

- 采矿和采矿业

第八章:市场估计与预测:按地区,2021 - 2034 年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 西班牙

- 义大利

- 欧洲其他地区

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 韩国

- 亚太其他地区

- 拉丁美洲

- 巴西

- 墨西哥

- 拉丁美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 阿联酋

- 中东和非洲其他地区

第九章:公司简介

- CertainTeed Corporation

- Colas Group

- Dynasol Group

- Ergon Inc.

- ExxonMobil Corporation

- Johns Manville

- Kraton Corporation

- LG Chem Ltd

- MBTechnology

- Nynas AB

- Polyglass USA, Inc

- Shell Global

- Siplast (Icopal Group)

- TotalEnergies SE

- Versalis SpA

The Global Modified Bitumen Market was valued at USD 27 billion in 2024 and is estimated to grow at a CAGR of 4.6% to reach USD 41.9 billion by 2034. The demand for enhanced bitumen formulations is steadily rising as the construction sector worldwide shifts focus toward high-performance, long-lasting materials for both roofing and paving. The increasing necessity for roads and infrastructure that can withstand harsh environmental conditions has fueled the adoption of modified binders with improved resilience and durability. A growing emphasis on climate adaptability has also prompted the use of bitumen variants that offer better resistance to thermal fluctuations, cracking, and oxidation. Industry operators are increasingly selecting polymer-modified alternatives to meet the performance requirements of high-traffic areas and challenging weather zones. In addition, growing awareness around sustainable infrastructure development is motivating manufacturers to produce materials that align with environmental standards and reduce the carbon impact of construction activities.

Governments in many parts of the world are pursuing ambitious infrastructure goals, prompting refiners and bitumen producers to expand their capacity for high-performance grades. Material choices in public and private sector projects are increasingly guided by climate-conscious engineering standards and lifecycle cost assessments. Modified bitumen's capacity to retain performance under extreme conditions has made it a preferred option for projects demanding long-term value and lower maintenance. Innovations in binder chemistry have contributed to the development of polymer formulations that exhibit improved elasticity, superior temperature stability, and higher UV resistance. These characteristics extend the life of pavements and roofing systems and contribute to the overall cost-efficiency of infrastructure investments. As a result, the material is becoming integral to long-term transportation and urban development plans, supported by rising investment in modern, sustainable construction practices.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $27 Billion |

| Forecast Value | $41.9 Billion |

| CAGR | 4.6% |

The market's growth is also supported by stringent regulatory shifts aimed at reducing emissions and promoting circularity in construction inputs. Modified bitumen blends incorporating eco-conscious materials-such as recycled rubber or low-emission polymers-are gaining traction as governments enforce green building certifications and encourage climate-resilient urbanization. Polymer-modified variants are especially prominent, with demand surging for options that balance performance with sustainability goals. Research efforts continue to focus on blending compatibility, low-temperature paving solutions, and carbon-reducing additives, all of which reflect the growing influence of environmental considerations on material selection. In this evolving landscape, manufacturers are responding by reengineering formulations that are both high performing and eco-friendly, allowing them to cater to a broader range of infrastructure needs while complying with sustainability frameworks.

Among the various modifiers used in the market, Styrene-Butadiene-Styrene (SBS) continues to dominate due to its ability to enhance elasticity, fatigue resistance, and temperature tolerance. These properties make SBS-modified binders particularly suitable for demanding environments with frequent temperature changes or heavy vehicular load. SBS modifications significantly improve surface durability by reducing deformation and cracking, ultimately extending the service life of roads and roofing systems. Its mechanical performance makes it a preferred choice in both new construction and rehabilitation projects, which helps explain its strong presence across diverse regional markets.

Modified bitumen is segmented by application into road construction and paving, roofing, waterproofing and sealing, and industrial and specialty uses. Roofing applications accounted for 41.4% of the global market share in 2024, driven by increasing demand for weather-resistant and energy-efficient building materials. The use of SBS and Atactic Polypropylene (APP) in roofing membranes enhances flexibility and resistance to UV degradation, making them ideal for modern urban buildings. The steady rise in commercial and residential construction, especially in regions undergoing rapid urbanization, has supported the shift toward these advanced materials in roofing systems. Enhanced insulation properties and compliance with stricter building codes have made modified roofing membranes increasingly popular in both developed and developing economies.

Manufacturing techniques also influence product quality and adaptability. The batch process remains widely used for producing polymer-modified bitumen, particularly for customized volumes or formulations where specific performance criteria-such as viscosity or elasticity-must be met. This method allows producers to respond to varying regional requirements and specialty project demands with more flexibility. It is especially beneficial for R&D applications or lower-volume projects where formulation adjustments are necessary.

Asia Pacific continues to hold a leading position in the global modified bitumen market, driven by robust construction activity, growing investments in transportation, and rising urban expansion. Countries across the region are investing heavily in infrastructure upgrades and new development, driving consistent demand for performance-modified surfacing materials. The market's upward momentum in the region is reinforced by government-backed initiatives and a growing number of large-scale transport and housing projects, all of which rely on high-quality, resilient inputs.

Key players in the global market include Shell Global, TotalEnergies SE, ExxonMobil Corporation, Nynas AB, and Kraton Corporation. These companies maintain a strong presence through a wide-ranging portfolio of SBS, APP, and hybrid-modified products designed for varying environmental and traffic conditions. Their expertise in product formulation, technical support, and supply reliability positions them as preferred suppliers for large infrastructure and industrial projects. These firms are also leading the shift toward sustainability by developing bio-based modifiers, recycled content compatibility, and next-generation binders aimed at reducing environmental impact. Through ongoing R&D and a focus on low-carbon innovations, these companies continue to shape the future of modified bitumen technologies while meeting global demand for durable, climate-resilient materials.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Polymer modified type

- 2.2.3 Application

- 2.2.4 End use industry

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Infrastructure development and urbanization growth

- 3.2.1.2 Climate resilience and extreme weather adaptation

- 3.2.1.3 Sustainability mandates and environmental regulations

- 3.2.1.4 Performance enhancement and lifecycle cost optimization

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High initial costs and economic barriers (60-70% premium)

- 3.2.2.2 Storage stability and handling complexities

- 3.2.2.3 Limited skilled installation workforce

- 3.2.2.4 Raw material price volatility and supply chain dependencies

- 3.2.3 Market opportunities

- 3.2.3.1 Emerging markets and infrastructure investment programs

- 3.2.3.2 Bio-based and recycled polymer integration

- 3.2.3.3 Smart infrastructure and IoT integration

- 3.2.3.4 Disaster-resilient construction requirements

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.6.1 Technology and Innovation Landscape

- 3.6.2 Current technological trends

- 3.6.3 Emerging technologies

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By product

- 3.8 Future market trends

- 3.9 Technology and Innovation Landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (HS code) (Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and Environmental Aspects

- 3.12.1 Sustainable Practices

- 3.12.2 Waste Reduction Strategies

- 3.12.3 Energy Efficiency in Production

- 3.12.4 Eco-friendly Initiatives

- 3.13 Carbon Footprint Considerations

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates and Forecast, By Polymer Modifier Type, 2021 - 2034 (USD Billion) (Kilo Tons)

- 5.1 Key trends

- 5.2 Styrene-butadiene-styrene (SBS) modified bitumen

- 5.2.1 SBS polymer grades and specifications

- 5.3 Atactic polypropylene (APP) modified bitumen

- 5.4 Ethylene vinyl acetate (EVA) modified bitumen

- 5.5 Thermoplastic elastomers (TPE) and other modifiers

- 5.6 Bio-based and recycled polymer Modifiers

- 5.7 Hybrid and multi-polymer systems

- 5.7.1 SBS-APP combination products

- 5.7.2 Polymer-rubber hybrid modifications

Chapter 6 Market Estimates and Forecast, By Application, 2021 - 2034 (USD Billion) (Kilo Tons)

- 6.1 Key trends

- 6.2 Roofing applications

- 6.2.1 Low-slope and flat roofing systems

- 6.2.1.1 Commercial and industrial building applications

- 6.2.1.2 Multi-ply system configurations and performance

- 6.2.2 Steep-slope roofing applications

- 6.2.2.1 Residential roofing

- 6.2.2.2 Underlayment and ice dam protection

- 6.2.2.3 Shingle and tile integration systems

- 6.2.1 Low-slope and flat roofing systems

- 6.3 Road construction and paving

- 6.3.1 Highway and interstate applications

- 6.3.2 Urban and municipal road systems

- 6.3.2.1 City street and arterial applications

- 6.3.2.2 Intersection and high-stress zone solutions

- 6.3.2.3 Maintenance and rehabilitation projects

- 6.3.3 Airport and industrial paving

- 6.4 Waterproofing and sealing applications

- 6.4.1 Below-grade waterproofing systems

- 6.4.1.1 Foundation and basement applications

- 6.4.1.2 Tunnel and underground structure protection

- 6.4.1.3 Bridge deck and infrastructure waterproofing

- 6.4.2 Above-grade waterproofing solutions

- 6.4.2.1 Plaza deck and balcony systems

- 6.4.2.2 Green roof and garden applications

- 6.4.2.3 Parking structure and podium deck protection

- 6.4.1 Below-grade waterproofing systems

- 6.5 Industrial and specialty applications

- 6.5.1 Adhesives and sealants

- 6.5.2 Coatings and protective systems

- 6.5.3 Pipe coating and corrosion protection

Chapter 7 Market Estimates and Forecast, By End Use Industry, 2021 - 2034 (USD Billion) (Kilo Tons)

- 7.1 Key trends

- 7.2 Construction and Building Industry

- 7.2.1 Residential Construction Market

- 7.2.1.1 Single-Family and Multi-Family Housing

- 7.2.1.2 Renovation and Retrofit Projects

- 7.2.1.3 Energy Efficiency and Green Building Requirements

- 7.2.2 Commercial Construction Sector

- 7.2.2.1 Office Buildings and Retail Centers

- 7.2.2.2 Healthcare and Educational Facilities

- 7.2.2.3 Hospitality and Entertainment Venues

- 7.2.3 Industrial Construction Applications

- 7.2.3.1 Manufacturing and Processing Facilities

- 7.2.3.2 Warehousing and Distribution Centers

- 7.2.3.3 Data Centers and Technology Infrastructure

- 7.2.1 Residential Construction Market

- 7.3 Transportation Infrastructure

- 7.3.1 Highway and Road Infrastructure

- 7.3.1.1 Interstate Highway System Maintenance

- 7.3.1.2 State and Local Road Networks

- 7.3.1.3 Bridge and Overpass Construction

- 7.3.2 Airport Infrastructure Development

- 7.3.2.1 Runway and Terminal Expansion Projects

- 7.3.2.2 Cargo and Freight Facility Development

- 7.3.3 Port and Marine Infrastructure

- 7.3.3.1 Container Terminal and Wharf Construction

- 7.3.3.2 Coastal Protection and Seawall Projects

- 7.3.1 Highway and Road Infrastructure

- 7.4 Energy and Utilities Sector

- 7.4.1 Power Generation Facilities

- 7.4.1.1 Solar Farm and Wind Energy Infrastructure

- 7.4.1.2 Traditional Power Plant Maintenance

- 7.4.2 Oil and Gas Infrastructure

- 7.4.2.1 Refinery and Processing Facility Applications

- 7.4.2.2 Pipeline and Storage Tank Protection

- 7.4.3 Water and Wastewater Treatment

- 7.4.3.1 Treatment Plant Infrastructure

- 7.4.3.2 Reservoir and Storage Facility Waterproofing

- 7.4.1 Power Generation Facilities

- 7.5 Government and Public Infrastructure

- 7.5.1 Federal and State Government Projects

- 7.5.2 Municipal and Local Government Applications

- 7.5.3 Military and Defense Infrastructure

- 7.6 Private and Specialty Markets

- 7.6.1 Sports and Recreation Facilities

- 7.6.2 Agricultural and Rural Infrastructure

- 7.6.3 Mining and Extractive Industries

Chapter 8 Market Estimates and Forecast, By Region, 2021 - 2034 (USD Billion) (Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Rest of Europe

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.4.6 Rest of Asia Pacific

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Rest of Latin America

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

- 8.6.4 Rest of Middle East and Africa

Chapter 9 Company Profiles

- 9.1 CertainTeed Corporation

- 9.2 Colas Group

- 9.3 Dynasol Group

- 9.4 Ergon Inc.

- 9.5 ExxonMobil Corporation

- 9.6 Johns Manville

- 9.7 Kraton Corporation

- 9.8 LG Chem Ltd

- 9.9 MBTechnology

- 9.10 Nynas AB

- 9.11 Polyglass U.S.A., Inc

- 9.12 Shell Global

- 9.13 Siplast (Icopal Group)

- 9.14 TotalEnergies SE

- 9.15 Versalis S.p.A