|

市场调查报告书

商品编码

1858833

可食用包装材料市场机会、成长驱动因素、产业趋势分析及预测Edible Packaging Materials Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast |

||||||

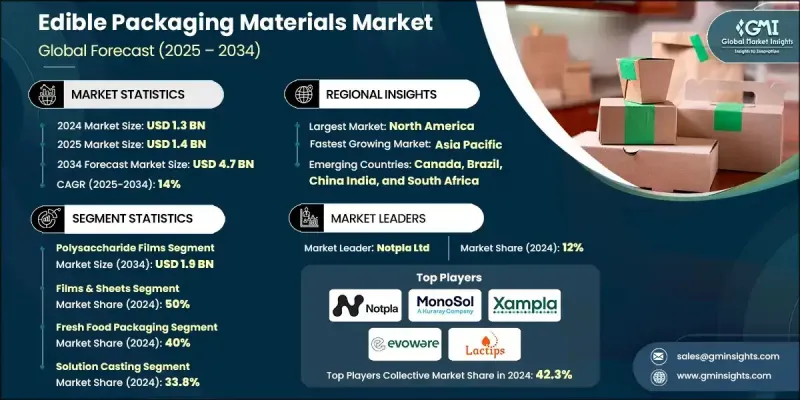

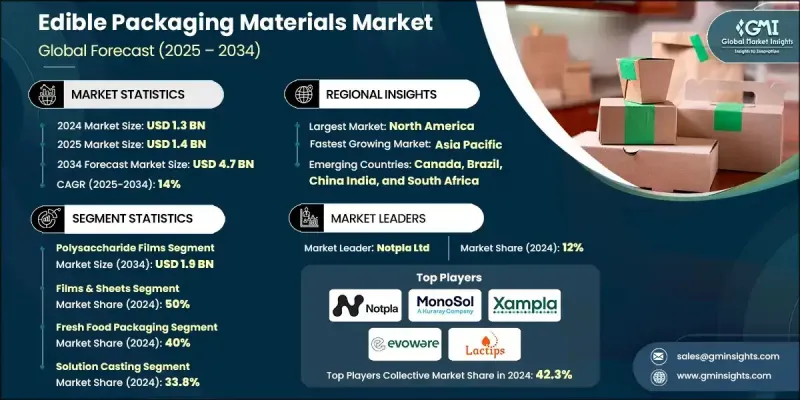

2024 年全球可食用包装材料市场价值为 13 亿美元,预计到 2034 年将以 14% 的复合年增长率增长至 47 亿美元。

可食用包装材料的广泛应用主要得益于日益严格的环境法规和各行业对永续发展的日益重视。随着各国实施更强有力的政策以减少塑胶垃圾,可食用包装材料正成为包装策略的重要组成部分,尤其是在餐饮服务、零售和食品杂货业。推动循环经济模式的全球倡议也促进了这一趋势。监管支持,例如美国的GRAS(公认安全物质)认证,简化了创新流程,加速了可食用包装材料的商业化。在一些地区,製造商正加大研发投入,并享有税收优惠和补助金,从而提高成本效益和生产规模。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 13亿美元 |

| 预测值 | 47亿美元 |

| 复合年增长率 | 14% |

市场正迅速扩张,从糖果领域扩展到新鲜农产品、饮料和加工食品等领域。生物基材料和阻隔性能的技术进步,使得其应用范围更加广泛。大型消费品公司内部的永续包装部门,如今正优先考虑符合长期环境目标的食用解决方案。萃取、配方和涂层方法的创新,使製造商能够开发出强度更高、水分控制更佳、保质期更长的食用产品,同时又不影响其生物降解性和安全性。

2024年,多醣薄膜市占率达到40%,预计2034年将达到19亿美元,年复合成长率(CAGR)为14.3%。这些薄膜之所以占据领先地位,是因为它们性能可靠、监管简便且生产成本低廉。淀粉和纤维素基薄膜具有理想的防潮性能,已被广泛应用于食品包装领域。奈米纤维素和化学改性多醣的最新进展正推动其在敏感食品包装领域的应用,预计到2034年,该领域的市场规模将扩大至47亿美元。

由于薄膜和片材与现有加工技术的兼容性以及其在各种包装形式中的多功能性,预计到2024年,薄膜和片材市场份额将达到50%。随着多层设计和增强阻隔性能创新技术的推出,该细分市场持续发展,这些技术有助于延长易腐产品的保质期。模塑容器虽然市场占有率较小,但成长迅速,这主要得益于其在即食食品和外卖食品应用领域的巨大潜力,在这些领域,坚固且可食用的包装备受青睐。

2024年,北美可食用包装材料市场占据35%的份额,市场规模达4.396亿美元。美国在该区域处于领先地位,这得益于其清晰的监管管道和政府对生物基解决方案的大力支持。来自私营和公共机构对包装创新持续不断的投资,进一步巩固了北美的领先地位。各州主导的倡议,包括塑胶禁令和环保包装强制令,在加速推广应用方面发挥了关键作用。联邦政府计画的采购优惠政策也进一步推动了可食用、可生物降解包装材料的使用。

全球可食用包装材料市场的主要企业包括 MonoSol LLC(可乐丽集团)、Glanbia PLC、Xampla Ltd.、Loliware Inc.、Notpla Ltd.、Kerry Group、FlexSea Ltd.、Evoware(PT. Evogaia Karya Indonesia)、Apeel Sciences、Mori(原 CamFM Corporation、PTOk PFM、PTO)、Apeel Sciences、Mori Corporation(原 Camix Corporation)这些企业正采取多管齐下的策略来巩固其市场地位。投资研发专有生物聚合物配方并为新型可食用薄膜技术申请专利是普遍做法,有助于提升产品性能并实现差异化。各公司正在扩建中试和大规模生产设施,以高效满足不断增长的市场需求。与食品製造商和零售品牌的合作有助于推动商业化应用,而联合品牌推广活动则有助于提高消费者认知度。此外,企业也积极与监管机构建立合作关係,以加速认证和合规进程。

目录

第一章:方法论与范围

第二章:执行概要

第三章:行业洞察

- 产业生态系分析

- 供应商格局

- 利润率

- 每个阶段的价值增加

- 影响价值链的因素

- 中断

- 产业影响因素

- 司机

- 陷阱与挑战

- 机会:

- 成长潜力分析

- 监管环境

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 波特的分析

- PESTEL 分析

- 价格趋势

- 按地区

- 按产品规格

- 未来市场趋势

- 技术与创新格局

- 当前技术趋势

- 新兴技术

- 专利格局

- 贸易统计(HS编码说明:仅提供重点国家的贸易统计)

- 主要进口国

- 主要出口国

- 永续性和环境方面

- 永续实践

- 减少废弃物策略

- 生产中的能源效率

- 环保倡议

- 碳足迹考量

第四章:竞争格局

- 介绍

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- MEA

- 按地区

- 公司矩阵分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 关键进展

- 併购

- 合作伙伴关係与合作

- 新产品发布

- 扩张计划

第五章:市场估算与预测:依产品划分,2021-2034年

- 主要趋势

- 蛋白质基薄膜

- 酪蛋白薄膜

- 乳清蛋白膜

- 明胶膜

- 胶原蛋白膜

- 大豆蛋白膜

- 小麦脸部筋膜

- 多醣膜

- 淀粉基薄膜

- 纤维素薄膜

- 壳聚醣薄膜

- 果胶膜

- 海藻酸盐薄膜

- 卡拉胶薄膜

- 脂质涂层

- 天然蜡涂层

- 脂肪酸膜

- 精油屏障

- 复合薄膜

- 蛋白质-多醣组合

- 多层薄膜技术

- 奈米复合材料集成

- 界面活性剂膜

- 卵磷脂基薄膜

- 特种乳化剂系统

第六章:市场估算与预测:依形式划分,2021-2034年

- 主要趋势

- 薄膜和片材

- 柔性薄膜

- 刚性板材

- 层压结构

- 涂层

- 喷涂涂层

- 浸涂

- 刷涂应用

- 模製容器

- 热成型容器

- 射出成型解决方案

- 3D列印包装

- 胶囊及封装

- 硬胶囊

- 软胶囊

- 微胶囊化

第七章:市场估算与预测:依屏障房产划分,2021-2034年

- 主要趋势

- 防潮层应用

- 高防潮层

- 可控渗透性

- 湿度响应系统

- 氧气阻隔应用

- 高氧屏障

- 选择性渗透性

- 主动氧清除

- 抗菌特性

- 天然抗菌剂

- 基于壳聚醣的系统

- 银奈米粒子集成

- 紫外线防护应用

- 光敏产品保护

- 光降解预防系统

- 色彩稳定性增强

第八章:市场估算与预测:依应用领域划分,2021-2034年

- 主要趋势

- 新鲜食品包装应用

- 水果和蔬菜

- 肉类和家禽

- 海鲜及海鲜

- 乳製品

- 加工食品包装应用

- 即食餐

- 冷冻食品

- 点心

- 烘焙食品

- 饮料应用

- 液体容器

- 饮料胶囊及单份装

- 瓶身涂层及瓶盖

- 糖果和烘焙应用

- 巧克力和糖果

- 蛋糕和糕点

- 冰淇淋和冷冻甜点

- 医药和营养保健品应用

- 药物输送系统

- 膳食补充剂

- 医用食品

第九章:市场估算与预测:依製造流程划分,2021-2034年

- 主要趋势

- 溶液铸造工艺

- 实验室规模生产

- 中试规模生产

- 商业规模营运

- 挤出工艺

- 吹膜挤出

- 流延薄膜挤出

- 共挤出

- 压缩成型

- 热压成型

- 冷压应用

- 真空成型

- 涂层和层压

- 喷涂系统

- 浸涂工艺

- 层压技术

第十章:市场估价与预测:依配销通路划分,2021-2034年

- 主要趋势

- 直接向製造商销售

- 食品饮料製造商

- 製药公司

- 合约包装组织

- 包装分销商和批发商

- 区域包装分销商

- 专业包装批发商

- 国际贸易公司

- 线上及数位管道

- B2B电子商务平台

- 厂商直销

- 特用化学品分销商

第十一章:市场估计与预测:按地区划分,2021-2034年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 西班牙

- 义大利

- 欧洲其他地区

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 韩国

- 亚太其他地区

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 拉丁美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 阿联酋

- 中东和非洲其他地区

第十二章:公司简介

- Notpla Ltd.

- MonoSol LLC (Kuraray Group)

- Xampla Ltd.

- Evoware (PT. Evogaia Karya Indonesia)

- Lactips

- FlexSea Ltd.

- Sway (Sway Innovation Co.)

- Apeel Sciences

- Loliware Inc.

- JRF Technology LLC

- Devro PLC

- Kerry Group

- Glanbia PLC

- FMC Corporation

- Mori (fka Cambridge Crops)

- Others

The Global Edible Packaging Materials Market was valued at USD 1.3 billion in 2024 and is estimated to grow at a CAGR of 14% to reach USD 4.7 billion by 2034.

The surge in adoption is largely fueled by tightening environmental regulations and heightened emphasis on sustainability across industries. As nations implement stronger policies to reduce plastic waste, edible alternatives are becoming integral to packaging strategies, particularly in food service, retail, and grocery sectors. Global initiatives pushing circular economy models are also boosting momentum. Regulatory support, such as the GRAS classification in the US, has streamlined innovation pipelines, accelerating the commercialization of edible packaging materials. Manufacturers are ramping up R&D investments, supported by tax incentives and grants in several regions, enhancing cost efficiency and production scalability.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $1.3 Billion |

| Forecast Value | $4.7 Billion |

| CAGR | 14% |

The market is seeing rapid expansion beyond confectionery to include segments like fresh produce, beverages, and processed foods. Technological advances in bio-based materials and barrier properties are allowing broader use cases. Sustainable packaging divisions within large CPG firms are now prioritizing edible solutions that align with long-term environmental goals. Innovations in extraction, formulation, and coating methods are enabling manufacturers to develop edible formats with superior strength, moisture control, and shelf-life extension, without compromising biodegradability or safety.

The polysaccharide films segment held a 40% share in 2024 and is expected to reach USD 1.9 billion by 2034, reflecting a CAGR of 14.3%. These films are leading due to their reliable performance, regulatory ease, and cost-effective production. Starch and cellulose-based films offer ideal moisture barrier properties and are widely adopted across food categories. New developments in nanocellulose and chemically modified polysaccharides are pushing their relevance into packaging for sensitive foods, expanding the product footprint to USD 4.7 billion by 2034.

The films and sheets segment held a 50% share in 2024, due to their compatibility with existing processing technologies and versatility across packaging formats. This segment continues to evolve with the introduction of multi-layered designs and enhanced barrier innovations that support the shelf life of perishable products. Molded containers, although smaller in share, are growing fast, driven by their potential in ready-to-eat and takeaway meal applications where rigid yet edible packaging is highly valued.

North America Edible Packaging Materials Market held 35% share and generated USD 439.6 million in 2024. The U.S. led the region, benefitting from clear regulatory channels and strong government support for biobased solutions. Ongoing investments in packaging innovation from both private and public entities are reinforcing North America's leadership. State-led initiatives, including plastic bans and eco-packaging mandates, have been instrumental in accelerating adoption. Procurement preferences through federal programs are further encouraging shifts toward edible, biodegradable options.

Key companies in the Global Edible Packaging Materials Market include MonoSol LLC (Kuraray Group), Glanbia PLC, Xampla Ltd., Loliware Inc., Notpla Ltd., Kerry Group, FlexSea Ltd., Evoware (PT. Evogaia Karya Indonesia), Apeel Sciences, Mori (formerly Cambridge Crops), JRF Technology LLC, Sway Innovation Co., Devro PLC, FMC Corporation, and Lactips. Major players in the Edible Packaging Materials Market are adopting multi-pronged strategies to establish strong market positions. Investments in proprietary biopolymer formulations and patenting new edible film technologies are common, enabling performance enhancements and differentiation. Firms are expanding pilot and full-scale production facilities to meet growing demand efficiently. Collaborations with food manufacturers and retail brands help drive commercial adoption, while co-branding initiatives support consumer awareness. Players are also engaging in regulatory partnerships to fast-track certifications and compliance.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Product type trends

- 2.2.2 Agricultural practice trends

- 2.2.3 Application trends

- 2.2.4 Packaging format trends

- 2.2.5 Distribution channel trends

- 2.2.6 Regional trends

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Drivers

- 3.2.2 Pitfalls & Challenges

- 3.2.3 Opportunities:

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By product format

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (HS code Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.13 Carbon footprint consideration

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates and Forecast, By Product, 2021-2034 (USD Million & Kilo Tons)

- 5.1 Key trends

- 5.2 Protein-based films

- 5.2.1 Casein films

- 5.2.2 Whey protein films

- 5.2.3 Gelatin films

- 5.2.4 Collagen films

- 5.2.5 Soy protein films

- 5.2.6 Wheat gluten films

- 5.3 Polysaccharide films

- 5.3.1 Starch-based films

- 5.3.2 Cellulose films

- 5.3.3 Chitosan films

- 5.3.4 Pectin films

- 5.3.5 Alginate films

- 5.3.6 Carrageenan films

- 5.4 Lipid-based coatings

- 5.4.1 Natural wax coatings

- 5.4.2 Fatty acid films

- 5.4.3 Essential oil-based barriers

- 5.5 Composite films

- 5.5.1 Protein-polysaccharide combinations

- 5.5.2 Multi-layer film technologies

- 5.5.3 Nanocomposite integration

- 5.6 Surfactant films

- 5.6.1 Lecithin-based films

- 5.6.2 Specialty emulsifier systems

Chapter 6 Market Estimates and Forecast, By Form, 2021-2034 (USD Million & Kilo Tons)

- 6.1 Key trends

- 6.2 Films & sheets

- 6.2.1 Flexible films

- 6.2.2 Rigid sheets

- 6.2.3 Laminated structures

- 6.3 Coatings

- 6.3.1 Spray-applied coatings

- 6.3.2 Dip coatings

- 6.3.3 Brush-on applications

- 6.4 Molded containers

- 6.4.1 Thermoformed containers

- 6.4.2 Injection molded solutions

- 6.4.3 3d printed packaging

- 6.5 Capsules & encapsulation

- 6.5.1 Hard capsules

- 6.5.2 Soft capsules

- 6.5.3 Microencapsulation

Chapter 7 Market Estimates and Forecast, By Barrier Properties, 2021-2034 (USD Million & Kilo Tons)

- 7.1 Key trends

- 7.2 Moisture barrier applications

- 7.2.1 High moisture barrier

- 7.2.2 Controlled permeability

- 7.2.3 Humidity-responsive systems

- 7.3 Oxygen barrier applications

- 7.3.1 High oxygen barrier

- 7.3.2 Selective permeability

- 7.3.3 Active oxygen scavenging

- 7.4 Antimicrobial properties

- 7.4.1 Natural antimicrobial agents

- 7.4.2 Chitosan-based systems

- 7.4.3 Silver nanoparticle integration

- 7.5 UV protection applications

- 7.5.1 Light-sensitive product protection

- 7.5.2 Photodegradation prevention systems

- 7.5.3 Color stability enhancement

Chapter 8 Market Estimates and Forecast, By Application, 2021-2034 (USD Million & Kilo Tons)

- 8.1 Key trends

- 8.2 Fresh food packaging applications

- 8.2.1 Fruits & vegetables

- 8.2.2 Meat & poultry

- 8.2.3 Seafood & marine products

- 8.2.4 Dairy products

- 8.3 Processed food packaging applications

- 8.3.1 Ready-to-eat meals

- 8.3.2 Frozen foods

- 8.3.3 Snack foods

- 8.3.4 Baked goods

- 8.4 Beverage applications

- 8.4.1 Liquid containers

- 8.4.2 Beverage pods & single-serve

- 8.4.3 Bottle coatings & closures

- 8.5 Confectionery & bakery applications

- 8.5.1 Chocolate & candy

- 8.5.2 Cake & pastry

- 8.5.3 Ice cream & frozen desserts

- 8.6 Pharmaceutical & nutraceutical applications

- 8.6.1 Drug delivery systems

- 8.6.2 Dietary supplements

- 8.6.3 Medical foods

Chapter 9 Market Estimates and Forecast, By Manufacturing Process, 2021-2034 (USD Million & Kilo Tons)

- 9.1 Key trends

- 9.2 Solution casting process

- 9.2.1 Laboratory-scale production

- 9.2.2 Pilot-scale manufacturing

- 9.2.3 Commercial-scale operations

- 9.3 Extrusion process

- 9.3.1 Blown film extrusion

- 9.3.2 Cast film extrusion

- 9.3.3 Co-extrusion

- 9.4 Compression molding

- 9.4.1 Hot press molding

- 9.4.2 Cold press applications

- 9.4.3 Vacuum forming

- 9.5 Coating & lamination

- 9.5.1 Spray coating systems

- 9.5.2 Dip coating processes

- 9.5.3 Lamination technologies

Chapter 10 Market Estimates and Forecast, By Distribution Channel, 2021-2034 (USD Million & Kilo Tons)

- 10.1 Key trends

- 10.2 Direct sales to manufacturers

- 10.2.1 Food & beverage manufacturers

- 10.2.2 Pharmaceutical companies

- 10.2.3 Contract packaging organizations

- 10.3 Packaging distributors & wholesalers

- 10.3.1 Regional packaging distributors

- 10.3.2 Specialty packaging wholesalers

- 10.3.3 International trading companies

- 10.4 Online & digital channels

- 10.4.1. B2B e-commerce platforms

- 10.4.2 Manufacturer direct sales

- 10.4.3 Specialty chemical distributors

Chapter 11 Market Estimates and Forecast, By Region, 2021-2034 (USD Million & Kilo Tons)

- 11.1 Key trends

- 11.2 North America

- 11.2.1 U.S.

- 11.2.2 Canada

- 11.3 Europe

- 11.3.1 Germany

- 11.3.2 UK

- 11.3.3 France

- 11.3.4 Spain

- 11.3.5 Italy

- 11.3.6 Rest of Europe

- 11.4 Asia Pacific

- 11.4.1 China

- 11.4.2 India

- 11.4.3 Japan

- 11.4.4 Australia

- 11.4.5 South Korea

- 11.4.6 Rest of Asia Pacific

- 11.5 Latin America

- 11.5.1 Brazil

- 11.5.2 Mexico

- 11.5.3 Argentina

- 11.5.4 Rest of Latin America

- 11.6 Middle East and Africa

- 11.6.1 Saudi Arabia

- 11.6.2 South Africa

- 11.6.3 UAE

- 11.6.4 Rest of Middle East and Africa

Chapter 12 Company Profiles

- 12.1 Notpla Ltd.

- 12.2 MonoSol LLC (Kuraray Group)

- 12.3 Xampla Ltd.

- 12.4 Evoware (PT. Evogaia Karya Indonesia)

- 12.5 Lactips

- 12.6 FlexSea Ltd.

- 12.7 Sway (Sway Innovation Co.)

- 12.8 Apeel Sciences

- 12.9 Loliware Inc.

- 12.10 JRF Technology LLC

- 12.11 Devro PLC

- 12.12 Kerry Group

- 12.13 Glanbia PLC

- 12.14 FMC Corporation

- 12.15 Mori (fka Cambridge Crops)

- 12.16 Others