|

市场调查报告书

商品编码

1913482

奈米纤维素市场机会、成长要素、产业趋势分析及2026年至2035年预测Nanocellulose Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2026 - 2035 |

||||||

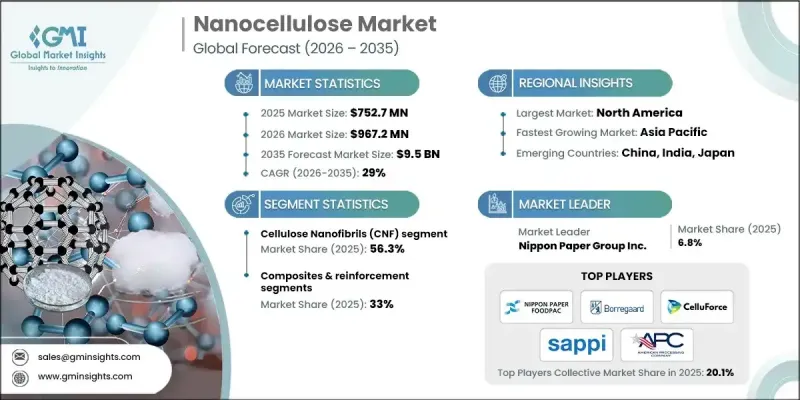

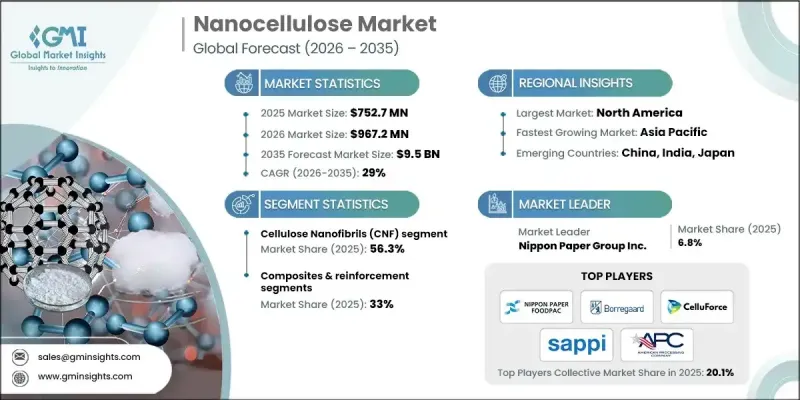

全球奈米纤维素市场预计到 2025 年将达到 7.527 亿美元,到 2035 年将达到 95 亿美元,年复合成长率为 29%。

奈米纤维素是一种源自纤维素(地球上最丰富的生物聚合物)的生物基奈米材料,具有优异的刚度重量比、高比表面积和可客製化的表面化学性质。其拉伸强度可达约10 GPa,纤维素奈米晶体的杨氏模数为140-150 GPa,使其成为高要求应用中石油基添加剂的理想替代品。目前,奈米纤维素市场主要围绕着三种类型:纤维素奈米晶体(CNC)、纤维素奈米纤维(CNF)和细菌奈米纤维素(BNC),每种类型都具有独特的形貌和製造方法,适用于特定的工业应用。可持续包装的日益普及、生物医学解决方案(例如创伤护理支架和水凝胶)的开发,以及奈米纤维素在穿戴式装置和下一代电池等储能装置中的应用,都进一步推动了永续纤维素市场的扩张。

| 市场覆盖范围 | |

|---|---|

| 开始年份 | 2025 |

| 预测年份 | 2026-2035 |

| 起始值 | 7.527亿美元 |

| 预测金额 | 95亿美元 |

| 复合年增长率 | 29% |

由于纤维素奈米纤维(CNF)在流变改质、涂层和增强等方面的广泛应用,预计到2025年,其市场份额将达到56.3%。挪威和日本等地区的大规模工业活动支撑着CNF的生产,CNF广泛应用于建筑外加剂、水性涂料和其他商业领域。透过酸水解法製备的纤维素奈米晶体(CNC)具有棒状晶体结构,结晶质度高,氧气阻隔性能优异,因此适用于先进薄膜和复合材料。

预计到2025年,复合材料和增强材料领域将占据33%的市场份额,因为汽车製造商和一级供应商都在寻求使用CNF增强工程塑胶来製造轻量化且耐用的汽车零件。在纸张和纸板应用领域,CNF用于提高拉伸强度和表面性能,同时减少纤维用量;而在包装和阻隔薄膜领域,对耐氧性和可堆肥性的应用需求持续成长。

预计到2025年,北美奈米纤维素市场份额将达到39.3%,这得益于其强大的研究基础设施、先导工厂以及产学研之间的积极合作。研究机构和政府部门的商业化支持措施进一步巩固了该地区的市场领先地位。

目录

第一章调查方法和范围

第二章执行摘要

第三章业界考察

- 生态系分析

- 供应商情况

- 利润率

- 每个阶段的附加价值

- 影响价值链的因素

- 中断

- 产业影响因素

- 司机

- 产业潜在风险与挑战

- 市场机会

- 成长潜力分析

- 监管环境

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 波特五力分析

- PESTEL 分析

- 价格趋势

- 按地区

- 按形式

- 未来市场趋势

- 科技与创新趋势

- 当前技术趋势

- 新兴技术

- 专利状态

- 贸易统计(HS编码)(註:仅提供主要国家的贸易统计)

- 主要进口国

- 主要出口国

第四章 竞争情势

- 介绍

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 按地区

- 企业矩阵分析

- 主要市场公司的竞争分析

- 竞争定位矩阵

- 重大进展

- 併购

- 伙伴关係与合作

- 新产品发布

- 业务拓展计划

第五章 2022-2035年按产品分類的市场估算与预测

- 纤维素奈米晶体(CNCs)

- 硫酸化C控制

- 羧基化CNC

- 其他化学改质纤维素奈米晶体

- 纤维素奈米纤维(CNF)

- 酵素处理的CNF

- TEMPO介导的氧化

- 羧甲基化

- 细菌奈米纤维素(BNC)

- 纤维素微晶(CMC/MCC)

- 表面改质和功能化的奈米纤维素

第六章 按应用领域分類的市场估算与预测,2022-2035年

- 复合材料和增强材料

- 聚合物基质的类型

- 热塑性复合材料

- 热固性复合材料

- 生物基聚合物复合材料

- 聚合物基质的类型

- 包装/阻隔膜

- 食品接触应用

- 氧气阻隔膜

- 防潮涂层

- 耐油包装

- 主动式智慧包装

- 可生物降解包装解决方案

- 食品接触应用

- 油漆和涂料

- 流变学调整

- 阻隔及保护涂层

- 防腐蚀应用

- 提高纸张和纸板的质量

- 生医医疗保健

- 过滤和薄膜技术

- 水处理应用

- 空气过滤

- 油水分离

- 重金属去除

- 储能和电子

- 电池隔离膜

- 超级电容电极

- 柔性电子基板

- 感测器和致动器

- 流变改性剂和添加剂

- 农业用途

- 建筑材料

- 水泥和混凝土添加剂

- 黏合剂和密封剂

- 木质复合材料/结构木材

第七章 2022-2035年各地区市场估算与预测

- 北美洲

- 美国

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 西班牙

- 义大利

- 其他欧洲地区

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 韩国

- 亚太其他地区

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 其他拉丁美洲地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 阿拉伯聯合大公国

- 其他中东和非洲地区

第八章:公司简介

- Sappi Limited

- Borregaard ASA

- CelluForce Inc.

- FPInnovations

- American Process Inc.(API)

- Kruger Inc.

- Daicel Corporation

- Nippon Paper Group Inc.

- Melodea Ltd.

- J. Rettenmaier &Sohne GmbH+Co. KG

- CelluComp Ltd.

- Asahi Kasei Corporation

- Oji Holdings Corporation

- Stora Enso

- Holmen AB

- Anomera

The Global Nanocellulose Market was valued at USD 752.7 million in 2025 and is estimated to grow at a CAGR of 29% to reach USD 9.5 billion by 2035.

Nanocellulose, a bio-based nanomaterial derived from cellulose, the planet's most abundant biopolymer, offers a remarkable stiffness-to-weight ratio, high specific surface area, and customizable surface chemistry. Its tensile strength can reach approximately 10 GPa, with a Young's modulus of 140-150 GPa for cellulose nanocrystals, enabling it to replace petroleum-based additives in demanding applications. The market revolves around three main types: cellulose nanocrystals (CNC), cellulose nanofibrils (CNF), and bacterial nanocellulose (BNC), each with unique morphologies and production methods suited to specific industrial applications. Growing adoption of sustainable packaging, development of biomedical solutions such as wound care scaffolds and hydrogels, and integration into energy storage devices for wearables and next-generation batteries are further accelerating market expansion.

| Market Scope | |

|---|---|

| Start Year | 2025 |

| Forecast Year | 2026-2035 |

| Start Value | $752.7 Million |

| Forecast Value | $9.5 Billion |

| CAGR | 29% |

The cellulose nanofibrils (CNF) segment captured 56.3% share in 2025 owing to their versatility in rheology modification, coatings, and reinforcement. CNF production is supported by large-scale industrial operations in regions such as Norway and Japan, and is applied across construction admixtures, waterborne coatings, and other commercial uses. Cellulose nanocrystals (CNC), produced through acid hydrolysis, deliver rod-like crystals with high crystallinity and excellent oxygen barrier properties, making them suitable for advanced films and composites.

The composites and reinforcement segment accounted for 33% share in 2025, driven by automakers and Tier 1 suppliers exploring CNF-reinforced engineering plastics for lightweight yet durable automotive components. Paper and paperboard applications leverage CNF to enhance tensile strength and surface properties while reducing fiber use, and packaging and barrier films continue to gain traction for applications requiring oxygen resistance and compostability.

North America Nanocellulose Market held 39.3% share in 2025, backed by robust research infrastructure, pilot plants, and active collaboration between industry and academia. Initiatives by research institutions and government agencies supporting commercialization have further strengthened the region's market leadership.

Key companies operating in the Global Nanocellulose Market include Borregaard ASA, Kruger Inc., FPInnovations, Sappi Limited, Stora Enso, CelluForce Inc., Oji Holdings Corporation, Holmen AB, Melodea Ltd., J. Rettenmaier & Sohne GmbH + Co. KG, CelluComp Ltd., Asahi Kasei Corporation, Daicel Corporation, and American Process Inc. (API). Market players in the Global Nanocellulose Market are adopting multiple strategies to solidify their presence and expand market share. These include investing in R&D for novel applications, forming strategic partnerships with end-use industries, and expanding production capacities through commercial-scale facilities. Companies are also prioritizing sustainable sourcing, enhancing process efficiencies, and exploring high-value applications in biomedical, packaging, and energy storage sectors. Additionally, marketing initiatives, intellectual property protection, and global distribution network expansion are key tactics employed to strengthen brand visibility and maintain leadership in a rapidly evolving market.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Product

- 2.2.3 Application

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By form

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (HS code) ( Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates and Forecast, By Product, 2022-2035 (USD Billion & Tons)

- 5.1 Key trends

- 5.2 Cellulose Nanocrystals (CNC)

- 5.2.1 Sulfated CNC

- 5.2.2 Carboxylated CNC

- 5.2.3 Other chemically modified CNC

- 5.3 Cellulose Nanofibrils (CNF)

- 5.3.1 Enzymatically treated CNF

- 5.3.2 TEMPO-Mediated Oxidation

- 5.3.3 Carboxymethylation

- 5.4 Bacterial Nanocellulose (BNC)

- 5.5 Cellulose Microcrystals (CMC/MCC)

- 5.6 Surface-Modified & Functionalized Nanocellulose

Chapter 6 Market Estimates and Forecast, By Application, 2022-2035 (USD Billion & Tons)

- 6.1 Key trends

- 6.2 Composites & Reinforcement

- 6.2.1 Polymer Matrix Types

- 6.2.1.1 Thermoplastic Composites

- 6.2.1.2 Thermoset Composites

- 6.2.1.3 Bio-Based Polymer Composites

- 6.2.1 Polymer Matrix Types

- 6.3 Packaging & Barrier Films

- 6.3.1 Food Contact Applications

- 6.3.1.1 Oxygen Barrier Films

- 6.3.1.2 Moisture Barrier Coatings

- 6.3.1.3 Grease-Resistant Packaging

- 6.3.2 Active & Intelligent Packaging

- 6.3.3 Biodegradable Packaging Solutions

- 6.3.1 Food Contact Applications

- 6.4 Coatings & Paints

- 6.4.1 Rheology Modification

- 6.4.2 Barrier & Protective Coatings

- 6.4.3 Anti-Corrosion Applications

- 6.5 Paper & Paperboard Enhancement

- 6.6 Biomedical & Healthcare

- 6.7 Filtration & Membranes

- 6.7.1 Water Treatment Applications

- 6.7.2 Air Filtration

- 6.7.3 Oil-Water Separation

- 6.7.4 Heavy Metal Removal

- 6.8 Energy Storage & Electronics

- 6.8.1 Battery Separators

- 6.8.2 Supercapacitor Electrodes

- 6.8.3 Flexible Electronics Substrates

- 6.8.4 Sensors & Actuators

- 6.9 Rheology Modifiers & Additives

- 6.10 Agricultural Applications

- 6.11 Construction Materials

- 6.11.1 Cement & Concrete Additives

- 6.11.2 Adhesives & Sealants

- 6.11.3 Wood Composites & Engineered Wood

Chapter 7 Market Estimates and Forecast, By Region, 2022-2035 (USD Billion & Tons)

- 7.1 Key trends

- 7.2 North America

- 7.2.1 U.S.

- 7.2.2 Canada

- 7.3 Europe

- 7.3.1 Germany

- 7.3.2 UK

- 7.3.3 France

- 7.3.4 Spain

- 7.3.5 Italy

- 7.3.6 Rest of Europe

- 7.4 Asia Pacific

- 7.4.1 China

- 7.4.2 India

- 7.4.3 Japan

- 7.4.4 Australia

- 7.4.5 South Korea

- 7.4.6 Rest of Asia Pacific

- 7.5 Latin America

- 7.5.1 Brazil

- 7.5.2 Mexico

- 7.5.3 Argentina

- 7.5.4 Rest of Latin America

- 7.6 Middle East and Africa

- 7.6.1 Saudi Arabia

- 7.6.2 South Africa

- 7.6.3 UAE

- 7.6.4 Rest of Middle East and Africa

Chapter 8 Company Profiles

- 8.1 Sappi Limited

- 8.2 Borregaard ASA

- 8.3 CelluForce Inc.

- 8.4 FPInnovations

- 8.5 American Process Inc. (API)

- 8.6 Kruger Inc.

- 8.7 Daicel Corporation

- 8.8 Nippon Paper Group Inc.

- 8.9 Melodea Ltd.

- 8.10 J. Rettenmaier & Sohne GmbH + Co. KG

- 8.11 CelluComp Ltd.

- 8.12 Asahi Kasei Corporation

- 8.13 Oji Holdings Corporation

- 8.14 Stora Enso

- 8.15 Holmen AB

- 8.16 Anomera