|

市场调查报告书

商品编码

1636446

欧洲电动车电池隔膜:市场占有率分析、产业趋势/统计、成长预测(2025-2030)Europe Electric Vehicle Battery Separator - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

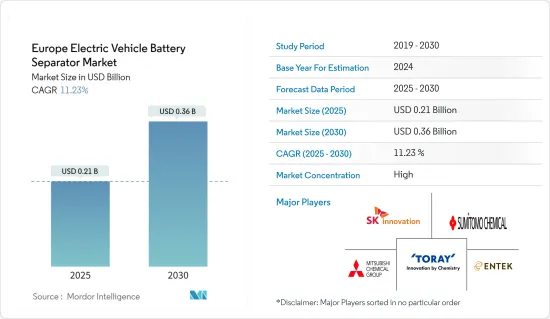

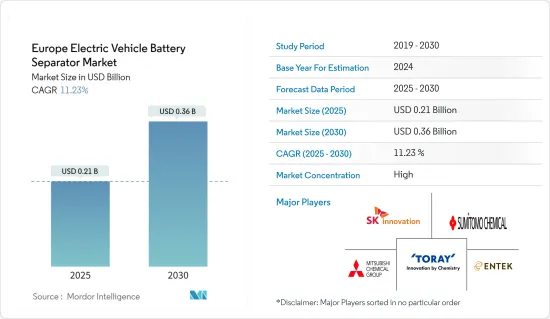

预计2025年欧洲电动车电池隔膜市场规模为2.1亿美元,2030年将达3.6亿美元,预测期内(2025-2030年)复合年增长率为11.23%。

主要亮点

- 电动车的普及和锂离子电池价格的下降预计将在中期推动市场发展。

- 相反,欧洲电池产业正遭受原物料成本上涨的影响。尤其是隔膜製造所必需的聚乙烯(PE)和聚丙烯(PP)等关键材料的价格大幅上涨。这种趋势对市场扩张提出了潜在的挑战。

- 然而,固态电池、先进锂离子电池和钠离子电池等替代电池化学材料的研究和开发正在蓬勃发展,为未来的市场成长带来了广阔的前景。

- 德国可能在预测期内的市场扩张中发挥关键作用,柏林、汉堡和慕尼黑等城市引领需求激增。

欧洲电动车电池隔膜市场趋势

锂离子电池领域可望主导市场

- 近年来,欧洲锂离子电池市场出现了显着的快速成长。由于有前景的投资,特别是公共基础设施和公共交通等公私合营计划,该国的锂离子电池销售显着增强。

- 除了非洲大陆越来越多地采用电动车之外,电池隔膜也受益于旨在遏制碳排放的各种政府倡议。这些倡议是成长的催化剂。此外,聚烯和陶瓷氧化物增强型锂离子电池的推出,以其稳定性、安全性、减少收缩和颗粒侵入的能力而闻名,正在为市场带来进一步的动力。

- 汽车的混合动力化和电气化正在全球范围内取得进展。这包括混合动力汽车(HEV)、插电式混合动力汽车和全电动汽车 (EV)。主导《巴黎协定》的欧洲积极推动内燃机汽车向电动车转型,并在此过程中实现了显着成长。

- 根据《2023 年欧洲运输与环境报告》,到 2030 年,英国锂矿开采能力预计将达到 7,000 吨。此外,2023年11月,英国政府宣布了一项25亿美元的先进製造计画。该计划包括一项由政府资助约 5,400 万美元的新电池策略,旨在 2030 年培育具有竞争力的电池供应链。该计划旨在随着汽车製造商转向本地电池生产并转向纯电动车(BEV),增强供应链的弹性。电池策略扩大了对零排放汽车、电池及其供应链的重点支持,在截至 2030 年的五年内提供专门资本和研发资金。

- 2023 年,全球隔膜製造领导者 Alteo 与 W Scope 签署协议,建立欧洲最大的隔膜製造厂。该合资企业对于培育法国和欧洲价值链至关重要,特别是考虑到多个超级工厂计划。特别值得注意的是,该工厂将是欧洲唯一完全依赖电能运作的工厂,生产的隔膜将由 SEPal 的高性能氧化铝製成。

- 基于这些发展,锂离子电池领域预计将在未来几年引领欧洲电动车电池隔膜市场。

德国可望主导市场

- 德国是领先的电动车(EV)中心,政府正在积极推动电动车的采用以减少排放。德国拥有世界上最好的充电基础设施之一,引领欧洲成为最大的电动车市场。与全球趋势类似,由于向永续交通途径的转变,德国对电动车的需求正在迅速增长,这推动了电池隔离膜市场的发展。

- 随着消费者和企业越来越多地采用电动车,对电池隔膜的需求也迅速增加。这一势头的推动因素包括环境问题、政府支持电动车采用的奖励以及电池技术的突破性进步,这些技术使电动车变得更容易获得和实用。

- 到2023年,德国插电式混合动力车销量将超过18万辆。展望未来,德国的目标是到 2030 年拥有 1500 万辆电动车。这项宏伟目标的核心是政府的支持政策和奖励。例如,在德国,政府和电动车製造商各自为售价高达 60,000 欧元的电动车提供 2,000 欧元,总合4,000 欧元。此外,电动车可免征10年车辆税,并且根据电池尺寸还有特殊税收奖励。

- 德国的吸引力超越了国界,吸引了全球投资建立锂离子电池製造中心。作为这一趋势的证据,宁德时代新能源科技有限公司(CATL)于 2023 年在德国开设了一家新的锂离子电池工厂。

- 另一个重要倡议是,获得德国政府 10 亿欧元资金的 Northvolt AB 宣布计划于 2023 年 5 月在德国北部建造第二座电池製造工厂。

- 欧洲产业政策预计,到2030年欧洲电池产能将超过1,000GWh,年增率超过20%。新推出的欧盟电池法规强调加强本地供应链。鑑于这些预测,德国对湿式分离器的需求将显着成长。

- 随着德国电动车市场的持续扩大,电动车电池隔膜的需求预计在预测期内也会增加。

欧洲电动汽车电池隔膜产业概况

欧洲电动车电池隔膜市场正在变得半固体。该市场的主要企业(排名不分先后)包括 Entek Manufacturing LLC、SK Innovation、三菱化学集团、东丽和住友化学。

其他好处

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第一章简介

- 调查范围

- 市场定义

- 研究场所

第二章调查方法

第三章执行摘要

第四章市场概况

- 介绍

- 2029年之前的市场规模与需求预测(单位:美元)

- 最新趋势和发展

- 政府法规政策

- 市场动态

- 促进因素

- 电动车的扩张

- 锂离子电池价格下降

- 抑制因素

- 原料成本上涨

- 促进因素

- 供应链分析

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代产品/服务的威胁

- 竞争公司之间的敌对关係

- 投资分析

第五章市场区隔

- 依电池类型

- 锂离子电池

- 铅酸电池

- 其他电池类型

- 按材质

- 聚丙烯

- 聚乙烯

- 其他材料

- 地区

- 英国

- 德国

- 义大利

- 西班牙

- 法国

- 荷兰

- 比利时

- 其他欧洲国家

第六章 竞争状况

- 併购、合资、联盟、协议

- 主要企业策略

- 公司简介

- Entek Manufacturing LLC

- SK Innovation Co. Ltd

- Mitsubishi Chemical Group Corporation

- Hitachi Chemical Company Ltd

- Toray Industries Inc.

- Sumitomo Chemical Co. Ltd

- UBE Corp

- Teijin Ltd

- Yunnan Enjie New Materials Co. Ltd

- Cangzhou Mingzhu Plastic Co. Ltd

- Senior Europe

- Market Ranking/Share(%)Analysis

- List of Other Prominent Companies

第七章 市场机会及未来趋势

- 活性化其他电池化学的研究和开发

简介目录

Product Code: 50003713

The Europe Electric Vehicle Battery Separator Market size is estimated at USD 0.21 billion in 2025, and is expected to reach USD 0.36 billion by 2030, at a CAGR of 11.23% during the forecast period (2025-2030).

Key Highlights

- The growing adoption of electric vehicles and the decreasing price of lithium-ion batteries are expected to drive the market over the medium term.

- Conversely, the European battery sector grapples with rising raw material costs. Key materials, especially polyethylene (PE) and polypropylene (PP) - crucial for separator manufacturing - are seeing significant price hikes. This trend poses a potential challenge to the market's expansion.

- However, heightened research and development into alternative battery chemistries, including solid-state batteries, advanced lithium-ion variants, and sodium-ion batteries, present promising opportunities for future market growth.

- Germany is set to play a pivotal role in the market's expansion during the forecast period, with cities like Berlin, Hamburg, and Munich leading the demand surge.

Europe Electric Vehicle Battery Separator Market Trends

Lithium-ion Battery Segment is Expected to Dominate the Market

- In recent years, the European nation has seen a notable surge in its lithium-ion battery market. Sales of lithium-ion batteries in the country have been significantly bolstered by promising investments from public-private partnership projects, particularly in civil infrastructure and public transit.

- In addition to the continent's growing adoption of electric vehicles, battery separators are reaping benefits from various government initiatives aimed at curbing carbon emissions. These initiatives serve as a catalyst for growth. Furthermore, the introduction of lithium-ion batteries enhanced with polyolefins and ceramic oxides-known for their stability, safety, and ability to reduce shrinkage and particle penetration-adds further momentum to the market.

- Globally, vehicles are increasingly adopting hybridization and electrification. The spectrum includes hybrid electric vehicles (HEVs), plug-in hybrids, and fully electric vehicles (EVs). Europe, being the initiator of the Paris Climate Pact, has actively championed the transition from internal combustion vehicles to EVs, witnessing substantial growth in the process.

- As per the European Transport & Environment Report 2023, the UK's lithium mining capacity is projected to reach 7,000 tonnes by 2030. Additionally, in November 2023, the UK government unveiled a USD 2.5 billion Advanced Manufacturing Plan. This plan encompasses a new Battery Strategy, backed by approximately USD 54 million in government funding, aimed at fostering a competitive battery supply chain by 2030. This initiative seeks to bolster supply chain resilience as automakers pivot towards localized battery production, aligning with the broader transition to battery electric vehicles (BEVs). The Battery Strategy is set to extend focused support for zero-emission vehicles, batteries, and their supply chains, with dedicated capital and R&D funding spanning five years, up to 2030.

- In 2023, global separator production leader Alteo, in collaboration with W-Scope, inked a deal to establish Europe's largest separator production facility. This venture is integral to nurturing both French and European value chains, especially in light of multiple gigafactory projects. Notably, this facility will be Europe's sole site powered entirely by electric energy, and the separators produced will feature SEPal's high-performance aluminas.

- Given these developments, the lithium-ion battery segment is poised to lead the European electric vehicle battery separator market in the coming years.

Germany is Expected to Dominate the Market

- Germany stands as a prominent hub for electric vehicles (EVs), with the government actively promoting their adoption to curb emissions. Boasting one of the world's most advanced charging infrastructures, Germany leads Europe as its largest EV market. Echoing global trends, Germany has witnessed a surge in EV demand, driven by a collective shift towards sustainable transportation solutions, subsequently bolstering the battery separator market.

- With the rising adoption of EVs by consumers and businesses alike, the demand for battery separators has surged in tandem. This momentum is fueled by environmental concerns, government incentives championing EV adoption, and breakthroughs in battery technology, rendering EVs more accessible and practical.

- By 2023, sales of plug-in hybrid electric vehicles in Germany surpassed 180,000 units. Setting its sights on the future, Germany aims to have 15 million EVs gracing its roads by 2030. Central to this ambitious goal are the government's supportive policies and incentives. For instance, both the government and EV manufacturers in Germany contribute EUR 2,000 each, totaling EUR 4,000 for electric cars valued up to EUR 60,000. Additionally, EVs enjoy a decade-long exemption from vehicle tax, complemented by a special tax bonus based on battery size.

- Germany's allure extends beyond its borders, drawing global investments to establish lithium-ion battery manufacturing hubs. A testament to this trend, in 2023, Contemporary Amperex Technology Co. Limited (CATL) inaugurated its new lithium-ion battery cell plant in Germany, starting with an 8 GWh annual capacity, with plans to scale up to 14 GWh.

- In another significant move, Northvolt AB, backed by a EUR 1 billion commitment from the German government, unveiled plans for its second battery manufacturing facility in northern Germany in May 2023.

- Looking ahead, European Industrial Policy forecasts Europe's battery production capacity to surpass 1,000 GWh by 2030, boasting a robust annual growth rate exceeding 20%. The newly introduced EU Battery Regulation emphasizes bolstering localized supply chains. Given these projections, the demand for wet process separators in Germany is poised for substantial growth.

- Given these dynamics, as Germany's electric vehicle landscape continues to expand, the demand for electric vehicle battery separators is set to rise correspondingly during the forecast period.

Europe Electric Vehicle Battery Separator Industry Overview

The Europe Electric Vehicle Battery Separator Market is semi-consolidated. Some of the major players in the market (in no particular order) include Entek Manufacturing LLC, SK Innovation Co. Ltd, Mitsubishi Chemical Group Corporation, Toray Industries Inc., and Sumitomo Chemical Co. Ltd, among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 The Growing Adoption of Electric Vehicles

- 4.5.1.2 Decreasing Price of Lithium-ion Batteries

- 4.5.2 Restraints

- 4.5.2.1 Escalating Raw Material Costs

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 Industry Attractiveness - Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Consumers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes Products and Services

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Battery Type

- 5.1.1 Lithium-Ion Batteries

- 5.1.2 Lead-Acid Batteries

- 5.1.3 Other type of Batteries

- 5.2 Material

- 5.2.1 Polypropylene

- 5.2.2 Polyethylene

- 5.2.3 Other Material Types

- 5.3 Geography

- 5.3.1 United Kingdom

- 5.3.2 Germany

- 5.3.3 Italy

- 5.3.4 Spain

- 5.3.5 France

- 5.3.6 Netherlands

- 5.3.7 Belgium

- 5.3.8 Rest of Europe

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 Entek Manufacturing LLC

- 6.3.2 SK Innovation Co. Ltd

- 6.3.3 Mitsubishi Chemical Group Corporation

- 6.3.4 Hitachi Chemical Company Ltd

- 6.3.5 Toray Industries Inc.

- 6.3.6 Sumitomo Chemical Co. Ltd

- 6.3.7 UBE Corp

- 6.3.8 Teijin Ltd

- 6.3.9 Yunnan Enjie New Materials Co. Ltd

- 6.3.10 Cangzhou Mingzhu Plastic Co. Ltd

- 6.3.11 Senior Europe

- 6.4 Market Ranking/Share (%) Analysis

- 6.5 List of Other Prominent Companies

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 The Increasing Research and Development of Other Battery Chemistries

02-2729-4219

+886-2-2729-4219