|

市场调查报告书

商品编码

1636538

电动汽车电池製造设备:市场占有率分析、行业趋势和统计、成长预测(2025-2030 年)Electric Vehicle Battery Manufacturing Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

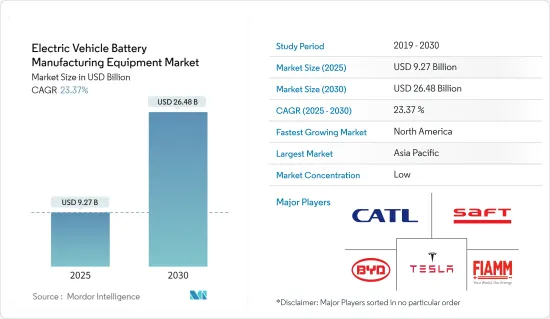

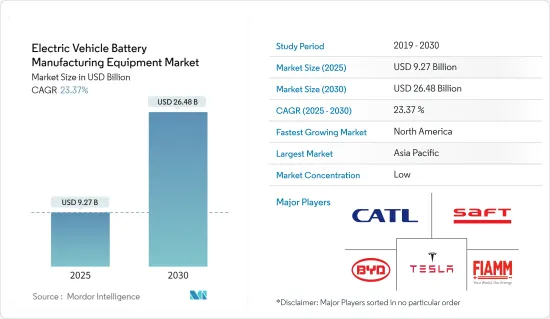

预计 2025 年电动车电池製造设备市场规模为 92.7 亿美元,到 2030 年将达到 264.8 亿美元,预测期内(2025-2030 年)的复合年增长率为 23.37%。

主要亮点

- 从长远来看,电动车的普及和电池原材料成本的下降预计将推动市场发展。

- 另一方面,长期依赖内燃机汽车可能会阻碍向电动车的快速转型,从而限制市场成长。

- 然而,更高容量和更低放电率的技术进步使得电池设备更加可行和高效,为电动车电池製造设备市场创造了巨大的机会。

- 亚太地区占据市场主导地位,其成长受到印度、中国和澳洲等国家不断增加的投资和政府政策的推动。

电动车电池製造设备市场趋势

电动车迅速普及,占据市场主导地位

- 由于汽油和天然气成本的剧烈波动以及各国对排放法规的要求日益严格,人们的注意力正从传统汽车转向电动车(EV)。电动车效率更高,电费更便宜,因此为电动车充电比加满汽油或柴油更便宜。使用可再生能源使电动车更加环保。

- 此外,随着对电动车的需求不断增长,汽车製造商正在为所有汽车领域设计和销售各种类型和设计的电动车。这种车辆设计的客製化为电池製造创造了巨大的成长机会,以满足汽车製造商的需求。

- 2023年10月,BMW将在慕尼黑附近开设新的电池单元试点工厂,实现其「本地为本地」的电池供应链和生产策略。 BMW电池製造能力中心(CMCC)将生产圆柱形电池,预计将提高公司电池生产和供应的效率、品质和稳定性。

- 预计近年来电动车的涌入将在预测期内推动对电池製造设备的需求。根据国际能源总署(IEA)的数据,2023年全球电动车总销量将达1,380万辆,高于去年的1,020万辆。

- 一些国家已决定在 2030 年增加电动车的份额。例如,中国的目标是到2030年,电动车占汽车销量的40%。随着电动车保有量的增加,预计电池需求也将大幅成长。根据国际能源总署 (IEA) 的数据,到 2035 年电动车电池的需求预计将比 2023 年增加七倍。

- 考虑到这种情况,预计汽车产业将成为预测期内成长最快的产业。

预计亚太地区市场将大幅成长

- 随着人们对环境问题的认识不断提高,以及可以改善日益恶化的环境的技术,亚太地区的电动车电池製造设备市场正在不断增长。亚太地区人口众多,经济成长迅速,其中中国、印度、东南亚国协等国家是市场推动力,预计该地区对电池的需求将稳定成长。

- 由于电动车产业的蓬勃发展、供应链中领先产业参与者的存在以及经济的快速成长,中国在电池製造设备市场占据主导地位。该地区拥有全球大部分的锂离子蕴藏量。根据国际能源总署预测,2023年中国电动车销量将达到约810万辆,高于去年的590万辆。这是亚太地区最高的。

- 预计亚太地区电动车电池製造超级工厂的成长将在未来几年推动製造设备市场的发展。例如,2023年1月,Recharge Industries宣布,到2024年将在澳洲吉朗地区每年生产2GWh的电动车电池,到2026年生产6GWh的电动车电池。该大型工厂价值 3 亿美元,预计将改善该国的电池供应价值链。

- 政府鼓励发展电动车的目标和倡议可能会进一步推动亚太地区的市场成长。例如,在印度,政府的目标是到 2030 年使电动车 (EV) 占个人汽车销量的 30%、商用车销量的 70% 以及两轮车和三轮车销量的 80%。

- 因此,由于产量增加、技术进步以及政府对电动车电池製造设备市场的支持政策,预计亚太地区将在预测期内占据市场主导地位。

电动汽车电池製造设备产业概况

电动车电池製造设备市场较为分散,参与者众多。主要参与者(不分先后顺序)包括 NEC、Duerr AG、Hitachi、Schuler AG 和 Buhler Holding AG。

其他福利:

- Excel 格式的市场预测 (ME) 表

- 3 个月分析师支持

目录

第 1 章 简介

- 研究范围

- 市场定义

- 调查前提

第 2 章执行摘要

第三章调查方法

第四章 市场概况

- 介绍

- 2029 年市场规模与需求预测(美元)

- 最新趋势和发展

- 政府法规和政策

- 市场动态

- 驱动程式

- 电动车日益普及

- 降低电池原物料成本

- 限制因素

- 长期依赖内燃机汽车

- 驱动程式

- 供应链分析

- 波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争对手之间的竞争

- 投资分析

第五章 市场区隔

- 按工艺

- 混合物

- 涂层

- 日历

- 狭缝/电极加工

- 其他流程

- 透过电池

- 锂离子

- 铅酸电池

- 镍氢电池

- 按地区

- 北美洲

- 美国

- 加拿大

- 北美其他地区

- 欧洲

- 英国

- 西班牙

- 北欧国家

- 土耳其

- 俄罗斯

- 其他欧洲国家

- 亚太地区

- 中国

- 印度

- 马来西亚

- 泰国

- 印尼

- 越南

- 韩国

- 其他亚太地区

- 南美洲

- 巴西

- 阿根廷

- 哥伦比亚

- 南美洲其他地区

- 中东和非洲

- 阿拉伯聯合大公国

- 沙乌地阿拉伯

- 埃及

- 奈及利亚

- 卡达

- 其他中东和非洲地区

- 北美洲

第六章 竞争格局

- 併购、合资、合作与协议

- 主要企业策略

- 公司简介

- NEC Corporation

- Duerr AG

- Hitachi Ltd

- Schuler AG

- Buhler Holding AG

- Manz AG

- Sovema Group SpA

- Komatsu NTC Ltd

- KROENERT GmbH & Co. KG.

- List of Other Prominent Companies

- 市场排名分析

第七章 市场机会与未来趋势

- 各种技术的进步日益

简介目录

Product Code: 50003971

The Electric Vehicle Battery Manufacturing Equipment Market size is estimated at USD 9.27 billion in 2025, and is expected to reach USD 26.48 billion by 2030, at a CAGR of 23.37% during the forecast period (2025-2030).

Key Highlights

- Over the long term, the increasing adoption of electric vehicles and the decline in the cost of raw battery materials are expected to drive the market.

- On the other hand, the long-term dependency on internal combustion engine vehicles could hinder the rapid transition to electric vehicles, which may restrain the growth of the market.

- However, the growing technological advancements in higher capacity and low discharge rates are expected to make battery equipment more feasible and efficient and create enormous opportunities for the electric vehicle battery manufacturing equipment market.

- Asia-Pacific dominates the market, and its growth will be linked to rising investments and conducive government policies in countries such as India, China, and Australia.

Electric Vehicle Battery Manufacturing Equipment Market Trends

Rapid Adoption of Electric Vehicles to Dominate the Market

- The increasing cost fluctuations of gasoline and natural gas and the growing demand for emission controls in various countries have shifted the focus from conventional vehicles to electric vehicles (EVs). Electric vehicles are more efficient, which, combined with the lower cost of electricity, makes charging an electric vehicle cheaper than filling up with petrol or diesel for your travel needs. Using renewable energy sources can make electric vehicles more eco-friendly.

- Moreover, as the demand for electric vehicles increases, automobile manufacturing companies are designing electric vehicles for all car segments in various types and designs to increase their sales. This customization in automobile design provides a significant growth opportunity for battery manufacturing to meet automobile manufacturers' demands.

- In October 2023, BMW established its new battery cell pilot plant near Munich to fulfill its 'local for local' battery supply chain and production strategy. BMW Cell Manufacturing Competence Center (CMCC) will manufacture cylindrical cells, which is expected to boost the company's efficiency, quality, and stability in battery production and supply.

- The influx of electric vehicles in recent years is expected to propel the demand for battery manufacturing equipment during the forecast period. According to the International Energy Agency (IEA), the total sales of electric vehicles worldwide were 13.8 million in 2023, an increase from 10.2 million the previous year.

- By 2030, several countries have decided to increase the share of electric vehicles. For instance, countries like China aim to have 40% of vehicles sold by 2030 to be electric. With the growth in the EV population, battery demand is expected to witness significant growth. According to the International Energy Agency, by 2035, EV battery demand is expected to increase by seven times compared to 2023.

- Considering such a scenario, the automotive industry is expected to be the fastest-growing segment during the forecast period.

Asia-Pacific is Expected to Witness Significant Growth in the Market

- The electric vehicle battery manufacturing equipment market is constantly rising in Asia-Pacific due to the rising public awareness of environmental issues and techniques to improve constantly deteriorating conditions. Due to the region's large population and fast-growing economy, the demand for batteries in Asia-Pacific is expected to grow steadily, with countries such as China, India, and the ASEAN countries driving the market.

- China dominates the battery manufacturing equipment market with a significant electric car industry, leading industry players across the supply chain, and a rapidly rising economy. The region has the majority of the world's lithium-ion reserves. As per the International Energy Agency, the sales of electric cars in China in 2023 were about 8.1 million, from 5.9 million in the previous year. This appeared to be the highest in Asia-Pacific.

- The growth of electric vehicle battery manufacturing gigafactors in Asia-Pacific is expected to push its manufacturing equipment market in the coming years. For instance, in January 2023, the Recharge Industries firm noted that it would construct close to 2 GWh of annual electric vehicle battery production by 2024 and 6 GWh by 2026 in Australia's Geelong region. The gigagactory worth USD 300 million is expected to improve the country's electric battery supply-value chain.

- Government targets and initiatives to expedite the development of electric vehicles could further drive market growth in Asia-Pacific. For instance, in India, by 2030, the government aims for electric vehicles (EVs) to make up 30% of private car sales, 70% of commercial vehicle sales, and 80% of sales of two- and three-wheelers.

- Hence, Asia-Pacific is expected to dominate the market during the forecast period due to increased production, technological advancements, and supportive government policies in the electric vehicle battery equipment manufacturing market.

Electric Vehicle Battery Manufacturing Equipment Industry Overview

The electric vehicle battery manufacturing equipment market is fragmented, with several players. Some of the major players (not in particular order) include NEC Corporation, Duerr AG, Hitachi Ltd, Schuler AG, and Buhler Holding AG.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Increasing adoption of electric vehicles

- 4.5.1.2 Decline in cost of battery raw materials

- 4.5.2 Restraints

- 4.5.2.1 Long-term dependency on internal combustion engine vehicles

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Consumers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes Products and Services

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Process

- 5.1.1 Mixing

- 5.1.2 Coating

- 5.1.3 Calendering

- 5.1.4 Slitting and electrode making

- 5.1.5 Other Processes

- 5.2 Battery

- 5.2.1 Lithium-ion

- 5.2.2 Lead-acid

- 5.2.3 Nickel Metal Hydride Battery

- 5.3 Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.1.3 Rest of North America

- 5.3.2 Europe

- 5.3.2.1 United Kingdom

- 5.3.2.2 Spain

- 5.3.2.3 NORDIC Countries

- 5.3.2.4 Turkey

- 5.3.2.5 Russia

- 5.3.2.6 Rest of Europe

- 5.3.3 Asia-Pacific

- 5.3.3.1 China

- 5.3.3.2 India

- 5.3.3.3 Malaysia

- 5.3.3.4 Thailand

- 5.3.3.5 Indonesia

- 5.3.3.6 Vietnam

- 5.3.3.7 South Korea

- 5.3.3.8 Rest of Asia-Pacific

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Colombia

- 5.3.4.4 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 United Arab Emirates

- 5.3.5.2 Saudi Arabia

- 5.3.5.3 Egypt

- 5.3.5.4 Nigeria

- 5.3.5.5 Qatar

- 5.3.5.6 Rest of Middle East and Africa

- 5.3.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 NEC Corporation

- 6.3.2 Duerr AG

- 6.3.3 Hitachi Ltd

- 6.3.4 Schuler AG

- 6.3.5 Buhler Holding AG

- 6.3.6 Manz AG

- 6.3.7 Sovema Group S.p.A

- 6.3.8 Komatsu NTC Ltd

- 6.3.9 KROENERT GmbH & Co. KG.

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Growing technological advancements in various technologies

02-2729-4219

+886-2-2729-4219