|

市场调查报告书

商品编码

1636469

东南亚国协电动车电池製造:市场占有率分析、产业趋势、成长预测(2025-2030)ASEAN Countries Electric Vehicle Battery Manufacturing - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

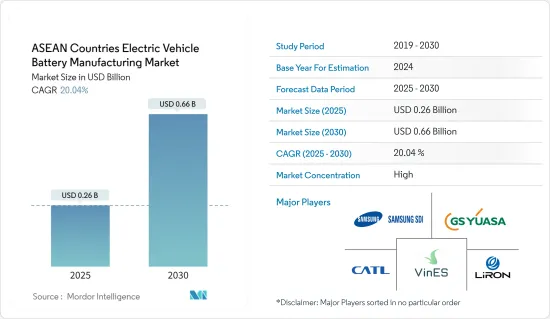

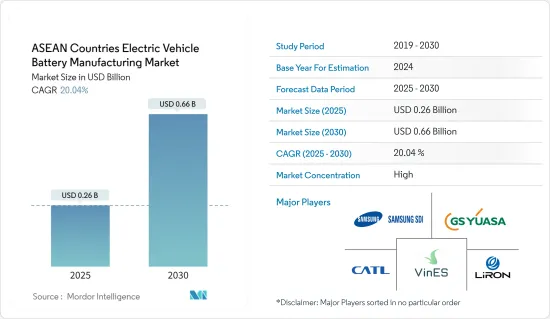

东南亚国协的电动车电池製造市场规模预计到2025年为2.6亿美元,预计到2030年将达到6.6亿美元,预测期内(2025-2030年)复合年增长率为20.04%。

主要亮点

- 从中期来看,电动车(EV)普及率的不断提高以及政府加强电池生产的支持措施和投资预计将在预测期内推动东南亚国协电动车电池製造市场的需求。

- 另一方面,原材料供需不匹配预计将阻碍预测期内的市场成长。

- 然而,电池技术的进步以及汽车製造商和电池製造商之间的合作预计将为未来各国的电动车电池製造市场创造重大机会。

- 在该地区所有国家中,由于参与电动车电池製造的企业数量不断增加,泰国预计将显着成长。

东南亚国协电动车电池製造市场趋势

乘用车板块实现大幅成长

- 东协(东南亚国家联盟)电动车(EV)电池製造市场预计将显着成长,尤其是在乘用车领域。这种快速增长的推动因素包括电动车的日益普及、政府支持清洁能源的倡议以及消费者对环境问题意识的不断增强。近年来,印尼、马来西亚、泰国、越南和菲律宾等国家已成为电动车领域的重要参与者。

- 根据东协汽车联合会(AAF)报告,2023年东协地区乘用车产量为274.8万辆,比2022年的266.5万辆增加3.11%。 2023年该地区产量约2,283,000辆,较上年的2,212,000辆成长3.21%。值得注意的是,印尼、马来西亚和泰国总合占该地区乘用车产量的83%以上。

- 展望未来,东协地区乘用车的成长预计将因政府促进电动车采用的支持措施而加强。因此,对电动车电池的需求将会增加。由于政府采取积极措施,泰国、印尼、新加坡、马来西亚和菲律宾等国家预计将迅速普及电动车。例如,菲律宾的目标是到 2030 年电动车占所有车辆的 21%,到 2040 年达到 50%。除其他福利外,菲律宾电动车协会 (EVAP) 大胆地将其 2030 年电动车普及率目标从 30 万辆提高到 100 万辆,并提供预期的行业奖励、监管明确性,我希望人们的意识会提高。

- 印尼的野心同样引人注目,目标是到 2025 年电动车占汽车销量的 20%,到 2030 年国内电动车产量达到 60 万辆。这些雄心壮志体现在整个电动车供应链的具体里程碑中,包括销售、生产和充电基础设施,推动了电动车电池製造业的发展。

- 为了支持这一势头,印尼于 2024 年 7 月在西爪哇省运作了第一家电动车电池工厂。该工厂由现代汽车集团、LG能源解决方案公司和印尼电池公司联合体联合建设,投资10亿美元,年产能将达到10吉瓦时(GWh),年产能将达10亿度(GWh)。 150,000 辆电动车相当于一辆汽车。该工厂将与现代汽车工厂无缝整合,每年将生产 50,000 辆 Kona 电动车。此外,该财团还制定了雄心勃勃的计划,在额外投资 20 亿美元的支持下,将工厂产能翻倍至 20GWh。

- 2023 年,菲律宾能源部 (DOE) 制定了一个雄心勃勃的目标,即到 2040 年拥有 630 万辆电动车 (EV),其中电动车占道路上所有车辆的 50%。同期安装约 147,000 个电动车充电站将支持此举。短期内,能源部计划在 2028 年部署约 245 万辆电动车、摩托车和巴士。如此大规模的计划印证了乘用车领域电池市场的快速成长,并将进一步支撑电动车电池市场的成长。

- 鑑于这些动态,乘用车市场将在未来几年大幅扩张。

泰国实现显着成长

- 泰国是汽车产业的投资目的地。 50年来,泰国已从单纯的汽车零件组装国家转变为东南亚汽车生产和出口的主要枢纽。随着汽车製造商投资的增加,泰国电池产业有望实现稳定成长,特别是支持电动车(EV)产量的快速成长。

- 根据泰国电动车协会 (EVAT) 的报告,2023 年泰国註册的电池式电动车(BEV) 约为 100,219 辆,与前一年同期比较激增 380%。这一势头仍在持续,截至 2024 年 2 月底,泰国新登记的纯电动车数量约为 22,278 辆,进一步增加了该国对电池的需求。

- 电动车采用率的激增得益于政府对购买者的奖励和对製造商的支持措施。例如,泰国推出了购买国产电动车的补贴计划,突显了其成为东南亚电动车生产中心的雄心壮志。 EV3.5计画将于2024年至2027年运行,将为每辆车提供5万泰铢(1,397.02美元)至10万泰铢(2,794.04美元)的补贴。

- 泰国的战略倡议符合其在 2030 年成为区域电动车生产中心的愿景,目标是电动车占汽车总销量的 30%。透过这些努力,泰国未来将成为电动车电池尤其是锂离子电池的中心,为电池製造商创造巨大的机会。

- 为了实现这一愿景,许多电池製造商正在增加在泰国的产能。一个着名的例子是宝马集团,该集团于 2024 年 3 月为其「第五代」高压电池製造工厂举行了奠基仪式。这座占地4,000平方公尺的电池组装厂位于泰国东岸的罗勇府,併入宝马现有的汽车工厂。新组装计划于 2025 年下半年开始推出电动车,将在BMW的全球电气化策略中发挥关键作用,将进口电池转换为高压电池模组。宝马在这个雄心勃勃的计划上投资超过 4200 万欧元。

- 鑑于这些发展,泰国预计将在预测期内引领东协地区的电动车电池製造格局。

东南亚国协电动车电池製造业概况

东南亚国协的电动车电池製造市场已适度整合。市场主要企业包括(排名不分先后)三星 SDI、VinES Energy Solutions Joint Stock Company、Contemporary Amperex Technology (CATL)、LiRON LIB Power Pte Ltd 和 GS Yuasa Corporation。

其他好处:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第一章简介

- 调查范围

- 市场定义

- 研究场所

第 2 章执行摘要

第三章调查方法

第四章市场概况

- 介绍

- 2029年之前的市场规模与需求预测(单位:美元)

- 最新趋势和发展

- 政府法规政策

- 市场动态

- 促进因素

- 电动车的扩张

- 政府支持措施和投资以加强电池生产

- 抑制因素

- 原料供需不匹配

- 促进因素

- 供应链分析

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 消费者议价能力

- 新进入者的威胁

- 替代产品/服务的威胁

- 竞争公司之间的敌对关係

- 投资分析

第五章市场区隔

- 依电池类型

- 锂离子

- 铅酸电池

- 镍氢电池

- 其他电池类型

- 按车型分类

- 客车

- 商用车

- 其他车型

- 透过促销

- 电池电动车

- 油电混合车

- 插电式混合动力电动车

- 按地区

- 泰国

- 印尼

- 菲律宾

- 马来西亚

- 越南

- 其他东南亚国协

第六章 竞争状况

- 併购、合资、联盟、协议

- 主要企业策略

- 公司简介

- Panasonic Corporation

- Samsung SDI Co., Ltd.

- Contemporary Amperex Technology Co. Ltd(CATL)

- LG Energy Solution Ltd.

- LiRON LIB Power Pte Ltd

- GS Yuasa Corporation

- VinES Energy Solutions Joint Stock Company

- SVOLT Energy Technology Co., Ltd.

- Energy Absolute Public Company Limited.

- Exide Industries

- 其他知名企业名单

- 市场排名分析

第七章 市场机会及未来趋势

- 汽车製造商和电池製造商之间的合作

- 电池技术的技术进步

The ASEAN Countries Electric Vehicle Battery Manufacturing Market size is estimated at USD 0.26 billion in 2025, and is expected to reach USD 0.66 billion by 2030, at a CAGR of 20.04% during the forecast period (2025-2030).

Key Highlights

- Over the medium term, increasing adoption of electric vehicles (EV) and supportive government initiatives and investments to enhance battery production are expected to drive the demand for the ASEAN countries electric vehicle battery manufacturing market during the forecast period.

- On the other hand, the demand-supply mismatch of raw materials is expected to hinder the market's growth during the forecast period.

- Nevertheless, technological advancements in battery technologies and automaker-battery manufacturer collaborations are expected to create vast opportunities for countries' electric vehicle battery manufacturing markets in the future.

- Among all the countries in the region, Thailand is expected to witness significant growth due to the increase in the number of players participating in EV battery manufacturing.

ASEAN Countries Electric Vehicle Battery Manufacturing Market Trends

Passenger Vehicle Segment to Witness Significant Growth

- The battery manufacturing market for electric vehicles (EVs) in ASEAN (Association of Southeast Asian Nations) countries is poised for substantial growth, especially in the passenger vehicle segment. This surge is driven by the increasing adoption of EVs, government initiatives championing clean energy, and heightened consumer awareness of environmental concerns. In recent years, ASEAN nations, notably Indonesia, Malaysia, Thailand, Vietnam, and the Philippines, have emerged as pivotal players in the EV landscape.

- As reported by the ASEAN Automotive Federation (AAF), the ASEAN region produced a total of 2.748 million passenger vehicles in 2023, marking a 3.11% rise from the 2.665 million units produced in 2022. In 2023, the region's production stood at approximately 2.283 million units, up 3.21% from 2.212 million units in the previous year. Notably, Indonesia, Malaysia, and Thailand collectively accounted for over 83% of the region's passenger vehicle output.

- Looking ahead, the growth of passenger vehicles in the ASEAN region is anticipated to be bolstered by supportive government initiatives promoting electric vehicle adoption. This, in turn, is set to drive demand for EV batteries. Countries like Thailand, Indonesia, Singapore, Malaysia, and the Philippines are on track for rapid EV adoption, thanks to proactive government measures. For instance, the Philippines aims for EVs to constitute 21% of its total vehicles by 2030 and 50% by 2040. Additionally, the Electric Vehicle Association of the Philippines (EVAP) has upped its e-vehicle adoption target from 300,000 units in 2030 to a bold 1.0 million units, banking on anticipated sector incentives, clearer regulations, and growing EV benefits awareness.

- Indonesia's ambitions are equally pronounced, targeting 20% EV representation in car sales by 2025 and a domestic production goal of 600,000 EVs by 2030. These aspirations translate into concrete milestones across the EV supply chain, encompassing sales, production, and charging infrastructure, thereby propelling the EV battery manufacturing industry.

- In a testament to this momentum, Indonesia inaugurated its first electric vehicle battery plant in West Java in July 2024. This plant, a collaborative effort with a USD 1 billion investment from a consortium of Hyundai Motor Group, LG Energy Solution, and the Indonesia Battery Corporation, boasts an annual capacity of 10 gigawatt hours (GWh), sufficient for 150,000 EVs. The facility is seamlessly integrated with Hyundai's auto factory, which is set to produce 50,000 units annually of the Kona Electric vehicle. Furthermore, the consortium has ambitious plans to double the plant's capacity to 20 GWh, backed by an additional USD 2 billion investment.

- In 2023, the Department of Energy (DOE) of the Philippines set an ambitious target to deploy 6.3 million electric vehicles (EVs) by 2040, aiming for them to represent 50% of all vehicles on the road. This initiative will be supported by the installation of approximately 147,000 EV charging points over the same timeframe. In the short term, the DOE plans to roll out around 2.45 million electric cars, motorcycles, and buses by 2028. Such expansive plans underscore the burgeoning market for batteries in the passenger vehicle segment, further fueling the growth of the EV battery market.

- Given these dynamics, the passenger vehicle segment is set for significant expansion in the coming years.

Thailand to Witness a Significant Growth

- Thailand stands out as a prime destination for investments in the automobile sector. Over the past five decades, Thailand has transformed from merely assembling auto components to becoming a dominant hub for automotive production and exports in Southeast Asia. With rising investments from automakers, Thailand's battery industry is poised for steady growth, especially to support the burgeoning production of electric vehicles (EVs).

- As reported by the Electric Vehicle Association of Thailand (EVAT), Thailand registered approximately 100,219 battery electric vehicles (BEVs) in 2023, marking a staggering 380% surge from the previous year. Continuing this momentum, by the end of February 2024, Thailand recorded around 22,278 new BEV registrations, further amplifying the country's battery demand.

- The surge in EV adoption can be attributed to government incentives for buyers and supportive measures for manufacturers. For instance, Thailand's introduction of a purchase subsidy scheme for domestically produced EVs underscores its ambition to be a Southeast Asian EV production hub. The EV3.5 scheme, running from 2024 to 2027, offers subsidies between THB 50,000 (USD 1,397.02) and THB 100,000 (USD 2,794.04) per vehicle, highlighting the government's dedication to nurturing the EV sector and drawing in foreign investments.

- Thailand's strategic moves align with its vision of becoming a regional EV production center by 2030, aiming for EVs to make up 30% of all vehicle sales. Such endeavors position Thailand as a future hub for EV batteries, especially lithium-ion variants, presenting vast opportunities for battery manufacturers.

- In line with this vision, numerous battery manufacturers are ramping up their production capabilities in Thailand. A notable example is BMW Group, which in March 2024, broke ground on its 'Gen-5' high-voltage battery manufacturing facility. Situated in Rayong, on Thailand's east coast, the 4,000 square meter battery assembly is integrated into BMW's existing car plant. With plans to start rolling out EVs in the latter half of 2025, this new assembly line will play a pivotal role in BMW's global electrification strategy, converting imported battery cells into modules for high-voltage batteries. BMW has committed over EUR 42 million to this ambitious project.

- Given these developments, Thailand is poised to lead the electric vehicle battery manufacturing landscape in the ASEAN region during the forecast period.

ASEAN Countries Electric Vehicle Battery Manufacturing Industry Overview

The ASEAN Countries Electric Vehicle Battery Manufacturing market is moderately consolidated. Some of the key players in the market (not in any particular order) include Samsung SDI Co. Ltd., VinES Energy Solutions Joint Stock Company, Contemporary Amperex Technology Co. Ltd (CATL), LiRON LIB Power Pte Ltd and GS Yuasa Corporation.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Scope of the Study

- 1.2 Market Definition

- 1.3 Study Assumptions

2 EXECUTIVE SUMMARY

3 RESEARCH METHODOLOGY

4 MARKET OVERVIEW

- 4.1 Introduction

- 4.2 Market Size and Demand Forecast in USD, till 2029

- 4.3 Recent Trends and Developments

- 4.4 Government Policies and Regulations

- 4.5 Market Dynamics

- 4.5.1 Drivers

- 4.5.1.1 Increasing Adoption of Electric Vehicles

- 4.5.1.2 Supportive Government Initiatives and Investments to Enhance the Battery Production

- 4.5.2 Restraints

- 4.5.2.1 Demand-Supply Mismatch of Raw Materials

- 4.5.1 Drivers

- 4.6 Supply Chain Analysis

- 4.7 Industry Attractiveness - Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Consumers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes Products and Services

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Investment Analysis

5 MARKET SEGMENTATION

- 5.1 Battery Type

- 5.1.1 Lithium-ion

- 5.1.2 Lead-Acid

- 5.1.3 Nickel Metal Hydride Battery

- 5.1.4 Other Battery Type

- 5.2 Vehicle Type

- 5.2.1 Passenger Vehicles

- 5.2.2 Commercial Vehicles

- 5.2.3 Other Vehicle Type

- 5.3 Propulsion

- 5.3.1 Battery Electric Vehicle

- 5.3.2 Hybrid Electric Vehicle

- 5.3.3 Plug-in Hybrid Electric Vehicle

- 5.4 Geography

- 5.4.1 Thailand

- 5.4.2 Indonesia

- 5.4.3 Philippines

- 5.4.4 Malaysia

- 5.4.5 Vietnam

- 5.4.6 Rest of ASEAN Countries

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Strategies Adopted by Leading Players

- 6.3 Company Profiles

- 6.3.1 Panasonic Corporation

- 6.3.2 Samsung SDI Co., Ltd.

- 6.3.3 Contemporary Amperex Technology Co. Ltd (CATL)

- 6.3.4 LG Energy Solution Ltd.

- 6.3.5 LiRON LIB Power Pte Ltd

- 6.3.6 GS Yuasa Corporation

- 6.3.7 VinES Energy Solutions Joint Stock Company

- 6.3.8 SVOLT Energy Technology Co., Ltd.

- 6.3.9 Energy Absolute Public Company Limited.

- 6.3.10 Exide Industries

- 6.4 List of Other Prominent Companies

- 6.5 Market Ranking Analysis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Automaker-Battery Manufacturer Collaborations

- 7.2 Technological Advancements in Battery Technologies