|

市场调查报告书

商品编码

1643008

网版印刷标籤:市场占有率分析、产业趋势与统计、成长预测(2025-2030 年)Screen Print Label - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

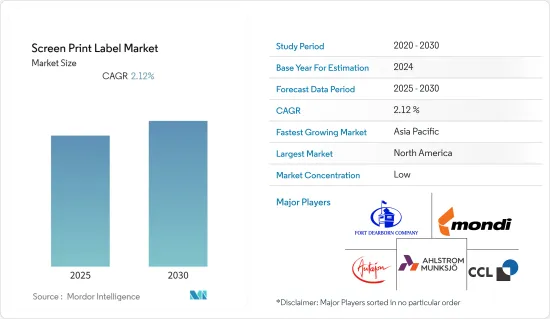

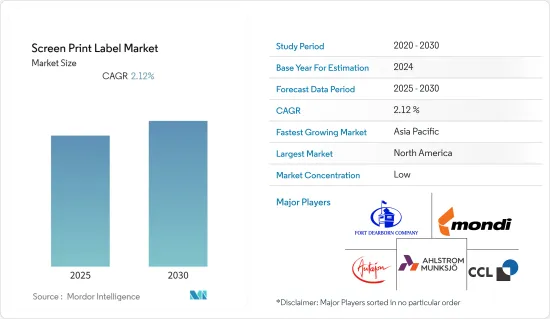

预计预测期内网版印刷标籤市场复合年增长率为 2.12%。

主要亮点

- 它的耐磨性、防潮性和光滑的油墨涂层比其他印刷工艺更能推动市场的发展。油墨厚度非常一致,使得此製程非常适合需要耐候(户外)、防潮、耐磨和耐化学品等特性的应用。这一特性使其非常适合用于饮料标籤。

- 此外,网版印刷相对于所有其他生产印刷製程的最大优势是可在基材上沉积的油墨量。 UV凸版可印製厚度为2~3.5微米的油墨,UV胶印可印製厚度为1.5~2.5微米的油墨,凹印可印製厚度为2~5微米的油墨,UV柔印可印製厚度为3~8微米的油墨。但UV丝网的墨层厚度一般在4微米至30微米以上。这种油墨厚度使网版印刷油墨比其他标籤印刷製程具有更高的不透明度。

- 此外,硅胶油墨在网版印刷的应用也推动了市场的发展。随着新型面料不断涌入市场,油墨供应商也在加紧推出新的和性能增强的产品,以使装饰者能够充分发挥他们的技能。硅胶油墨主要以尖端硅胶聚合物为基础,为现代性能布料提供极致的弹性和手感。这些油墨经过创新设计,将硅胶化学的优点和好处引入印染网印刷作业。未来,对于服装以外的应用,用于3D热压转印标籤的高密度硅胶油墨的趋势将备受关注。

- 昂贵的多色印刷解决方案对市场成长是一项挑战。为了降低成本,适合多色印刷的数位印刷是有效的选择。此外,由于油墨厚度的原因,小文字的网版印刷可能会很困难,而数位印刷和柔版印刷则非常适合印刷精细的图像。

- 疫情为印刷标籤企业带来的两个最大问题是提高生产效率和远端客户服务。疫情初期的持续需求给标籤公司的製造能力带来了巨大压力,凸显了产品生命週期各个阶段对自动化的需求。此外,俄罗斯-乌克兰战争也对整个市场产生影响。

网版印刷标籤市场趋势

时尚服饰占很大市场占有率

- 随着全球服装市场价值的不断上升,对网版印刷标籤技术的需求也随之增加。标籤製造商不断为服饰标籤提出创新理念、新材料、新饰面和其他设计方法。服饰标籤对于品牌来说非常重要,消费者保护机构也在推行严格的服饰护理标籤要求。此外,国际标准化组织 (ISO) 等独立组织也有标籤要求,想要获得认证的公司必须遵守。

- 服装业的网版印刷织物标籤为客自订的复杂设计提供了卓越的细节。它适合婴儿服装、T 恤和女用贴身内衣。本公司采用轮转印刷和网版印刷技术生产印刷缎面标籤。然而,RFID 和基于织物的标籤已成为市场上的严峻挑战,因为它们可以为行业带来进一步的优势,并为未来的机会带来挑战。

- 印在棉质床单织物上的标籤的外观和感觉与棉麻床单相似。这些通常用于较大尺寸的徽标,例如 2.75" x 2.5"。边缘会因洗涤而磨损,从而呈现出復古的外观。透过在有机棉上进行网版印刷,可以使用多种颜色创建带有复杂徽标的标籤。

北美可望引领创新

- 美国的网版印刷标籤製造商发现其大部分需求来自食品、饮料和服装业。在该地区,国内外各类参与者都在透过技术创新和合作促进市场成长。

- 此外,自订网版印刷的需求也不断增加。这种网版印刷工艺允许客户将任何所需的图形、公司徽标、图例标示、标籤等直接印刷到成品上。

- 网版印刷可用于在任何尺寸、形状和厚度的基材上进行印刷。网版印刷允许在基材上施加更厚的油墨,从而产生其他印刷技术通常无法实现的效果,例如点字、闪光、刮擦和凸起字体。这也是影响网版印刷标籤市场成长的关键因素。

- 总部位于加州的 Fabri-Tech 提供自订网版印刷,其印刷功能可实现多种颜色、各种字体或客户设计所需的任何其他内容。 Fabri-Tech 采用网版标籤印刷方法,可在多种基材上印刷,包括纸张、PET、PC、PMMA、PP、PS、ABS、PU 塑胶、橡胶和各种金属。

网版印刷标籤产业概况

网版印刷标籤市场由多家大型参与者组成,竞争激烈且本质上分散。此外,参与者正在投资新机器,以透过独特的增值来占领市场占有率。主要企业有 Fort Dearborn Company、Mondi PLC 等。

2022 年 8 月,行销、包装、印刷和供应链解决方案提供商 RR Donnelley & Sons Company (RRD) 宣布,为直接回应客户需求,其直接热感无底纸标籤生产能力已提高一倍约 40%。 RRD 位于威斯康辛州门罗的工厂最近增加了第二台无底纸印刷机,使该公司能够提供尖端、易于使用的标籤解决方案,满足不断增长的生产和永续性需求。

其他福利

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第 1 章 简介

- 研究假设和市场定义

- 研究范围

第二章调查方法

第三章执行摘要

第四章 市场动态

- 市场概况

- 市场驱动因素

- 耐磨、防潮、光滑的油墨涂层

- 采用硅胶油墨进行网版印刷

- 市场限制

- 多色印刷的昂贵解决方案

- 价值链分析

- 产业吸引力-波特五力模型

- 新进入者的威胁

- 购买者/消费者的议价能力

- 供应商的议价能力

- 替代品的威胁

- 竞争对手之间的竞争强度

第五章 市场区隔

- 按类型

- 收缩套筒标籤

- 无底纸标籤

- 湿胶标籤

- 其他类型

- 按最终用户

- 时尚与服饰

- 食物

- 饮料

- 化妆品和个人护理

- 其他最终用户

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

第六章 竞争格局

- 公司简介

- Fort Dearborn Company

- Mondi PLC

- Ahlstrom-Munksjo Oyj

- Autajon Group

- CCL Industries Inc.

- Coveris Inc.

- Constantia Flexibles Group GmbH

- 3M Company

- Gallus Ferd. Ruesch AG

第七章 市场机会与未来趋势

The Screen Print Label Market is expected to register a CAGR of 2.12% during the forecast period.

Key Highlights

- Abrasion and moisture-resistant properties and smooth ink coating drive the market over other printing process. The ink film thickness is so appropriate that this process excels in applications where properties such as resistance to weather (outdoors), moisture, abrasion, and chemicals, are needed. This property makes a natural fit for beverage labels.

- Additionally, the single greatest advantage that screen printing has over all other production printing processes is in the volume of ink that can be laid onto a substrate. UV letterpress can deposit ink as thick as 2 to 3.5 microns; UV offset is 1.5 to 2.5 microns; gravure is 2 to 5 microns; and UV flexo can lay down from 3 to 8 microns. However, the UV screen has an ink thickness ranging from 4 to 30 microns and beyond. The thickness of the ink provides screen-printed inks with opaque properties than in other printing process for labeling.

- Moreover, the adoption of screen-printing silicon ink is driving the market. With new fabric availability in the market, ink suppliers are stepping up to the plate to offer new, enhanced products that enable decorators to use their skills fully. Silicone inks are highly based on cutting-edge silicone polymers for delivering the ultimate stretch and feel on the latest performance fabrics. The inks have been innovatively designed, which brings out the strengths and benefits of silicone chemistry to the textile screen printing operation. In the future, the trend will focus on its usage of high-density silicone ink for 3D heating press transfer labels in applications other than apparel.

- Expensive solution for printing with many colors challenges the market growth. The alternative to lower the cost is a digital printing solution, which provides a better option when printing with many colors. Moreover, fine text may be difficult to screen print due to the thickness of the ink, whereas digital or flexographic printing is a good option for fine imagery.

- The two biggest problems the epidemic created for print label companies were productivity growth and remote customer service. The consistent demand throughout the epidemic's early stages put enormous pressure on the manufacturing capacity of the labeling companies, stressing the necessity for automation throughout the different stages of the product life cycle. Furthermore, the Russia-Ukrain war has an impact on the overall market.

Screen Print Label Market Trends

Fashion and Apparels to Hold Significant Market Share

- With the increasing value of the apparel market worldwide, the demand for screen print label technology is increasing. Label manufacturers are continuously thinking of innovative ideas for clothing labels and novel materials, finishes, and other methods of designing. Clothes labeling is considered critical for the brands promoting consumer protection agencies to have stringent apparel care labeling requirements. Additionally, independent organizations such as the International Organization for Standardization (ISO) have their labeling requirements that the companies must follow if they wish to receive certification.

- Screen-printed fabric labels for the apparel industry achieve excellent detail on custom complex designs. It is comfortable for baby clothes, t-shirts, and lingerie apparel. Firms manufacture printed satin labels using rotary printing and screen printing techniques. However, RFID and fabric-based labels have emerged as a serious challenge for the market as they offer additional industry advantages and may create challenges for future opportunities.

- Printed labels on cotton sheet fabric look and feel like a cotton linen sheet. These are typically used for logos with larger sizes, e.g., 2.75" x 2.5". With washing, edges fray to give a vintage appearance. A label with numerous colors and a difficult logo can be achieved with a silkscreen print on organic cotton.

North America is Expected to Drive Technology Innovation

- The screen print label manufacturers in the United States experience most of the demand from the food, beverage, and apparel segments. Various players, locally and globally in the region contribute to the market's growth through innovations, partnerships, etc.

- Furthermore, the demand for custom silkscreen printing is increasing. This silkscreen printing process allows printing any graphics, company logos, legends, or labels the customers would like directly onto their finished products.

- Screen printing enables printing on substrates of any size, shape, and thickness. The greater thickness of the ink that can be applied to the substrate with screen printing, which is generally not possible with other printing techniques, enables the creation of effects like braille, glitter, scratch-offs, and raised text. This is another significant factor influencing the growth of the market for screen-printed labels.

- California-based Fabri-Tech offers custom silkscreen printing where their printing capabilities allow for multiple colors, varying fonts, or anything else that customer requires in design. Fabri-Tech uses its silkscreen label printing methods on various substrates, such as paper, PET, PC, PMMA, PP, PS, ABS and PU plastics, rubber, and different metals.

Screen Print Label Industry Overview

The screen print label market is fragmented in nature, as the market is highly competitive and consists of several major players. Furthermore, players invest in new machinery to gain market share through their unique addition. Key players are Fort Dearborn Company, Mondi PLC, etc.

In August 2022, in direct response to customer demand, R.R. Donnelley & Sons Company (RRD), a marketing, packaging, print, and supply chain solutions provider, said that it had doubled its capacity for direct thermal linerless label production by almost 40%. At its facility in Monroe, Wisconsin, RRD recently added a second linerless press, positioning it to offer a cutting-edge and easily accessible labeling solution that satisfies increased production and sustainability demands.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Abrasion and Moisture Resistant Properties, Along with Smooth Ink Coating

- 4.2.2 Adoption of Screen Printing Silicon Ink

- 4.3 Market Restraints

- 4.3.1 Expensive Solution for Printing with Many Colors

- 4.4 Industry Value Chain Analysis

- 4.5 Industry Attractiveness - Porter Five Forces

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers/Consumers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION

- 5.1 Type

- 5.1.1 Shrink Sleeves Label

- 5.1.2 Linerless Label

- 5.1.3 Wet-Glued Label

- 5.1.4 Other Types

- 5.2 End User

- 5.2.1 Fashion and Apparels

- 5.2.2 Food

- 5.2.3 Beverages

- 5.2.4 Cosmetics and Personal Care

- 5.2.5 Other End Users

- 5.3 Geography

- 5.3.1 North America

- 5.3.2 Europe

- 5.3.3 Asia-Pacific

- 5.3.4 Latin America

- 5.3.5 Middle-East and Africa

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Fort Dearborn Company

- 6.1.2 Mondi PLC

- 6.1.3 Ahlstrom-Munksjo Oyj

- 6.1.4 Autajon Group

- 6.1.5 CCL Industries Inc.

- 6.1.6 Coveris Inc.

- 6.1.7 Constantia Flexibles Group GmbH

- 6.1.8 3M Company

- 6.1.9 Gallus Ferd. Ruesch AG