|

市场调查报告书

商品编码

1871185

酵素法食品加工解决方案市场机会、成长驱动因素、产业趋势分析及预测(2025-2034年)Enzymatic Food Processing Solutions Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

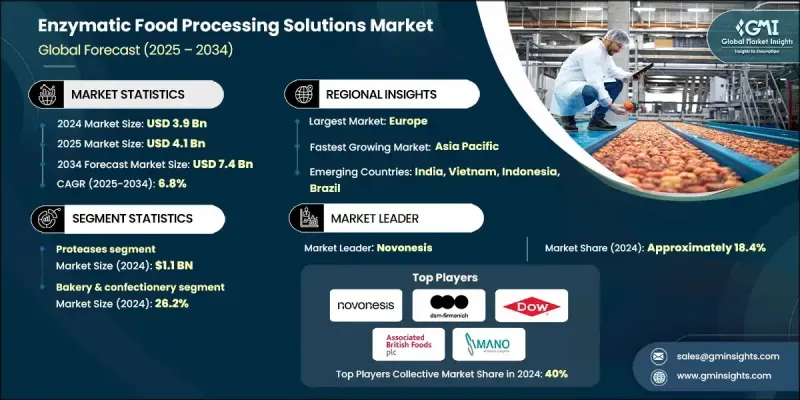

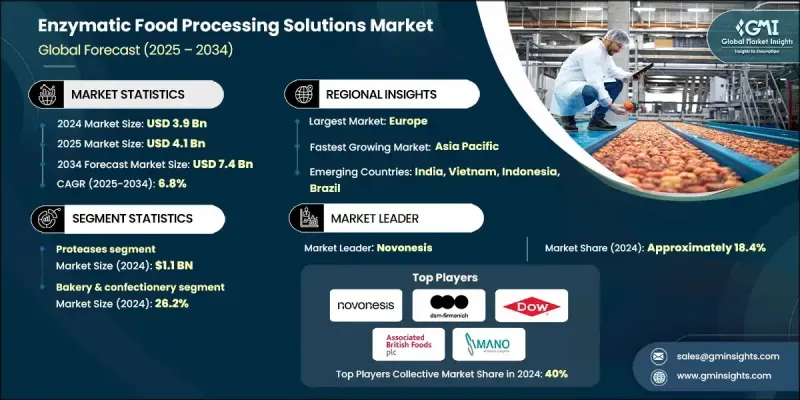

2024 年全球酵素法食品加工解决方案市值为 39 亿美元,预计到 2034 年将以 6.8% 的复合年增长率成长至 74 亿美元。

随着酵素在提升加工效率、产品品质和永续性方面发挥日益重要的作用,包括乳製品、淀粉和甜味剂、烘焙食品、饮料、植物性蛋白质以及油脂等多个食品类别,市场正经历强劲增长。这些解决方案已从发挥基本功能性作用发展成为与数位化加工环境相契合的整合平台。消费者对清洁标籤产品的需求不断增长、有利于天然加工助剂使用的监管框架以及精准发酵技术的广泛应用,都进一步推动了市场成长。製造商还利用酵素系统来降低成本、延长保质期和优化工艺,使这些解决方案成为工业食品生产线上的关键差异化因素。

| 市场范围 | |

|---|---|

| 起始年份 | 2024 |

| 预测年份 | 2025-2034 |

| 起始值 | 39亿美元 |

| 预测值 | 74亿美元 |

| 复合年增长率 | 6.8% |

该行业的成长得益于标准化酶浓缩物和高价值定制混合物的商业化,这些混合物可提供针对性的性能优势。其中包括用于改善植物蛋白应用质地的蛋白酶和用于大规模生产的烘焙淀粉酶等成分。先进的配方,通常辅以酶活性优化和热稳定性提升,使生产商能够获得更高的产量和产品一致性。供应商尤其关注价格敏感型买家的市场,提供多功能混合物,以取代合成添加剂,而无需增加投入成本。酵素作为加工助剂的监管定位,使得清洁标籤食品(尤其是在严格监管的市场中)能够实现无缝配方调整。

转谷氨酰胺酶、过氧化氢酶和葡萄糖氧化酶等细分领域酶製剂在2024年合计占据15.3%的市场份额,预计到2034年将以7.2%的复合年增长率增长。这些专业酵素製剂可为复杂製程提供客製化解决方案,并越来越多地与客户合作开发,以实现最佳的剂量精度、降低批次差异并增强操作控制。这些混合物凭藉其特殊的功能和配方的多样性,具有卓越的价值。

2024年,饮料业占据14.1%的市场份额,这主要得益于对果胶酶解决方案的需求。果胶酶能够提高果汁、酿造和葡萄酒等产品的产量、透明度和加工速度。同时,植物蛋白领域也不断成长,并持续采用蛋白酶和碳水化合物酶来克服常见的质地和溶解度问题,最终打造更具吸引力的终端产品。儘管酵素製剂的整体投入成本较低,但在大量生产中,它们却能持续带来可衡量的效率提升和产品性能改进,使其变得越来越不可或缺。

2024年美国酵素法食品加工解决方案市场规模为9.487亿美元,预计将以6.7%的复合年增长率成长,到2034年达到18亿美元。美国市场的成长得益于强劲的清洁标籤趋势、先进的研发能力以及烘焙、乳製品和饮料等食品行业的广泛自动化。市场正日益采用复杂的酵素系统,特别是多酵素混合物,以改善产品的一致性、柔软度和货架稳定性。人工智慧驱动的配方技术也在淀粉和烘焙生产中广泛应用,提高了精准度和性能可预测性。

主导酵素製剂食品加工解决方案市场的关键企业包括 Codexis Inc.、Biocatalysts Ltd、Chr. Hansen Holding A/S、Kerry Group PLC、DSM-Firmenich、Novonesis、Dow、Amano Enzyme Inc.、Deerland Probiotics & Enzymes 和 Advanced Enme Technologies Ltd.。这些企业致力于客製化酵素製剂配方、先进的发酵技术和数位化流程集成,以提升产品性能。产业领导者正加大研发投入,开发适用于现代化加工环境的耐热多功能酵素。与食品生产商建立策略合作伙伴关係,有助于客製化酵素製剂解决方案,以满足具体的生产需求。此外,企业也利用人工智慧驱动的建模技术来优化用量、降低加工变异性并提高产量效率。

目录

第一章:方法论与范围

第二章:执行概要

第三章:行业洞察

- 产业生态系分析

- 供应商格局

- 利润率

- 每个阶段的价值增加

- 影响价值链的因素

- 中断

- 产业影响因素

- 成长驱动因素

- 产业陷阱与挑战

- 市场机会

- 成长潜力分析

- 监管环境

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- 中东和非洲

- 波特的分析

- PESTEL 分析

- 价格趋势

- 按地区

- 依酶类型

- 未来市场趋势

- 技术与创新格局

- 当前技术趋势

- 新兴技术

- 专利格局

- 贸易统计

- 主要进口国

- 主要出口国(註:仅提供重点国家的贸易统计)

- 永续性和环境方面

- 永续实践

- 减少废弃物策略

- 生产中的能源效率

- 环保倡议

- 碳足迹考量

第四章:竞争格局

- 介绍

- 公司市占率分析

- 按地区

- 北美洲

- 欧洲

- 亚太地区

- 拉丁美洲

- MEA

- 按地区

- 公司矩阵分析

- 主要市场参与者的竞争分析

- 竞争定位矩阵

- 关键进展

- 併购

- 合作伙伴关係与合作

- 新产品发布

- 扩张计划

第五章:市场估算与预测:依酵素类型划分,2021-2034年

- 主要趋势

- 蛋白酶

- 丝胺酸蛋白酶(枯草桿菌蛋白酶、胰凝乳蛋白酶)

- 天门冬胺酸蛋白酶(胃蛋白酶、凝乳酶/凝乳酶)

- 半胱氨酸蛋白酶(木瓜蛋白酶、凤梨蛋白酶、无花果蛋白酶)

- 金属蛋白酶(中性蛋白酶)

- 淀粉酶

- α-淀粉酶(内切酶,液化酶)

- β-淀粉酶(外切酶,糖化酶)

- 葡糖淀粉酶(葡萄糖生成)

- 普鲁兰酶(脱支酶)

- 脂肪酶

- 动物脂肪酶

- 微生物脂肪酶

- 磷脂酶

- 碳水化合物酶

- 果胶酶

- 纤维素酶和半纤维素酶

- 乳糖酶(β-半乳糖苷酶)

- 特化酶

- 转谷氨酰胺酶

- 葡萄糖异构酶

- 过氧化氢酶和葡萄糖氧化酶

第六章:市场估算与预测:依应用领域划分,2021-2034年

- 主要趋势

- 烘焙食品和糖果

- 麵团调理应用

- 防老化溶液

- 麸质改质技术

- 乳製品加工

- 乳酪生产应用

- 乳糖减量技术

- 蛋白质修饰方案

- 饮料生产

- 酿造应用

- 果汁加工解决方案

- 葡萄酒酿造技术

- 肉类和海鲜加工

- 招标申请

- 蛋白质结合溶液

- 产量提昇技术

- 淀粉和甜味剂生产

- 淀粉液化过程

- 糖化技术

- 异构化应用

- 植物性蛋白质和替代蛋白

- 蛋白质功能增强

- 纹理修改方案

- 提高消化率的技术

- 油脂加工

- 利息化应用

- 脱胶过程

- 风味开发解决方案

- 其他的

第七章:市场估计与预测:依地区划分,2021-2034年

- 主要趋势

- 北美洲

- 我们

- 加拿大

- 欧洲

- 德国

- 英国

- 法国

- 西班牙

- 义大利

- 欧洲其他地区

- 亚太地区

- 中国

- 印度

- 日本

- 澳洲

- 韩国

- 亚太其他地区

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 拉丁美洲其他地区

- 中东和非洲

- 沙乌地阿拉伯

- 南非

- 阿联酋

- 中东和非洲其他地区

第八章:公司简介

- Advanced Enzyme Technologies Ltd

- Amano Enzyme Inc.

- Aralez Bio

- Associated British Foods Plc

- Biocatalysts Ltd

- Cascade Biocatalysts Inc.

- Chr. Hansen Holding A/S

- Codexis Inc.

- Creative Enzymes

- Deerland Probiotics & Enzymes

- DSM-Firmenich

- Dow

- Dyadic International Inc.

- Enzyme Development Corporation

- Enzyme Research Laboratories Inc.

- Jiangsu Boli Bioproducts Co., Ltd

- Kerry Group PLC

- Novonesis

- Solugen Inc.

- Specialty Enzymes & Probiotics

The Global Enzymatic Food Processing Solutions Market was valued at USD 3.9 Billion in 2024 and is estimated to grow at a CAGR of 6.8% to reach USD 7.4 Billion by 2034.

The market is experiencing robust growth as enzymes play an increasingly central role in enhancing processing efficiency, product quality, and sustainability across multiple food categories, including dairy, starch and sweeteners, bakery, beverages, plant-based proteins, and oils and fats. These solutions have evolved from serving basic functional roles to becoming integrated platforms that align with digital processing environments. Growth is further supported by rising consumer demand for clean-label products, favorable regulatory frameworks promoting natural processing aids, and the expanding use of precision fermentation technologies. Manufacturers are also leveraging enzyme systems for cost reduction, shelf life extension, and process optimization, making these solutions a key differentiator across industrial food lines.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $3.9 Billion |

| Forecast Value | $7.4 Billion |

| CAGR | 6.8% |

Growth in this sector is fueled by the commercialization of both standardized enzyme concentrates and high-value, customized blends that deliver targeted performance benefits. These include ingredients like proteases designed to improve texture in plant protein applications and baking amylases used for large-scale production. Advanced formulations, often supported by enzyme activity optimization and thermostability, allow producers to achieve higher yields and product consistency. Suppliers are particularly focused on markets with price-sensitive buyers by offering multi-functional blends that replace synthetic additives without increasing input costs. Regulatory positioning of enzymes as processing aids enables seamless reformulation in clean-label foods, especially within tightly regulated markets.

The niche categories, such as transglutaminases, catalases, and glucose oxidases, collectively held a 15.3% share in 2024 and will grow at a CAGR of 7.2% through 2034. These specialized enzymes deliver customized solutions for complex processes and are increasingly co-developed with clients to achieve optimal dosing precision, reduced batch variability, and enhanced operational control. These blends offer premium value due to their specialized functionality and formulation versatility.

The beverages segment held 14.1% share in 2024, driven by demand for pectinase-based solutions that improve yield, product clarity, and processing time across categories like fruit juices, brewing, and wine production. In parallel, the growing segment of plant-based proteins continues to adopt proteases and carbohydrases to overcome common texture and solubility issues, ultimately creating more appealing end products. Despite low overall input cost, enzymatic solutions consistently deliver measurable efficiency gains and product enhancements in high-volume manufacturing, making them increasingly indispensable.

US Enzymatic Food Processing Solutions Market generated USD 948.7 million in 2024 and is projected to grow at a CAGR of 6.7%, hitting USD 1.8 Billion by 2034. Growth in the US is supported by strong clean label trends, advanced research and development capabilities, and widespread automation across food sectors like bakery, dairy, and beverages. The market is witnessing increased adoption of complex enzyme systems, particularly multi-enzyme blends, to improve product consistency, softness, and shelf stability. AI-driven formulation techniques are also gaining ground across starch and bakery operations, enhancing precision and performance predictability.

Key companies shaping the Enzymatic Food Processing Solutions Market include Codexis Inc., Biocatalysts Ltd, and Chr. Hansen Holding A/S, Kerry Group PLC, DSM-Firmenich, Novonesis, Dow, Amano Enzyme Inc., Deerland Probiotics & Enzymes, and Advanced Enzyme Technologies Ltd. Companies in the enzymatic food processing solutions market are focusing on custom enzyme formulation, advanced fermentation techniques, and digital process integration to enhance product performance. Leaders are strengthening R&D investments to develop thermostable and multi-functional enzymes suitable for modern processing environments. Strategic partnerships with food manufacturers help tailor enzyme solutions to meet exact production needs. Firms are also leveraging AI-driven modeling to optimize dosage, reduce processing variability, and boost yield efficiency.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 enzyme type

- 2.2.3 Application

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By enzyme type

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries Note: the trade statistics will be provided for key countries only)

- 3.12 Sustainability and Environmental Aspects

- 3.12.1 Sustainable Practices

- 3.12.2 Waste Reduction Strategies

- 3.12.3 Energy Efficiency in Production

- 3.12.4 Eco-friendly Initiatives

- 3.13 Carbon Footprint Considerations

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates and Forecast, By Enzyme Type, 2021 - 2034 (USD Billion)

- 5.1 Key trends

- 5.2 Proteases

- 5.2.1 Serine proteases (subtilisin, chymotrypsin)

- 5.2.2 Aspartic proteases (pepsin, rennet/chymosin)

- 5.2.3 Cysteine proteases (papain, bromelain, ficin)

- 5.2.4 Metalloproteases (neutral proteases)

- 5.3 Amylases

- 5.3.1 Α-amylases (endo-acting, liquefaction)

- 5.3.2 Β-amylases (exo-acting, saccharification)

- 5.3.3 Glucoamylases (glucose production)

- 5.3.4 Pullulanases (debranching enzymes)

- 5.4 Lipases

- 5.4.1 Animal lipases

- 5.4.2 Microbial lipases

- 5.4.3 Phospholipases

- 5.5 Carbohydrases

- 5.5.1 Pectinases

- 5.5.2 Cellulases & hemicellulases

- 5.5.3 Lactases (β-galactosidase)

- 5.6 Specialized enzymes

- 5.6.1 Transglutaminases

- 5.6.2 Glucose isomerases

- 5.6.3 Catalases & glucose oxidases

Chapter 6 Market Estimates and Forecast, By Application, 2021 - 2034 (USD Billion)

- 6.1 Key trends

- 6.2 Bakery & confectionery

- 6.2.1 Dough conditioning applications

- 6.2.2 Anti-staling solutions

- 6.2.3 Gluten modification technologies

- 6.3 Dairy processing

- 6.3.1 Cheese production applications

- 6.3.2 Lactose reduction technologies

- 6.3.3 Protein modification solutions

- 6.4 Beverage production

- 6.4.1 Brewing applications

- 6.4.2 Juice processing solutions

- 6.4.3 Wine making technologies

- 6.5 Meat & seafood processing

- 6.5.1 Tenderization applications

- 6.5.2 Protein binding solutions

- 6.5.3 Yield enhancement technologies

- 6.6 Starch & sweetener production

- 6.6.1 Starch liquefaction processes

- 6.6.2 Saccharification technologies

- 6.6.3 Isomerization applications

- 6.7 Plant-based & alternative proteins

- 6.7.1 Protein functionality enhancement

- 6.7.2 Texture modification solutions

- 6.7.3 Digestibility improvement technologies

- 6.8 Oil & fat processing

- 6.8.1 Interesterification applications

- 6.8.2 Degumming processes

- 6.8.3 Flavor development solutions

- 6.9 Others

Chapter 7 Market Estimates and Forecast, By Region, 2021 - 2034 (USD Billion)

- 7.1 Key trends

- 7.2 North America

- 7.2.1 U.S.

- 7.2.2 Canada

- 7.3 Europe

- 7.3.1 Germany

- 7.3.2 UK

- 7.3.3 France

- 7.3.4 Spain

- 7.3.5 Italy

- 7.3.6 Rest of Europe

- 7.4 Asia Pacific

- 7.4.1 China

- 7.4.2 India

- 7.4.3 Japan

- 7.4.4 Australia

- 7.4.5 South Korea

- 7.4.6 Rest of Asia Pacific

- 7.5 Latin America

- 7.5.1 Brazil

- 7.5.2 Mexico

- 7.5.3 Argentina

- 7.5.4 Rest of Latin America

- 7.6 Middle East and Africa

- 7.6.1 Saudi Arabia

- 7.6.2 South Africa

- 7.6.3 UAE

- 7.6.4 Rest of Middle East and Africa

Chapter 8 Company Profiles

- 8.1 Advanced Enzyme Technologies Ltd

- 8.2 Amano Enzyme Inc.

- 8.3 Aralez Bio

- 8.4 Associated British Foods Plc

- 8.5 Biocatalysts Ltd

- 8.6 Cascade Biocatalysts Inc.

- 8.7 Chr. Hansen Holding A/S

- 8.8 Codexis Inc.

- 8.9 Creative Enzymes

- 8.10 Deerland Probiotics & Enzymes

- 8.11 DSM-Firmenich

- 8.12 Dow

- 8.13 Dyadic International Inc.

- 8.14 Enzyme Development Corporation

- 8.15 Enzyme Research Laboratories Inc.

- 8.16 Jiangsu Boli Bioproducts Co., Ltd

- 8.17 Kerry Group PLC

- 8.18 Novonesis

- 8.19 Solugen Inc.

- 8.20 Specialty Enzymes & Probiotics