|

市场调查报告书

商品编码

1629792

欧洲流程自动化:市场占有率分析、产业趋势与成长预测(2025-2030)Europe Process Automation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

价格

※ 本网页内容可能与最新版本有所差异。详细情况请与我们联繫。

简介目录

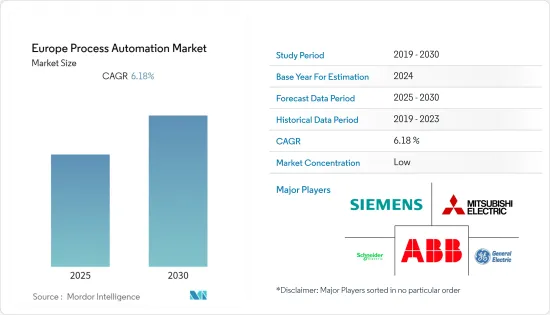

欧洲製程自动化市场预计在预测期内复合年增长率为 6.18%

主要亮点

- 物联网需求趋势预计在不久的将来将从消费需求转向工业领域,主要由各种工业4.0应用推动。英国等国家正处于工业革命的边缘,资料在生产中大规模使用,并与整个供应链中的各种製造系统整合。

- 欧洲国家一直处于实施工业自动化解决方案的最前沿,并得到了政府的持续支持。例如,英国政府宣布了一项“产业战略”,计划到 2020 年每年投资 20 亿英镑用于新技术的研发。智慧製造和物联网 (IIot) 将建立在过去几年自动化已经完成的工作的基础上。专注于自动化解决方案带来的可能性将为多个产业提供挑战创新极限的机会,这对于英国脱欧后的经济至关重要。自动化解决方案有望彻底改变流程工业。

- 此外,化学品和石化、造纸和纸浆、水和污水处理、能源和公共产业、石油和天然气、製药以及食品和饮料等加工行业预计将推动成长。

- 工业系统设计师、整合商和机器製造商正在利用互联运算的进步来帮助製造设施更有效率地运作。製造业对即时智慧、更好地控制营运、调度以及巨量资料分析市场渗透率不断提高的需求预计将在不久的将来创造对先进製程自动化的需求。巨量资料分析被用来改善复杂的流程和管理供应链。

- 此外,巨量资料分析允许公司利用工厂自动化从反应性实践转向预测性实践。这项变更旨在提高流程效率和产品效能。

欧洲流程自动化市场趋势

医药产业可望占据较大市场占有率

- 自动化正在融入活性药物成分 (API) 等主要方面和包括包装和分销在内的其他次要方面。数位转型为该地区的製药公司提供了新的业务效率、品质、流程自动化和员工生产力。

- 此外,Lonza 选择罗克韦尔自动化来帮助实现 Lonza 的战略愿景,即在 9 个生产药物胶囊的前 Capsugel 工厂实施数位化工厂。该公司选择罗克韦尔自动化的 PharmaSuite MES 软体来实现製造业务的数位化。该解决方案将有助于避免在大量即时订单按需生产期间出现混乱。

- 此外,Lonza 可以使用 PharmaSuite MES 软体和 FactoryTalk InnovationSuite 软体来追踪产品直至单个胶囊盒,从而更深入地了解性能和生产。透过分离 SAP 和 PharmaSuite MES,我们能够实施工作流程并收集必要的信息,以避免因 World Enterprise Resource Planning ERP 关闭和所需维护而造成中断。

- 此外,后 COVID-19 员工和组织可能会采用新的、更有效率的工作方式。随着劳动力从体力技能转向更具技术性的技能,营运职能也需要新的能力。随着自动化程度的提高,製药公司的营运可能对能够编程、操作和解释这些新技术资料的人员的需求不断增加。这可能需要大量的技能提升和能力建构工作,以及持续的策略规划。

- 过去三个月,欧洲多家製药公司动员员工远距办公。在这种情况下,自动化可以帮助基本流程不受阻碍地继续进行。药物发现的自动化透过最大限度地减少人为错误、提高通量和提高再现性来提高整个过程的可靠性。

英国占最大市场占有率

- 食品和饮料行业在提供大规模生产系统的同时保持国内最高的卫生标准。此外,竞争力要求营运效率,包括原料消耗和生产成本。实现这些目标是在这个行业中生存的关键因素。需求和劳动力的季节性也推动该行业采用自动化,帮助市场成长。

- 食品产业的自动化透过消除错误和浪费、提高效率和生产力以及扩大利润率来增强竞争。节省的成本可以用于研发或其他业务改进。

- 此外,政府为重振遭受疫情打击的英国经济而推出的投资凸显了基础设施和电子产业以及中小型企业的成长,成为主要受益者。基础设施和电子产业是工业控制系统硬体产品和软体解决方案的大量用户,预计将产生直接的正面影响。

- 此外,流程发现、流程最佳化、流程智慧和流程协作等技术和术语正在成为机器人流程自动化 (RPA) 的重要组成部分。未来,业务流程管理 (BPM) 和 RPA 之间的关係将持续发展。

- 此外,可以使用虚拟机器在工厂车间的不同位置轻鬆存取单一实体伺服器上的不同工业自动化系统,例如 SCADA、PLC 和 MES。该国已采用它来降低伺服器的总成本,并提高流程和离散製造业中工业自动化系统和软体实施的灵活性。

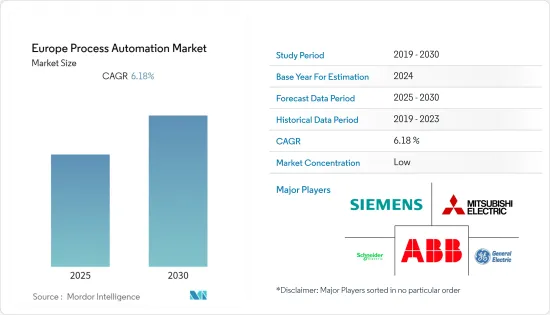

欧洲流程自动化产业概况

欧洲过程自动化市场适度分散,几乎没有新参与企业和一些主导参与者。公司不断创新并结成策略伙伴关係以维持市场占有率。近期市场发展趋势如下:

- 2020 年 8 月 -Schneider Electric完成一项交易,将其低压和工业自动化产品业务与 Larsen & Toubro 的电气和自动化业务合併。

- 2020年5月-无线工业自动化与物联网解决方案供应商OleumTech宣布推出新型智慧压力感测器(HGPT智慧表压力感测器)。这些传送器是该公司快速发展的 H 系列硬布线製程仪器产品线的补充,是石化、化学、电力、上游石油和天然气以及污水处理等製程产业的理想选择。

其他好处:

- Excel 格式的市场预测 (ME) 表

- 3 个月的分析师支持

目录

第一章简介

- 研究假设和市场定义

- 调查范围

第二章 研究方法

第三章执行摘要

第四章市场动态

- 市场概况

- 产业吸引力-波特五力分析

- 供应商的议价能力

- 买方议价能力

- 新进入者的威胁

- 替代品的威胁

- 竞争公司之间的敌对关係

- 产业价值链分析

- 市场驱动因素(日益关注能源效率和降低成本|安全自动化系统的需求|工业物联网的出现)

- 市场挑战(成本和实施挑战)

- 行业标准和法规

- 英国、德国和法国主要工业自动化地点的分析 - 根据过去三年的投资者活动和扩张活动确定。

第 5 章:评估 COVID-19 对欧洲流程自动化产业的影响

- 根据疫情中短期影响所确定的关键主题分析-V型復苏、中期復苏、低迷復苏

- 英国製程自动化市场—基于最终用户效能的基本变数分析

- 德国製程自动化市场—基于最终用户效能的基本变数分析

- 法国製程自动化市场—基于最终用户效能的基本变数分析

- 供应相关挑战的影响以及市场监管在市场振兴中的作用

第六章 市场细分

- 按通讯协定

- 有线

- 无线的

- 依系统类型

- 按系统硬体

- 监控和资料采集系统(SCADA)

- 集散控制系统(DCS)

- 可程式逻辑控制器(PLC)

- 製造执行系统(MES)

- 阀门和致动器

- 马达

- 人机介面 (HMI)

- 製程安全系统

- 感测器和发射器

- 依软体类型

- APC(独立和客製化解决方案)

- 先进的监理控制

- 多变量模型

- 推理与连续式

- 基于资料分析和彙报的软体

- 其他软体和服务

- 按系统硬体

- 按最终用户产业

- 石油和天然气

- 化工/石化

- 电力/公共产业

- 用水和污水

- 饮食

- 纸/纸浆

- 製药

- 其他最终用户产业

- 按国家/地区

- 英国

- 德国

- 法国

- 其他欧洲国家

第七章 竞争格局

- 公司简介

- ABB Ltd

- Siemens AG

- Schneider Electric

- General Electric Co.

- Mitsubishi Electric

- Rockwell Automation

- Emerson Electric Co.

- Honeywell International Inc.

- Fuji Electric

- Eaton Corporation

- Delta Electronics Limited

- Yokogawa Electric

第8章过程自动化产业关键创新者与挑战分析

第九章投资分析及市场展望

简介目录

Product Code: 56741

The Europe Process Automation Market is expected to register a CAGR of 6.18% during the forecast period.

Key Highlights

- The IoT demand trend is expected to shift toward industrial space from consumer demand over the near future, primarily driven by various Industry 4.0 applications. Countries like the United Kingdom are on the verge of the industrial revolution, as data is being used on a large scale for production while integrating it with various manufacturing systems throughout the supply chain.

- European nations have been at the forefront of adopting industrial automation solutions and have been under the government's constant support. For instance, the UK government revealed the Industrial Strategy primarily outlined a plan to invest GBP 2 billion per year by 2020 for new research and development in the technology sector. Smart manufacturing and the Industrial Internet of Things (IIot) will be built upon the work that automation has already forged over these years. Focusing on the possibilities that the automation solutions will enable will present the opportunity for multiple industries to push the boundaries of technological innovation, which is crucial for the UK economy in a post-Brexit phase. Automation solutions are expected to revolutionize the process industries.

- Furthermore, process industries, such as chemical and petrochemical, paper and pulp, water and wastewater treatment, energy and utilities, oil and gas, pharmaceutical, food, and beverages, are expected to fuel growth.

- Industrial system architects, integrators, and machine builders have leveraged connected computing advances to aid manufacturing facilities function more efficiently. The rising need for real-time intelligence, better control of operations, scheduling, and increasing market penetration of big data analytics in the manufacturing industry is expected to generate demand for advanced process automation in the near future. Big data analytics has been used to refine complicated processes and manage supply chains.

- Moreover, big data analytics allows an enterprise to use factory automation to shift from reactionary practices to predictive ones. This change targets to improve the efficiency of the process and performance of the product.

Europe Process Automation Market Trends

Pharmaceutical Industry is Expected to Hold Significant Market Share

- Automation is embedded in primary aspects such as Active Pharma Ingredients (API) and other secondary aspects, including packaging and distribution. Digital transformation provides new operational efficiency, quality, process automation, and employee productivity to pharmaceutical companies in the region.

- Furthermore, Lonza selected Rockwell Automation to implement the Lonza strategic vision of bringing the digital factory to nine former Capsugel facilities that manufacture drug capsules. The company has selected Rockwell Automation's PharmaSuite MES software to digitize the operations in its manufacturing operations. This solution would help avoid disruptions during high volume periods of just-in-time orders for on-demand production.

- Additionally, Lonza would use PharmaSuite MES software and FactoryTalk InnovationSuite software to better trace products down to the individual capsule carton and gain insights into performance and production. Segregation of SAP and PharmaSuite MES helped avoid the disruption of a global enterprise resource planning ERP shutdown or required maintenance by enforcing workflows and collecting necessary information.

- Moreover, the post-COVID-19 workforce and organization would also likely adopt new, more efficient ways of working. New capabilities would also be needed within operations functions as the workforce shifts from manual skills to more technical skills. As the adoption of automation increases, pharmaceutical-operations organizations might have a greater need for talent that can program, operate, and interpret data from these new technologies. This would require significant up-skilling and capability-building efforts alongside ongoing strategic planning.

- Over the past three months, many pharma companies in Europe have mobilized their employees to remote working conditions. In such a scenario, automation helps them continue the essential processes unobstructed. Automation in drug discovery enhances the reliability of the entire process by minimizing manual errors, augments the throughput, and improves the ability to reproduce.

United Kingdom Accounts for the Largest Market Share

- The food and beverage industry maintains some of the highest hygiene standards in the country while delivering high-volume production systems. In addition, competitive forces demand that a business is efficient, both in terms of the raw materials consumed and the cost of manufacturing. Delivering these objectives is a crucial part of remaining in the industry. Seasonality of demand and labor forces have also prompted the industry to adopt increased automation, thus assisting the market's growth.

- Automation in the food industry increases competitiveness by eliminating errors and waste, enhancing efficiency and productivity, and expanding profit margins. Cost savings can be diverted to R&D and other business improvements.

- Moreover, with investment roll-outs by the government to revive the pandemic hit United Kingdom economy, infrastructure, and the electronics industry are marked as the primary beneficiaries alongside the growth of small and medium-sized enterprises. The infrastructure and electronics industry are heavy users of the industrial control systems' hardware products and software solutions and are expected to have a direct positive effect.

- Additionally, technologies and terminologies such as process discovery, process optimization, process intelligence, and process orchestration are becoming a more significant part of Robotic Process Automation (RPA). There is an ongoing trend of increasing a closer relationship between business process management (BPM) and RPA in the future.

- Further, different industrial automation systems, such as SCADA, PLCs, and MES on a single physical server, can be easily accessed at a different location on the plant floor using virtual machines. It has been adopted in the country to reduce the overall cost for servers and increase the flexibility in adopting industrial automation systems and software in the process and discrete industries.

Europe Process Automation Industry Overview

The European Process Automation Market is moderately fragmented, with few new entrants and few dominant players. The companies keep on innovating and entering into strategic partnerships to retain their market share. Some of the recent developments in the market are:

- August 2020 - Schneider Electric completes transaction to combine its Low Voltage and Industrial Automation Product business with Larsen & Toubro's Electrical & Automation business.

- May 2020 - OleumTech, wireless industrial automation and IoT solutions provider announced the launch of new intelligent pressure transmitters (HGPT Smart Gauge Pressure Transmitters). These transmitters are an addition to its fast-growing H Series line of hardwired process instrumentation and claimed to deliver remarkable performance, accuracy, and reliability ideal for process industries, such as petrochemical, chemical, power, upstream oil and gas, and wastewater.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHADOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Market Drivers (Growing emphasis on energy efficiency & cost reduction| Demand for Safety Automation Systems| Emergence of IIoT)

- 4.5 Market Challenges (Cost & Implementation Challenges)

- 4.6 Industry Standards & Regulations

- 4.7 Analysis of the major Industrial Automation hubs in the United Kingdom, Germany, and France - To be identified based on the investor activity & expansion activities undertaken over the last 3 years

5 ASSESSMENT OF THE IMPACT OF COVID-19 ON THE PROCESS AUTOMATION INDUSTRY IN EUROPE

- 5.1 Analysis of the key themes identified based on the near & medium-term effects of the pandemic - V-shaped recovery, Mid-range recovery & Slump recovery

- 5.2 United Kingdom Process Automation Market - Base variable analysis based on end-user performance

- 5.3 Germany Process Automation Market - Base variable analysis based on end-user performance

- 5.4 France Process Automation Market - Base variable analysis based on end-user performance

- 5.5 Impact of Supply-related challenges & the role of market regulations in spurring activity

6 MARKET SEGMENTATION

- 6.1 By Communication Protocol

- 6.1.1 Wired

- 6.1.2 Wireless

- 6.2 By System Type

- 6.2.1 By System Hardware

- 6.2.1.1 Supervisory Control and Data Acquisition System (SCADA)

- 6.2.1.2 Distributed Control System (DCS)

- 6.2.1.3 Programmable Logic Controller (PLC)

- 6.2.1.4 Manufacturing Execution System (MES)

- 6.2.1.5 Valves & Actuators

- 6.2.1.6 Electric Motors

- 6.2.1.7 Human Machine Interface (HMI)

- 6.2.1.8 Process Safety Systems

- 6.2.1.9 Sensors & Transmitters

- 6.2.2 By Software Type

- 6.2.2.1 APC (Standalone & Customized Solutions)

- 6.2.2.1.1 Advanced Regulatory Control

- 6.2.2.1.2 Multivariable Model

- 6.2.2.1.3 Inferential & Sequential

- 6.2.2.2 Data Analytics & Reporting-based Software

- 6.2.2.3 Other Software & Services

- 6.2.1 By System Hardware

- 6.3 By End-user Industry

- 6.3.1 Oil and Gas

- 6.3.2 Chemical and Petrochemical

- 6.3.3 Power and Utilities

- 6.3.4 Water & Wastewater

- 6.3.5 Food and Beverage

- 6.3.6 Paper & Pulp

- 6.3.7 Pharmaceutical

- 6.3.8 Other End-user Industries

- 6.4 By Country

- 6.4.1 United Kingdom

- 6.4.2 Germany

- 6.4.3 France

- 6.4.4 Rest of Europe

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 ABB Ltd

- 7.1.2 Siemens AG

- 7.1.3 Schneider Electric

- 7.1.4 General Electric Co.

- 7.1.5 Mitsubishi Electric

- 7.1.6 Rockwell Automation

- 7.1.7 Emerson Electric Co.

- 7.1.8 Honeywell International Inc.

- 7.1.9 Fuji Electric

- 7.1.10 Eaton Corporation

- 7.1.11 Delta Electronics Limited

- 7.1.12 Yokogawa Electric

8 ANALYSIS OF MAJOR INNOVATORS & CHALLENGERS IN THE PROCESS AUTOMATION INDUSTRY

9 INVESTMENT ANALYSIS & MARKET OUTLOOK

02-2729-4219

+886-2-2729-4219